Professional Documents

Culture Documents

Swimming Pool تصميم المسابح

Uploaded by

samehCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Swimming Pool تصميم المسابح

Uploaded by

samehCopyright:

Available Formats

PIPE FRICTION CALCULATION

The average velocity v in a pipe is calculated based on the formula [1] and the appropriate units

are indicated in parentheses. (see the last page for a table of all the symbols)

The Reynolds Re number is calculated based on formula [2].

If the Reynolds number is below 2000 than the flow is said to be in a laminar regime. If the

Reynolds number is above 4000 the regime is turbulent. The velocity is usually high enough in

industrial processes to make the flow regime turbulent. The viscosity of many fluids can be

found in the Cameron Hydraulic data book. The viscosity of water at 60F is 1.13 cSt.

If the flow is laminar then the friction parameter f is calculated with the laminar flow equation [3].

If the flow is turbulent then the friction parameter f is calculated based on the Swamee-Jain

equation [4].

In the turbulent flow regime the friction factor f depends on the absolute roughness of the pipe

inner wall. Table 1 provide some values for various materials.

ε

STEEL 0.0018

ST.ST. 0.0018

CAST IRON 0.0102

PVC 0.00006

The friction factor DHFP/L is calculated with the Darcy-Weisback equation [5]

g =32.17 ft/s²

The pipe friction loss DHFP is calculated with equation [6]

ENG. FAISAL ALRAI

FEB.22.2008

calculation

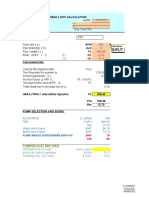

ESTIMATING PIPELINE HEAD LOSS AND PUMP SELECTION Project : CRESCENT BY / INFRASTRUCT Date : 22/ 02 / 08

USING DARCY WEISBACH METHOD System : FIRE HYDRAND SYSTEM Prepared By ; Eng. Faisal Alrai

INPUT

Liquid type : DATA Water

q = flow rate Usgpm (GPM) m³ 180 792.6

D = pipe diameter in (inch) 6 6.165 UPVC CLASS E BS3505

L = pipe length ft (feet) m 2600 8530

v velocity ft/s (feet/second)

The average velocity v in the pipe is:

V = 0.4085 Xq / D² = 8.52 Ft / s

μ = viscosity CSt (centistokes) , WATER at 60 °F ν 1.13

The Reynolds Re number is:

Re = 7745.8 x V *D / μ = 359999.74

Re^0.9 100155

ε

ε = pipe roughness Ft (feet) 0.00006 PVC STEEL 0.0018

f = friction parameter Non dimensional ST.ST. 0.0018

The friction parameter f is: CAST IRON 0.0102

f = 0.25 / {Log10 (ε /3.7*D + 5.74 / Re^0.9)} ² 0.015232 PVC 0.00006

0.01523

∆HFP / L friction factor (feet of fluid/100 ft) of pipe

g = acceleration due to gravity (32.17 ft/s2) 32.17

The friction factor ∆HFP / L is calculated with the Darcy-Weisback equation

∆HFP / L = 1200 f * V² / D * 2g 3.34 Ft./100Ft of pipe

The pipe friction loss ∆HFP is:

∆HFP = ∆HFP / L * ( L/100) 285.27 Feet

ENG. FAISAL ALRAI

FEB.22.2008

Page 1 of 4

ESTIMATING PIPELINE HEAD LOSS AND PUMP SELECTION Project : CRESCENT BY / INFRASTRUCTURE Date : 22/ 02 / 08

USING DARCY WEISBACH METHOD System : FIRE HYDRAND SYSTEM Prepared By ; Eng. Faisal Alrai

A- PIPE LOSS CALCULATION Table:1 CONVERSION FACTORS FOR HEAD LOSS FORMULA

hL = ( c1 X f X L X q² ) / (d)^5 ( Ft. ) FLOW (q) c1 hL L d

hL = head loss Input data ft³ /min 6260 Ft of fluid Ft in

c1=conversion factor for head loss calculation (table1). 0.0311 gal /min 0.0311 Ft of fluid Ft in

f = darcy friction factor from moody curve 0.01523242 m³ /s 8.265x(10)10 Ft of fluid Ft mm

L = pipe length (feet) 2600 m 8530.18 q² Lit. /min 22950 Ft of fluid Ft mm

q = flowrat gal/min 180 m³ / h 3000 792.60 792.6 628214.76

d = pipe iside diameter ( inch) 150 mm upvc class E 6.165 .

