Professional Documents

Culture Documents

ITP All

ITP All

Uploaded by

Syafril AkbarCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ITP For Geotecnical InvestigationsDocument5 pagesITP For Geotecnical InvestigationsAtuk Safiz80% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Audit Plan 1 Dec 2018Document1 pageAudit Plan 1 Dec 2018Atuk SafizNo ratings yet

- PTS 60.0303Document112 pagesPTS 60.0303Atuk SafizNo ratings yet

- ISRM-11CONGRESS-2007-166 - A Realistic Approach To Estimate Stand-Up TimeDocument4 pagesISRM-11CONGRESS-2007-166 - A Realistic Approach To Estimate Stand-Up Timecastille1956No ratings yet

- Bonding Practice Test PDFDocument15 pagesBonding Practice Test PDFpeterjo raveloNo ratings yet

- Rapid Project Spot Inspection Report: AttendeeDocument9 pagesRapid Project Spot Inspection Report: AttendeeAtuk SafizNo ratings yet

- Audit Schedule Detail 12 Jan 2018 - 17 Jan 2018Document9 pagesAudit Schedule Detail 12 Jan 2018 - 17 Jan 2018Atuk SafizNo ratings yet

- Audit Finding CPP - Eng & PruDocument1 pageAudit Finding CPP - Eng & PruAtuk SafizNo ratings yet

- Construction Audit Check ListDocument1 pageConstruction Audit Check ListAtuk SafizNo ratings yet

- Rapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingDocument13 pagesRapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingAtuk Safiz100% (1)

- Ms For Buttering of Thinning Area - Rev.0 - ReviewedDocument2 pagesMs For Buttering of Thinning Area - Rev.0 - ReviewedAtuk SafizNo ratings yet

- Senaman HarimauDocument10 pagesSenaman HarimauAtuk SafizNo ratings yet

- Psp-Resak Hti-24 Pre-Commissioning & Commissioning ProcedureDocument44 pagesPsp-Resak Hti-24 Pre-Commissioning & Commissioning ProcedureAtuk SafizNo ratings yet

- Rapid P0030 CPP Qac PRC 0001 0024 - A CCDocument14 pagesRapid P0030 CPP Qac PRC 0001 0024 - A CCAtuk SafizNo ratings yet

- QAQC Calendar - Rev3Document1 pageQAQC Calendar - Rev3Atuk SafizNo ratings yet

- P Package 1 Petro 14-Utilities Onas Rapid S, Intercon D Project Nnecting, O Offsite Un Nits Rep OrtDocument2 pagesP Package 1 Petro 14-Utilities Onas Rapid S, Intercon D Project Nnecting, O Offsite Un Nits Rep OrtAtuk SafizNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- RAPID-P0030-CPP-PMG-WPR-0001-0020 - 0 质量9.16Document15 pagesRAPID-P0030-CPP-PMG-WPR-0001-0020 - 0 质量9.16Atuk Safiz100% (1)

- Urea BrochureDocument0 pagesUrea BrochureiosiiosiNo ratings yet

- Fluid and Electrolytes Lecture NotesDocument85 pagesFluid and Electrolytes Lecture NotesVince Peliño De MesaNo ratings yet

- Fire Tube BoilerDocument14 pagesFire Tube BoilersadvdsNo ratings yet

- LABORATORY NO. 4 Specific Gravity and Absorption of Fine AggregatesDocument4 pagesLABORATORY NO. 4 Specific Gravity and Absorption of Fine AggregatesGlen Vincent IsraelNo ratings yet

- MSDS EtanolDocument9 pagesMSDS EtanolwynneralphNo ratings yet

- Phenomenex Clinical Aplication NotebookDocument136 pagesPhenomenex Clinical Aplication NotebookjrventurimNo ratings yet

- KimaDocument3 pagesKimaOsama Ben DawNo ratings yet

- Naim2015 Desalination of Simulated Seawater by Purge-AirDocument11 pagesNaim2015 Desalination of Simulated Seawater by Purge-AircptnastroNo ratings yet

- Jindal Steel Power Catálogo PDFDocument17 pagesJindal Steel Power Catálogo PDFikamelyaastutiNo ratings yet

- Floating Leaf Lab ConclusionDocument3 pagesFloating Leaf Lab Conclusionapi-243423763No ratings yet

- Protocols For Root Tip Chromosome Observation Including ReferencesDocument3 pagesProtocols For Root Tip Chromosome Observation Including ReferencesxprakashNo ratings yet

