Professional Documents

Culture Documents

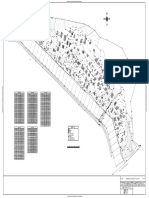

Conexion Viga Columna Principal

Uploaded by

Antonio PérezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conexion Viga Columna Principal

Uploaded by

Antonio PérezCopyright:

Available Formats

Project:

Project no:

Author:

Project data

Project name

Project number

Author

Description

Date 03/12/2019

Design code AISC 360-10

Material

Steel A36, A572 Gr.50, A500, Gr. B

Concrete 4000 psi

CON2

Connection

Item

Name CON2

Description

Analysis Stress, strain/ simplified loading

Design code AISC - LRFD

Beams and columns

β – Direction γ - Pitch α - Rotation Offset ex Offset ey Offset ez

Name Cross-section

[°] [°] [°] [m] [m] [m]

C 5 - HSS(Imp)6X6X1/4 0.0 90.0 0.0 0.000 0.000 0.000

W8-D 6 - W(Imp)8X15 0.0 0.0 0.0 0.075 0.000 0.000

W8-I 6 - W(Imp)8X15 180.0 0.0 0.0 0.075 0.000 0.000

W6-I 1 - Vigueta(W(Imp)6X12) -90.0 0.0 0.0 0.075 0.000 0.000

W6-D 1 - Vigueta(W(Imp)6X12) 90.0 0.0 0.0 0.075 0.000 0.000

Cross-sections

Name Material

5 - HSS(Imp)6X6X1/4 A500, Gr. B

6 - W(Imp)8X15 A572 Gr.50

6 - W(Imp)8X15 A572 Gr.50

1 - Vigueta(W(Imp)6X12) A572 Gr.50

1 - Vigueta(W(Imp)6X12) A572 Gr.50

7 - L(Imp)2X2X3/16 A36

7 - L(Imp)2X2X3/16 A36

7 - L(Imp)2X2X3/16 A36

7 - L(Imp)2X2X3/16 A36

Material

Steel A36, A500, Gr. B, A572 Gr.50

Load effects

03/12/2019 22:16:50 p. m. 1/6

Project:

Project no:

Author:

X N Vy Vz Mx My Mz

Name Member Pos.

[m] [kN] [kN] [kN] [kNm] [kNm] [kNm]

LE1 W8-D End 0.000 0.000 0.000 -51.400 0.00 39.56 0.00

W8-I End 0.000 0.000 0.000 -69.150 0.00 45.51 0.00

W6-I End 0.000 0.000 0.000 -21.730 0.00 0.00 0.00

W6-D End 0.000 0.000 0.000 -16.840 0.00 0.00 0.00

Results

Summary

Name Value Check status

Analysis 100.0% OK

Plates 0.7 < 5% OK

Welds 84.3 < 100% OK

Buckling Not calculated

Plates

Thickness σEd εPl

Name Material Loads Check status

[in] [ksi] [%]