Table:2 CONVERSION FACTORS FOR REYNOLDS NO. FORMULA

To find the friction factor ( f ) from curve , Re & Rr sould be calculated: FLOW (q) c2 F. density(ρ) absol.visc(μ)

Reynolds no. Re = (c2 X q X ρ) / d X µ dXµ ft³ /sec 22700 lb/ft³ cp

Relative roughness of the pipe Rr =ε /d 6.782 gal /min 50.6 lb/ft³ cp

c2 = conversion factor for reynolds No. calculation 50.6 m³ /s 1273000 kg/m³ cp

ρ = fluid weight density 62.34 Lit. /min 22950 kg/m³ cp

µ = fluid absolute viscosity 1.1

ε = Absolute reoughness values for clean pipe : 0.00006 Table:3 (ε)TYPICAL ABSOLUT ROUGHNESS VALUES FOR CLEAN PIPE

MATERIAL ε

Reynolds No. R. Roughness Inches Millimeters

Re Rr =ε /d STEEL 0.0018 0.046

368676.63649635 0.0000097 ST.ST. 0.0018 0.046

3.686766365 CAST IRON 0.0102 0.259

Note: PVC 0.00006 0.0015

f =64/Re for laminar flow Re less than 2000

f - for turbulant flow Re greater than 2000 Table:4 DENSITIES AND VISCOOSITIES OF TYPICAL FLUIDS AT 60˚ F

FLUID Density Viscosity

f = 0.25 / {Log10 (ε /3.7*D + 5.74 / Re^0.9)} ² f = 0.0152324 ρ lb/ft³ μ

Table:5 CONVERSION FACTORS FOR VALVES AND FITTINGS FORMULA WATER 62.34 1.1

FLOW (q) C3 DIAMETER ETHAN 23 0.05

ft³ /sec 522 in PROPANE 31.2 0.12

gal /min 0.00259 in BUTANE 44.3 0.19

m³ /s 8265X(10)7 mm ETHYL ALCOHOL 49.9 1.3

Lit. /min 22.96 mm

ENG. FAISAL RAI

Feb.15.2008

Page 2 of 4

For flowrate (q) { gal/min} &water at 60˚F . Data and Factors will be: v = 0.4085*q/d²

section flowrate factor factor density viscosity pip diam. friction pipe rough. pipe L hL V ( Ft/s )

q c1 c2 ρ µ d f ε L(Ft) Ft

L1 792.6 0.0311 50.6 62.34 1.1 6.165 0.01523 0.00006 8530.18373 285.06 8.52

L2 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

L3 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

L4 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

L5 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

L6 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

L7 0 0.0311 50.6 62.34 1.1 1 0 0.0018 0 0 0.00

Pipe Head Loss h L ( Ft ) 8530.18373 285.06

B- VALVES AND FITTINGS HEAD LOSS

hLvf = c3 X K Xq²/d^4 ( Ft. ) K FOR FITTINGS AND VALVES TYPE :

c3 = conversion factor for valve head loos calculation TYPE K

K = valve resistance coefficient Pipe entrance,inward proj. 0.78

K = f T X (L/d) Pipe entrance, Flush 0.5

f T = turbulant friction factors for a partucular pipe diam. Pipe Exit , all 1 OR

Ka 1.5 1.78

L/d for valves and fittings type : PIPE DIA.= 6 Ref. A&B

Type L/d from fT fitting Qty K1…n K1…n =[ f T X (L/d )] x No. of valve or fitting type

Gate valve 8 0.013 11 1.144 Table : 6 f T = turbulant friction factors for a partucular pipe diam.

Ball valve 6 0.013 0 0 Reference: A Reference: B

Butterfly valve 35 0.013 0 0 Fitting L/D pipe size fT

globe valve 340 0.013 2 8.84 Globe Valve 340 1 0.023

Check valve , lift 600 0.013 0 0 Gate Valve 8 1 1/4 0.022

Check valve , swing 50 0.013 1 0.65 Lift Check Valve 600 1 1/5 0.021

Check valve , tilting disc 20 0.013 0 0 Swing Check Valve 50 2 0.019

Ccheck valve , stop check 400 0.013 1 5.2 Ball Valve 6 2 1/2 - 3 0.018

Elbow -90 30 0.013 4 1.56 Butterfly Valve 35 4 0.017

Elbow-45 16 0.013 0 0 Pipe Entrance 0.5 6 0.015

Tee, flow through run 20 0.013 1 0.26 Pipe Exit 1 8 to 10 0.014

Tee, flow through branch 60 0.013 0 0 Tee Through 20 12 t0 16 0.013

Bend r/D=3 12 0.013 0 0 Tee- Branch flow 60 18 to 24 0.012

Bend r/D=6 17 0.013 0 0 Elbow-90 30

Bend r/D=12 34 0.013 0 0 Elbow -45 16

Bend r/D=20 50 0.013 0 0 Bend r/D=3 12

K b fittings 17.654 Bend r/D=6 17

Bend r/D=12 34

Bend r/D=20 50

ENG. FAISAL RAI

Feb.15.2008

kc for Equipment Page 3 of 4

Equipment kc

Equip. Qty. kc kc

CHIL. COIL 0 11 0

AHU COIL 0 0 Pipe Head Loss

H.Exch. 0 0 h L ( Ft. )