- Seafood Research From Fish To DishDocument569 pagesSeafood Research From Fish To DishDewi SetiyowatiNo ratings yet

- Disappearing Cross Experiment CourseworkDocument7 pagesDisappearing Cross Experiment Courseworkxdqflrobf100% (2)

- DSF 1101401 436 6300 DCC PRC 0302 - A1 Document Control ProcedureDocument36 pagesDSF 1101401 436 6300 DCC PRC 0302 - A1 Document Control ProcedureGiovanniStirelli100% (2)

- Dye Penetrant TestingDocument2 pagesDye Penetrant TestingshreeambhasankaranNo ratings yet

- Return Grilles PDFDocument11 pagesReturn Grilles PDFAmr Adeeb Abd-ElaahNo ratings yet

- Corrioson TestDocument14 pagesCorrioson Testcombahee100% (1)

- EAMCET 2015 Engineering Answer KeyDocument44 pagesEAMCET 2015 Engineering Answer KeyIshaq KhanNo ratings yet

- 11HS - Atomic Structure - Electron Config PracticeDocument5 pages11HS - Atomic Structure - Electron Config PracticeVictoria LowmanNo ratings yet

- LDI300 Dupont Lser PhotoresistDocument5 pagesLDI300 Dupont Lser Photoresistdaniel eduardo neumanNo ratings yet

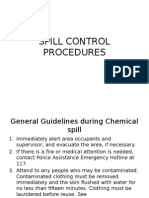

- Spill Control ProceduresDocument7 pagesSpill Control ProceduresCherryRoseSaguinsin0% (1)

- ChemistryDocument2 pagesChemistryGokul VishwaNo ratings yet

- Liquid Pipelines Surge Basic ExplainationDocument6 pagesLiquid Pipelines Surge Basic ExplainationbryandownNo ratings yet

- 07 Science Ws Ch14 04 JCDocument3 pages07 Science Ws Ch14 04 JCChiruhaasNo ratings yet

- Knockout DrumDocument9 pagesKnockout Drumgautam_96948069No ratings yet

- White ToppingDocument11 pagesWhite ToppingGossetto75% (4)

- The Bigger PictureDocument39 pagesThe Bigger Picturewhitefluffy982No ratings yet

- A Filter PressDocument0 pagesA Filter Pressraneshkumar1992No ratings yet

ITP All

ITP All

Uploaded by

Syafril AkbarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITP All

ITP All

Uploaded by

Syafril AkbarCopyright:

Available Formats

TABLE 1 : TYPICAL DPFC-GRP INSPECTION AND TEST PLAN

Applicable Standard

Test Type Product Type SN Component Test Designation / Method Frequency

(Procedure)

1. RAW MATERIAL

1.1 Reactivity (QC-1) Each lot

Resin

1.2 Viscosity (QC-2) Each lot

1.3 Visual N/A Each lot

On Receipt Raw Material 1.4 Glass Reinforcement Textural (QC-10) Each lot

1.5 Moisture Content (QC-5) Each lot

1.6 Sieve Analysis (QC-3) Each lot

Silica Sand

1.7 Moisture Content (QC-4) Each lot

2. PIPES & COUPLINGS

2.1 Resin Gel Time (QC-1) Each Production

2.2 Wall Thickness Pipe Wall Thickness ASTM D3567 (QC-16) Each side of Pipe

In-Process

2.3 Pipe Laminate Laminate Thickness ASTM D3567 Each production

Pipe & Coupling Pipe 2.4 Spigot Dimensions Min. / Max O.D. ASTM D3567 (QC-16) Each Pipe

2.5 Pipe Visual Interior & Exterior Defects ASTM D2563 (QC-17) 100%

Non-

2.6 Pipe Dimensions Dimensions Control ASTM D3567 / BS 5480(QC-16) 100%

Destructive

2.7 Barcol Hardness Resin Curing ASTM D2583 (QC-12) 100%

Pipe 2.8 Impact Test Impact Resistance BS 5480 (QC-24) 1 in 30 Pipes or in a Shift

100% for pressure, For

gravity 1 in 30

2.9 Hydrostatic Pressure Pressure Test BS 5480 (QC-13)

Pipe & Coupling Pipes/coupling or in one

Shift (Other upon request)

Destructive

2. 10 Material Composition Loss on Ignition ASTM D2584 (QC-9) 1 in 30 Pipes or in a Shift

