Professional Documents

Culture Documents

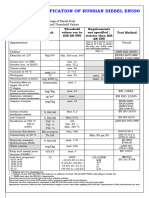

Specification For BIODIESEL (B100) - ASTM D6751-09: Property ASTM Method Limits Units

Uploaded by

Abraham Garcia MaldonadoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification For BIODIESEL (B100) - ASTM D6751-09: Property ASTM Method Limits Units

Uploaded by

Abraham Garcia MaldonadoCopyright:

Available Formats

SPECIFICATION FOR

BIODIESEL (B100) – ASTM D6751-09

Nov. 2008

Biodiesel is defined as the mono alkyl esters of long chain fatty acids derived from vegetable oils or animal fats,

for use in compression-ignition (diesel) engines. This specification is for pure (100%) biodiesel prior to use or

blending with diesel fuel. #

Property ASTM Method Limits Units

Calcium & Magnesium, combined EN 14538 5 maximum ppm (ug/g)

Flash Point (closed cup) D 93 93 minimum degrees C

Alcohol Control (One of the following must be met)

1. Methanol Content EN14110 0.2 maximum % mass

2. Flash Point D93 130 minimum Degrees C

Water & Sediment D 2709 0.05 maximum % vol.

Kinematic Viscosity, 40 C D 445 1.9 - 6.0 mm2/sec.

Sulfated Ash D 874 0.02 maximum % mass

Sulfur

S 15 Grade D 5453 0.0015 max. (15) % mass (ppm)

S 500 Grade D 5453 0.05 max. (500) % mass (ppm)

Copper Strip Corrosion D 130 No. 3 maximum

Cetane D 613 47 minimum

Cloud Point D 2500 report degrees C

Carbon Residue 100% sample D 4530* 0.05 maximum % mass

Acid Number D 664 0.50 maximum mg KOH/g

Free Glycerin D 6584 0.020 maximum % mass

Total Glycerin D 6584 0.240 maximum % mass

Phosphorus Content D 4951 0.001 maximum % mass

Distillation, T90 AET D 1160 360 maximum degrees C

Sodium/Potassium, combined EN 14538 5 maximum ppm

Oxidation Stability EN 14112 3 minimum hours

Cold Soak Filtration Annex to D6751 360 maximum seconds

For use in temperatures below -12 C Annex to D6751 200 maximum seconds

BOLD = BQ-9000 Critical Specification Testing Once Production Process Under Control

* The carbon residue shall be run on the 100% sample.

# A considerable amount of experience exists in the US with a 20% blend of biodiesel with 80% diesel fuel (B20).

Although biodiesel (B100) can be used, blends of over 20% biodiesel with diesel fuel should be evaluated on a

case-by-case basis until further experience is available.

You might also like

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Specification for biodiesel (B100) - ASTM D6751-08Document1 pageSpecification for biodiesel (B100) - ASTM D6751-08Alejandra RojasNo ratings yet

- ASTM 6751 Spec PDFDocument2 pagesASTM 6751 Spec PDFAlush Joe0% (1)

- Astm d6751 b100 Specification PDFDocument1 pageAstm d6751 b100 Specification PDFZak YanNo ratings yet

- ASTM D6751-06 BioDiesel SpecsDocument1 pageASTM D6751-06 BioDiesel SpecsJavier CardonaNo ratings yet

- Specification For Biodiesel B100Document1 pageSpecification For Biodiesel B100anggaeryantoNo ratings yet

- Astm d6751 (b100) SpecificationDocument1 pageAstm d6751 (b100) SpecificationPía RivadeneiraNo ratings yet

- Jet A or Jet A-1 aviation fuel specification sheetDocument1 pageJet A or Jet A-1 aviation fuel specification sheetnishilgeorgeNo ratings yet

- ASTM D6751 - 07aDocument1 pageASTM D6751 - 07aSYAMSUL BACHRIENo ratings yet

- D2 JP54 Spec PDFDocument3 pagesD2 JP54 Spec PDFcesarjabbour1No ratings yet

- Implementasi B35 Rev01Document21 pagesImplementasi B35 Rev01ppd brcgNo ratings yet

- 2022 TSA Petrol Import SpecificationDocument2 pages2022 TSA Petrol Import Specificationmohamed fikryNo ratings yet

- ENGEN GASOIL Import Spec - Diesel 10Document2 pagesENGEN GASOIL Import Spec - Diesel 10basharat121100% (2)

- Astm D6751Document2 pagesAstm D6751SYAMSUL BACHRIENo ratings yet

- Super Gasoline 95 RONDocument1 pageSuper Gasoline 95 RONxtrooz abiNo ratings yet

- Specification For BIODIESEL (B100) - ASTM D6751-09: Property ASTM Method Limits UnitsDocument1 pageSpecification For BIODIESEL (B100) - ASTM D6751-09: Property ASTM Method Limits UnitsIzzul HazimNo ratings yet