0 285.06

0

0 TOTAL VALVES & FITTINGS HEAD LOOS

Equip.kc = 0 c3 K q2 (d)^4

0.00259 19.154 628214.76 1444.54915

K = Ka+(K1 + K2 + K3 …+Kn )+kc for valves + fittings & Equipment valves & fittings Head Loss

h L ( Ft. )

K = Ka + Kb + Kc 21.57 SEE NOTE

19.154

C TOTAL PRESSURE LOSS Bernoulli theorem

H = Z+[144 X P / ρ] + [ V² / (2 X g)]

( pressure head and velocity head )

H = total head

Z = elevation above a reference level

p = pressure

v = mean velocity of the fluid in the pipeline

g = gravitional constat ( 32.2 ft/sec²) US units.

Total head loss in the pipe line (h L)

PIPE LINE ,VALVES & FITTINGS

306.63 Ft.

Differintial pressure calculation

(Δp) = p1-p2 = ρ /144 { Z2 - Z1 + (v2² - v1² ) / 2g + h L}

IF NO CHANGE IN PIPE SIZE , ,THE VELOSITY DROPS = 0

Pipe inlet Elivation (Z1) Pipe disch. Elev.(Z2)

0 15.81 Ft. 4.82 m

ρ /144 hL Z2 - Z1 (v2² - v1² ) / 2g (Δp) PSI Δp Ft Mtr Bar

0.4329166667 306.63 15.81 0 139.58983 322.45 96.74 9.63

Δh Ft fluid = 2.31 p (psi) / SG

ENG. FAISAL RAI

Feb.15.2008

D PUMP SELECTION AND SIZING

HEAD ( TDH ) = Static head (Hs) + friction head (Hf) + pressure hesd ( Hp) + velocity head(Hv) Page 4 of 4

Static head ( Hs) = is measured from the surface of the liquid in the section vessel to the surface

of the liquid in the vessel where the liquid is being delivered. In closed-loop system , the total static head = 0 .

Fittings & valves Friction head Hf = K X V² / 2g 21.57

Pipe Friction head ( From friction loss chart ) Hf = f X L /100 285.06

Velocity head Hv = V² / 2g 0

f = friction ft/ 100 ft 0.01523242 Static Head 15.81

K = resistance coefficient 19.154 TOTAL DH ( Ft ) 322.44

V = Fluid velocity ft/sec. 8.52

g = acceleration due gravity = 32.2 ft./sec² 32.2 Mtr 96.73

Result PSI 139.58

BAR 9.63

Design velocity = ( 4 - 6 ) ft / sec for section

= ( 6 - 8 ) ft / sec for discharge

1 PUMP Horsepower and efficiency:

water horsepower ( WHP ) = Outpot of the pump handlind a liquid

WHP = (Q X H X sg) / 3960

2 Brake horsepower ( BHP ) = Actual supplied power from motor

BHP = ( Q X H X sg ) / 3960 X ή = WHP / ή

ή = pump efficiency

3 Electric current for sizing starters and wire ( I ) [ Amp.]

I = 746 X BHP / 1.73 X E X PF X Eff for 3 ph

I = 746 X BHP / E X PF X Eff for 1 ph

E = Voltage ( volts) 380

PF = Power Factor 0.85

EFF. = Motor efficiency 0.75

1.73 242.25

419.09

Q ( GPM) H (Ft.) SG WHP BHP I ( AMP.)

792.6 322.44 1 64.54 86.05 153.17

PUMP BRAKE HORSPOWER BHP WILL BE +10% = 94.65 HP

100 HP

ENG. FAISAL RAI

Feb.15.2008

OTHER METHOD

TOTAL PUMPING HEAD

Q (m3/s) H(m)

0.0500 98.31

ID = inch m

6.165 0.156591

f L(m) V ( m /s ) D(m) g

0.0152324222 2600.67 2.59720436 0.156591 9.81

hf = 4f X L x V² / 2Dg = 93.48

hz hf hp H(m)

4.82 93.48 0.00 98.31

Q ( m³ /s ) 0.0500

W ( Kg/m3) 1000

H(m) 98.31

Eff. 0.75

WHP = Q X W X H / 75 = 65.54

HP / 0.75 = 87.38

HP kw

87.38 65.19

96.12

ENG. FAISAL RAI

Feb.15.2008

f = .005 ( 1 + 1 / 40 D ) ; D = Mtr.