C A500, Gr. B 1/4" LE1 38.0 0.5 OK

W8-D-bfl 1 A572 Gr.50 5/16" LE1 23.7 0.0 OK

W8-D-tfl 1 A572 Gr.50 5/16" LE1 23.7 0.0 OK

W8-D-w 1 A572 Gr.50 1/4" LE1 45.1 0.2 OK

W8-I-bfl 1 A572 Gr.50 5/16" LE1 25.6 0.0 OK

W8-I-tfl 1 A572 Gr.50 5/16" LE1 25.6 0.0 OK

W8-I-w 1 A572 Gr.50 1/4" LE1 45.2 0.7 OK

W6-I-bfl 1 A572 Gr.50 1/4" LE1 43.7 0.0 OK

W6-I-tfl 1 A572 Gr.50 1/4" LE1 43.2 0.0 OK

W6-I-w 1 A572 Gr.50 1/4" LE1 10.6 0.0 OK

W6-D-bfl 1 A572 Gr.50 1/4" LE1 34.8 0.0 OK

W6-D-tfl 1 A572 Gr.50 1/4" LE1 34.6 0.0 OK

W6-D-w 1 A572 Gr.50 1/4" LE1 8.1 0.0 OK

CLEAT1-bfl 1 A36 3/16" LE1 32.4 0.1 OK

CLEAT1-w 1 A36 3/16" LE1 32.4 0.1 OK

CLEAT2-bfl 1 A36 3/16" LE1 32.5 0.2 OK

CLEAT2-w 1 A36 3/16" LE1 32.5 0.3 OK

CLEAT3-bfl 1 A36 3/16" LE1 32.5 0.2 OK

CLEAT3-w 1 A36 3/16" LE1 32.5 0.3 OK

CLEAT4-bfl 1 A36 3/16" LE1 32.4 0.1 OK

CLEAT4-w 1 A36 3/16" LE1 32.4 0.1 OK

WID1a A36 5/16" LE1 27.1 0.1 OK

WID1b A36 5/16" LE1 27.1 0.1 OK

WID2a A36 5/16" LE1 32.5 0.4 OK

WID2b A36 5/16" LE1 32.5 0.4 OK

Design data

fy εlim

Material

[ksi] [1e-4]

A500, Gr. B 42.1 500.0

A572 Gr.50 50.0 500.0

A36 36.0 500.0

03/12/2019 22:16:50 p. m. 2/6

Project:

Project no:

Author:

Strain check, LE1

Equivalent stress, LE1

Welds

Thickness Leg size S Length Fn φRnw Ut

Item Edge Material Loads Check status

[in] [in] [m] [kN] [kN] [%]

C-w 3 WID1a E70xx ◢3/16"◣ ◢1/4"◣ 0.120 LE1 24.304 29.037 83.7 OK

E70xx ◢3/16"◣ ◢1/4"◣ 0.120 LE1 24.300 29.037 83.7 OK

W8-D-tfl 1 WID1a E70xx ◢3/16"◣ ◢1/4"◣ 0.200 LE1 17.094 28.259 60.5 OK

E70xx ◢3/16"◣ ◢1/4"◣ 0.200 LE1 17.098 28.259 60.5 OK

C-w 3 WID1b E70xx ◢3/16"◣ ◢1/4"◣ 0.120 LE1 24.300 29.037 83.7 OK

03/12/2019 22:16:50 p. m. 3/6

Project:

Project no:

Author:

Thickness Leg size S Length Fn φRnw Ut

Item Edge Material Loads Check status

[in] [in] [m] [kN] [kN] [%]

