Professional Documents

Culture Documents

Oxygen Tanks and Gas Regulator

Uploaded by

Larry Micks0 ratings0% found this document useful (0 votes)

30 views2 pagesInformation on attaching a gas regulator to a Oxygen tank

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentInformation on attaching a gas regulator to a Oxygen tank

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views2 pagesOxygen Tanks and Gas Regulator

Uploaded by

Larry MicksInformation on attaching a gas regulator to a Oxygen tank

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

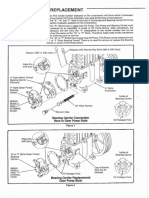

Set-Up Instructions

Attaching Regulators, Hoses and Torch

(WRENCH NOT INCLUDED)

1. Secure gas cylinders, if used, in upright position.

Note: Check contents of the cylinders before startup to assure

an adequate supply for the intended operating cycle.

2. Open cylinder valve (Fig. 1) slightly to blow out dirt, the close.

DO NOT discharge flow of gas at any person or flammable

material.

3. Attach regulators (Fig. 2 and 3) using standard CGA Figure 3. Attaching Fuel Gas Regulator

inletconnection and tighten firmly.

4. Attach hoses to regulators (Fig. 4) and tighten.

Note: The fuel gas (red) hose connections are left hand threads

and the oxygen (green) hose connections are right hand threads.

5. Attach fuel gas hose to torch valve (Fig. 5) marked “Gas” (left

hand thread).

Figure 4. Attaching Hose to Regulator

Figure 1. Opening Oxygen Cylinder Valve

Figure 5. Attaching Hose to Torch

6. Attach oxygen hose to torch valve marked “OX” (righthand thread).

7. Install correct size tip (Figs. 6 and 7) for metal thickness to be

welded or cut. make sure the tip seat is free of nicks or burrs.

Welding tips should be hand-tightened only. Cutting tips should

be wrench tightened.

8. Close both valves on torch (Fig. 6) (clockwise) before opening

cylinders.

Figure 2. Attaching Oxygen Regulator

4 The Harris Products Group • Gainesville, GA U.S.A.

Figure 8. Regulator Adjusting Key

Figure 6. Installing Welding Tip

Figure 9. Opening Fuel Gas Cylinder Valve

3. To prevent a sudden increase in pressure, slowly open fully

the oxygen cylinder valve (Fig. 10). and set regulator to required

operating pressure.

Note: The oxygen cylinder valve should always be wide open

when operating.

Figure 7. Installing Cutting Tip

4. Test connections and regulators for leaks by brushing with a

soapy water solution while observing for presence of any

Adjusting Pressure bubbles. If bubbles are observed, tighten fittings and wipe off

soap solution. Refer to Regulator Test in the Maintenance

To identify equal pressure or universal pressure torches, set 25 ± instructions.

5 PSI on oxygen supply, disconnect fuel gas hose and check

valve with mixer or cutting attachment on torch. Open all gas

valves and check fuel gas inlet. If pressure is found, equipment

is equal pressure type. If suction is noted, equipment is universal

pressure type. Reconnect check valve and hose and purge

thoroughly before lighting.

Note: 1. For Equal Pressure Torches (sometimes called

“medium pressure”). This equipment requires fuel gas

pressures above 1 PSIG. Positive pressure is used to mix fuel

gas with oxygen.

2. For Universal Pressure Torches (sometimes called “low

pressure”). This equipment operates with less than 1 PSIG fuel Figure 10. Opening Oxygen valve

gas pressure. Oxygen, at pressure, creates suction that pulls the

fuel gas into the mixer. Operating Instructions

1. Be sure both regulator adjusting keys (Fig. 8) are free, by turn- Lighting Torch for Acetylene and Mapp® Fuel Gas

ing counter-clockwise until loose.

1. Purge system. Refer to Maintenance Instructions.

2. Slowly open fuel gas cylinder valve (Fig. 9) not over one (1) turn

and set regulator key for required operating pressure. Keep handle 2. Open torch fuel “GAS” valve (Fig. 11) approximately one half

or valve wrench on cylinder valve to allow rapid shutdown. turn and ignite fuel gas.