2.11 Hoop Flexural Stiffness ASTM D2412 / BS 5480 (QC-7) 1 in 30 Pipes or in a Shift

Pipe 2.12 Hoop Tensile Hoop Tensile Strength ASTM D2290 / BS 5480 (QC-6) 1 in 30 Pipes or in a Shift

2.13 Axial Strength Axial Tensile Strength ASTM D638 / BS 5480 (QC-8) 1 in 30 Pipes or in a Shift

Pipe & Coupling 2.14 Stenciling Marking QP-5 100%

Final Product

Pipe & Coupling 2.15 Visual Visual ASTM D2563 (QC-17) 100%

3. FITTINGS

Pre- 3.1 Visual Visual 100%

Pipe

Fabrication 3.2 Length Dimensional 100%

3.3 Internal Lay-up length Dimensional 100%

External lay-up Bond

3.4 Dimensional 100%

Length

Final Product Fitting 3.5 Barcol Hardness Resin Curing 100%

3.6 Stenciling Marking 100%

3.7 Final Dimensional Dimensional 100%

3. MANHOLE LINERS

4.1 Resin Gel Time (QC-1) Each production

4.2 Wall Thickness Pipe Wall Thickness ASTM D3567 (QC-16) Each side of Pipe

In-Process

4.3 Pipe Laminate Laminate Thickness ASTM D3567 Each production

4.4 Inside Diameter Dimensional ASTM D3567 (QC-16) Each Production

Manhole Liner Pipe

4.5 Pipe Visual Interior & Exterior Defects ASTM D2563 (QC-17) 100%

Non-

4.6 Length Dimensional ASTM D3567 / BS 5480(QC-16) 100%

Destructive

4.7 Barcol Hardness Resin Curing ASTM D2583 (QC-12) 100%

Destructive 4.8 Material Composition Loss on Ignition ASTM D2584 (QC-9) 1 in 30 Pipes or in a Shift

4.9 Visual Visual 100%

Cover Slab 4.10 Dimensions Dimensional 100%

4.11 Barcol Hardness Resin Curing ASTM D2583 (QC-12) 100%

In-Process 4.12 Internal & External Thickness 100%

4.13 Dimensions Bond Length 100%

Lamination

4.14 Visual Visual 100%

4.15 Barcol Hardness Resin Curing ASTM D2583 (QC-12) 100%

4.16 Length Dimensional 100%

Final Product Manhole Liner

4.17 Stenciling Marking 100%

Note: QC-1 to 17 and QP-5 are internal work instructions documented in the Quality System Manual

413184303.xls 1 of 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ITP For Geotecnical InvestigationsDocument5 pagesITP For Geotecnical InvestigationsAtuk Safiz80% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Audit Plan 1 Dec 2018Document1 pageAudit Plan 1 Dec 2018Atuk SafizNo ratings yet

- PTS 60.0303Document112 pagesPTS 60.0303Atuk SafizNo ratings yet

- ISRM-11CONGRESS-2007-166 - A Realistic Approach To Estimate Stand-Up TimeDocument4 pagesISRM-11CONGRESS-2007-166 - A Realistic Approach To Estimate Stand-Up Timecastille1956No ratings yet

- Bonding Practice Test PDFDocument15 pagesBonding Practice Test PDFpeterjo raveloNo ratings yet

- Rapid Project Spot Inspection Report: AttendeeDocument9 pagesRapid Project Spot Inspection Report: AttendeeAtuk SafizNo ratings yet

- Audit Schedule Detail 12 Jan 2018 - 17 Jan 2018Document9 pagesAudit Schedule Detail 12 Jan 2018 - 17 Jan 2018Atuk SafizNo ratings yet

- Audit Finding CPP - Eng & PruDocument1 pageAudit Finding CPP - Eng & PruAtuk SafizNo ratings yet

- Construction Audit Check ListDocument1 pageConstruction Audit Check ListAtuk SafizNo ratings yet

- Rapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingDocument13 pagesRapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingAtuk Safiz100% (1)

- Ms For Buttering of Thinning Area - Rev.0 - ReviewedDocument2 pagesMs For Buttering of Thinning Area - Rev.0 - ReviewedAtuk SafizNo ratings yet

- Senaman HarimauDocument10 pagesSenaman HarimauAtuk SafizNo ratings yet

- Psp-Resak Hti-24 Pre-Commissioning & Commissioning ProcedureDocument44 pagesPsp-Resak Hti-24 Pre-Commissioning & Commissioning ProcedureAtuk SafizNo ratings yet

- Rapid P0030 CPP Qac PRC 0001 0024 - A CCDocument14 pagesRapid P0030 CPP Qac PRC 0001 0024 - A CCAtuk SafizNo ratings yet