E70xx ◢3/16"◣ ◢1/4"◣ 0.120 LE1 24.304 29.037 83.7 OK

W8-D-bfl 1 WID1b E70xx ◢3/16"◣ ◢1/4"◣ 0.200 LE1 17.105 28.266 60.5 OK

E70xx ◢3/16"◣ ◢1/4"◣ 0.200 LE1 17.102 28.266 60.5 OK

C-w 1 WID2a E70xx ◢3/16"◣ ◢1/4"◣ 0.120 LE1 24.539 29.100 84.3 OK

E70xx ◢3/16"◣ ◢1/4"◣ 0.120 LE1 24.543 29.100 84.3 OK

W8-I-tfl 1 WID2a E70xx ◢3/16"◣ ◢1/4"◣ 0.200 LE1 18.766 28.759 65.3 OK

E70xx ◢3/16"◣ ◢1/4"◣ 0.200 LE1 18.763 28.758 65.2 OK

C-w 1 WID2b E70xx ◢3/16"◣ ◢1/4"◣ 0.120 LE1 24.543 29.100 84.3 OK

E70xx ◢3/16"◣ ◢1/4"◣ 0.120 LE1 24.539 29.100 84.3 OK

W8-I-bfl 1 WID2b E70xx ◢3/16"◣ ◢1/4"◣ 0.200 LE1 18.776 28.769 65.3 OK

E70xx ◢3/16"◣ ◢1/4"◣ 0.200 LE1 18.779 28.769 65.3 OK

C-w 1 W8-D-w 1 E70xx ◢3/16"◣ ◢1/4"◣ 0.198 LE1 23.759 28.658 82.9 OK

E70xx ◢3/16"◣ ◢1/4"◣ 0.198 LE1 23.758 28.658 82.9 OK

C-w 3 W8-I-w 1 E70xx ◢3/16"◣ ◢1/4"◣ 0.198 LE1 23.986 28.714 83.5 OK

E70xx ◢3/16"◣ ◢1/4"◣ 0.198 LE1 23.987 28.714 83.5 OK

W6-D-bfl 1 CLEAT1-bfl 1 E70xx ◢3/16" ◢1/4" 0.041 LE1 7.579 14.590 51.9 OK

W6-D-bfl 1 CLEAT1-bfl 1 E70xx ◢3/16" ◢1/4" 0.041 LE1 7.670 14.523 52.8 OK

W6-D-bfl 1 CLEAT1-bfl 1 E70xx ◢3/16" ◢1/4" 0.075 LE1 2.748 10.727 25.6 OK

C-w 2 CLEAT1-w 1 E70xx ◢3/16" ◢1/4" 0.048 LE1 5.207 13.876 37.5 OK

C-w 2 CLEAT1-w 1 E70xx ◢3/16" ◢1/4" 0.048 LE1 4.147 13.773 30.1 OK

C-w 2 CLEAT1-w 1 E70xx ◢3/16" ◢1/4" 0.075 LE1 2.188 10.767 20.3 OK

W6-I-bfl 1 CLEAT2-bfl 1 E70xx ◢3/16" ◢1/4" 0.041 LE1 10.301 14.641 70.4 OK

W6-I-bfl 1 CLEAT2-bfl 1 E70xx ◢3/16" ◢1/4" 0.041 LE1 10.286 14.688 70.0 OK

W6-I-bfl 1 CLEAT2-bfl 1 E70xx ◢3/16" ◢1/4" 0.075 LE1 3.558 10.455 34.0 OK

C-w 4 CLEAT2-w 1 E70xx ◢3/16" ◢1/4" 0.048 LE1 7.666 13.681 56.0 OK

C-w 4 CLEAT2-w 1 E70xx ◢3/16" ◢1/4" 0.048 LE1 8.512 13.785 61.7 OK

C-w 4 CLEAT2-w 1 E70xx ◢3/16" ◢1/4" 0.075 LE1 2.180 11.018 19.8 OK

W6-I-tfl 1 CLEAT3-bfl 1 E60xx ◢3/16" ◢1/4" 0.041 LE1 9.496 12.640 75.1 OK

W6-I-tfl 1 CLEAT3-bfl 1 E60xx ◢3/16" ◢1/4" 0.041 LE1 9.500 12.608 75.3 OK

W6-I-tfl 1 CLEAT3-bfl 1 E60xx ◢3/16" ◢1/4" 0.075 LE1 3.493 8.921 39.2 OK

C-w 4 CLEAT3-w 1 E60xx ◢3/16" ◢1/4" 0.048 LE1 8.611 11.857 72.6 OK

C-w 4 CLEAT3-w 1 E60xx ◢3/16" ◢1/4" 0.048 LE1 7.776 11.781 66.0 OK

C-w 4 CLEAT3-w 1 E60xx ◢3/16" ◢1/4" 0.075 LE1 2.179 9.433 23.1 OK

W6-D-tfl 1 CLEAT4-bfl 1 E60xx ◢3/16" ◢1/4" 0.041 LE1 7.959 12.465 63.8 OK

W6-D-tfl 1 CLEAT4-bfl 1 E60xx ◢3/16" ◢1/4" 0.041 LE1 7.855 12.520 62.7 OK

W6-D-tfl 1 CLEAT4-bfl 1 E60xx ◢3/16" ◢1/4" 0.075 LE1 2.737 9.200 29.8 OK

C-w 2 CLEAT4-w 1 E60xx ◢3/16" ◢1/4" 0.048 LE1 4.493 11.841 37.9 OK

C-w 2 CLEAT4-w 1 E60xx ◢3/16" ◢1/4" 0.048 LE1 5.532 11.912 46.4 OK

C-w 2 CLEAT4-w 1 E60xx ◢3/16" ◢1/4" 0.075 LE1 2.186 9.234 23.7 OK

Buckling

Buckling analysis was not calculated.