- Specification for B100 Biodiesel FuelDocument1 pageSpecification for B100 Biodiesel FuelErlangga SatyawanNo ratings yet

- The Specification of Diesel Oil 0.005% Sulfur: No. The Specification Items Unit Standard Test MethodDocument1 pageThe Specification of Diesel Oil 0.005% Sulfur: No. The Specification Items Unit Standard Test MethodVo KhoaNo ratings yet

- Jet A-1 fuel standard specificationDocument3 pagesJet A-1 fuel standard specificationbj100% (1)

- Literature Review 2.1 BiodieselDocument18 pagesLiterature Review 2.1 BiodieselRichard ObinnaNo ratings yet

- Jetfuel Typea1 SpecificationsDocument1 pageJetfuel Typea1 SpecificationsFariz Azwar AzmiNo ratings yet

- Specifications, Quality and Standard: Diesel Automotive Gas Oil (Ago)Document1 pageSpecifications, Quality and Standard: Diesel Automotive Gas Oil (Ago)Ardana SNo ratings yet

- ASTM MethodsDocument9 pagesASTM MethodsLe Nguyen Phuc ThienNo ratings yet

- COMPANY PROFILE PT. TAWU INTI BAKU - 2019 VersionDocument22 pagesCOMPANY PROFILE PT. TAWU INTI BAKU - 2019 VersionTeknik MarinaNo ratings yet

- PDS - ETRO 6plus - 2022.01Document1 pagePDS - ETRO 6plus - 2022.01Sawan TaylorNo ratings yet

- Guaranteed Specification of Russian Diesel Automotive Gas Oil (Ago)Document1 pageGuaranteed Specification of Russian Diesel Automotive Gas Oil (Ago)Andrew AtotuomahNo ratings yet

- Biodiesel Emissions Champions Meeting InsightsDocument27 pagesBiodiesel Emissions Champions Meeting InsightsPablo Luis Pérez PostigoNo ratings yet

- Pds Etro 4plus 2022.01Document1 pagePds Etro 4plus 2022.01Samee84No ratings yet

- Central West SpecificationsDocument67 pagesCentral West Specificationseko handoyoNo ratings yet

- PDS_EQUINAS 8_2023.v3Document1 pagePDS_EQUINAS 8_2023.v3Orhan IRMAKNo ratings yet

- Specification For BIODIESEL (B100) - ASTM 6751-11a: Property ASTM Method Limits UnitsDocument1 pageSpecification For BIODIESEL (B100) - ASTM 6751-11a: Property ASTM Method Limits UnitsPin Pin OhNo ratings yet

- U. S. Oil & Refining Co.: Naval Distillate, F-76Document1 pageU. S. Oil & Refining Co.: Naval Distillate, F-76Ashwani KumarNo ratings yet

- Tds Biodiesel 20Document2 pagesTds Biodiesel 20Gian TeryNo ratings yet

- Biodeisel Using FuelProDocument4 pagesBiodeisel Using FuelProSylab InstrumentsNo ratings yet

- Full Range NaphthaDocument1 pageFull Range Naphthasurya.hadinata999No ratings yet

- Certificate of Analysis: Test Method Unit Specification ResultDocument1 pageCertificate of Analysis: Test Method Unit Specification ResultOfek LevyNo ratings yet

- Certificate of Analysis: Test Method Unit Specification ResultDocument1 pageCertificate of Analysis: Test Method Unit Specification ResultOfek LevyNo ratings yet

- 2 Specification Russian EN590Document1 page2 Specification Russian EN590Sephiwe MafilikaNo ratings yet

- Jordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentDocument2 pagesJordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentMohammed Nuseir100% (1)

- 450F HsdviDocument2 pages450F HsdviJoJo kNo ratings yet

- Extracted Pages From A001064 - 12EDocument4 pagesExtracted Pages From A001064 - 12EAwais8888No ratings yet

- Ceypetco SpecificationDocument1 pageCeypetco Specificationbasharat121No ratings yet

- AMOC Base OilsDocument3 pagesAMOC Base Oilsmgamal1080No ratings yet

- Electrical Transformer Insulation Oil SpecificationDocument1 pageElectrical Transformer Insulation Oil SpecificationBRENTON CCACHA FRANCONo ratings yet

- Bio Diesel b20, En590 b5 SpecificationsDocument1 pageBio Diesel b20, En590 b5 Specificationsmohammed wajidNo ratings yet

- Datasheet KetonesmibkasiapacificDocument3 pagesDatasheet Ketonesmibkasiapacificnitin birajdarNo ratings yet

- Shellsol A150 ND q7497 Eu 18042016Document3 pagesShellsol A150 ND q7497 Eu 18042016sizmaruNo ratings yet

- BP DieselDocument3 pagesBP Dieselariyamanjula2914No ratings yet

- Standard Spec FAME-EBTKE+PETDocument1 pageStandard Spec FAME-EBTKE+PETMuhamad Firmansyah Hermana PutraNo ratings yet