- QAQC Calendar - Rev3Document1 pageQAQC Calendar - Rev3Atuk SafizNo ratings yet

- P Package 1 Petro 14-Utilities Onas Rapid S, Intercon D Project Nnecting, O Offsite Un Nits Rep OrtDocument2 pagesP Package 1 Petro 14-Utilities Onas Rapid S, Intercon D Project Nnecting, O Offsite Un Nits Rep OrtAtuk SafizNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- RAPID-P0030-CPP-PMG-WPR-0001-0020 - 0 质量9.16Document15 pagesRAPID-P0030-CPP-PMG-WPR-0001-0020 - 0 质量9.16Atuk Safiz100% (1)

- Urea BrochureDocument0 pagesUrea BrochureiosiiosiNo ratings yet

- Fluid and Electrolytes Lecture NotesDocument85 pagesFluid and Electrolytes Lecture NotesVince Peliño De MesaNo ratings yet

- Fire Tube BoilerDocument14 pagesFire Tube BoilersadvdsNo ratings yet

- LABORATORY NO. 4 Specific Gravity and Absorption of Fine AggregatesDocument4 pagesLABORATORY NO. 4 Specific Gravity and Absorption of Fine AggregatesGlen Vincent IsraelNo ratings yet

- MSDS EtanolDocument9 pagesMSDS EtanolwynneralphNo ratings yet

- Phenomenex Clinical Aplication NotebookDocument136 pagesPhenomenex Clinical Aplication NotebookjrventurimNo ratings yet

- KimaDocument3 pagesKimaOsama Ben DawNo ratings yet

- Naim2015 Desalination of Simulated Seawater by Purge-AirDocument11 pagesNaim2015 Desalination of Simulated Seawater by Purge-AircptnastroNo ratings yet

- Jindal Steel Power Catálogo PDFDocument17 pagesJindal Steel Power Catálogo PDFikamelyaastutiNo ratings yet

- Floating Leaf Lab ConclusionDocument3 pagesFloating Leaf Lab Conclusionapi-243423763No ratings yet

- Protocols For Root Tip Chromosome Observation Including ReferencesDocument3 pagesProtocols For Root Tip Chromosome Observation Including ReferencesxprakashNo ratings yet

- Seafood Research From Fish To DishDocument569 pagesSeafood Research From Fish To DishDewi SetiyowatiNo ratings yet

- Disappearing Cross Experiment CourseworkDocument7 pagesDisappearing Cross Experiment Courseworkxdqflrobf100% (2)

- DSF 1101401 436 6300 DCC PRC 0302 - A1 Document Control ProcedureDocument36 pagesDSF 1101401 436 6300 DCC PRC 0302 - A1 Document Control ProcedureGiovanniStirelli100% (2)

- Dye Penetrant TestingDocument2 pagesDye Penetrant TestingshreeambhasankaranNo ratings yet

- Return Grilles PDFDocument11 pagesReturn Grilles PDFAmr Adeeb Abd-ElaahNo ratings yet

- Corrioson TestDocument14 pagesCorrioson Testcombahee100% (1)

- EAMCET 2015 Engineering Answer KeyDocument44 pagesEAMCET 2015 Engineering Answer KeyIshaq KhanNo ratings yet

- 11HS - Atomic Structure - Electron Config PracticeDocument5 pages11HS - Atomic Structure - Electron Config PracticeVictoria LowmanNo ratings yet

- LDI300 Dupont Lser PhotoresistDocument5 pagesLDI300 Dupont Lser Photoresistdaniel eduardo neumanNo ratings yet

- Spill Control ProceduresDocument7 pagesSpill Control ProceduresCherryRoseSaguinsin0% (1)

- ChemistryDocument2 pagesChemistryGokul VishwaNo ratings yet

- Liquid Pipelines Surge Basic ExplainationDocument6 pagesLiquid Pipelines Surge Basic ExplainationbryandownNo ratings yet

- 07 Science Ws Ch14 04 JCDocument3 pages07 Science Ws Ch14 04 JCChiruhaasNo ratings yet

- Knockout DrumDocument9 pagesKnockout Drumgautam_96948069No ratings yet

- White ToppingDocument11 pagesWhite ToppingGossetto75% (4)

- The Bigger PictureDocument39 pagesThe Bigger Picturewhitefluffy982No ratings yet

- A Filter PressDocument0 pagesA Filter Pressraneshkumar1992No ratings yet