Bill of material

Manufacturing operations

Plates Welds Length

Name Shape Nr. Bolts Nr.

[m] [in] [m]

WID1 P5/16"x0.1-0.2 (A36) 2 Double fillet: a = 3/16" 0.6

WID2 P5/16"x0.1-0.2 (A36) 2 Double fillet: a = 3/16" 0.6

Welds

Thickness Length

Type Material

[in] [m]

Double fillet E70xx 3/16" 1.7

Fillet E70xx 3/16" 0.3

Fillet E70xx 3/16" 0.3

Fillet E60xx 3/16" 0.3

Fillet E60xx 3/16" 0.3

Bolts

Name Count

Drawing

03/12/2019 22:16:50 p. m. 4/6

Project:

Project no:

Author:

WID1

03/12/2019 22:16:50 p. m. 5/6

Project:

Project no:

Author:

WID2

Symbol explanation

Symbol Symbol explanation

εPl Strain

σEd Eq. stress

Fn Force in weld

φRnw Weld resistance AISC 360-10 J2.4

Ut Utilization

Code setting

Item Value Unit Reference

Friction coefficient - concrete 0.25 - Design guide 01 3.5.1

Friction coefficient in slip-resistance 0.30 - AISC 360-10 - J3-4

Limit plastic strain 0.05 -

Weld stress evaluation Plastic redistribution

Detailing No

Distance between bolts [d] 2.66 - AISC 360-10 - J3

Concrete cone breakout resistance Yes

03/12/2019 22:16:50 p. m. 6/6

You might also like

- F-1144 NormaDocument7 pagesF-1144 NormaAntonio Pérez100% (1)

- Idaan InformaDocument22 pagesIdaan InformaAntonio PérezNo ratings yet

- CC Utilcritmanual Rules ManualDocument37 pagesCC Utilcritmanual Rules ManualAntonio PérezNo ratings yet

- Walling: Design ManualDocument30 pagesWalling: Design ManualAntonio PérezNo ratings yet

- How To Make Arepas (3 Ingredients!) - Minimalist BakerDocument3 pagesHow To Make Arepas (3 Ingredients!) - Minimalist BakerAntonio PérezNo ratings yet

- 2E-1 ManualDocument12 pages2E-1 ManualAntonio PérezNo ratings yet

- RAM Connection Standalone CE Units System: S Current Date: SDocument1 pageRAM Connection Standalone CE Units System: S Current Date: SAntonio PérezNo ratings yet

- Pavimentos Compuestos BackcalculationDocument505 pagesPavimentos Compuestos BackcalculationAntonio PérezNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductAntonio PérezNo ratings yet

- Pavimentos Compuestos BackcalculationDocument505 pagesPavimentos Compuestos BackcalculationAntonio PérezNo ratings yet

- LWD Fundamentals: 12 Annual Minnesota Paving Conference February 14, 2008 St. Paul, MinnesotaDocument31 pagesLWD Fundamentals: 12 Annual Minnesota Paving Conference February 14, 2008 St. Paul, MinnesotaAntonio PérezNo ratings yet

- E-STUDIO2050C - 2550C Brochure (Ver3)Document6 pagesE-STUDIO2050C - 2550C Brochure (Ver3)Antonio PérezNo ratings yet

- ASTM Standard D4695-03Document6 pagesASTM Standard D4695-03Antonio Pérez100% (2)

- ASTM Standard D4695-03Document6 pagesASTM Standard D4695-03Antonio Pérez100% (2)

- 8 - Virtual WorkDocument184 pages8 - Virtual WorkAntonio PérezNo ratings yet

- Human Resource ManagementDocument27 pagesHuman Resource ManagementAyesha Fareed KhanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Refrigeration PipingDocument43 pagesRefrigeration PipingenigmazeeNo ratings yet

- Unit II: Analysis of Bars of Varying Cross SectionsDocument15 pagesUnit II: Analysis of Bars of Varying Cross Sectionsermias0% (1)

- Lifting Lug Calculation - Concrete BucketDocument3 pagesLifting Lug Calculation - Concrete Bucketali akbarNo ratings yet