ENG. FAISAL RAI

Feb.15.2008

Relative roughness for some common materials can be found in the table below :

Roughness - k

Surface x 10 m

-3

feet

Copper, Lead, Brass, Aluminum (new) 0.001 - 0.002 3.33 - 6.7 10-6

PVC and Plastic Pipes 0.0015 - 0.007 0.5 - 2.33 10-5

Epoxy, Vinyl Ester and Isophthalic pipe 0.005 1.7 10-5

Stainless steel 0.015 5 10-5

Steel commercial pipe 0.045 - 0.09 1.5 - 3 10-4

Stretched steel 0.015 5 10-5

Weld steel 0.045 1.5 10-4

Galvanized steel 0.15 5 10-4

Rusted steel (corrosion) 0.15 - 4 5 - 133 10-4

New cast iron 0.25 - 0.8 8 - 27 10-4

Worn cast iron 0.8 - 1.5 2.7 - 5 10-3

Rusty cast iron 1.5 - 2.5 5 - 8.3 10-3

Sheet or asphalted cast iron 0.01 - 0.015 3.33 - 5 10-5

Smoothed cement 0.3 1 10-3

Ordinary concrete 0.3 - 1 1 - 3.33 10-3

Coarse concrete 0.3 - 5 1 - 16.7 10-3

Well planed wood 0.18 - 0.9 6 - 30 10-4

Ordinary wood 5 16.7 10-3

ENG. FAISAL RAI

Feb.15.2008

0

ENG. FAISAL RAI

Feb.15.2008

HEAD LOOS & PUMP SELECTION AND SIZING

HEAD ( H ) = Static head (Hs) + friction head (Hf) + pressure head ( Hp) + velocity head(Hv)

Static head ( Hs) = is measured from the surface of the liquid in the section

vessel to the surface of the liquid in the vessel where the liquid is being delivered.

In closed-loop system , the total static head = 0 .other equesions :

