Professional Documents

Culture Documents

(Expansion Tank) 198005 PDF

(Expansion Tank) 198005 PDF

Uploaded by

alvinchuanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Expansion Tank) 198005 PDF

(Expansion Tank) 198005 PDF

Uploaded by

alvinchuanCopyright:

Available Formats

Fundamentals to frontiers

Expansion tanks

By WILLIAM J. COAD afid sizing of a closed expansion the temperature limits, and the

tank since the article "Compression pressure limits, but also t o how the

Tank Selection for Hot Watet Heat- trulk is dc~sigi7rdi t ~ t ot l ~ esystrm!

ing Systems," by H. A. Lockhart The derivation of the formulas for

The fundamental components of a and 6 . F. Carlson, appeared in the sizing tanks is rather fundamental if

hydronic system a r e the heat A S H R A E Journal Section of it can be assumed that the air cush-

source, load, circulator, piping, and Hecrtir~glPi~~rngiAir Co~lditioilingin ion behaves as a perfect gas. For

expansion tank. Strangly enough, April 1953! Yet, since that time, such equations, all the necessary

the most complex device of the five there have been immense strides in values that are not established as

is probably the one that would ap- the application of hydronic sys- design parameters are readily avail-

pear to be the least complicated - tems. able from any steam table. The only

the expansion tank. Considering the The correct sizing of expansion complications are those relative to

fundamentals, the expansion tank tanks is becoming ever more critical how the tank is employed in the sys-

serves a dual purpose. It allows for as larger volume systems are being tem. As an example, if it is assumed

the volumetric changes in the flu- employed. Not only are large vol- that the water in the tank always

id, resulting from temperature umes a result of large capacity sys- remains at its initial temperature,

changes, to occur between planned tems, but they are also an integral that compression and expansion of

pressure limits; and it establishes part of solar systems and other the air in the tank are isothermal,

the point of constant or known pres- power conserving systems that and that the air in the tank was ini-

sure in the system. In many cases. utillze thermal storage through liq- tially compressed from atmospheric

the tank serves the additional pur- uid phase temperature changes. The pressure in the tank, Equation 1 (see

pose of being an integral part of the very important observation made in table) can be readily derived. Thus,

air control subsystem. the article cited above was that the if a designer uses this equation and

It appears that very little has sizing of a tank relates not only to anticipates the system performance

been published regarding the design the volume of water in the system, to be in accordance with his design,

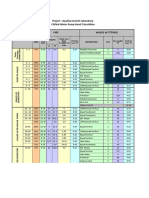

Equations f o r expansion t a n k siztng

-- -- -- - - - - - -- - --- --

Equation Example tank

No Equation Assumptions size gal

Air compresses isothermally ( t l )

* Water in tank is at temperature tl

Initial air charge is atmospheric

Air comDresses isothermallv it11

V liv2 v1 1) - 3ult1

2 v = .- -L - --- * Water in tank is at temperature t 2

lo,lp, - P,,/Pz)- (vzIv1 I ) (I - p JP,)

lnit~alair charge IS atmospheric

Air compresses isothermally ( t ~ )

Initial air charge is at pressure pl

where, with volumes in consistent units:

V,, = volume of water in system t2 - highertemperature F

(piping heat exchangers etc )'

V, - volume of expansion tank

vl

v2 -

speciftc volume of water at temperature t l

specific volume of water at temperature t7

p,, - atmospher~cpressure psia

(2 - linear coefficient of thermal expansion 1 deg F

pl - pressure at lower temperature, psia

St hignei temperature minus lower teiriperature F

p2 pressure at higher temperature psia

tl lower temperature F

*At t , and not including water in the tank

Fundamentals to frontiers tank is used to provide the expan- as possible.

sion cushion. From the standpoints of ther-

If the initial air charge in the tank modynamics and hydraulics, these

is not compressed from atmos- equations can be used to size ex-

he must take all possible steps to pheric pressure in the tank itself pansion tanks with an equal degree

asbure that his design will satisfy the but rather is forced into the tank at a of accuracy for heating water sys-

assumptions. This might include design operating pressure (either tems, chilled water systems, and

leaving the tank uninsulated and in- from a compressed air system or as dual temperature systems. When a

stalled in such a way that thermal with a precharged diaphragm type tank with a liquid-gas interface is

circulation between the piping and tank) and the air is assumed to com- used in a chilled water system,

the tank will be minimal. press and expand isothermally, however, unless extreme pre-

