Professional Documents

Culture Documents

Passingen PDF

Uploaded by

Anonymous Z4Jo4fXVOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Passingen PDF

Uploaded by

Anonymous Z4Jo4fXVCopyright:

Available Formats

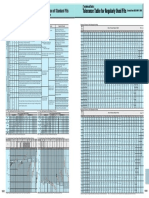

〔Technical Data〕 〔Technical Data〕

Basis of Selection for Fitting/Fitting Conditions Tolerances of Shafts and Holes by Common Usage Excerpt from JIS B 0401(1999)

Excerpt from "Usage of JIS Series" Manual for Designing(Precision Ver.) Excerpt from JIS B0401(1999)

The dimension tolerance of shaft used for fittings which are in constant use.

H6 H7 H8 H9 Applicable Part Functional Classification Application Example

Standard

Dimension Class of Tolerance Range for Shafts Unit μm

Loose fit

It is fine even if there is a large clearance space or the part requires clearance space. Functionally, the part requires large clearance space. Piston ring and piston ring groove.

(mm)

c9 The part that can be enlarged to make clearance space to make assembly easier. Expansion occurs. Positioning error is large.

The part requires proper clearance space in the high temperature. Length of fit is long. Fitting of loosening safety pin. b9

beyond or less c9 d8 d9 e7 e8 e9 f6 f7 f8 g5 g6 h5 h6 h7 h8 h9 js5 js6 js7 k5 k6 m5 m6 n5 * n6 p6 r6 s6 t6 u6 x6

−140 −60 −20 −20 −14 −14 −14 −6 −6 −6 −2 −2 0 0 0 0 0 +4 +6 +6 +8 +8 +10 +12 +16 +20 +24 +26

− 3 ±2 ±3 ±5.5 −

−165 −85 −34 −45 −24 −28 −39 −12 −16 −20 −6 −8 −4 −6 −10 −14 −25 +2 +2 +4 +4 +6 +10 +14 +18 +20

It is fine even if there is a large clearance space or the part requires When reducing costs. Crank web and pin bearing(Side surface) . 0 0

Can be moved relatively

Light rolling fit

d9 d9 clearance space. Production cost Exhaust valve cage and travelling part of spring sheet. 3 6

−140 −70 −30 −30 −20 −20 −20 −10 −10 −10 −4 −4 0 0 0 0 0

±2.5 ±4 ±6.5

+6 +9 +9 +12 +13 +16 +20 +23 +27

−

+31 +36

Safety cost Piston ring and piston ring groove. −170 −100 −48 −60 −32 −38 −50 −18 −22 −28 −9 −12 −5 −8 −12 −18 −30 +1 +1 +4 +4 +8 +8 +12 +15 +19 +23 +28

−150 −80 −40 −40 −25 −25 −25 −13 −13 −13 −5 −5 0 0 0 0 0 +7 +10 +12 +15 +16 +19 +24 +28 +32 +37 +43

Clearance fit

6 10 ±3 ±4.5 ±7.5 −

It is fine even if there is a slight clearance space or the part requires clearance space. Fitting of exhaust valve seat. −186 −116 −62 −76 −40 −47 −61 −22 −28 −35 −11 −14 −6 −9 −15 −22 −36 +1 +1 +6 +6 +10 +10 +15 +19 +23 +28 +34

e7 e8 e9 The bearing part that has slight clearance space and good lubrication. The general parts rotating or travelling. Main bearing for crank-shaft. +51

The bearing part that is working under the condition of high temperature, high speed and high load.(High grade pressure feed lubrication) (The required condition that is good for lubrication.) General travelling part. 10 14

−150 −95 −50 −50 −32 −32 −32 −16 −16 −16 −6 −6 0 0 0 0 0 +9 +12 +15 +18 +20 +23 +29 +34 +39 +44 +40

±4 ±5.5 ±9.5 −

−193 −138 −77 −93 −50 −59 −75 −27 −34 −43 −14 −17 −8 −11 −18 −27 −43 +1 +1 +7 +7 +12 +12 +18 +23 +28 +33 +56