The Harris Products Group • Gainesville, GA U.S.A. 5

You might also like

- Chevrolet 327 V8 Engine Rebuild ManualDocument120 pagesChevrolet 327 V8 Engine Rebuild ManualAlissa Davis0% (1)

- Detroit s60 Valve Adjustment PDFDocument12 pagesDetroit s60 Valve Adjustment PDFDiego Monroy50% (2)

- Landlord HarassmentDocument2 pagesLandlord HarassmentElena HernadezNo ratings yet

- Bản sao của DX55W SM EN PDFDocument1,122 pagesBản sao của DX55W SM EN PDFtùng phạm100% (1)

- 2016 Grand Cherokee - 3.0L TURBO DIESEL PDFDocument665 pages2016 Grand Cherokee - 3.0L TURBO DIESEL PDFprueba2No ratings yet

- Rules of Criminal Procedure Post-070118Document185 pagesRules of Criminal Procedure Post-070118Larry MicksNo ratings yet

- Common Motions and Notices in Superior CourtDocument25 pagesCommon Motions and Notices in Superior CourtLarry Micks100% (1)

- 2018-182 IS21 Concrete Spraying Machine Operating Manual - Spare Parts - DRAFTDocument1,214 pages2018-182 IS21 Concrete Spraying Machine Operating Manual - Spare Parts - DRAFThernan guillermo fuentes castillo100% (1)

- Manual de Oxicorte (Harris)Document8 pagesManual de Oxicorte (Harris)Todo en Ingenieria TEI C.A.No ratings yet

- How To Recharge N2 Gas of HB BreakerDocument8 pagesHow To Recharge N2 Gas of HB BreakerTrevor BurnettNo ratings yet

- Страницы из 3.0L-181CID-Parts-Manual - 3 PDFDocument1 pageСтраницы из 3.0L-181CID-Parts-Manual - 3 PDFАлександрNo ratings yet

- DETROIT DIESEL OIL PRESSURE REGULATOR AND RELIEF VALVESDocument1 pageDETROIT DIESEL OIL PRESSURE REGULATOR AND RELIEF VALVESRicky BurtonshawNo ratings yet

- Module 1 Week 2-3, TVE SMAW 10Document13 pagesModule 1 Week 2-3, TVE SMAW 10Daryl TesoroNo ratings yet

- Log Splitter Hydraulic TroubleshootingDocument13 pagesLog Splitter Hydraulic TroubleshootingTim MckennaNo ratings yet

- Bomba Myers D35-20DVDocument12 pagesBomba Myers D35-20DVdiroperacionesNo ratings yet

- Precharge Kit 5000PSI PDFDocument2 pagesPrecharge Kit 5000PSI PDFmetal_dung2No ratings yet

- Setup and Shutdown Procedure For Oxyfuel Cutting TorchDocument7 pagesSetup and Shutdown Procedure For Oxyfuel Cutting Torchayodeleadeyemi250No ratings yet

- Users Manual Lagaay Oxygen Bag Contents of The Lagaay Oxygen BagDocument5 pagesUsers Manual Lagaay Oxygen Bag Contents of The Lagaay Oxygen BagСергей МалышевNo ratings yet

- Adjusting valves and IEGR-unit on D6E engineDocument5 pagesAdjusting valves and IEGR-unit on D6E engineHendry PardedeNo ratings yet

- Maintenance Working Hours Flow For Gas TurbineDocument7 pagesMaintenance Working Hours Flow For Gas TurbineHilmi HanoinNo ratings yet

- P I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsDocument2 pagesP I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsRonaldNo ratings yet

- Wilkins 70 Pressure Reducing ValveDocument2 pagesWilkins 70 Pressure Reducing ValveStevieB5252No ratings yet

- Ajuste y TorqueDocument6 pagesAjuste y TorqueAlberjose Sanchez RuizNo ratings yet

- Operating and Maintenance Instructions On Tobul AccumulatorsDocument8 pagesOperating and Maintenance Instructions On Tobul AccumulatorszhenyupanNo ratings yet

- Lubrication System Assembly and Maintenance GuideDocument39 pagesLubrication System Assembly and Maintenance GuideСергей ПриймакNo ratings yet

- Assemble in The Order Indicated in The Table.: Timing Belt Assembly (Wlt-1, Wlt-2, Wl-3)Document2 pagesAssemble in The Order Indicated in The Table.: Timing Belt Assembly (Wlt-1, Wlt-2, Wl-3)arifNo ratings yet

- Maintenance and Troubleshooting of A Bop Control SystemDocument12 pagesMaintenance and Troubleshooting of A Bop Control SystemHamid Reza BabaeiNo ratings yet