If, on the other hand, the assump- Equation 3 results. The significance cautions are taken there is a con-

tions are that the initial charge of of recognizing the differences in tinual pumping effect that removes

water in the tank changes tempera- these assumptions can be illustrated air from the tank by absorption in

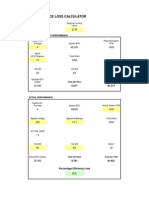

ture with the main volume of water, with an example. Assume that a sys- the water, thus causing the small

that the air in the tank is at its initial tem contains 10,000 gal of water, tanks designed by these relation-

charge temperature and compresses has a fill pressure of 15 psig at the ships to water log frequently. One

and expands isothermally, and that tank with a maximum limit set at 25 option is to provide oversized tanks

the air in the tank was initially com- psig, and is designed to operate over t o minimize t h e frequency of

pressed in the tank from atmos- a temperature range of 70 F (fill) to needed air charging; another is to

pheric pressure, Equation 2 re- 220 F. design such systems to prevent the

sults. The equation becomes a bit The calculated tank sizes for the absorption phenomenon, which has

more complex if the air in the tank is three different conditions are shown numerous other detrimental effects

assumed to increase in temperature in t h e table along with the on system performance. R

with the liquid (it must be remem- equations. The differences among

bered that the total pressure of the these sizes are seen to be signifi-

O n this page errch m o n t h , the airrhor

gas in the tank is the sum of the cant, indicating that in the selection shares his engineering philosophy by explor-

partial pressures of the air and water of the tank, the designer must: ing ( I wide vurieiy o f topics ranging ,from

vapor and that a saturated condition 1) Determine what operating as- .fzrndamentals to new frontier:, , ns tliey relate

always exists). Although not totally sumptions are to be employed in t o bitilding rnvirorimental s y s t e m s . MI..

Cond is vice president o f Charles J . R .

accurate, this equation would be a selecting the tank sizing equation. McClrtre & Associates cind qffiliuie prcges-

fair approximation of the condition 2 ) Design the system to achieve sor. of ~nechnnicalengineering at Washing-

where a portion of a thermal storage the assumed conditions as closely rorr Unii,ettriiy, St. Lo~ris,1Mo.

HeatingIPipinglAir Conditioning, May 1980

You might also like

- Calculating Pressure Drop in Chilled Water CircuitsDocument8 pagesCalculating Pressure Drop in Chilled Water Circuitsmohdnazir100% (1)

- Need For Balancing ValvesDocument12 pagesNeed For Balancing ValvesBubai111No ratings yet

- Example 6 - Cal Supply Air Quantity FCUDocument11 pagesExample 6 - Cal Supply Air Quantity FCUHo Dac ThanhNo ratings yet

- HVAC Coil DesignDocument7 pagesHVAC Coil DesignAnonymous 73gEYyEtLNo ratings yet

- Chiller Heat Load & Water FlowDocument3 pagesChiller Heat Load & Water FlowDan NugrahaNo ratings yet

- A Theoretical and Practical Guide To The Basics of Designing Air Flow SystemsDocument3 pagesA Theoretical and Practical Guide To The Basics of Designing Air Flow Systemsmarcoo8No ratings yet

- Selection Sheet - 30XA452 Screw ChillerDocument1 pageSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478No ratings yet

- Expansion Tank Sizing ASRAEDocument5 pagesExpansion Tank Sizing ASRAEMurat Kavas100% (1)

- Sizing and Selection Guide of ASME Bladder Type Expansion Tanks For Chilled Water SystemsDocument4 pagesSizing and Selection Guide of ASME Bladder Type Expansion Tanks For Chilled Water SystemsAntonio LebrunNo ratings yet

- Reverse Return/Direct Return PipingDocument2 pagesReverse Return/Direct Return Pipingmaddy_giftNo ratings yet

