Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

10 viewsFiberboard PDF

Fiberboard PDF

Uploaded by

Joeryl MongcalCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Helicopter Fire Fighting and RescueDocument5 pagesHelicopter Fire Fighting and Rescuermaffireschool100% (2)

- Steel AsiaDocument4 pagesSteel AsiaAimee Layson PolancoNo ratings yet

- Statoil Minimum Criteria For TankersDocument2 pagesStatoil Minimum Criteria For TankersAnonymous 7z6OzoNo ratings yet

- Eid CR (6) 12149 FR Master Plan 01Document151 pagesEid CR (6) 12149 FR Master Plan 01Ramadan DurakuNo ratings yet

- "Carry A Friend To Jesus": None of Us Have To Be Paralyzed When We Have FriendsDocument1 page"Carry A Friend To Jesus": None of Us Have To Be Paralyzed When We Have FriendsAimee Layson PolancoNo ratings yet

- Unitops - ch9 ProblemsDocument4 pagesUnitops - ch9 ProblemsAimee Layson Polanco100% (1)

- Walkway Disaster SummaryDocument2 pagesWalkway Disaster SummaryAimee Layson PolancoNo ratings yet

- Unitops - ch8 ProblemsDocument7 pagesUnitops - ch8 ProblemsAimee Layson PolancoNo ratings yet

- Simple Interaction MatrixDocument1 pageSimple Interaction MatrixAimee Layson Polanco100% (1)

- Log SheetDocument1 pageLog SheetAimee Layson PolancoNo ratings yet

- A. Safety Hazard: "Hazards" I. Hazard IdentificationDocument4 pagesA. Safety Hazard: "Hazards" I. Hazard IdentificationAimee Layson PolancoNo ratings yet

- War of The Wits MechanicsDocument1 pageWar of The Wits MechanicsAimee Layson PolancoNo ratings yet

- Hno3 PropertiesDocument2 pagesHno3 PropertiesAimee Layson PolancoNo ratings yet

- College Semester Budget Worksheet: Income $ Budgeted $ Actual $ DifferenceDocument4 pagesCollege Semester Budget Worksheet: Income $ Budgeted $ Actual $ DifferenceAimee Layson PolancoNo ratings yet

- Abhijit Sharma: Operating SystemDocument3 pagesAbhijit Sharma: Operating SystemAimee Layson PolancoNo ratings yet

- LaTeX Math SymbolsDocument9 pagesLaTeX Math SymbolsAimee Layson PolancoNo ratings yet

- War of The Wits: (This Was Based in BLOCKBUSTERS GAME SHOW)Document1 pageWar of The Wits: (This Was Based in BLOCKBUSTERS GAME SHOW)Aimee Layson PolancoNo ratings yet

- Aimee L. Polanco Ench-4A August 6, 2014: Mechanical Properties ActivityDocument2 pagesAimee L. Polanco Ench-4A August 6, 2014: Mechanical Properties ActivityAimee Layson PolancoNo ratings yet

- Goosegrass For Cellulosic EthanolDocument10 pagesGoosegrass For Cellulosic EthanolAimee Layson Polanco0% (1)

- Sample Paper MathematicsDocument6 pagesSample Paper MathematicsAimee Layson PolancoNo ratings yet

- Republic of The Philippines Bacolod City College Sum-Ag, Bacolod CityDocument2 pagesRepublic of The Philippines Bacolod City College Sum-Ag, Bacolod CityAimee Layson PolancoNo ratings yet

- F021 (MRP)Document18 pagesF021 (MRP)Dey JayjeetNo ratings yet

- Product Attributes and Retail Format Choice Among U.S. Apparel PurchasersDocument0 pagesProduct Attributes and Retail Format Choice Among U.S. Apparel PurchasersNuman AliNo ratings yet

- China RubberDocument46 pagesChina RubberEndi SingarimbunNo ratings yet

- Developing NewProductsDocument490 pagesDeveloping NewProductsEllie BernalNo ratings yet

- Wps PQRDocument6 pagesWps PQRneelson_099No ratings yet

- Traditional Commerce: I, DefinitionDocument5 pagesTraditional Commerce: I, DefinitionQuỳnh Anh PhạmNo ratings yet

- Skin Care in India Datagraphics PDFDocument4 pagesSkin Care in India Datagraphics PDFshettyswapnil93No ratings yet

- BrochureDocument3 pagesBrochurealhumdulilahNo ratings yet

- Company Profile PT. Global Jaya MaritimindoDocument23 pagesCompany Profile PT. Global Jaya Maritimindoindoseafarer100% (3)