- Kbu KBZ2Document8 pagesKbu KBZ2Andrew VNo ratings yet

- Edward Vacuum Pump Rebuild Guide: July 2019Document41 pagesEdward Vacuum Pump Rebuild Guide: July 2019Srikanth GedelaNo ratings yet

- PistonDocument5 pagesPistonAna Paula Maia LimaNo ratings yet

- Regulator Manual PDFDocument12 pagesRegulator Manual PDFSadot GutierrezNo ratings yet

- Disassembly and reassembly of piston style steering accumulatorsDocument4 pagesDisassembly and reassembly of piston style steering accumulatorsPablo MarquezNo ratings yet

- Check Anaesthetic MachineDocument3 pagesCheck Anaesthetic MachinePaulaTracanaNo ratings yet

- CAT CS533E Engine Part 4Document6 pagesCAT CS533E Engine Part 4Oecox Cah DjadoelNo ratings yet

- Calibracion Inyector n3 Ddec VDocument6 pagesCalibracion Inyector n3 Ddec VJosue Juaniquina LucanaNo ratings yet

- Operating and Maintenance Instructions On Tobul AccumulatorsDocument8 pagesOperating and Maintenance Instructions On Tobul AccumulatorsGuru VagaNo ratings yet

- Checking The Primer Pump Checking The Fuel JointDocument1 pageChecking The Primer Pump Checking The Fuel JointPHUONG NGUYENNo ratings yet

- Fordson Major Systeme HydrauliqueDocument23 pagesFordson Major Systeme HydrauliqueNicolas100% (1)

- Kbu KBZ7Document7 pagesKbu KBZ7Andrew VNo ratings yet

- Especificaciones Acumulador de Direccion CAT789C Prueba y CargaDocument8 pagesEspecificaciones Acumulador de Direccion CAT789C Prueba y CargaRafael RodriguezNo ratings yet

- 191-491 bearing carrier changeDocument3 pages191-491 bearing carrier changepablo292No ratings yet

- The Tilt CylindersDocument11 pagesThe Tilt CylindersweldsaidiNo ratings yet

- Model 21150 Differential Sticking TesterDocument31 pagesModel 21150 Differential Sticking Testerwaleed El-azabNo ratings yet

- Pages From Cummins NTA855 Operation and Maintenance Manual-2Document2 pagesPages From Cummins NTA855 Operation and Maintenance Manual-2Clarence ClarNo ratings yet

- DPC 2802 Startup ProcedureDocument6 pagesDPC 2802 Startup ProcedureMuhammad Asad100% (1)

- TVL Smaw11 Q1 M 2Document10 pagesTVL Smaw11 Q1 M 2Earl Christian BonaobraNo ratings yet

- KAESER DSD Service ManualDocument7 pagesKAESER DSD Service ManualVishnuNo ratings yet

- Adjust valves on BHL, BL60 BRDocument4 pagesAdjust valves on BHL, BL60 BRCostaNo ratings yet

- Dual Plate Wafer Style Check Valve Installation Instructions EN PDFDocument7 pagesDual Plate Wafer Style Check Valve Installation Instructions EN PDFManuelNo ratings yet

- Beamex PGL Manual ENGDocument16 pagesBeamex PGL Manual ENGbiotech666No ratings yet

- Las Tle Smaw 9 - Q1 - W4-6Document11 pagesLas Tle Smaw 9 - Q1 - W4-6Daryl TesoroNo ratings yet

- Service Guide: High-Pressure Bucket PumpDocument10 pagesService Guide: High-Pressure Bucket PumpRodrigoNo ratings yet

- Series 60 - Section 6.3 Intake ManifoldDocument7 pagesSeries 60 - Section 6.3 Intake ManifoldJuan RiveraNo ratings yet

- Benjamin Marauder Regulator Installation GuideDocument7 pagesBenjamin Marauder Regulator Installation Guidestb androidNo ratings yet

- Manometer Instructions PortfolioDocument5 pagesManometer Instructions Portfolioapi-594255167No ratings yet

- Страницы из 3.0L-181CID-Parts-Manual - 4 PDFDocument1 pageСтраницы из 3.0L-181CID-Parts-Manual - 4 PDFАлександрNo ratings yet

- How to set up a cutting torch for metalworkDocument19 pagesHow to set up a cutting torch for metalworkArya YudistiraNo ratings yet

