Professional Documents

Culture Documents

How To Grind Lathe Tools PDF

How To Grind Lathe Tools PDF

Uploaded by

Daniel0 ratings0% found this document useful (0 votes)

18 views16 pagesOriginal Title

How_To_Grind_Lathe_Tools.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views16 pagesHow To Grind Lathe Tools PDF

How To Grind Lathe Tools PDF

Uploaded by

DanielCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

How to Grind

Lathe Tool Cutter Bits

Grinding a Lathe Too! Cutter Bit,

_ Price 10 Cents

Postpaid to Any Address

Claes US! nie Act

SOUTH BEND LATHE WORKS

425 E. Madison Street

SOUTH BEND 82, INDIANA, U.S.A.

Fig. 1. A bar of stesl being machined in the lathe with a correctly ground

eS Cutter bit inserted in a lathe tool holder,

Bulletin No. 35

Modern Shop Practice for Grinding

Lathe Tool Cutter Bits

The cutting tool is one of the most important things to con-

sider in the machining of metal in the lathe. In order to machine

metal accurately and.efficiently it is important that the cutter

bit have a keen cutting edge, ground with the correct clearance,

rake, etc., for the particular kind of metal being machined, and

that the cutter bit be set at the correct height.

In this booklet the latest shop practice for grinding various

types of lathe tool cutter bits is outlined. The methods shown

are used in our own shop, where we operate 150 Back-Geared,

Screw-Cutting Lathes on all kinds of machine work.

South Bend Lathe Works

Seventh reprint, 1946

Copyright, 1938, by South Bend Lathe Works. All rights reserved.

TOP RAGE

Tool Holder

Fig. 2. Lathe tool holder with

How to Grind Lathe Tool Cutter Bits

The cutter bit is that part of the lathe tool

which cuts the metal that must be removed to

bring the work to the desired size and shape.

The cutter bit is usually made of high speed steel,

and held in a lathe tool holder as shown in Fig. 2

at the top of the page.

High speed steel cutter bits are hardened and

are ready for use when properly ground. Fig. 3

at the right shows an unground cutter bit and

Fig. 4 shows the same cutter bit after grinding.

In Fig. 5 the cutter bit is shown mounted in the

lathe tool holder, ready for use.

Correct grinding of the lathe tool cutter bit is

essential for good lathe work, because a properly

ground cutter bit will produce better results, last

longer and cut more freely than one improperly

ground.

The forged steel tool holder as shown at the

top of the page is made in three types, straight,

right hand, and left hand, as shown at the right

in Figs. 6, 7 and 8. These tool holders are also

made in various sizes so they may be used in

various size lathes. These different size tool

holders also accommodate high speed steel cutter

bits of the most practical size for the work they

are intended to do. It is advisable when obtain-

ing a tool holder to specify the size lathe on

which it is to be used.

Fig. 3. Unground cutter bit,

Fig. 4. Cutter bit after grinding.

Fig. 7. Right hand tool holder.

Yess

Fig. 8. Left hand tool holde

You might also like

- Machinery's Handbook Guide: A Guide to Tables, Formulas, & More in the 31st EditionFrom EverandMachinery's Handbook Guide: A Guide to Tables, Formulas, & More in the 31st EditionRating: 5 out of 5 stars5/5 (2)

- 365 Sex Positions PDFDocument387 pages365 Sex Positions PDFsysrerun50% (90)

- Hercus TextBook of TurningDocument56 pagesHercus TextBook of TurningFrancois Marais100% (2)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionFrom EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNo ratings yet

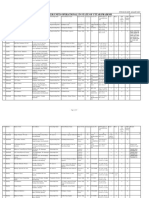

- Performance Profile Sheet NCCER Training-1Document10 pagesPerformance Profile Sheet NCCER Training-1Chris HutchinsonNo ratings yet

- Filipino Construction Terms in ArchitectureDocument2 pagesFilipino Construction Terms in ArchitectureMarj Oblinada100% (3)

- CNC Machining Handbook: Building, Programming, and ImplementationFrom EverandCNC Machining Handbook: Building, Programming, and ImplementationNo ratings yet

- CNC Milling for Makers: Basics - Techniques - ApplicationsFrom EverandCNC Milling for Makers: Basics - Techniques - ApplicationsRating: 4.5 out of 5 stars4.5/5 (6)