- Ishrae Variable Volume Pumping SystemDocument14 pagesIshrae Variable Volume Pumping SystemAidrus AliNo ratings yet

- The Armstrong Humidification HandbookDocument40 pagesThe Armstrong Humidification HandbookCraig RochesterNo ratings yet

- ASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - TaylorDocument7 pagesASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - Taylorsajuhere100% (1)

- Duct DesignDocument49 pagesDuct DesignabianshbaralNo ratings yet

- Expansion Tank PDFDocument9 pagesExpansion Tank PDFKrishna Chaitanya KalagaNo ratings yet

- Coil DesignDocument5 pagesCoil DesigngaryckfanNo ratings yet

- Fgas Refrigerant CalculatorDocument10 pagesFgas Refrigerant CalculatorKumar sssssNo ratings yet

- Understanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDocument13 pagesUnderstanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDavid O. AlmeidaNo ratings yet

- Project:: Chilled Water Pump Head CalculationDocument1 pageProject:: Chilled Water Pump Head CalculationClarkFedele27No ratings yet

- Psychrometric ProcessesDocument9 pagesPsychrometric ProcessesArt JamesNo ratings yet

- Project: Quality Control Laboratory Chilled Water Pump Head Calculation Pipe Valves & FittingsDocument15 pagesProject: Quality Control Laboratory Chilled Water Pump Head Calculation Pipe Valves & FittingsZain ShariffNo ratings yet

- AC Duct Design PDFDocument6 pagesAC Duct Design PDFkumar123rajuNo ratings yet

- HVAC Design & Thumb RulesDocument61 pagesHVAC Design & Thumb RulesBommu RajNo ratings yet

- Hap Ehelp 025Document17 pagesHap Ehelp 025Abed NaemNo ratings yet

- Stair PressDocument5 pagesStair Press45saulNo ratings yet

- TABS SiemensDocument22 pagesTABS SiemensOana MocanuNo ratings yet

- Calculation/Sketch: Expansion Tank Sizing PipeDocument3 pagesCalculation/Sketch: Expansion Tank Sizing PipeMythili BysaniNo ratings yet

- COIL Selection Formulas PDFDocument3 pagesCOIL Selection Formulas PDFWalter100% (1)

- DOAS and Humidity Control ASHRAE JNL May 08 PDFDocument7 pagesDOAS and Humidity Control ASHRAE JNL May 08 PDFAshraf Adel Nashed ZakiNo ratings yet

- Flash Card - AspeDocument36 pagesFlash Card - Aspesunil_v5No ratings yet

- Waste Heat Recovery System For RefrigeratorDocument10 pagesWaste Heat Recovery System For RefrigeratorlalkrishnaNo ratings yet

- Buffer Tank Hydraulic SeparatorDocument4 pagesBuffer Tank Hydraulic SeparatorJohn MoreNo ratings yet

- 0000 NFPA Gas System SizingDocument9 pages0000 NFPA Gas System Sizing1985PolytechNo ratings yet

- Relief Valve SizingDocument3 pagesRelief Valve SizingcutefrenzyNo ratings yet

- Head Calculation Hydronic PipingDocument18 pagesHead Calculation Hydronic Pipingjomy_pj8106No ratings yet

- Expansion Vessel Sizing To UploadDocument6 pagesExpansion Vessel Sizing To UploadsmcsamindaNo ratings yet

- Afinity Law - CalculationsDocument1 pageAfinity Law - CalculationsShivraj SawantNo ratings yet

- HVAC Systems Duct Design-Duct P DropDocument1 pageHVAC Systems Duct Design-Duct P DropmhmdjdgmailcomNo ratings yet

- Petrofac Case StudyDocument2 pagesPetrofac Case StudyRalphMarrugoNo ratings yet

- HVAC Psychrometric Analysis To Avoid Moisture ProblemsDocument30 pagesHVAC Psychrometric Analysis To Avoid Moisture ProblemsmohdrashidNo ratings yet

- Designing Dedicated Outdoor Air SystemsDocument4 pagesDesigning Dedicated Outdoor Air Systemsrogel_ganaNo ratings yet