- GM Engines v-6, V-8Document23 pagesGM Engines v-6, V-8jads301179No ratings yet

- Llave de Varillas de BombeoDocument28 pagesLlave de Varillas de BombeoGianna Frola100% (1)

- Grand Cherokee 2008 5.7LDocument254 pagesGrand Cherokee 2008 5.7LlefontNo ratings yet

- Hydraulic Tilt Install 2007 Honey Bee HeaderDocument4 pagesHydraulic Tilt Install 2007 Honey Bee HeaderJohannes BeckerNo ratings yet

- Marley ValveDocument4 pagesMarley ValveM Fadli AzhariNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Loss Prevention Manual Dec 2010Document23 pagesLoss Prevention Manual Dec 2010Larry MicksNo ratings yet

- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 Case #SWF1400013 & Case #SWF1501444Document12 pages1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 Case #SWF1400013 & Case #SWF1501444Larry MicksNo ratings yet

- Reported: August 28, 2014Document22 pagesReported: August 28, 2014Larry MicksNo ratings yet

- Ijii 1 101 PDFDocument3 pagesIjii 1 101 PDFLarry MicksNo ratings yet

- Sacramento Superior Court Criminal ProceduresDocument10 pagesSacramento Superior Court Criminal ProceduresLarry MicksNo ratings yet

- 19 Defendants' Motion To DismissDocument55 pages19 Defendants' Motion To DismissLarry MicksNo ratings yet

- Challenging Defects in Criminal Charging DocumentsDocument26 pagesChallenging Defects in Criminal Charging DocumentsVideh VaishNo ratings yet

- Memorandum Decision and Order Denying Motion To Dismiss: Docket No. 1052Document8 pagesMemorandum Decision and Order Denying Motion To Dismiss: Docket No. 1052Larry MicksNo ratings yet

- CA DOJ Law Enforcement Complaint PolicyDocument3 pagesCA DOJ Law Enforcement Complaint PolicyLarry MicksNo ratings yet

- Scratchers Prize Tier Odds June 2020Document19 pagesScratchers Prize Tier Odds June 2020Larry MicksNo ratings yet

- Defense Motions Guide for Superior CourtDocument54 pagesDefense Motions Guide for Superior CourtLarry Micks100% (1)

- The Criminal Indictment: Fatal Defect, Fatal Variance, and AmendmentDocument54 pagesThe Criminal Indictment: Fatal Defect, Fatal Variance, and AmendmentLarry MicksNo ratings yet

- 2007 06 21 Kozenyv Order To Dismiss PDFDocument46 pages2007 06 21 Kozenyv Order To Dismiss PDFLarry MicksNo ratings yet

- 2007 06 21 Kozenyv Order To Dismiss PDFDocument46 pages2007 06 21 Kozenyv Order To Dismiss PDFLarry MicksNo ratings yet

- 101 Youth Football Coaching Sessions Volume 2 TonyDocument6 pages101 Youth Football Coaching Sessions Volume 2 TonyLarry MicksNo ratings yet

- Studies On The Oxidation of Terpenes With Ozone PDFDocument21 pagesStudies On The Oxidation of Terpenes With Ozone PDFLarry MicksNo ratings yet

- HANDOUT - LockoutDocument1 pageHANDOUT - LockoutLarry MicksNo ratings yet

- Optimum Levels of IodineDocument14 pagesOptimum Levels of IodineK AnjaliNo ratings yet

- EDTA IV and Oral Chelation ProtocolDocument10 pagesEDTA IV and Oral Chelation ProtocolAla MakotaNo ratings yet

- 1801 00349 PDFDocument30 pages1801 00349 PDFLarry MicksNo ratings yet

- Methylene Blue Facilitates The Extinction of Fear in An Animal Model of Susceptibility To Learned HelplessnessDocument9 pagesMethylene Blue Facilitates The Extinction of Fear in An Animal Model of Susceptibility To Learned HelplessnessLarry MicksNo ratings yet

- Constructive EvictionDocument1 pageConstructive EvictionLarry MicksNo ratings yet

- Police Civil Liability Paper FINALDocument79 pagesPolice Civil Liability Paper FINALLarry MicksNo ratings yet

- 8 2 4 Speed TrainingDocument3 pages8 2 4 Speed Traininggalgo2448No ratings yet

- Dimethylsulfoxyde MSDSDocument12 pagesDimethylsulfoxyde MSDSLarry MicksNo ratings yet

