Professional Documents

Culture Documents

Astm A269-04

Uploaded by

DANIEL PEREZOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm A269-04

Uploaded by

DANIEL PEREZCopyright:

Available Formats

Not For Production Use (For Reference Only)

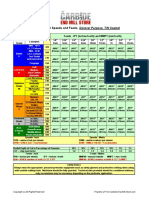

ASTM A269-04 and UI

Specification for Welded Austenitic Stainless Steel Tubing for General Service

ASTM Chemical Requirements

304 304L 316 316L 321

Elements S30400 S30403 S31600 S31603 S32100

(C) Carbon, max 0.080 0.035 0.080 0.035 0.080

(Mn) Manganese, max 2.000 2.000 2.000 2.000 2.000

(P) Phosphorus, max 0.045 0.045 0.045 0.045 0.045

(S) Sulfur, max 0.030 0.030 0.030 0.030 0.030

(Si) Silicon 1.000 1.000 1.000 1.000 1.000

(Ni) Nickel 8.0-11.0 8.0-12.0 10.0-14.0 10.0-14.0 9.0-12.0

(Cr) Chromium 18.0-20.0 18.0-20.0 16.0-18.0 16.0-18.0 17.0-19.0

(Mo) Molybdenum N/A N/A 2.0-3.0 2.0-3.0 N/A

(Ti) Titanium N/A N/A N/A N/A 5xC - 0.070

Mechanical Testing Test Heat Treatment

Test ASTM United - The material will be heat treated by heating to 1900 F minimum and then quenching.

Flare Not Required Required

Flatten Not Required Required Surface Condition

Flange Required Required - The tube surface will be free of scale by pickling or bright annealing (ASTM).

Reverse Bend Not Required Required

Reverse Flatten Required Required Stencil

Eddy Current Required* Required - Man. Name or brand, spec number, and grade.

Hydrostatic Required* Not Required - Marked "welded", "NDE" if eddy current tested, "HT" and the anneal temp if <1900F.

Hardness, max 90 Rb 90 Rb

Pressure Not Required Required *

*Air pressure test 30 psi tubes over 20' for HBA / 180 grit / ID Polish tubes

* ASTM required either an Eddy Current or a Hydrostatic test be performed.

Dimensional Requirements

Outside Diameter Squareness Length** Straightness Weld Height Wall***

Size ASTM United ASTM United ASTM United ASTM United ASTM United ASTM United

1/2" +/- .005 +/- .005 N/A .010 -0 +1/8 -0 +1/8 .030/36" .030/36" .004 +.006 +/- 10% +/- 10%

3/4" +/- .005 +/- .005 N/A .010 -0 +1/8 -0 +1/8 .030/36" .030/36" .004 +.006 +/- 10% +/- 10%

1" +/- .005 -.005 / .002 N/A .015 -0 +1/8 -0 +1/8 .030/36" .030/36" .006 +.006 +/- 10% +/- 10%

1-1/2" +/- .010 -.006/+.002 N/A .025 -0 +3/16 -0 +3/16 .030/36" .030/36" .006 +.006 +/- 10% +/- 10%

2" +/- .010 -.006/+.002 N/A .035 -0 +3/16 -0 +3/16 .030/36" .030/36" .006 +.006 +/- 10% +/- 10%

2-1/2" +/- .010 -.008/+.002 N/A .040 -0 +3/16 -0 +3/16 .030/36" .030/36" .010 +.010 +/- 10% +/- 10%

3" +/- .010 -.008/+.003 N/A .045 -0 +3/16 -0 +3/16 .030/36" .030/36" .010 +.010 +/- 10% +/- 10%

3-1/2" +/- .015 -.008/+.003 N/A .045 -0 +3/16 -0 +3/16 .030/36" .030/36" .010 +.010 +/- 10% +/- 10%

4" +/- .015 -.008/+.003 N/A .045 -0 +3/16 -0 +3/16 .030/36" .030/36" .010 +.010 +/- 10% +/- 10%

4 1/2" +/- .015 -.008/+.003 N/A .045 -0 +3/16 -0 +3/16 .030/36" .030/36" .010 +.010 +/- 10% +/- 10%

6" +/- .030 +/- .015 N/A .045 -0 +3/16 -0 +3/16 .030/36" .030/36" .010 +.010 +/- 10% +/- 10%

** These tolerances apply to 24 ft. lengths or less. For lengths over 24 ft. add a tolerance of 1/8 in. for each 10 ft., or fraction thereof, up to a max of 1/2 in.