Fittings & valves Friction head Hf = K X V² / 2g

Pipe Friction head ( From friction loss chart ) Hf = f X L /100

Velocity head Hv = V² / 2g

f = friction ft/ 100 ft

K = resistance coefficient

V = Fluid velocity ft/sec.= V= 0.4085 * q / d² 8.52

g = acceleration due gravity = 32.2 ft./sec²

Design velocity = ( 4 - 6 ) ft / sec for section

= ( 6 - 8 ) ft / sec for discharge

SUMMERY HEAD LOOS

PRESSURE HEAD LOOS DUE TO PIPE FRICTION

SECTION FLOW DIAM. VELOSITY f ( Hfp/L ) L Hfp

GPM in ft/s ft/100 ft pipe ft ft fluid

L1 792.6024 6.165 8.52 3.34 8530.184 285.271

0 #DIV/0! 0 0 0.000

#DIV/0! 0 0 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000

#DIV/0! 0.000 m

Hfp=L x f /100 SUBTOTAL 8530.184 285.271 86.97

Z1 = 0 Z2 = 15.81

Static head ΔELIV. Z2 - Z1 15.81

PRESSURE HEAD LOOS DUE TO FITTINGS

TYPE SECTION FLOW QTY DIA. VEL. v² /2g k ΔHfF

GPM in ft/s ft fluid ft fluid

ENTRANCE 792.6024 1 16 8.52 1.13 1 1.13

BUTTERFLY 0 0 16 8.52 1.13 1 1.13

ELBOW 792.6024 6 16 8.52 1.13 0.28 0.32

TEE 90 0 1 16 0.00 0.00 0.7 0.00

GATE VALVE 792.6024 2 16 8.52 1.13 8 9.03

BALL VALVE 0 0 16 8.52 1.13 0.00

GLOB VALVE 0 0 16 0.00 0.00 0.00

1 5 8.52 1.13 1 1.13

1 5 0.00 0.00

1 5 0.00 0.00

1 5 0.00 0.00

ΔHfF ( ft fluid )= k x V²(ft/s)² / 2 x 32.2 (ft/s²) SUB TOTAL 12.73

PRESSURE LOOS DUE TO EQUIPMENT

SECTION FLOW TYPE QTY ΔP SG ΔP Δh equip

GPM in PSI Ft fluid ft fluid

250 filter 0 0.00 0.98 0.00 0.00

250 H. EXCH 0 0.00 0.98 0.00 0.00

250 Cont.valve 0 0.00 0.98 0.00 0.00

0.00

0.00

0.00

SUB TOTAL 0.00

Δh Ft fluid = 2.31 p (psi) / SG

SUMMERY

PIPE Hf = f X L /100 285.27

FITTINGS Hf = K X V² / 2g 12.73

EQUIP.. Δh equip 0.00

VEL.HEAD Hv = V² / 2g 3.70

Static Head Hs 15.81 m

TOTAL HEAD LOOS 317.50 96.8001552

PSI 137.44784

HEAD LOOS & PUMP SELECTION AND SIZING

1 Horsepower and efficiency:

water horsepower ( WHP ) = Outpot of the pump handlind a liquid

WHP = (Q X H X sg) / 3960

2 Brake horsepower ( BHP ) = Actual supplied power from motor

BHP = ( Q X H X sg ) / 3960 X ή = WHP / ή

ή = pump efficiency

3 Electric current for sizing starters and wire ( I ) [ Amp.]

I = 746 X BHP / 1.73 X E X PF X Eff for 3 ph

I = 746 X BHP / E X PF X Eff for 1 ph

E = Voltage ( volts) 380

PF = Power Factor 0.85

EFF. = Motor efficienc 0.75

1.73 242.25

419.0925

Q ( GPM) H (Ft.) SG WHP BHP I ( AMP.)

792.6024 317.50 1 63.549199 84.73227 150.8265

93

The Friction Coefficient - λ The flow is

The Friction Coefficient for Laminar Flow laminar when Re < 2300

λ= 64 / Re (7) transient when 2300 < Re < 4000

The Friction Coefficient for Turbulent Flow turbulent when Re > 4000

λ = f( Re, k / dh )

k = relative roughness of tube or duct wall (mm, ft)

k / dh = the roughness ratio

Relative roughness for materials are determined by experiments.

Relative roughness for some common materials can be found in the table below :

Roughness - k

Surface x 10-3 m feet

Copper, Lead, Brass, Aluminum (new) 0.001 - 0.002 3.33 - 6.7 10-6

PVC and Plastic Pipes 0.0015 - 0.007 0.5 - 2.33 10-5

Epoxy, Vinyl Ester and Isophthalic pipe 0.005 1.7 10-5

Stainless steel 0.015 5 10-5

Steel commercial pipe 0.045 - 0.09 1.5 - 3 10-4

Stretched steel 0.015 5 10-5

Weld steel 0.045 1.5 10-4

Galvanized steel 0.15 5 10-4

Rusted steel (corrosion) 0.15 - 4 5 - 133 10-4

New cast iron 0.25 - 0.8 8 - 27 10-4

Worn cast iron 0.8 - 1.5 2.7 - 5 10-3

Rusty cast iron 1.5 - 2.5 5 - 8.3 10-3

Sheet or asphalted cast iron 0.01 - 0.015 3.33 - 5 10-5

Smoothed cement 0.3 1 10-3

Ordinary concrete 0.3 - 1 1 - 3.33 10-3

Coarse concrete 0.3 - 5 1 - 16.7 10-3

Well planed wood 0.18 - 0.9 6 - 30 10-4

Ordinary wood 5 16.7 10-3

The friction coefficient - λ - can be calculated by the Colebrooke Equation:

1 / λ1/2 = -2,0 log10 [ (2,51 / (Re λ1/2)) + (k / dh) / 3,72 ] (9)

Roughness Ratio - k / dh.

You might also like

- 2018 International Swimming Pool and Spa CodeDocument104 pages2018 International Swimming Pool and Spa CodeEngFaisal Alrai100% (3)

- INTERNSHIP REPORT FinaleDocument58 pagesINTERNSHIP REPORT FinaleAkshay bv100% (2)

- Total Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Document41 pagesTotal Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Anonymous 1fyKr9XSeGNo ratings yet

- JP5 Pump CalculationDocument1 pageJP5 Pump CalculationalvinchuanNo ratings yet

- PSV-Tag No.: K K CFDocument3 pagesPSV-Tag No.: K K CFoas217No ratings yet

- Friction LossesDocument34 pagesFriction LossesTahaNo ratings yet

- Orifice Plate Calculator Pressure Drop CalculationDocument6 pagesOrifice Plate Calculator Pressure Drop Calculationlutfi awnNo ratings yet

- Static Pressure Calculation SheetDocument22 pagesStatic Pressure Calculation SheetsafaldNo ratings yet

- Pressure Drop in PipelineDocument13 pagesPressure Drop in PipelineNilambar BarihaNo ratings yet

- Hazen Williams EquationDocument1 pageHazen Williams EquationNur IzzaidahNo ratings yet

- All Cooling Load RulesDocument3 pagesAll Cooling Load RulesEngFaisal AlraiNo ratings yet

- Crane Vs Eqvlnt Length Method For FittingsDocument177 pagesCrane Vs Eqvlnt Length Method For FittingsSamuel OnyewuenyiNo ratings yet

- Control Valve Sizing - EnggcyclopediaDocument4 pagesControl Valve Sizing - EnggcyclopediaazitaggNo ratings yet

- Centrifugal Pump Calculation SpreadsheetDocument8 pagesCentrifugal Pump Calculation SpreadsheetsamvendanNo ratings yet