- Bessemer FurnaceDocument4 pagesBessemer FurnaceHariman El EmirNo ratings yet

- Swagelok Fittings SpecificationsDocument3 pagesSwagelok Fittings SpecificationsSam Chong Ks100% (1)

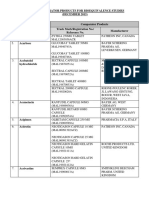

- Malaysia-NPRA List of Comparator Products For Bioequivalence Studies December 2015Document47 pagesMalaysia-NPRA List of Comparator Products For Bioequivalence Studies December 2015Noples RozaliaNo ratings yet

- Behaviour of Reinforced Concrete Beams With Coconut Shell As Coarse AggregatesDocument8 pagesBehaviour of Reinforced Concrete Beams With Coconut Shell As Coarse AggregatesUmair BaigNo ratings yet

- List of ScripsDocument348 pagesList of ScripsVínãy KumarNo ratings yet

- Walter Drilling eDocument155 pagesWalter Drilling eAbdulrahman Al-sNo ratings yet

- Raw Materials Test Sample Status (Received On 2020)Document44 pagesRaw Materials Test Sample Status (Received On 2020)GaFf ArNo ratings yet

- Chapter 6 - Metal WorkDocument27 pagesChapter 6 - Metal WorkIjal HaizalNo ratings yet

- Primary Aluminium Casting Alloys 2010 - Rheinfelden Alloys - ENDocument117 pagesPrimary Aluminium Casting Alloys 2010 - Rheinfelden Alloys - ENtahera aqeelNo ratings yet

- Civil Aviation Requirement Section 3 Series M Part IV Facilities On Delayed Cancelled FlightsDocument7 pagesCivil Aviation Requirement Section 3 Series M Part IV Facilities On Delayed Cancelled FlightsDevesh AgarwalNo ratings yet

- 418d4e9b-48b0-48a9-a4cb-7a14fb756d18Document6 pages418d4e9b-48b0-48a9-a4cb-7a14fb756d18Mohamed Arbi Ben YounesNo ratings yet

- Name: Nim: Capsule (Pharmacy) : Single-Piece Gel Encapsulation ("Soft Capsules")Document5 pagesName: Nim: Capsule (Pharmacy) : Single-Piece Gel Encapsulation ("Soft Capsules")Muhammad ArwanNo ratings yet

- Curtain WallDocument3 pagesCurtain WalljitenderaNo ratings yet

- Internationally Acclaimed Qualification World Class TrainingDocument12 pagesInternationally Acclaimed Qualification World Class TrainingSachin ChaudhariNo ratings yet

- Implement Indian Roads Congress IRC:116-2014 To Solve Pothole Problem Across IndiaDocument20 pagesImplement Indian Roads Congress IRC:116-2014 To Solve Pothole Problem Across IndiaProf. Prithvi Singh Kandhal100% (2)

- Data List / Active Test: Seat Belt - Seat Belt Warning SystemDocument3 pagesData List / Active Test: Seat Belt - Seat Belt Warning SystemdiemnganNo ratings yet

- Crestabond Brochure UkDocument8 pagesCrestabond Brochure UkNduong NguyenNo ratings yet

- AkzoNobel PresentationDocument47 pagesAkzoNobel PresentationSudhir BansalNo ratings yet

Fiberboard PDF

Fiberboard PDF

Uploaded by

Joeryl Mongcal0 ratings0% found this document useful (0 votes)

10 views2 pagesOriginal Title

fiberboard.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesFiberboard PDF

Fiberboard PDF

Uploaded by

Joeryl MongcalCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

10.

Drying and conditioning of the boards

11. Trimming/sizing of the boards

EQUIPMENT/MACHINERY COCONUT FIBERBOARD

The major equipment/machinery used in the

manufacture of CFB are all fabricated locally except the lifter

and include the following:

1. Decorticating machine

2. Hydraulic press

3. Blending machine

4. Trimming machine

5. Lifter

USES OF CFB

Production of CFB is expected to contribute to the

government’s low-cost housing program. CFB can replace

traditional construction materials such as tiles, bricks, plywood,

asbestos and cement hollow blocks. It can be used for internal

and exterior walls, partitions and ceiling or as a component in

the fabrication of furniture (tables, chairs, desks, etc.), cabinets,

boxes and vases.

For more information, please contact:

Mr. Gerardo A Santos

Department Manager III

PCA-Zamboanga Research Center

San Ramon, 7000 Zamboanga City

E-mail: wesmarrdec@wmsu.edu.ph

Phone: 09175496548 Fax: 062 9921676

PRODUCT DESCRIPTION .