*** Applicable only when nominal wall is specified. When minimum wall is specified, the tolerance is -0 +18%.

OP-05-01-D ISSUE: 02/26/97 REV: 05/23/05 ref: 2005 ASTM Standard Vol. 01.01

You might also like

- Astm A270-03 S2 / Asme Bpe and Ui: Not For Production Use (For Reference Only)Document1 pageAstm A270-03 S2 / Asme Bpe and Ui: Not For Production Use (For Reference Only)Federico RevelloNo ratings yet

- ASTM A554 Ek SyfDocument1 pageASTM A554 Ek SyfALİ YİĞİTNo ratings yet

- Tabla de Referencias de Aceros Inoxidables (ASTM A213)Document1 pageTabla de Referencias de Aceros Inoxidables (ASTM A213)Baltasar BuchiniNo ratings yet

- Not For Production Use (For Reference Only) : ASTM A778-01Document1 pageNot For Production Use (For Reference Only) : ASTM A778-01Abu Bakr AsharefNo ratings yet

- Sanitary TubingDocument2 pagesSanitary TubingfitiranNo ratings yet

- ASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingDocument6 pagesASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingJose TorresNo ratings yet

- Armox 370T Class 1: General Product DescriptionDocument2 pagesArmox 370T Class 1: General Product DescriptionSuneelNo ratings yet

- Stainless Steel Molecular Etching PDFDocument6 pagesStainless Steel Molecular Etching PDFp.designNo ratings yet

- ASTM A106 Pipe Specifications - American Piping ProductsDocument7 pagesASTM A106 Pipe Specifications - American Piping ProductsJonnah Faye MojaresNo ratings yet

- PressedDocument46 pagesPressedsameh aboulsoudNo ratings yet

- Stainless Steel & Heat Resistant Steel Electrodes: (Vacuum Pack)Document1 pageStainless Steel & Heat Resistant Steel Electrodes: (Vacuum Pack)Waqas WaqasNo ratings yet

- ASTM A249/A249M-04a and UI: Not For Production Use (For Reference Only)Document1 pageASTM A249/A249M-04a and UI: Not For Production Use (For Reference Only)nieav280No ratings yet

- A 249 - A 249m - 03 Qti0os9bmjq5ts1sruqDocument11 pagesA 249 - A 249m - 03 Qti0os9bmjq5ts1sruqAntonio ChangNo ratings yet

- Hobart Maxal 1100Document2 pagesHobart Maxal 1100jclenerNo ratings yet

- Chemical CompositionDocument13 pagesChemical Compositionssharma3474No ratings yet

- A 53 - A 53m - 00 QtuzltawDocument7 pagesA 53 - A 53m - 00 QtuzltawPablo CzNo ratings yet

- Astm A554-Asme Sa554 Welded Stainless Steel Mechanical TubingDocument3 pagesAstm A554-Asme Sa554 Welded Stainless Steel Mechanical TubingBudy SinagaNo ratings yet

- Technical Data Sheet 15cdv6Document2 pagesTechnical Data Sheet 15cdv6mahmood750No ratings yet

- Astm A493 16Document2 pagesAstm A493 16wongNo ratings yet

- A4-80 Stainless Steel Grade Specification - Midland Bright SteelsDocument4 pagesA4-80 Stainless Steel Grade Specification - Midland Bright SteelsramonaghergheNo ratings yet

- External Threads For Machine Screws and SEMSDocument2 pagesExternal Threads For Machine Screws and SEMSez1010No ratings yet

- Rath Sanitary Tube Uid182010340122 PDFDocument2 pagesRath Sanitary Tube Uid182010340122 PDFthanhquang1001No ratings yet

- Rubber JointsDocument19 pagesRubber Jointsvalentinlupascu33No ratings yet

- As1548 Pt46onrlo l20 August2010bDocument3 pagesAs1548 Pt46onrlo l20 August2010bchoopoNo ratings yet

- Steel Grade Indian StandardsDocument5 pagesSteel Grade Indian StandardsPriyanathan ThayalanNo ratings yet

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- Swagelok TubingDocument1 pageSwagelok TubingMmstevens00No ratings yet

- Commercial Quality SteelDocument2 pagesCommercial Quality Steeljamal nasirNo ratings yet

- Drawn Square Steel BarshDocument8 pagesDrawn Square Steel BarshHmed Ben MohamedNo ratings yet

- Bonded Seals BrochureDocument8 pagesBonded Seals BrochureembasianNo ratings yet

- Manometro Badotherm BP-004-005Document2 pagesManometro Badotherm BP-004-005Luis Alberto Portugal MariacalNo ratings yet