- Friction Loss in Pipe LineDocument3 pagesFriction Loss in Pipe LineAvinash VasudeoNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEBayu AjiNo ratings yet

- Calculation of Height of The Siphon SystemDocument2 pagesCalculation of Height of The Siphon SystemPhyu Mar Thein Kyaw100% (1)

- Pressure Drop Calculation - ExampleDocument1 pagePressure Drop Calculation - ExampleBandi ThaguruNo ratings yet

- Gas Line Pressure LossesDocument4 pagesGas Line Pressure Lossesyash saragiyaNo ratings yet

- The Following Are The Data For The Pipe and FittingsDocument2 pagesThe Following Are The Data For The Pipe and FittingsmohdnazirNo ratings yet

- CPCDocument2 pagesCPCUok RitchieNo ratings yet

- Net Positive Suction HeadDocument7 pagesNet Positive Suction HeadNenad MutavdzicNo ratings yet

- FF SupDocument8 pagesFF SupMurugan RaghuNo ratings yet

- PRV-1 StepxStep PDFDocument8 pagesPRV-1 StepxStep PDFmiltonNo ratings yet

- Design Calculation For Gaseous SystemsDocument16 pagesDesign Calculation For Gaseous Systemsshashi ranjanNo ratings yet

- NPSH PT 244Document4 pagesNPSH PT 244mazzam75No ratings yet

- Centrifugal Pump FundamentalsDocument140 pagesCentrifugal Pump FundamentalsLizbeth CamachoNo ratings yet

- ZM KV Idag eDocument6 pagesZM KV Idag elutfi awnNo ratings yet

- ParalDocument9 pagesParalTahirJabbarNo ratings yet

- Total Length Calcs For Pipes Valves and Fittings RevADocument11 pagesTotal Length Calcs For Pipes Valves and Fittings RevAjduran_65No ratings yet

- Prepd. by - Dhananjay Thorat Blue: Ref.-Introduction To Chemical Engg. by Ghosal, Sanyal & DattaDocument2 pagesPrepd. by - Dhananjay Thorat Blue: Ref.-Introduction To Chemical Engg. by Ghosal, Sanyal & DattaJojolasNo ratings yet

- Compresses Air TableDocument13 pagesCompresses Air TableAnonymous BJ9omONo ratings yet

- Understanding NPSHDocument34 pagesUnderstanding NPSHeliyanto budiartoNo ratings yet

- Piping Pressure Drop and Pump Design Calculation Sheet: Operating Conditions Discharge ConditionsDocument17 pagesPiping Pressure Drop and Pump Design Calculation Sheet: Operating Conditions Discharge ConditionsDhanny Miharja100% (1)

- Thumb Rules For PumpsDocument6 pagesThumb Rules For PumpsSarjit ChoksiNo ratings yet

- Pump CurveDocument2 pagesPump Curvepitagoras73100% (1)

- Pipeline Hydraulics Modification ReqdDocument6 pagesPipeline Hydraulics Modification ReqdchemtahirNo ratings yet

- Louver and Pump SizeDocument1 pageLouver and Pump SizeShabeer HamzaNo ratings yet

- CCC1Document5 pagesCCC1Uok RitchieNo ratings yet

- Appendix 1 - Production Separator Sizing - Rev.0Document5 pagesAppendix 1 - Production Separator Sizing - Rev.0Thái Xuân QuangNo ratings yet

- 1 Inlet 1 Outlet 2 Inlet 2 Outlet 3 Inlet 3 Outlet 12333 11 184 0Document1 page1 Inlet 1 Outlet 2 Inlet 2 Outlet 3 Inlet 3 Outlet 12333 11 184 0AbdulNo ratings yet

- Progresiva (KM)Document97 pagesProgresiva (KM)Avinash VasudeoNo ratings yet

- SeparadorDocument12 pagesSeparadorSergio RodriguezNo ratings yet

- Pump Cost v10Document98 pagesPump Cost v10Taris BellNo ratings yet

- Sizing For Two PhaseDocument6 pagesSizing For Two PhaseKong LingweiNo ratings yet

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaiseNo ratings yet

- Tri P10Document10 pagesTri P10Dvd Davide La CruzNo ratings yet

- Cavitation-Pump-Pipe-Skid CalcDocument56 pagesCavitation-Pump-Pipe-Skid CalcOltun KAYANo ratings yet

- Centrifugal Pump Calculation Summary Sheet: ConfidentialDocument3 pagesCentrifugal Pump Calculation Summary Sheet: ConfidentialPrafitri KurniawanNo ratings yet

- R-Pump Cal Sheet2Document3 pagesR-Pump Cal Sheet2ggdgdfgdfgdfgdgddddNo ratings yet