Coconut fiberboard (CFB) is a new product Raw Materials

manufactured from fibrous materials like coconut coir, fronds, Cement = Portland cement, type I

spathes and shredded wood that are mixed with Portland Coir = 25% by weight

cement at a predetermined ratio of 70% cement to 30% fiber by Fronds/Spathe = 50%

weight. CFB is made by forming the cement-fiber mixture into Shredded wood = 25%

mats and pressing them to the desired thickness ranging from 8

mm to 25 mm. The board is 244 cm long by 61 cm wide.

CFB can provide panels of good strength properties. It MANUFACTURING PROCESS

is considered cheap, durable and requires low maintenance

cost. The production technology is simple and the The production of CFB involves the following steps:

manufacturing process requires equipment that do not need

highly skilled labor. It can be fabricated into modular structures 1. Soaking of dried husk/spathe in tap water for 24 to

to accelerate building construction. It is a good insulating 48 hours

material and has fire retardant characteristics. It is water- 2. Decorticating of husk/spathe to produce fibers

resistant. It is also nailable, plasterable, sawable and resistant 3. Cutting and shredding of wood billets/coconut

against attack of wood-boring insects and decay fungi, fronds

4. Soaking of fibers in separate dipping tank for 2 days

to remove the extractives

TECHNICAL DATA 5. Draining of the fibers

6. Mixing the required amount of fiber, cement and

A. Dimension water in the blending machine

Length = 244 cm 7. Mat-forming using wooden form box and plywood

Width = 61 cm cauls lined with plastic sheets

Thickness = 12.5 mm, 25 mm, 50 mm and 100 mm 8. Pressing the mat to the desired thickness for 24

Board Density = 700 kg/cu. m. hours using the hydraulic press machine

Cement: Fiber Mixing Proportion = 70: 30 9. Fillet-stacking for air drying/conditioning

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Helicopter Fire Fighting and RescueDocument5 pagesHelicopter Fire Fighting and Rescuermaffireschool100% (2)

- Steel AsiaDocument4 pagesSteel AsiaAimee Layson PolancoNo ratings yet

- Statoil Minimum Criteria For TankersDocument2 pagesStatoil Minimum Criteria For TankersAnonymous 7z6OzoNo ratings yet

- Eid CR (6) 12149 FR Master Plan 01Document151 pagesEid CR (6) 12149 FR Master Plan 01Ramadan DurakuNo ratings yet

- "Carry A Friend To Jesus": None of Us Have To Be Paralyzed When We Have FriendsDocument1 page"Carry A Friend To Jesus": None of Us Have To Be Paralyzed When We Have FriendsAimee Layson PolancoNo ratings yet

- Unitops - ch9 ProblemsDocument4 pagesUnitops - ch9 ProblemsAimee Layson Polanco100% (1)

- Walkway Disaster SummaryDocument2 pagesWalkway Disaster SummaryAimee Layson PolancoNo ratings yet

- Unitops - ch8 ProblemsDocument7 pagesUnitops - ch8 ProblemsAimee Layson PolancoNo ratings yet

- Simple Interaction MatrixDocument1 pageSimple Interaction MatrixAimee Layson Polanco100% (1)

- Log SheetDocument1 pageLog SheetAimee Layson PolancoNo ratings yet

- A. Safety Hazard: "Hazards" I. Hazard IdentificationDocument4 pagesA. Safety Hazard: "Hazards" I. Hazard IdentificationAimee Layson PolancoNo ratings yet

- War of The Wits MechanicsDocument1 pageWar of The Wits MechanicsAimee Layson PolancoNo ratings yet

- Hno3 PropertiesDocument2 pagesHno3 PropertiesAimee Layson PolancoNo ratings yet

- College Semester Budget Worksheet: Income $ Budgeted $ Actual $ DifferenceDocument4 pagesCollege Semester Budget Worksheet: Income $ Budgeted $ Actual $ DifferenceAimee Layson PolancoNo ratings yet

- Abhijit Sharma: Operating SystemDocument3 pagesAbhijit Sharma: Operating SystemAimee Layson PolancoNo ratings yet

- LaTeX Math SymbolsDocument9 pagesLaTeX Math SymbolsAimee Layson PolancoNo ratings yet

- War of The Wits: (This Was Based in BLOCKBUSTERS GAME SHOW)Document1 pageWar of The Wits: (This Was Based in BLOCKBUSTERS GAME SHOW)Aimee Layson PolancoNo ratings yet

- Aimee L. Polanco Ench-4A August 6, 2014: Mechanical Properties ActivityDocument2 pagesAimee L. Polanco Ench-4A August 6, 2014: Mechanical Properties ActivityAimee Layson PolancoNo ratings yet

- Goosegrass For Cellulosic EthanolDocument10 pagesGoosegrass For Cellulosic EthanolAimee Layson Polanco0% (1)