- Production Engineering: Jig and Tool DesignFrom EverandProduction Engineering: Jig and Tool DesignRating: 4 out of 5 stars4/5 (9)

- The Art of ShootingDocument164 pagesThe Art of Shootingcharlie20377240100% (1)

- The Art of ShootingDocument164 pagesThe Art of Shootingcharlie20377240100% (1)

- Arcoy DovetailerDocument8 pagesArcoy Dovetailernk186967% (3)

- Advanced Gear Manufacturing and Finishing: Classical and Modern ProcessesFrom EverandAdvanced Gear Manufacturing and Finishing: Classical and Modern ProcessesRating: 3.5 out of 5 stars3.5/5 (2)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- Practical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsFrom EverandPractical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsNo ratings yet

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)

- Metalworking for Home Machinists: 53 Practical Projects to Build YourselfFrom EverandMetalworking for Home Machinists: 53 Practical Projects to Build YourselfNo ratings yet

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- 16 Metalworking Workshop Projects for Home Machinists: Practical & Useful Ideas for the Small ShopFrom Everand16 Metalworking Workshop Projects for Home Machinists: Practical & Useful Ideas for the Small ShopRating: 5 out of 5 stars5/5 (1)

- Metalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopFrom EverandMetalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopVic SmeedNo ratings yet

- Measuring and Marking Metals for Home Machinists: Accurate Techniques for the Small ShopFrom EverandMeasuring and Marking Metals for Home Machinists: Accurate Techniques for the Small ShopRating: 4 out of 5 stars4/5 (1)

- Metalworking: Tools, Materials, and Processes for the HandymanFrom EverandMetalworking: Tools, Materials, and Processes for the HandymanRating: 5 out of 5 stars5/5 (1)

- Shop Theory (Henry Ford Trade School)From EverandShop Theory (Henry Ford Trade School)No ratings yet

- Turning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningFrom EverandTurning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningRating: 2.5 out of 5 stars2.5/5 (2)

- Mechanical Appliances, Mechanical Movements and Novelties of ConstructionFrom EverandMechanical Appliances, Mechanical Movements and Novelties of ConstructionRating: 4 out of 5 stars4/5 (2)

- Mechanics of Sheet Metal FormingFrom EverandMechanics of Sheet Metal FormingJack HuRating: 5 out of 5 stars5/5 (3)

- Drop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsFrom EverandDrop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsRating: 5 out of 5 stars5/5 (1)

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Design Principles of Metal-Cutting Machine ToolsFrom EverandDesign Principles of Metal-Cutting Machine ToolsRating: 4 out of 5 stars4/5 (4)

- Advances in Machine Tool Design and Research 1969: Proceedings of the 10th International M.T.D.R. Conference, University of Manchester Institute of Science and Technology, September 1969From EverandAdvances in Machine Tool Design and Research 1969: Proceedings of the 10th International M.T.D.R. Conference, University of Manchester Institute of Science and Technology, September 1969S. A. TobiasNo ratings yet

- Measuring Tools Machinery's Reference Series Number 21From EverandMeasuring Tools Machinery's Reference Series Number 21Rating: 4 out of 5 stars4/5 (1)

- Metal Forming and Impact Mechanics: William Johnson Commemorative VolumeFrom EverandMetal Forming and Impact Mechanics: William Johnson Commemorative VolumeS. R. ReidRating: 5 out of 5 stars5/5 (1)

- Advances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967From EverandAdvances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967S. A. TobiasRating: 4 out of 5 stars4/5 (1)

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Tech BookDocument57 pagesTech Bookcharlie20377240No ratings yet

- EmpanadasDocument3 pagesEmpanadascharlie20377240No ratings yet

- NRG Greenboard Spec Booklet V7 2013 - 0Document36 pagesNRG Greenboard Spec Booklet V7 2013 - 0charlie20377240No ratings yet

- Wall Frames Text Part 1Document32 pagesWall Frames Text Part 1charlie20377240No ratings yet

- Renew Your Architraves and Skirting BoardsDocument4 pagesRenew Your Architraves and Skirting Boardscharlie20377240No ratings yet

- Sako75kc LHDocument62 pagesSako75kc LHcharlie20377240No ratings yet

- Tech Brochures Truss Facts AusDocument28 pagesTech Brochures Truss Facts AusDee Reyes100% (1)