- Weekly Assessment No.4 3rd QuarterDocument1 pageWeekly Assessment No.4 3rd QuarterLORLITO MALABORBORNo ratings yet

- Determination of Coefficient of Discharge of A Venturi MeterDocument1 pageDetermination of Coefficient of Discharge of A Venturi MeterJoffer Gallamaso50% (2)

- Hydraulic StructureDocument7 pagesHydraulic Structurekartikey papnoiNo ratings yet

- Fermenter DesignDocument31 pagesFermenter DesignV0% (1)

- A07 52si PDFDocument20 pagesA07 52si PDFAndrei Alexandru TulbureanuNo ratings yet

- Grade 8 Act 2Document10 pagesGrade 8 Act 2Charis Dela CruzNo ratings yet

- Venturi, Orifice, RotameterDocument34 pagesVenturi, Orifice, RotameterVinod VadithyaNo ratings yet

- 8.03 Experimental Evaluation of A Polyester Geogrid As Anti-Reflective Cracking Interlayer On OverlaysDocument8 pages8.03 Experimental Evaluation of A Polyester Geogrid As Anti-Reflective Cracking Interlayer On OverlaysDanilo Rojas MartinezNo ratings yet

- Introduction To Aerospace PropulsionDocument11 pagesIntroduction To Aerospace PropulsionmgskumarNo ratings yet

- Chapter Two-2-Deflection & End Block PDFDocument28 pagesChapter Two-2-Deflection & End Block PDFAmirul Asyhraf ArsadNo ratings yet

- Wind DesignDocument5 pagesWind DesignSedin HodžićNo ratings yet

- Matprop HYPERMESH 1DDocument12 pagesMatprop HYPERMESH 1DSaurabh MistryNo ratings yet

- High Delta T Chilled Water SystemDocument13 pagesHigh Delta T Chilled Water SystemShivraj Sawant100% (3)

- Per: AISI Spec S100-12 For: Lipped Z Cold Formed SectionDocument4 pagesPer: AISI Spec S100-12 For: Lipped Z Cold Formed SectionTri huỳnhNo ratings yet

- Fluent12 Workshop05 CentrifugalDocument29 pagesFluent12 Workshop05 CentrifugalAboMuhmadSr.No ratings yet

- Torsion of Prismatic BarDocument6 pagesTorsion of Prismatic BarPramod Sharma PNo ratings yet

- AS 3600-2009 Ex001Document8 pagesAS 3600-2009 Ex001Antonius AjalahNo ratings yet

- Take Home RCDDocument2 pagesTake Home RCDWilfredo OchavezNo ratings yet

- BS-117 (R) 2015 Scour Depth Estimation, Countermeasures and Monitoring at Bridge Crossing - Guide For EngineersDocument47 pagesBS-117 (R) 2015 Scour Depth Estimation, Countermeasures and Monitoring at Bridge Crossing - Guide For EngineersM PMNo ratings yet

- MPPT-2 - Centrifugal PumpsDocument71 pagesMPPT-2 - Centrifugal Pumpsnaughty dela cruzNo ratings yet

- Gas Dynamics-Fanno FlowDocument29 pagesGas Dynamics-Fanno FlowRahulNo ratings yet

- Bolted Connection Angle Brace TensionDocument2 pagesBolted Connection Angle Brace TensionRajib MaharjanNo ratings yet

- Lecture17 Slides PDFDocument17 pagesLecture17 Slides PDFAfraz SeholeNo ratings yet

- Solar Water Heating - WikipDocument22 pagesSolar Water Heating - Wikipbekku100% (1)

- Fracture Toughness Evaluation of WC-Co Alloys by Indentation TestingDocument12 pagesFracture Toughness Evaluation of WC-Co Alloys by Indentation TestingFjodorSergNo ratings yet

- Analysis of Pier Structures Supported On Battered Piles Using MotemsDocument27 pagesAnalysis of Pier Structures Supported On Battered Piles Using MotemsJaymin PatilNo ratings yet

- Unit I Heat ConductionDocument22 pagesUnit I Heat Conductionishwarkp17No ratings yet