14 18

Push fit Pulley fit Precision rolling fit Rolling fit

Fit that can be mobile due to proper clearance space.(The general cold bearing part of grease or oil lubrication.) Ordinary fit parts. Insert port for the cooling exhaust valve casing. +45

f7

f6 f7 (Disassembling is often done.) General shaft and bushing. 18 24 −

+54 +67

f8 The general cold bearing part of grease or oil lubrication. Lever for link system and bushing. −160 −110 −65 −65 −40 −40 −40 −20 −20 −20 −7 −7 0 0 0 0 0 +11 +15 +17 +21 +24 +28 +35 +41 +48 +41 +54

±4.5 ±6.5 ±10.5

−212 −162 −98 −117 −61 −73 −92 −33 −41 −53 −16 −20 −9 −13 −21 −33 −52 +2 +2 +8 +8 +15 +15 +22 +28 +35 +54 +61 +77

24 30

The continuous rotary part of light load precision machine. Pin for link system and lever. +41 +48 +64

The part requires precision movement

g5 g6 Fit that can be mobile in spite of small clearance space(Spigot and positioning). Key and key groove. −170 −120 +64 +76

without any slack. 30 40

Precision travelling part. Valve stem of precision control valve. −232 −182 −80 −80 −50 −50 −50 −25 −25 −25 −9 −9 0 0 0 0 0 +13 +18 +20 +25 +28 +33 +42 +50 +59 +48 +60

±5.5 ±8 ±12.5 −

−180 −130 −119 −142 −75 −89 −112 −41 −50 −64 −20 −25 −11 −16 −25 −39 −62 +2 +2 +9 +9 +17 +17 +26 +34 +43 +70 +86

40 50

h7 Fit that can be moved manually with using a lubricator(High grade positioning). Fitting of rim and boss. −242 −192 +54 +70

h5 h6 h9 Special precision travelling part. −190 −140 +60 +72 +85 +106

h8 Stationary part that is not of great importance. Fitting of toothed gear of precision gear mechanism. 50 65

−264 −214 −100 −100 −60 −60 −60 −30 −30 −30 −10 −10 0 0 0 0 0 +15 +21 +24 +30 +33 +39 +51 +41 +53 +66 +87

±6.5 ±9.5 ±15.5 −

−200 −150 −146 −174 −90 −106 −134 −49 −60 −76 −23 −29 −13 −19 −30 −46 −74 +2 +2 +11 +11 +20 +20 +32 +62 +78 +94 +121

Mounting parts that allow slight interference. Fitting between joint flanges. 65 80

h5 −274 −224 +43 +59 +75 +102

js6 High-precision positioning where both are unmobile. Governor way and pin. −220 −170 +73 +93 +113 +146

h6 Transmission of power 80 100

Fitting that allows assemble and disassemble using a wood or lead hammer. Fitting of rim of toothed gear and boss. −307 −257 −120 −120 −72 −72 −72 −36 −36 −36 −12 −12 0 0 0 0 0 +18 +25 +28 +35 +38 +45 +59 +51 +71 +91 +124

±7.5 ±11 ±17.5 −

Transition fit

cannot be done by only −240 −180 −174 −207 −107 −126 −159 −58 −71 −90 −27 −34 −15 −22 −35 −54 −87 +3 +3 +13 +13 +23 +23 +37 +76 +101 +126 +166

Fit that can be assembled and disassembled by an ironhammer or hand junction power of fit. 100 120

Capable of assembling and Reamer bolts for securing the gear pump −327 −267 +54 +79 +104 +144

js5 k6 press.(The key or such items are required to prevent other components from rotating.) disassembling without shaft and casing. −260 −200 +88 +117 +147

Driving fit

120 140

High precision positioning. damaging components. −360 −300 +63 +92 +122

Reamer Bolt. −280 −210 −145 −145 −85 −85 −85 −43 −43 −43 −14 −14 +21 +28 +33 +40 +52 +68 +90 +125 +159

Cannot be moved relatively

0 0 0 0 0 − − −

Same as the above for assembling and disassembling. 140 160 ±9 ±12.5 ±20.5

Securing the hydraulic device piston and the shaft. −380 −310 −208 −245 −125 −148 −185 −68 −83 −106 −32 −39 −18 −25 −40 −63 −100 +3 +3 +15 +15 +27 +43 +65 +100 +134

k5 m6

High-precision positioning that does not tolerate any clearance space. Fitting of joint flange and shaft. −310 −230 +93 +133 +171