- Jaco DerringerDocument4 pagesJaco DerringerFunkpiratNo ratings yet

- Japanese Architecture QuizDocument42 pagesJapanese Architecture QuizJohn Rod RecopuertoNo ratings yet

- Low Budget Duplex House Design With Modern Exterior - : 19 Lakh For ConstructionDocument3 pagesLow Budget Duplex House Design With Modern Exterior - : 19 Lakh For Constructionsaneesh81No ratings yet

- 2003-10 Agrandisssement TransformationDocument33 pages2003-10 Agrandisssement TransformationGuy LeuzingerNo ratings yet

- Interior Design Market Survey PDFDocument4 pagesInterior Design Market Survey PDFOmei KhaireNo ratings yet

- Arrow-Pak Retrievingtool: Specification GuideDocument7 pagesArrow-Pak Retrievingtool: Specification GuideTech AlfaNo ratings yet

- Klutch Mini Metal Lathe - 7in X 12inDocument13 pagesKlutch Mini Metal Lathe - 7in X 12inVicente Banda ZuñigaNo ratings yet

- Atlas Construction Company BidDocument1 pageAtlas Construction Company BidStephanie HartNo ratings yet

- Es-Muebles de Construcción SencillaDocument381 pagesEs-Muebles de Construcción SencillaJuan Cruz FernándezNo ratings yet

- Orden OperacionalDocument17 pagesOrden OperacionalNicolas VeraNo ratings yet

- Jamonero de Promoción SerranoDocument1 pageJamonero de Promoción SerranobirutillasNo ratings yet

- Timber Product Stage 1Document68 pagesTimber Product Stage 1Ayush GuptaNo ratings yet

- Hilti Te 80 Atc Avr Specification SheetDocument1 pageHilti Te 80 Atc Avr Specification Sheetlogistica 902No ratings yet

- Trabajo Obra BlancaDocument6 pagesTrabajo Obra Blancaluis lopezNo ratings yet

- Chain Saw: Identify Carpentry Power Tools and Their UsageDocument3 pagesChain Saw: Identify Carpentry Power Tools and Their UsageJc SantosNo ratings yet

- Maili Cove Guidelines 2019 - 1st EditionDocument5 pagesMaili Cove Guidelines 2019 - 1st Editionapi-516209903No ratings yet

- Herramientas de Carpinteria Con Definicion y Las Imagnes Estan Otro LadoDocument7 pagesHerramientas de Carpinteria Con Definicion y Las Imagnes Estan Otro LadoAbner TzejNo ratings yet

- Posi-Strut Brochure 2011Document2 pagesPosi-Strut Brochure 2011lekhanathpaudel2022No ratings yet

- Edoc - Pub Techniques de Mesure Et de ControlepdfDocument10 pagesEdoc - Pub Techniques de Mesure Et de Controlepdfdalo17No ratings yet

- Carta Tecnologica TorneadoDocument4 pagesCarta Tecnologica Torneadoyassell bassillNo ratings yet

- Sanchez Acosta Construccion en Entramado de Madera CPF Allen 2022Document97 pagesSanchez Acosta Construccion en Entramado de Madera CPF Allen 2022martin sanchez acostaNo ratings yet

- Multi Spindle Drilling Machine Project FileDocument28 pagesMulti Spindle Drilling Machine Project FileRoyalAryans100% (5)

- S.M Interiors: Subject Quotation For FlatDocument5 pagesS.M Interiors: Subject Quotation For FlatkiranNo ratings yet

- Propuesta Alpha ChungarDocument4 pagesPropuesta Alpha ChungarEducación UniversitariaNo ratings yet

- New Final List of Veneer - Plywood Jan 2017Document27 pagesNew Final List of Veneer - Plywood Jan 2017PLYMAN INDUSTRIESNo ratings yet

- Setup Sheet Report: Lathe DefaultDocument22 pagesSetup Sheet Report: Lathe Defaultjamesbond1212No ratings yet

- Boston Public Library Central Branch 99Document155 pagesBoston Public Library Central Branch 99enrique málagaNo ratings yet

- Japan Modern - New Ideas For Contemporary Living (PDFDrive)Document284 pagesJapan Modern - New Ideas For Contemporary Living (PDFDrive)thảo huỳnh100% (1)