- Storm Z2 Rev4Document20 pagesStorm Z2 Rev4TahirJabbarNo ratings yet

- Erosion Velocity CalculationsDocument9 pagesErosion Velocity CalculationsMANISH GUPTANo ratings yet

- Hydraulic CalculationsDocument6 pagesHydraulic CalculationsmehranNo ratings yet

- TIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredDocument3 pagesTIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredAnonymous BJ9omONo ratings yet

- Hazen WilliamsDocument2 pagesHazen WilliamssushilkumarNo ratings yet

- Pump Desing SpreadsheetDocument10 pagesPump Desing SpreadsheetAnonymous a4Jwz14WNo ratings yet

- Pressure Drop For Two Phase Flow in Horizontal Pipe: Chemical Engineer's GuideDocument5 pagesPressure Drop For Two Phase Flow in Horizontal Pipe: Chemical Engineer's GuideAbhijeet SachanNo ratings yet

- Liquid Pipe Sizing: Group Technology SolutionsDocument1 pageLiquid Pipe Sizing: Group Technology SolutionsAhmad SiddiqNo ratings yet

- All System Pump Head LoosDocument33 pagesAll System Pump Head LoosEngFaisal Alrai100% (1)

- Cooling Tower Package Engineering in Halliburton - Multi Chem Batch PlantDocument3 pagesCooling Tower Package Engineering in Halliburton - Multi Chem Batch PlantragulNo ratings yet

- CW Pipe Thickness Calculation - 80% Vacuum - With RCCDocument39 pagesCW Pipe Thickness Calculation - 80% Vacuum - With RCCAshitava Sen0% (1)

- Water DemandDocument3 pagesWater DemandRaxKitNo ratings yet

- 06- شيت للمخزون باللغة الانجليزيةDocument6 pages06- شيت للمخزون باللغة الانجليزيةEngFaisal AlraiNo ratings yet

- DMAIC Method in Six Sigma - 5 Phases Complete OverviewDocument16 pagesDMAIC Method in Six Sigma - 5 Phases Complete OverviewEngFaisal AlraiNo ratings yet

- Pharmastate: User Requirements Specification (Urs) ForDocument9 pagesPharmastate: User Requirements Specification (Urs) ForEngFaisal AlraiNo ratings yet

- Different Types of Pipe Support Clamps Hangers 1711554224Document21 pagesDifferent Types of Pipe Support Clamps Hangers 1711554224EngFaisal AlraiNo ratings yet

- Gamp5 Categories & Validation DeliverablesDocument20 pagesGamp5 Categories & Validation DeliverablesEngFaisal AlraiNo ratings yet

- 2 - Hvac Duck WorkDocument41 pages2 - Hvac Duck WorkEngFaisal AlraiNo ratings yet

- AC Duct Cal. REV. 2Document6 pagesAC Duct Cal. REV. 2EngFaisal AlraiNo ratings yet

- All NFPA Tables Fire Sprinklers & Fire Pump: Classification of OccupanciesDocument5 pagesAll NFPA Tables Fire Sprinklers & Fire Pump: Classification of OccupanciesEngFaisal AlraiNo ratings yet

- Chilled Water LabelDocument3 pagesChilled Water LabelEngFaisal AlraiNo ratings yet

- Acoustic Calculation of Ventilation SystemsDocument4 pagesAcoustic Calculation of Ventilation SystemsEngFaisal AlraiNo ratings yet

- 300 Lit Water Tanks Stem Heating CalculationDocument8 pages300 Lit Water Tanks Stem Heating CalculationEngFaisal AlraiNo ratings yet

- AE Calcs WebDocument18 pagesAE Calcs WebEngFaisal AlraiNo ratings yet

- EXcavation Cost AnalysisDocument8 pagesEXcavation Cost AnalysisEngFaisal AlraiNo ratings yet

- Software ImplementationDocument1 pageSoftware ImplementationEngFaisal AlraiNo ratings yet

- X Y and Partners: Steel Beam DesignDocument34 pagesX Y and Partners: Steel Beam DesignEngFaisal Alrai100% (1)

- Web Design Work Breakdown Structure (WBS) : Practice Standard For Work Breakdown Structures-Second EditionDocument2 pagesWeb Design Work Breakdown Structure (WBS) : Practice Standard For Work Breakdown Structures-Second EditionEngFaisal AlraiNo ratings yet

- Calculation POWorkbookDocument66 pagesCalculation POWorkbookEngFaisal AlraiNo ratings yet

- Design Weather Parameters & MshgsDocument7 pagesDesign Weather Parameters & MshgsEngFaisal AlraiNo ratings yet

- Air Duct CalculatorDocument1 pageAir Duct CalculatorEngFaisal AlraiNo ratings yet