- Aluminum 6061-O: To View All Available Suppliers For This MaterialDocument2 pagesAluminum 6061-O: To View All Available Suppliers For This MaterialAlonso ReynaNo ratings yet

- A269Document5 pagesA269Jeffrey StokesNo ratings yet

- Astm A240 A240m 23Document7 pagesAstm A240 A240m 23Venkatesh KumarNo ratings yet

- UntitledDocument11 pagesUntitledzaxaxazNo ratings yet

- SA/AS1548 - 7 - 460R: XlerplateDocument3 pagesSA/AS1548 - 7 - 460R: XlerplatenavNo ratings yet

- Qualitat Cargols I FemellesDocument34 pagesQualitat Cargols I FemelleshecdomNo ratings yet

- Seamles Tubing Fractional (MS-01-153-SCS) R8Document2 pagesSeamles Tubing Fractional (MS-01-153-SCS) R8herysyam1980No ratings yet

- Sae J933 1998 (En)Document8 pagesSae J933 1998 (En)Oh No PotatoNo ratings yet

- Homologation Low Flow Coefficient Setting Range: TypeDocument2 pagesHomologation Low Flow Coefficient Setting Range: TypeCarlos BernussiNo ratings yet

- Home About Us Products Display News Contact ProductsDocument8 pagesHome About Us Products Display News Contact ProductsBosz InNo ratings yet

- 405-Rezne Data Pre Plosne ZahlbnikyDocument1 page405-Rezne Data Pre Plosne ZahlbnikytomasykNo ratings yet

- Project Report On Aluminium Dross Processing and Scrap Melting UnitDocument8 pagesProject Report On Aluminium Dross Processing and Scrap Melting UnitEIRI Board of Consultants and PublishersNo ratings yet

- Threaded Rod: Key Benefits - PlainDocument6 pagesThreaded Rod: Key Benefits - PlainGuTyNo ratings yet

- Din 17102Document10 pagesDin 17102julio_rocha_1No ratings yet

- Tubular Frame Power Unit D & 10 SeriesDocument4 pagesTubular Frame Power Unit D & 10 SeriesluisedonossaNo ratings yet

- Carbide End Mill Feeds and Speeds General Purpose TiNDocument1 pageCarbide End Mill Feeds and Speeds General Purpose TiNjoshNo ratings yet

- Tube FittingsDocument12 pagesTube FittingsspiritveluNo ratings yet

- Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser TubesDocument10 pagesWelded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubesquiensabe0077No ratings yet

- End Mill Speed FeedDocument12 pagesEnd Mill Speed FeedkxeNo ratings yet

- Stainless Steel: General Information ApplicationsDocument11 pagesStainless Steel: General Information ApplicationscanettijNo ratings yet

- Unibraze ER316L PDFDocument1 pageUnibraze ER316L PDFsmpoe017No ratings yet

- Product CatalogueDocument16 pagesProduct CatalogueGaneshNo ratings yet

- Mag General Business: Quality CertificateDocument1 pageMag General Business: Quality CertificateJohan F. MonroyNo ratings yet

- Product Description Wire RodDocument3 pagesProduct Description Wire RodEngr Farrukh RehanNo ratings yet

- Stainless Steel Properties PDFDocument8 pagesStainless Steel Properties PDFprajash007No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Super Duplex Valve PDFDocument87 pagesSuper Duplex Valve PDFMohamed YousufNo ratings yet

- S-562Qv19-01 Quality Requirements For Ball ValvesDocument13 pagesS-562Qv19-01 Quality Requirements For Ball ValvesDANIEL PEREZ100% (1)

- S-563v18-12-MDS For Piping and Valve Comp PDFDocument189 pagesS-563v18-12-MDS For Piping and Valve Comp PDFRajesh RadeNo ratings yet

- Series 50 52 Delval Butterfly ValvesDocument4 pagesSeries 50 52 Delval Butterfly Valvesajo2402No ratings yet

- WEG Severe Duty Is Standard With Weg w22 Motors Brochure Usaw22sevduty Brochure EnglishDocument16 pagesWEG Severe Duty Is Standard With Weg w22 Motors Brochure Usaw22sevduty Brochure EnglishDANIEL PEREZNo ratings yet

- A Comparison of Current AGMA, ISO and API Gear Rating MethodsDocument39 pagesA Comparison of Current AGMA, ISO and API Gear Rating MethodsharryNo ratings yet