- Fire Relief Dynamic StudyDocument2 pagesFire Relief Dynamic StudyImtinan Mohsin100% (1)

- Examples of Psychrometric Calculations For Summer and Winter PDFDocument9 pagesExamples of Psychrometric Calculations For Summer and Winter PDFamitbslpawarNo ratings yet

- Heat Gain From Common Electrical EquipmentDocument4 pagesHeat Gain From Common Electrical EquipmentsauroNo ratings yet

- Cooling Coil 03Document18 pagesCooling Coil 03Sam Wang Chern Peng100% (3)

- Expansion Vessel Calculation (For Pressurization Unit) : Project - Pump ArrangementDocument1 pageExpansion Vessel Calculation (For Pressurization Unit) : Project - Pump Arrangementkumar123rajuNo ratings yet

- Heating, Cooling ChillerDocument23 pagesHeating, Cooling ChillerMyo TuntheinNo ratings yet

- Efficiency CalculatowrDocument1 pageEfficiency CalculatowrAbhik BhattacharjeeNo ratings yet

- Optimizing CHW Plants MinnesotaDocument51 pagesOptimizing CHW Plants MinnesotaJasper_HVACNo ratings yet

- Carrier Recommended Minimum CW Fluid Loop VolumeDocument1 pageCarrier Recommended Minimum CW Fluid Loop VolumeRyan Carter100% (2)

- Duct Pressure Loss CalculationDocument24 pagesDuct Pressure Loss CalculationbernardsilvanoNo ratings yet

- Pressure Volume Calculator 02Document6 pagesPressure Volume Calculator 02Jenny Cecilia Ureña ZuriNo ratings yet

- Pharmaceutical Facility DesignDocument27 pagesPharmaceutical Facility Designmdalt9180No ratings yet

- 8-12 How Do You Calculate GPMDocument2 pages8-12 How Do You Calculate GPMlutfi awnNo ratings yet

- Ref Pipe Sizing Ver 02 21 11Document12 pagesRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- OGJ Hot Vapor Bypass DesignDocument6 pagesOGJ Hot Vapor Bypass DesignJesse Haney III100% (2)

- Control of High Speed Wind Tunnel Stagnation PressureDocument12 pagesControl of High Speed Wind Tunnel Stagnation PressureClaus WehmannNo ratings yet

- Aik Papyr 1707 Aiche J V41 Iss2 PP241 250 Y1995Document10 pagesAik Papyr 1707 Aiche J V41 Iss2 PP241 250 Y1995fallo1989No ratings yet

- The Professional Competency Examinations: The Structure, The Format, The SyllabiDocument91 pagesThe Professional Competency Examinations: The Structure, The Format, The SyllabiSK NG100% (1)

- 7 ACMV SystemsDocument270 pages7 ACMV SystemsSK NGNo ratings yet

- ABB Transformer VentilationDocument4 pagesABB Transformer VentilationSK NGNo ratings yet

- ABB Transformer VentilationDocument4 pagesABB Transformer VentilationSK NGNo ratings yet

- Masters Thesis Projects in Sound and VibrationDocument19 pagesMasters Thesis Projects in Sound and VibrationSK NGNo ratings yet

- Analytical Exact Solutions of Heat Conduction Problems For Ani So Tropic Multi-Layered MediaDocument13 pagesAnalytical Exact Solutions of Heat Conduction Problems For Ani So Tropic Multi-Layered MediaSK NGNo ratings yet

- Kkskkqxyk&Ee Pl&Syxgs Tfrrli Sdn. BF (D.: ?'fue Frqpcess CmrraxgmfedDocument12 pagesKkskkqxyk&Ee Pl&Syxgs Tfrrli Sdn. BF (D.: ?'fue Frqpcess CmrraxgmfedSK NGNo ratings yet

- Dutile IronDocument9 pagesDutile IronSaravanan ManiNo ratings yet

- Soln DE03Document11 pagesSoln DE03AdzLinkBalaoangNo ratings yet

- Scattering Coefficient Damis CacavelosDocument17 pagesScattering Coefficient Damis CacavelosFederico Nahuel CacavelosNo ratings yet