- CA Eviction Defense Packet Advocates and SurvivorsDocument6 pagesCA Eviction Defense Packet Advocates and SurvivorsLarry MicksNo ratings yet

- GEA33861 - Fuel Flexible Gas Turbines As Enablers For A Low Carbon Energy EcosystemDocument16 pagesGEA33861 - Fuel Flexible Gas Turbines As Enablers For A Low Carbon Energy EcosystemStephen MwangiNo ratings yet

- Betonieră Imer Syntesi 350 LADocument1 pageBetonieră Imer Syntesi 350 LAdiconNo ratings yet

- DESB-NOE-MDR-OO1 Rev A (Master Document Register)Document2 pagesDESB-NOE-MDR-OO1 Rev A (Master Document Register)Amy100% (1)

- Customised Engineered Packages: Reciprocating Air CompressorsDocument4 pagesCustomised Engineered Packages: Reciprocating Air Compressorsmogwai71No ratings yet

- Blending Fuel Gas To Optimize Use of Off-Spec Natural GasDocument13 pagesBlending Fuel Gas To Optimize Use of Off-Spec Natural Gassevero97100% (1)

- P150P2 / P165E2: Perkins 1106C-E66TAG3Document1 pageP150P2 / P165E2: Perkins 1106C-E66TAG3MH..2023No ratings yet

- ASTM D3279 - 2007 - Asphaltenes (N-Heptane Insolubles)Document4 pagesASTM D3279 - 2007 - Asphaltenes (N-Heptane Insolubles)Constantinos ChristodoulouNo ratings yet

- Used Oil Recovery Refining) Plants-PrintDocument20 pagesUsed Oil Recovery Refining) Plants-PrintRahul Dalal100% (1)

- IWCF COMBINED DRILLER EQUIPMENT PAPER NO. 1Document21 pagesIWCF COMBINED DRILLER EQUIPMENT PAPER NO. 1andrzema67% (3)

- Wa0081 PDFDocument28 pagesWa0081 PDFmiteshNo ratings yet

- VAPEXDocument45 pagesVAPEXIng Jose BelisarioNo ratings yet

- Hankinson PDFDocument8 pagesHankinson PDFJuan GalvesNo ratings yet

- Properties of FluidDocument41 pagesProperties of FluidSyauqi SubriNo ratings yet

- Fuel System Components and OperationDocument20 pagesFuel System Components and OperationNem AwidNo ratings yet

- Multi Air Engine Seminar ReportDocument23 pagesMulti Air Engine Seminar ReportVishal ChauhanNo ratings yet

- Chevron From ScribdDocument15 pagesChevron From ScribdcelinaNo ratings yet

- Briggs & Stratton Parts List MS5535 - H - HIDocument16 pagesBriggs & Stratton Parts List MS5535 - H - HIdakehi11883421No ratings yet

- Mee1013 Fuel-Cells TH 1.1 47 Mee1013 Fuel CellsDocument2 pagesMee1013 Fuel-Cells TH 1.1 47 Mee1013 Fuel CellsVyom AgarwalNo ratings yet

- Chap - 3i - Structural Fire PrecautionsDocument162 pagesChap - 3i - Structural Fire Precautionsundertaker55No ratings yet

- Lombardini 9LD625-2Document88 pagesLombardini 9LD625-2Ricardo Fonseca67% (3)

- Over Hauling of 125 KVA DG SetDocument6 pagesOver Hauling of 125 KVA DG SetmukelectNo ratings yet

- Matter and Its Changes: Choose The Correct AnswerDocument26 pagesMatter and Its Changes: Choose The Correct AnswerMurniaty HamzahNo ratings yet

- Operator's Manual: AUS AustraliaDocument65 pagesOperator's Manual: AUS AustraliaJimmy ReyesNo ratings yet

- 2010 XFWorkshop 3 LDDocument3,260 pages2010 XFWorkshop 3 LDHakan ŞenNo ratings yet

- COGENERATION: Technology and Economics: Electricity Out Fuel in Heat or Cooling OutDocument4 pagesCOGENERATION: Technology and Economics: Electricity Out Fuel in Heat or Cooling OutShrikant KajaleNo ratings yet

- HH220 IDocument2 pagesHH220 Iprimelly0% (1)

- Lec 13Document5 pagesLec 13Ghazy alshyalNo ratings yet

- Rolls RoyceDocument29 pagesRolls RoyceriajdcNo ratings yet