- 05 PumpsDocument80 pages05 PumpsRoberto O'ConnorNo ratings yet

- All Cooling Load RulesDocument3 pagesAll Cooling Load RulesEngFaisal AlraiNo ratings yet

- All Cooling Load RulesDocument31 pagesAll Cooling Load RulesEngFaisal AlraiNo ratings yet

- Distribution of Clays and Shales in The ReservoirDocument2 pagesDistribution of Clays and Shales in The ReservoirRachel Panjaitan100% (1)

- Two-Stage Air CompressorDocument31 pagesTwo-Stage Air CompressorEjad Afifi33% (3)

- IMO BookDocument154 pagesIMO Bookbharatheeeyudu100% (2)

- Valve Leakage ClassificationDocument2 pagesValve Leakage ClassificationFacundo Argüello100% (1)

- Estimate Vibration Risk For Relief and Process PipingDocument27 pagesEstimate Vibration Risk For Relief and Process Pipingmatrix69100% (1)

- Codex Alimentarius - Quick Frozen SpinachDocument7 pagesCodex Alimentarius - Quick Frozen SpinachAlexandru D. GateaNo ratings yet

- Flame ArrestorDocument14 pagesFlame ArrestorVishnu TejaNo ratings yet

- BE Chemical EngineeringDocument102 pagesBE Chemical EngineeringVaibhav PardeshiNo ratings yet

- SKY2000 Gas Detector User ManualDocument5 pagesSKY2000 Gas Detector User Manualrina hudayaNo ratings yet

- Protein FunctionDocument39 pagesProtein FunctionDeana Namirembe100% (1)

- C1666 1207960-1Document4 pagesC1666 1207960-1Fabio Teodoro100% (1)

- Reviewer Quality ControlDocument25 pagesReviewer Quality ControlKC PalattaoNo ratings yet

- 3-A Sanitary Standards For Uninsulated Tanks For Milk and Milk Products, Number 32-03Document10 pages3-A Sanitary Standards For Uninsulated Tanks For Milk and Milk Products, Number 32-03CHRISTIAN ZAVALANo ratings yet

- Solid Lipid Microparticles As Carriers of Vaccinium Myrtillus and Schinus Molle Linn Additives For Food ApplicationDocument8 pagesSolid Lipid Microparticles As Carriers of Vaccinium Myrtillus and Schinus Molle Linn Additives For Food ApplicationHerald Scholarly Open AccessNo ratings yet

- Research Paper On Bottom AshDocument8 pagesResearch Paper On Bottom Ashaflbtrnpf100% (1)

- Al-Fasi Et Al.2015 PDFDocument8 pagesAl-Fasi Et Al.2015 PDFUmroh NuryantoNo ratings yet

- Smith Ch08 Lecture EditDocument60 pagesSmith Ch08 Lecture EditfaithNo ratings yet

- NCKH - Cải thiện độ tan và độ hòa tan của meloxicam với hệ phân tán rắnDocument9 pagesNCKH - Cải thiện độ tan và độ hòa tan của meloxicam với hệ phân tán rắnkamakaballestas87No ratings yet

- Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemDocument5 pagesSikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemJay PadamaNo ratings yet

- Colloid Chemistry - Chapter 1 - Introduction of Colloid ChemistryDocument29 pagesColloid Chemistry - Chapter 1 - Introduction of Colloid ChemistryKhang DuongNo ratings yet

- Bridge Health Monitoring SystemDocument139 pagesBridge Health Monitoring Systemradhakrishnan100% (1)

- ME198 Main Engine Cylinder Liner TroubleDocument2 pagesME198 Main Engine Cylinder Liner TroubleRani NoumanNo ratings yet

- Chapter 1 (Lecture 1)Document29 pagesChapter 1 (Lecture 1)Fnur FatihahNo ratings yet

- Disclosure To Promote The Right To InformationDocument35 pagesDisclosure To Promote The Right To InformationRanganathan SekarNo ratings yet

- Lubrication Basics For Wire RopesDocument5 pagesLubrication Basics For Wire RopesGuru Raja Ragavendran NagarajanNo ratings yet

- Notes of CH 3 Atoms and Molecules Class 9th ScienceDocument11 pagesNotes of CH 3 Atoms and Molecules Class 9th ScienceSingh JNo ratings yet

- Nitrogen CompoundsDocument129 pagesNitrogen CompoundsSherey FathimathNo ratings yet

- Sterling - JEE - Physics - (Elasticity Thermal Exp, Calorimetry & Heat Transfer) - EngDocument51 pagesSterling - JEE - Physics - (Elasticity Thermal Exp, Calorimetry & Heat Transfer) - EngRamJiPandeyNo ratings yet

- DR Fixit Pidicrete MPB 71 1Document3 pagesDR Fixit Pidicrete MPB 71 1amandeepsuperanNo ratings yet