- Ionic and Covalent Bonding Comics GuidelinesDocument1 pageIonic and Covalent Bonding Comics GuidelinesArch Broqueza33% (3)

- PSCExample1ASeminar JLS Jul05Document10 pagesPSCExample1ASeminar JLS Jul05Ekky CecilNo ratings yet

- The Ellipse RevisedDocument17 pagesThe Ellipse RevisedJoren BausingNo ratings yet

- Effect of Bilateral Excitation On The Seismic Performance of Reinforced Concrete Bridge ColumnsDocument1 pageEffect of Bilateral Excitation On The Seismic Performance of Reinforced Concrete Bridge ColumnsMuntasir BillahNo ratings yet

- Ansi C37.51-1989Document26 pagesAnsi C37.51-1989YogialkNo ratings yet

- Musicologist Guide To Sonic VisualizerDocument20 pagesMusicologist Guide To Sonic VisualizerArtist RecordingNo ratings yet

- Telephone Directory IITR 2011Document65 pagesTelephone Directory IITR 2011shaukat779sdNo ratings yet

- #9 CPTu Dissipation Tests (Compatibility Mode)Document21 pages#9 CPTu Dissipation Tests (Compatibility Mode)henry tovarNo ratings yet

- Official Preboard Structural Engineering and ConstructionDocument7 pagesOfficial Preboard Structural Engineering and ConstructionDexter Dote0% (2)

- Fluid Mechanics FormulaDocument6 pagesFluid Mechanics FormulaJhon Oliver De JoseNo ratings yet

- How To Select The Best Earthing SystemDocument50 pagesHow To Select The Best Earthing SystemShrikant Kajale100% (2)

- RetrofittingDocument36 pagesRetrofittingNagesh ChitariNo ratings yet

- Air Conditioning System For Your CarDocument9 pagesAir Conditioning System For Your CarSanjeev GuptaNo ratings yet

- Bacc P131-142Document12 pagesBacc P131-142bobo69No ratings yet

- Experiment 2 - Aldehyde and KetonesDocument3 pagesExperiment 2 - Aldehyde and KetonesFaris Syahmi100% (2)

- Notes-PDE pt2 - 2 PDFDocument27 pagesNotes-PDE pt2 - 2 PDFFirman ErizalNo ratings yet

- Nelson SPWLA 1994 V35n3a4Document37 pagesNelson SPWLA 1994 V35n3a4ridha hNo ratings yet

- Co-Efficient of Static FrictionDocument9 pagesCo-Efficient of Static Frictionatul_gangwar0% (1)

- Vernier Calipers 1Document2 pagesVernier Calipers 1Zahra ShahzebNo ratings yet

- Pelton Turbine1Document8 pagesPelton Turbine1rjrahul25No ratings yet

- MnO2 Phase SelectionDocument10 pagesMnO2 Phase SelectionJacob SchmidtNo ratings yet

- Air Quality: A Global Problem: Particulate Matter (PM) Nitrogen Oxides (Nox) Ozone (O) Sulphur Oxides (Sox)Document34 pagesAir Quality: A Global Problem: Particulate Matter (PM) Nitrogen Oxides (Nox) Ozone (O) Sulphur Oxides (Sox)Vesko IlijaziNo ratings yet

- Hilti Epoxy Technical InfoDocument69 pagesHilti Epoxy Technical InfoAnonymous xcFcOgMiNo ratings yet

- Andrea GibsonDocument8 pagesAndrea Gibsonann de leon100% (1)

- Capo TestDocument5 pagesCapo Testaditya2053No ratings yet

- Chapter 2 DMMDocument57 pagesChapter 2 DMMPratibha GoswamiNo ratings yet

- Production Engg - Herriot Watt Series 1. Performance of Flowing WellsDocument7 pagesProduction Engg - Herriot Watt Series 1. Performance of Flowing WellsNitin GandhareNo ratings yet

- Motox Geared MotorDocument326 pagesMotox Geared Motorawangga putra maulanaNo ratings yet