- Sample Paper MathematicsDocument6 pagesSample Paper MathematicsAimee Layson PolancoNo ratings yet

- Republic of The Philippines Bacolod City College Sum-Ag, Bacolod CityDocument2 pagesRepublic of The Philippines Bacolod City College Sum-Ag, Bacolod CityAimee Layson PolancoNo ratings yet

- F021 (MRP)Document18 pagesF021 (MRP)Dey JayjeetNo ratings yet

- Product Attributes and Retail Format Choice Among U.S. Apparel PurchasersDocument0 pagesProduct Attributes and Retail Format Choice Among U.S. Apparel PurchasersNuman AliNo ratings yet

- China RubberDocument46 pagesChina RubberEndi SingarimbunNo ratings yet

- Developing NewProductsDocument490 pagesDeveloping NewProductsEllie BernalNo ratings yet

- Wps PQRDocument6 pagesWps PQRneelson_099No ratings yet

- Traditional Commerce: I, DefinitionDocument5 pagesTraditional Commerce: I, DefinitionQuỳnh Anh PhạmNo ratings yet

- Skin Care in India Datagraphics PDFDocument4 pagesSkin Care in India Datagraphics PDFshettyswapnil93No ratings yet

- BrochureDocument3 pagesBrochurealhumdulilahNo ratings yet

- Company Profile PT. Global Jaya MaritimindoDocument23 pagesCompany Profile PT. Global Jaya Maritimindoindoseafarer100% (3)

- Bessemer FurnaceDocument4 pagesBessemer FurnaceHariman El EmirNo ratings yet

- Swagelok Fittings SpecificationsDocument3 pagesSwagelok Fittings SpecificationsSam Chong Ks100% (1)

- Malaysia-NPRA List of Comparator Products For Bioequivalence Studies December 2015Document47 pagesMalaysia-NPRA List of Comparator Products For Bioequivalence Studies December 2015Noples RozaliaNo ratings yet

- Behaviour of Reinforced Concrete Beams With Coconut Shell As Coarse AggregatesDocument8 pagesBehaviour of Reinforced Concrete Beams With Coconut Shell As Coarse AggregatesUmair BaigNo ratings yet

- List of ScripsDocument348 pagesList of ScripsVínãy KumarNo ratings yet

- Walter Drilling eDocument155 pagesWalter Drilling eAbdulrahman Al-sNo ratings yet

- Raw Materials Test Sample Status (Received On 2020)Document44 pagesRaw Materials Test Sample Status (Received On 2020)GaFf ArNo ratings yet

- Chapter 6 - Metal WorkDocument27 pagesChapter 6 - Metal WorkIjal HaizalNo ratings yet

- Primary Aluminium Casting Alloys 2010 - Rheinfelden Alloys - ENDocument117 pagesPrimary Aluminium Casting Alloys 2010 - Rheinfelden Alloys - ENtahera aqeelNo ratings yet

- Civil Aviation Requirement Section 3 Series M Part IV Facilities On Delayed Cancelled FlightsDocument7 pagesCivil Aviation Requirement Section 3 Series M Part IV Facilities On Delayed Cancelled FlightsDevesh AgarwalNo ratings yet

- 418d4e9b-48b0-48a9-a4cb-7a14fb756d18Document6 pages418d4e9b-48b0-48a9-a4cb-7a14fb756d18Mohamed Arbi Ben YounesNo ratings yet

- Name: Nim: Capsule (Pharmacy) : Single-Piece Gel Encapsulation ("Soft Capsules")Document5 pagesName: Nim: Capsule (Pharmacy) : Single-Piece Gel Encapsulation ("Soft Capsules")Muhammad ArwanNo ratings yet

- Curtain WallDocument3 pagesCurtain WalljitenderaNo ratings yet

- Internationally Acclaimed Qualification World Class TrainingDocument12 pagesInternationally Acclaimed Qualification World Class TrainingSachin ChaudhariNo ratings yet

- Implement Indian Roads Congress IRC:116-2014 To Solve Pothole Problem Across IndiaDocument20 pagesImplement Indian Roads Congress IRC:116-2014 To Solve Pothole Problem Across IndiaProf. Prithvi Singh Kandhal100% (2)

- Data List / Active Test: Seat Belt - Seat Belt Warning SystemDocument3 pagesData List / Active Test: Seat Belt - Seat Belt Warning SystemdiemnganNo ratings yet

- Crestabond Brochure UkDocument8 pagesCrestabond Brochure UkNduong NguyenNo ratings yet

- AkzoNobel PresentationDocument47 pagesAkzoNobel PresentationSudhir BansalNo ratings yet