160 180

−410 −330 +68 +108 +146

Strong pressfit・Shrink agefit・Cooling fit Strong press fit Light press fit

Fit that requires considerable power for assembling and disassembling. Flexible plate coupling and gear(passive side). −340 −240 +106 +151

180 200

m5 n6 Precision fitting. −455 −355 +77 +122

High-precision fixed mounting.(The key is required for large torque transmission.) Insertion of valve guide for inlet valve. −380 −260 −170 −170 −100 −100 −100 −50 −50 −50 −15 −15 0 0 0 0 0 +24 +33 +37 +46 +60 +79 +109 +159

200 225 ±10 ±14.5 ±23.5 − − − −

Small power can be −495 −375 −242 −285 −146 −172 −215 −79 −96 −122 −35 −44 −20 −29 −46 −72 −115 +4 +4 +17 +17 +31 +50 +80 +130

n5 Fit that requires considerable power for assembling and disassembling.(The key is required for large torque transmission.) transmitted by Insertion of valve guide for inlet valve. −420 −280 +113 +169

225 250

p6 However, when non-ferrous components are fitted together, press fit power will be activated. junction power of fit. Fixation of gear and shaft(small torque). −535 −395 +84 +140

n6 Standard press fitting fix between iron and iron or between bronze and copper. Flexible plate coupling and gear(lnboard). −480 −300 +126

250 280

−610 −430 −190 −190 −110 −110 −110 −56 −56 −56 −17 −17 0 0 0 0 0 +27 +36 +43 +52 +66 +88 +94

±11.5 ±16 ±26.5 − − − − −

Same as the above for assembling and disassembling. −540 −330 −271 −320 −162 −191 −240 −88 −108 −137 −40 −49 −23 −32 −52 −81 −130 +4 +4 +20 +20 +34 +56 +130

p5 r6 Joint and shaft. 280 315

−670 −460 +98

Shrinkage fit, cooling fit and strong press fit for large dimension components. Hard to disassemble

Close fit

−600 −360 +144

without damaging 315 355

r5 s6 Fixation of bushing for bearing. −740 −500 −210 −210 −125 −125 −125 −62 −62 −62 −18 −18 0 0 0 0 0 +29 +40 +46 +57 +73 +98 +108

componets. ±12.5 ±18 ±28.5 − − − − −

Considerable power −680 −400 −299 −350 −182 −214 −265 −98 −119 −151 −43 −54 −25 −36 −57 −89 −140 +4 +4 +21 +21 +37 +62 +150

355 400

Insertion of valve seat for inlet valve. −820 −540 +114

t6 Fixed firmly together, so that permanent assembling can be sought with shrinkage fit, can be transmitted by

−760 −440 +166

junction power of fit. Fixation of joint flange and shaft(large torque). 400 450

cooling fit and strong press fit for assembling. Press fit for light alloy. −915 −595 −230 −230 −135 −135 −135 −68 −68 −68 −20 −20 0 0 0 0 0 +32 +45 +50 +63 +80 +108 +126

u6 ±13.5 ±20 ±31.5 − − − − −

Fixation of driving gear and boss. −840 −480 −327 −385 −198 −232 −290 −108 −131 −165 −47 −60 −27 −40 −63 −97 −155 +5 +5 +23 +23 +40 +68 +172

450 500

−995 −635 +132

x6 Fixation of bushing for bearing.

The dimension tolerance of holes used for fittings which are in constant use.

1.1 Hole base fits in constant use. 2.1 Shaft base fittings which are in constant use. Standard

Class of Tolerance Range for Shafts Class of Tolerance Range for Shafts Dimension Class of Tolerance Range for Holes Unit μm

Base Hole Reference axis (mm)

Clearance fit Transition fit Close fit Clearance fit Transition fit Close fit

g5 h5 js5 k5 m5 h5 H6 JS6 K6 M6 N6 * P6 beyond or less B10 C9 C10 D8 D9 D10 E7 E8 E9 F6 F7 F8 G6 G7 H6 H7 H8 H9 H10 JS6 JS7 K6 K7 M6 M7 N6 N7 P6 P7 R7 S7 T7 U7 X7

H6 +180 +85 +100 +34 +45 +60 +24 +28 +39 +12 +16 +20 +8 +12 +6 +10 +14 +25 +40 −2 −2 −4 −4 −6 −6 −10 −14 −18 −20

f6 g6 h6 js6 k6 m6 n6 * p6 * F6 G6 H6 JS6 K6 M6 N6 P6 * − 3 ±3 ±5.5

0 0

−

h6 +140 +60 +60 +20 +20 +20 +14 +14 +14 +6 +6 +6 +2 +2 0 0 0 0 0 −6 −10 −8 −12 −10 −14 −12 −16 −20 −24 −28 −30

f6 g6 h6 js6 k6 m6 n6 p6 * r6 * s6 t6 u6 x6 F7 G7 H7 JS7 K7 M7 N7 P7 * R7 S7 T7 U7 X7

H7 +188 +100 +118 +48 +60 +78 +32 +38 +50 +18 +22 +28 +12 +16 +8 +12 +18 +30 +48 +2 +3 −1 0 −5 −4 −9 −8 −11 −15 −19 −24

e7 f7 h7 js7 E7 F7 H7 3 6 ±4 ±6.5 −

h7 +140 +70 +70 +30 +30 +30 +20 +20 +20 +10 +10 +10 +4 +4 0 0 0 0 0 −6 −9 −9 −12 −13 −16 −17 −20 −23 −27 −31 −36

f7 h7 F8 H8 +208 +116 +138 +62 +76 +98 +40 +47 +61 +22 +28 +35 +14 +20 +9 +15 +22 +36 +58 +2 +5 −3 0 −7 −4 −12 −9 −13 −17 −22 −28

6 10 ±4.5 ±7.5 −

H8 e8 f8 h8 D8 E8 F8 H8 +150 +80 +80 +40 +40 +40 +25 +25 +25 +13 +13 +13 +5 +5 0 0 0 0 0 −7 −10 −12 −15 −16 −19 −21 −24 −28 −32 −37 −43

h8 −33

d9 e9 D9 E9 H9 10 14

d8 e8 h8 D8 E8 H8 +220 +138 +165 +77 +93 +120 +50 +59 +75 +27 +34 +43 +17 +24 +11 +18 +27 +43 +70 +2 +6 −4 0 −9 −5 −15 −11 −16 −21 −26 −51

±5.5 ±9.5 −

H9 +150 +95 +95 +50 +50 +50 +32 +32 +32 +16 +16 +16 +6 +6 0 0 0 0 0 −9 −12 −15 −18 −20 −23 −26 −29 −34 −39 −44 −38

c9 d9 e9 h9 h9 C9 D9 E9 H9 14 18

−56

H10 b9 c9 d9 B10 C10 D10 −33 −46

[Note] *Fits will make an exception according to the classification of dimensions. 18 24 −

[Note]* Fits will make an exception according to the classification of dimensions. +244 +162 +194 +98 +117 +149 +61 +73 +92 +33 +41 +53 +20 +28 +13 +21 +33 +52 +84 +2 +6 −4 0 −11 −7 −18 −14 −20 −27 −54 −67

±6.5 ±10.5

+160 +110 +110 +65 +65 +65 +40 +40 +40 +20 +20 +20 +7 +7 0 0 0 0 0 −11 −15 −17 −21 −24 −28 −31 −35 −41 −48 −33 −40 −56

24 30

1.2 Mutual relationship between tolerance range and hole base fitting which are in constant use. 2.2 Mutual relationship between tolerance range and shaft base fittings which are in constant use. −54 −61 −77

+270 +182 +220 −39 −51

Base Hole H6 H7 H8 H9 H10 Reference axis h5 h6 h7 h8 h9 30 40

+170 +120 +120 +119 +142 +180 +75 +89 +112 +41 +50 +64 +25 +34 +16 +25 +39 +62 +100 +3 +7 −4 0 −12 −8 −21 −17 −25 −34 −64 −76

Clearance fit Transition fit Close fit Clearance fit ±8 ±12.5 −

Transition fit

Transition fit

Clearance fit

Transition fit

+280 +192 +230 +80 +80 +80 +50 +50 +50 +25 +25 +25 +9 +9 −13 −18 −20 −25 −28 −33 −37 −42 −50 −59 −45 −61

Clearance fit

Clearance fit

Clearance fit

Clearance fit

Clearance fit

Clearance fit

Clearance fit

Close fit

Close fit

Close fit

0 0 0 0 0

40 50

+180 +130 +130 −70 −86

Driving fit

Strong press fit

Loose rolling fit

Light rolling fit

Rolling fit

Press fit

Pulley fit

Shrunk fit

Fit Fit

+310 +214 +260 −30 −42 −55 −76

50 65

+190 +140 +140 +146 +174 +220 +90 +106 +134 +49 +60 +76 +29 +40 +19 +30 +46 +74 +120 +4 +9 −5 0 −14 −9 −26 −21 −60 −72 −85 −106

Class of Tolerance Range for Shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9 d8 d9 g8 e9 h8 h9 b9 c9 d9 Class of Tolerance ±9.5 ±15.5 −

Range for Hole M6 JS6 K5 M6 N6 P6 F6 F7 G6 G7 H6 H7 JS6 JS7 K6 K7 M6 M7 N6 N7 P6 P7 R7 S7 T7 U7 X7 E7 F7 F8 H7 H8 D8 D9 E8 E9 F8 H8 H9 B10 C9 C10 D8 D9 D10 E8 E9 H8 H9 +320 +224 +270 +100 +100 +100 +60 +60 +60 +30 +30 +30 +10 +10 0 0 0 0 0 −15 −21 −24 −30 −33 −39 −45 −51 −32 −48 −64 −91

65 80

+200 +150 +150 −62 −78 −94 −121

+360 +257 +310 −38 −58 −78 −111

80 100

+220 +170 +170 +174 +207 +260 +107 +126 +159 +58 +71 +90 +34 +47 +22 +35 +54 +87 +140 +4 +10 −6 0 −16 −10 −30 −24 −73 −93 −113 −146

±11 ±17.5 −

+380 +267 +320 +120 +120 +120 +72 +72 +72 +36 +36 +36 +12 +12 0 0 0 0 0 −18 −25 −28 −35 −38 −45 −52 −59 −41 −66 −91 −131

50 200 100 120

+240 +180 +180 −76 −101 −126 −166

H10 +420 +300 +360 −48 −77 −107

120 140

(μm) H9 (μm) +260 +200 +200 −88 −117 −147

H7 H8 +440 +310 +370 +208 +245 +305 +125 +148 +185 +68 +83 +106 +39 +54 +25 +40 +63 +100 +160 +4 +12 −8 0 −20 −12 −36 −28 −50 −85 −119

H6 140 160 ±12.5 ±20.5 − −

+280 +210 +210 +145 +145 +145 +85 +85 +85 +43 +43 +43 +14 +14 −21 −28 −33 −40 −45 −52 −61 −68 −90 −125 −159

Variation of tolerance

Variation of tolerance

0 150 0 0 0 0 0

+470 +330 +390 −53 −93 −131

160 180

+310 +230 +230 −93 −133 −171

+525 +355 +425 −60 −105

180 200

+340 +240 +240 −106 −151

−50 100

+565 +375 +445 +242 +285 +355 +146 +172 +215 +79 +96 +122 +44 +61 +29 +46 +72 +115 +185 +5 +13 −8 0 −22 −14 −41 −33 −63 −113

200 225 ±14.5 ±23.5 − − −

+380 +260 +260 +170 +170 +170 +100 +100 +100 +50 +50 +50 +15 +15 0 0 0 0 0 −24 −33 −37 −46 −51 −60 −70 −79 −109 −159

+605 +395 +465 −67 −123

225 250

+420 +280 +280 −113 −169

−100 50 +690 +430 +510 −74

250 280

+480 +300 +300 +271 +320 +400 +162 +191 +240 +88 +108 +137 +49 +69 +32 +52 +81 +130 +210 +5 +16 −9 0 −25 −14 −47 −36 −126

±16 ±26.5 − − − −

+750 +460 +540 +190 +190 +190 +110 +110 +110 +56 +56 +56 +17 +17 0 0 0 0 0 −27 −36 −41 −52 −57 −66 −79 −88 −78

280 315

+540 +330 +330 −130

−150 0 h5 h6 h6

+830 +500 +590 −87

h7 315 355

h8 +600 +360 +360 +299 +350 +440 +182 +214 +265 +98 +119 +151 +54 +75 +36 +57 +89 +140 +230 +7 +17 −10 0 −26 −16 −51 −41 −144

±18 ±28.5 − − − −

h9 +910 +540 +630 +210 +210 +210 +125 +125 +125 +62 +62 +62 +18 +18 0 0 0 0 0 −29 −40 −46 −57 −62 −73 −87 −98 −93

355 400

+680 +400 +400 −150

−200 −50 +1010 +595 +690 −103

400 450

+760 +440 +440 +327 +385 +480 +198 +232 +290 +108 +131 +165 +60 +83 +40 +63 +97 +155 +250 +8 +18 −10 0 −27 −17 −55 −45 −166

±20 ±31.5 − − − −

1379 * This table shows the case when basic dimension is over 18mm to 30mm. *This table shows the case when basic dimension is over 18mm to 30mm.

450 500

+1090 +635 +730 +230 +230 +230 +135 +135 +135 +68 +68 +68 +20 +20

+840 +480 +480

0 0 0 0 0 −32 −45 −50 −63 −67 −80 −95 −108 −109

−172 1380

Reference This table shows that upper figures are the upper dimension tolerance and lower figures are the lower dimension tolerance. [Note] *:Although n5 is an old JIS standard, it is included here as it applies to many of MISUMI products.

You might also like

- NutsDocument49 pagesNutsIshant JaiswalNo ratings yet

- General Kinematics - UncoalerDocument38 pagesGeneral Kinematics - UncoalerJogesh NarulaNo ratings yet

- Rochi 2019 PDFDocument26 pagesRochi 2019 PDFGautamNo ratings yet

- Natural RubberDocument7 pagesNatural RubberFrancis AdrianNo ratings yet

- Linatex Screen O&m ManualDocument23 pagesLinatex Screen O&m ManualsirercksNo ratings yet

- Basic of FastenersDocument53 pagesBasic of FastenersKomal TagraNo ratings yet

- Vertical Shaft Impactor - Sand Making MachineDocument37 pagesVertical Shaft Impactor - Sand Making Machineaaronshakti100% (1)

- CRS Manual (Operation)Document23 pagesCRS Manual (Operation)Serhidra SASNo ratings yet

- Technical Data (Thai) 3Document1 pageTechnical Data (Thai) 3NatKThNo ratings yet

- HighTens EN25Document2 pagesHighTens EN25Annamali Thiayagarajan0% (1)

- Wear ProtectionDocument6 pagesWear ProtectionRafael CortezNo ratings yet

- Deepak Project On Jaw CrusherDocument96 pagesDeepak Project On Jaw CrusherAnil Kumar KnNo ratings yet

- Wecall CatalogDocument20 pagesWecall Catalogpdoherty100% (2)

- Terex Jaques Torrent ScreensDocument16 pagesTerex Jaques Torrent ScreensKarin AndersonNo ratings yet

- Mechanical OPerationDocument10 pagesMechanical OPerationAnshika RajputNo ratings yet

- Mvi Vertical ShaftDocument4 pagesMvi Vertical ShaftMarcel BaqueNo ratings yet

- Rollsizers enDocument5 pagesRollsizers enIrvanda ZiaurrahmanNo ratings yet

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForDocument13 pagesEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method Forraulpalma93No ratings yet

- Spring Design 101: Ace Wire Spring & Form Co., IncDocument15 pagesSpring Design 101: Ace Wire Spring & Form Co., IncmshameliNo ratings yet

- Gray Iron ASTM Class 40B Material StandardDocument4 pagesGray Iron ASTM Class 40B Material StandardRIYASNo ratings yet

- Is 6051 1970Document15 pagesIs 6051 1970harshal161987100% (1)

- SP IM S214.556 enDocument66 pagesSP IM S214.556 enLucky OkoteNo ratings yet

- Fit Selection BasicDocument1 pageFit Selection Basicapi-3848892100% (2)

- Tolerances FabDocument1 pageTolerances FabAnwarNo ratings yet

- H-E Parts Case Study C160 & C200 Jaw PerformanceDocument1 pageH-E Parts Case Study C160 & C200 Jaw PerformanceJorge VillalobosNo ratings yet

- Tightening ForceDocument1 pageTightening ForceLuisLauShNo ratings yet

- ASTM A356 A356M - 07 Steel CastingsDocument6 pagesASTM A356 A356M - 07 Steel CastingsMacario LeyvaNo ratings yet

- HE Crushing Solutions Engineeing and MN OverviewDocument48 pagesHE Crushing Solutions Engineeing and MN OverviewJorge VillalobosNo ratings yet

- Slurry Pump The KproDocument11 pagesSlurry Pump The Kpro4lk0nNo ratings yet

- Fineness Modulus of Sand - Fineness Modulus of Fine Aggregate - Fineness Modulus of Sand CalculationDocument7 pagesFineness Modulus of Sand - Fineness Modulus of Fine Aggregate - Fineness Modulus of Sand CalculationWaqas SadiqNo ratings yet

- Flender Technical HandbookDocument79 pagesFlender Technical HandbookKADİR durmazNo ratings yet

- Heat Treatment-1 PDFDocument104 pagesHeat Treatment-1 PDFSagnik ChakrabortyNo ratings yet

- SDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Document15 pagesSDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Ali YükselNo ratings yet

- Non Contact SealDocument24 pagesNon Contact Sealsetiadi pratondoNo ratings yet

- 2013 Oscillating MountingsDocument40 pages2013 Oscillating MountingspcmfilhoNo ratings yet

- Dewatering Screens Spec Sheet: Series 9000Document2 pagesDewatering Screens Spec Sheet: Series 9000ekrem0867No ratings yet

- EU Emission Standards PDFDocument5 pagesEU Emission Standards PDFStephanie StewartNo ratings yet

- Liner Development Process SummaryDocument3 pagesLiner Development Process SummaryJorge VillalobosNo ratings yet

- MANUAL1 - Copia - 4Document50 pagesMANUAL1 - Copia - 4Jose NoriegaNo ratings yet

- H-E Parts Case Study Improved Cone Crusher PerformanceDocument1 pageH-E Parts Case Study Improved Cone Crusher PerformanceJorge VillalobosNo ratings yet

- Quotation of Wheel Type Mobile Granite Crushing & Screening Plant About 150TPH 20110429Document4 pagesQuotation of Wheel Type Mobile Granite Crushing & Screening Plant About 150TPH 20110429Solomon MiNo ratings yet

- DK1915 CH10Document55 pagesDK1915 CH10gao379No ratings yet

- Vertical and Horizontal Screw ConveyorsDocument4 pagesVertical and Horizontal Screw ConveyorsLLNo ratings yet

- Telsmith Product OverviewDocument12 pagesTelsmith Product OverviewRicardoNo ratings yet

- Optitooth Jaw Plates - Customer Testimonial Data - 2017Document8 pagesOptitooth Jaw Plates - Customer Testimonial Data - 2017danielNo ratings yet

- PresentationDocument46 pagesPresentationDanielSantosNo ratings yet

- Cone Ranger: Mobile Cone Crushing UnitsDocument2 pagesCone Ranger: Mobile Cone Crushing UnitsYousef AlipourNo ratings yet

- Thyssenkrupp - Jaw Crusher PDFDocument7 pagesThyssenkrupp - Jaw Crusher PDFFernando MilmanNo ratings yet

- B-99 Recycling IndustryDocument6 pagesB-99 Recycling IndustryAntony MayuziNo ratings yet

- 09 Engineering and Technical DataDocument58 pages09 Engineering and Technical Dataeeng_nnabilNo ratings yet

- Suncor Catalog Vol10Document152 pagesSuncor Catalog Vol10larosemaximeNo ratings yet

- Eirez Vibratory Feeders and Conveyors BrochureDocument20 pagesEirez Vibratory Feeders and Conveyors BrochureJay Ryan SantosNo ratings yet

- How To Size A ThickenerDocument7 pagesHow To Size A ThickenerJesus Sing RoblesNo ratings yet

- DIN 1683-1-General Toleranve and Maching Allowance of Steel CastingDocument4 pagesDIN 1683-1-General Toleranve and Maching Allowance of Steel Castingrajksharma100% (1)

- Wheeled-Range Broch LowqDocument12 pagesWheeled-Range Broch LowqLee LiNo ratings yet

- Toleransi 1Document1 pageToleransi 1trisakti.agusNo ratings yet

- Tolerance Fit ChartDocument1 pageTolerance Fit ChartHien Bui XuanNo ratings yet

- Fitting & ToleranceDocument2 pagesFitting & Tolerancenama sayaNo ratings yet

- Dimension Tolerance & FittingDocument1 pageDimension Tolerance & FittingpawargdNo ratings yet

- Tabel Tolerante Arbori Si AlezajeDocument1 pageTabel Tolerante Arbori Si AlezajeCosmin RobuNo ratings yet

- Pds Luxathane 5000 VocDocument2 pagesPds Luxathane 5000 Vocmuthukumar100% (1)

- Software Quality Assurance IntroductionDocument72 pagesSoftware Quality Assurance Introductionfmohiy100% (6)

- Normas ISO TelecomunicacionesDocument38 pagesNormas ISO Telecomunicacionesjolao AlmeidaNo ratings yet

- Operation and Maintenance Manual: Mux-2200E Integrated Service MultiplexerDocument82 pagesOperation and Maintenance Manual: Mux-2200E Integrated Service Multiplexerlee.tetleie1675No ratings yet

- ABB Wireless Communications For Mining OperationsDocument38 pagesABB Wireless Communications For Mining OperationsAymanNo ratings yet

- Trial and Error: Failure and Innovation in Criminal Justice ReformDocument5 pagesTrial and Error: Failure and Innovation in Criminal Justice ReformAzim MohammedNo ratings yet

- CS2305 PP Lecture Notes PDFDocument367 pagesCS2305 PP Lecture Notes PDFVijai KirubaNo ratings yet

- Fis-Opf Ach PaymentsDocument5 pagesFis-Opf Ach PaymentscrazytrainNo ratings yet

- Manual Ni Usrp 2920Document56 pagesManual Ni Usrp 2920Anghye Plata100% (1)

- Dism Repair Tools PDFDocument21 pagesDism Repair Tools PDFprashant4455No ratings yet

- DPP Series 1 PDFDocument1 pageDPP Series 1 PDFsukainaNo ratings yet

- Juniper Practice QuestionsDocument32 pagesJuniper Practice QuestionsDasaradhiNidamarthyNo ratings yet

- PhillipsDocument22 pagesPhillipsArthur RodriguezNo ratings yet

- Homework 1&2 Report EE440Document19 pagesHomework 1&2 Report EE440Võ Hoàng Chương100% (1)

- Cat 15Document2 pagesCat 15Gustavo Vargas0% (1)

- Pricing - Biznet GIO - Cloud Service Provider Indonesia PDFDocument1 pagePricing - Biznet GIO - Cloud Service Provider Indonesia PDFTohirNo ratings yet

- Viola - David Tudor - The Delicate Art of FallingDocument9 pagesViola - David Tudor - The Delicate Art of FallingRobin ParmarNo ratings yet

- TIA Workshop ITBDocument48 pagesTIA Workshop ITBFirman Suhendra100% (1)

- Trodat Standard Self Inking Stamp and Accessory Mini CatalogDocument12 pagesTrodat Standard Self Inking Stamp and Accessory Mini CatalogpromotesourceNo ratings yet

- Tramlink Low-Floor Light Rail Vehicle: Rostocker Strassenbahn Ag, Rostock, GermanyDocument2 pagesTramlink Low-Floor Light Rail Vehicle: Rostocker Strassenbahn Ag, Rostock, GermanyLuca Marius CristianNo ratings yet

- Noise Control in BuildingsDocument36 pagesNoise Control in BuildingsEmily Ong100% (1)

- ABB Ability Safety Plus For Hoists BrochureDocument12 pagesABB Ability Safety Plus For Hoists BrochureCarlos Bruno MatosNo ratings yet

- 2 Combined Dci Standards 6 13 13Document7 pages2 Combined Dci Standards 6 13 13api-32776059No ratings yet

- Em 59717521644Document68 pagesEm 59717521644Mostafa MirbaghriNo ratings yet

- CAAYE Annual Report 2013Document26 pagesCAAYE Annual Report 2013Rahul MirchandaniNo ratings yet

- PS2 VerilogDocument11 pagesPS2 Veriloglizhi0007No ratings yet

- Module 8: Numerical Relaying I: Fundamentals: Fourier AlgorithmsDocument15 pagesModule 8: Numerical Relaying I: Fundamentals: Fourier Algorithmsjijo123408No ratings yet

- 390 Track Bolt M0079195Document2 pages390 Track Bolt M0079195joshpbenzNo ratings yet

- 5 Blasting Limit GuidelinesDocument7 pages5 Blasting Limit GuidelinesTry Oka Afandy SinagaNo ratings yet

- G3508 - 600kvaDocument7 pagesG3508 - 600kvaJim Patrick ChombaNo ratings yet