- SKF Cylindircal Roller Bearings PDFDocument36 pagesSKF Cylindircal Roller Bearings PDFurp30234No ratings yet

- Personal Property Services, Leases Supervision and InspectionDocument15 pagesPersonal Property Services, Leases Supervision and InspectionDANIEL PEREZNo ratings yet

- Heresite Corrosion ProtectionDocument2 pagesHeresite Corrosion ProtectionDANIEL PEREZNo ratings yet

- Materials and Processes Quiz 3Document6 pagesMaterials and Processes Quiz 3RuthNo ratings yet

- Phosphorus, Sulfur, and Silicon and The Related ElementsDocument18 pagesPhosphorus, Sulfur, and Silicon and The Related ElementsGerry Mark GubantesNo ratings yet

- K30Document48 pagesK30mlachenal5237No ratings yet

- Zincform G350 PDFDocument2 pagesZincform G350 PDFadityavicky1No ratings yet

- Astm A27 (2010) PDFDocument4 pagesAstm A27 (2010) PDFStuar TencioNo ratings yet

- M & H Valve: Distributor Price ListDocument36 pagesM & H Valve: Distributor Price Listjuan rodriguezNo ratings yet

- Ball Valves enDocument28 pagesBall Valves enmahdiNo ratings yet

- Steel ForgingsDocument143 pagesSteel ForgingsSiavash BayeganNo ratings yet

- A4 Catalogo TX - 12111Document29 pagesA4 Catalogo TX - 12111msajanjNo ratings yet

- Specific Heat MetalsDocument1 pageSpecific Heat Metalsagibson556No ratings yet

- Turbaloy 410 (SS 410) Data SheetDocument1 pageTurbaloy 410 (SS 410) Data SheetcandraNo ratings yet

- Podfa AluminumDocument8 pagesPodfa AluminumAnonymous TfZRkQYNo ratings yet

- M525 Application Guide - Speed & Feed (Inch) : Common Machining FormulasDocument1 pageM525 Application Guide - Speed & Feed (Inch) : Common Machining FormulasRobotNo ratings yet

- Thermal Conductivity TableDocument1 pageThermal Conductivity Tablejeffrey jazarenoNo ratings yet

- Microsoft Word - CarpentryDocument2 pagesMicrosoft Word - CarpentrykokueiNo ratings yet

- 304 Chromic Acid AnodizingDocument6 pages304 Chromic Acid AnodizingPuguh Cahpordjo BaeNo ratings yet

- 2 - SM Watches Father's Day Promotion - June 2023Document11 pages2 - SM Watches Father's Day Promotion - June 2023Shekhar NillNo ratings yet

- Ground ResistorDocument2 pagesGround Resistorashoksince2005No ratings yet

- Verification of Johnson-Cook Material Model Constants of Aa2024-T3 For Use in Finite Element Simulation of Friction Stir Welding and Its Utilization in Severe Plastic DeformationDocument5 pagesVerification of Johnson-Cook Material Model Constants of Aa2024-T3 For Use in Finite Element Simulation of Friction Stir Welding and Its Utilization in Severe Plastic DeformationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Technical Information: Various Kinds of Bending Processes Various Kinds of Bending ProcessesDocument2 pagesTechnical Information: Various Kinds of Bending Processes Various Kinds of Bending ProcessesأبومحمدالزياتNo ratings yet

- SAE L6, Steel Grades, Tool SteelDocument1 pageSAE L6, Steel Grades, Tool SteelMayur12345dt0% (1)

- Dsaud0032801 PDFDocument29 pagesDsaud0032801 PDFsujanto widjajaNo ratings yet

- GREASe Process ReportDocument110 pagesGREASe Process Reportrazamalik01No ratings yet

- Abstracts About WeldingDocument9 pagesAbstracts About WeldingVinayak BhustalimathNo ratings yet

- How and Why Are Butterfly Valves UsedDocument2 pagesHow and Why Are Butterfly Valves UsedMOHAMMAD ASIFNo ratings yet

- Indian Standard Carbon Steel Billets, Blooms, Slabs Bars For Forgings - Specu3Catio'N (Fifih Revision)Document13 pagesIndian Standard Carbon Steel Billets, Blooms, Slabs Bars For Forgings - Specu3Catio'N (Fifih Revision)jbt1311No ratings yet

- Materials For Sour Service Nao SPC D MW 001Document26 pagesMaterials For Sour Service Nao SPC D MW 001Tahir AlzuhdNo ratings yet

- Ssangyong - Compliance Statement-02022017Document11 pagesSsangyong - Compliance Statement-02022017rexNo ratings yet