- Quality Control of Products in Petroleum RefiningDocument29 pagesQuality Control of Products in Petroleum RefiningAdrian RodriguezNo ratings yet

- Xylene T1404 TDS - 10-3-2016Document2 pagesXylene T1404 TDS - 10-3-2016Faez Ahammad MazumderNo ratings yet

- Bio Diesel b20, En590-Biodiesel b5 SpecsDocument1 pageBio Diesel b20, En590-Biodiesel b5 Specsmohammed wajid100% (1)

- Shellsol A150 q7493 Eu 18042016Document3 pagesShellsol A150 q7493 Eu 18042016Henry FloresNo ratings yet

- Ago 50ppmDocument3 pagesAgo 50ppmanil divveNo ratings yet

- Attachment2 - Euro 5 B0Document1 pageAttachment2 - Euro 5 B0ShahrilNo ratings yet

- Shellsol T q7412 PDFDocument3 pagesShellsol T q7412 PDFmeNo ratings yet

- Shellsol T q7412 AmDocument3 pagesShellsol T q7412 AmRagavendra Prabu GovindarajuNo ratings yet

- Gasoil Specification SPC 2016Document1 pageGasoil Specification SPC 2016Mohamed GasimNo ratings yet

- Petroleum Licence Register 2011Document7 pagesPetroleum Licence Register 2011Abdulhakim AbdullaNo ratings yet

- Marcol 82: Product DescriptionDocument2 pagesMarcol 82: Product Descriptionangel de mi guardaNo ratings yet

- Calorific Test For Gaseous FuelsDocument18 pagesCalorific Test For Gaseous FuelsJhay-Pee QueliopeNo ratings yet

- Leica - Configuratie Tehnica HistoCore Arcadia H+C - AC0031 ENDocument6 pagesLeica - Configuratie Tehnica HistoCore Arcadia H+C - AC0031 ENciunganmNo ratings yet

- Boiler 5Document4 pagesBoiler 5Shams TabrezNo ratings yet

- InternshipDocument17 pagesInternshipShivam TiwariNo ratings yet

- Aircraft Fuel Systems. AYR CDocument37 pagesAircraft Fuel Systems. AYR CAKANKSHA PANDEYNo ratings yet

- Gas Cylinder SafetyDocument5 pagesGas Cylinder SafetyS C GaurNo ratings yet

- Case BP MobilDocument4 pagesCase BP MobilLucky_pragneshNo ratings yet

- ESP HandBookDocument67 pagesESP HandBookEmad JamshidiNo ratings yet

- 110me0300 10Document46 pages110me0300 10Liya StaariNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- Chapter 05Document39 pagesChapter 05pdaga19691383No ratings yet

- Control of Industrial Major Hazards RegulationsDocument34 pagesControl of Industrial Major Hazards RegulationsAnonymous A9I48xm6jNo ratings yet

- FOB Rotterdam Zenth ND Preston 05 23 2015 PDFDocument2 pagesFOB Rotterdam Zenth ND Preston 05 23 2015 PDFamir.workNo ratings yet

- WCECS2008 pp123-127Document5 pagesWCECS2008 pp123-127Syukri ShahNo ratings yet

- DTS Catalog 2016Document206 pagesDTS Catalog 2016duque_sade100% (1)

- Suction Caisson Anchors - A Better Option For Deep Water ApplicationsDocument6 pagesSuction Caisson Anchors - A Better Option For Deep Water ApplicationscupyoungerNo ratings yet

- SB Office-Gas Slip FormDocument1 pageSB Office-Gas Slip FormRichard C. AmoguisNo ratings yet

- Needed: SMK English Exam Practice TestDocument9 pagesNeeded: SMK English Exam Practice TestMohamad Fauzan100% (1)

- Linear ProgramingDocument5 pagesLinear ProgramingSimon LiNo ratings yet

- CNG Industry in PakistanDocument42 pagesCNG Industry in Pakistanzeeshan_dhillo100% (2)

- CRDiDocument18 pagesCRDiSuhel InamdarNo ratings yet

- FCC TRNG PDFDocument27 pagesFCC TRNG PDFrameshkarthik810No ratings yet

- 0620 m19 QP 12 PDFDocument16 pages0620 m19 QP 12 PDFmariaNo ratings yet

- SPE 88446 Making Steerable Bits: Separating Side-Force From Side-CuttingDocument7 pagesSPE 88446 Making Steerable Bits: Separating Side-Force From Side-CuttingmsmsoftNo ratings yet

- Astm d4294Document9 pagesAstm d4294Danilo SolanoNo ratings yet

- Business PlanDocument74 pagesBusiness PlanandysupaNo ratings yet

- CP de Diversas SustanciasDocument6 pagesCP de Diversas SustanciasZimNo ratings yet

- 763 - v3800 CR Ti E4 EnglishDocument43 pages763 - v3800 CR Ti E4 EnglishgeorgeNo ratings yet