0% found this document useful (0 votes)

440 views1 pagePVC Material Properties Guide

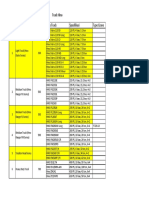

This document summarizes the general properties of PVC (Polyvinyl Chloride), including its:

- Density range of 0.047-0.0538 lb/ft3 or 1,300-1,490 kg/m3

- Mechanical properties like yield strength of 6-7.64 ksi or 41,400-52,700 kPa and elongation of 40-80% strain

- Thermal properties such as a maximum service temperature of 122-149°F or 50-65°C and being an insulator

- Environmental properties including a CO2 footprint of 1.85-2.04 kg/kg and being recyclable

Uploaded by

UM'mer FarooqCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

440 views1 pagePVC Material Properties Guide

This document summarizes the general properties of PVC (Polyvinyl Chloride), including its:

- Density range of 0.047-0.0538 lb/ft3 or 1,300-1,490 kg/m3

- Mechanical properties like yield strength of 6-7.64 ksi or 41,400-52,700 kPa and elongation of 40-80% strain

- Thermal properties such as a maximum service temperature of 122-149°F or 50-65°C and being an insulator

- Environmental properties including a CO2 footprint of 1.85-2.04 kg/kg and being recyclable

Uploaded by

UM'mer FarooqCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd