Professional Documents

Culture Documents

Wb2092e E7024 PDF

Wb2092e E7024 PDF

Uploaded by

cwiksjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wb2092e E7024 PDF

Wb2092e E7024 PDF

Uploaded by

cwiksjCopyright:

Available Formats

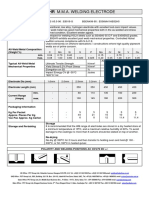

WB2092E M.M.A.

WELDING ELECTRODE

Classifications AWS A5.1-91 : E7024 BSEN 499-95 : E42 3RR 7 4

Product Description High deposition rutile electrode with a self detaching slag and a nominal recovery of

180%

Applications Mild and medium C-Mn steels up to 15mm thick with a UTS of 500 N/mm² max.

BS4360 grades 42A-50B - BS3601 320-410 and AP15L A-B, X42.

All-Weld Metal Composition

(Weight %) C Mn Si S P Ni Cr Mo V Cu

min. 0.08 0.50 0.40 - - - - - - -

max. 0.12 1.25 0.90 0.020 0.025 0.05 0.05 0.03 0.050 0.050

Typical All-Weld Metal Ultimate Tensile Strength N/mm² 547

Mechanical Properties Yield Stress/0.2% Proof Stress N/mm² 446

Elongation on 5D % 29

Impact Energy CV @ -30°C Joules 39

As-welded

Electrode Dia (mm) 1.6mm 2.0mm 2.5mm 3.2mm 4.0mm 5.0mm 6.0mm

Electrode Length (mm) - - 350 450 450 450 -

min. - - 90 140 175 220 -

Current Range

(Amps) max. - - 120 175 220 280 -

Packaging Information

Kg Per Packet - - 5 5 5 5 -

Approx. Pieces Per Kg - - 40 18 12 7 -

Storage

Storage and Re-baking It is recommended that the WB range of electrodes are stored in a dry heated store at

a minimum temperature of 18C, and a maximum relative humidity of 60%. To avoid

damage to the coatings no more than 6 cartons should be staked on top of another.

Re-drying

If these electrodes become excessively damp re-dry @ 100C for 1 hour.

Current Conditions AC OCV70 DC +/- and Welding Positions

You might also like

- Type of SealantDocument6 pagesType of SealantAn-an ChanNo ratings yet

- AMS-2404 - Plating, Electroless NickelDocument10 pagesAMS-2404 - Plating, Electroless NickelnaveedNo ratings yet

- Rate AnalysisDocument54 pagesRate AnalysisSahir Suman SangroulaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Detailed Specification of The BuildingDocument5 pagesDetailed Specification of The Buildingsaravanan4286100% (4)

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsNo ratings yet

- Asme Section IxDocument47 pagesAsme Section Ixمحمودالوصيف100% (8)

- 11 Prestressed Concrete Chapter 11Document52 pages11 Prestressed Concrete Chapter 11Hor Ka Wai100% (1)

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- Wb2000e E6013Document1 pageWb2000e E6013cwiksjNo ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- WB5525E ENiCrMo-5Document1 pageWB5525E ENiCrMo-5cwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2Document1 pageWb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2lathasri78No ratings yet

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78No ratings yet

- WB56S E7016-1Document1 pageWB56S E7016-1cwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Basic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660Document1 pageBasic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660mohamed AdelNo ratings yet

- LINCOLN Nicromo 60-16Document2 pagesLINCOLN Nicromo 60-16AbdülHak ÖZkaraNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Excelitas C30659 Series DatasheetDocument11 pagesExcelitas C30659 Series Datasheetasimkumar2222No ratings yet

- Hottech BZX55CDocument3 pagesHottech BZX55CFábio Freitas OliveiraNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- TDS - Nimrod C276KSDocument1 pageTDS - Nimrod C276KSImmalatulhusnaNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- BrightPhoton - VCSEL - LD0940-B130-0014CC-1035 Spec V.01Document4 pagesBrightPhoton - VCSEL - LD0940-B130-0014CC-1035 Spec V.01黄孙峰No ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- 21crmov5-7: Steel GradeDocument1 page21crmov5-7: Steel GradeEdward PongracNo ratings yet

- 12a DPST Miniature Power RelayDocument2 pages12a DPST Miniature Power RelaykarkeraNo ratings yet

- 410 NiMo MigDocument2 pages410 NiMo MigAnonymous skBAwexNo ratings yet

- Shielded Power Inductors - MOS6020Document2 pagesShielded Power Inductors - MOS6020mauricio alfonsoNo ratings yet

- SL20GDocument2 pagesSL20Gridho_48No ratings yet

- Wire Spec 44 PDFDocument5 pagesWire Spec 44 PDFAdnan khanNo ratings yet

- TT - Electronics 898 3 R100K Datasheet PDFDocument4 pagesTT - Electronics 898 3 R100K Datasheet PDFelnegritoheberNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Alloy 308Document4 pagesAlloy 308Branko FerenčakNo ratings yet

- AbcDocument2 pagesAbcsurendarNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- AUTOMIG 80S Ni1 - TIGFIL 80S Ni1Document1 pageAUTOMIG 80S Ni1 - TIGFIL 80S Ni1Kalyan Chakravathi A GNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999No ratings yet

- Carbo 4842 Ac-E310Document1 pageCarbo 4842 Ac-E310ali torabiNo ratings yet

- Description Appearance: Axial-Leaded 1.5 Watt Zener DiodesDocument4 pagesDescription Appearance: Axial-Leaded 1.5 Watt Zener DiodesJorge VillanuevaNo ratings yet

- American - Zettler AZ732 053 52 DatasheetDocument2 pagesAmerican - Zettler AZ732 053 52 DatasheetZoro DNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- 1%ni For Improved Toughness: Data SheetDocument4 pages1%ni For Improved Toughness: Data Sheetmohamed AdelNo ratings yet

- Standard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Document7 pagesStandard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Bhagoo HatheyNo ratings yet

- Electrode ComparisionDocument1 pageElectrode ComparisionAnilNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- Technical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2Document8 pagesTechnical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2StuxnetNo ratings yet

- K034 - Daikoflux 940Document1 pageK034 - Daikoflux 940cwiksjNo ratings yet

- Robo TiPTiG Data Sheet FinalDocument2 pagesRobo TiPTiG Data Sheet FinalcwiksjNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- A Max WearplateDocument1 pageA Max WearplatecwiksjNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- WB5525E ENiCrMo-5Document1 pageWB5525E ENiCrMo-5cwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- WB56S E7016-1Document1 pageWB56S E7016-1cwiksjNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- Mep Vendor List-2Document6 pagesMep Vendor List-2Mahmoud AliNo ratings yet

- QW 482Document4 pagesQW 482Jesus Silva HenaoNo ratings yet

- Ggbs in Cement Paste and MortarDocument6 pagesGgbs in Cement Paste and MortarsaiNo ratings yet

- IksDocument24 pagesIksX800XLNo ratings yet

- Vanos: Journal of Mechanical Engineering EducationDocument10 pagesVanos: Journal of Mechanical Engineering EducationAde KunNo ratings yet

- Rawlplug XPT Throughbolt Technical DatasheetDocument7 pagesRawlplug XPT Throughbolt Technical DatasheetAh MedNo ratings yet

- Ncma Tek: Steel Reinforcement For Concrete Masonry TEK 12-4DDocument4 pagesNcma Tek: Steel Reinforcement For Concrete Masonry TEK 12-4DReinaldo Andrei SalazarNo ratings yet

- Cold Shrink TubeDocument4 pagesCold Shrink TubeezioNo ratings yet

- The EAF Technology Evolution and The Consteel® System: P. Argenta, M. Bianchi FerriDocument7 pagesThe EAF Technology Evolution and The Consteel® System: P. Argenta, M. Bianchi FerriWISHAL FATIMANo ratings yet

- Zilmet Heat Exchanger Lit Piece 1Document9 pagesZilmet Heat Exchanger Lit Piece 1Andone GigiNo ratings yet

- קטלוגDocument158 pagesקטלוגנמירוב מערכותNo ratings yet

- Age HardeningDocument33 pagesAge HardeningYudikaNo ratings yet

- Standarde MaterialeDocument2 pagesStandarde MaterialeDanutz DukkiNo ratings yet

- Inventory HSN Code RequiredDocument21 pagesInventory HSN Code RequiredPralhad PadwalNo ratings yet

- Flat Roofs: Isaac AdejumoDocument79 pagesFlat Roofs: Isaac AdejumoNahom TasewNo ratings yet

- Packinglist Unit 5Document24 pagesPackinglist Unit 5francisco alberto molina garciaNo ratings yet

- Aerogel Eemtg032011 - c19 - Aerogel - Insul PDFDocument14 pagesAerogel Eemtg032011 - c19 - Aerogel - Insul PDFGeoffreyHunterNo ratings yet

- A Review On The Utilization of Quarry and Ornamental Stone Industry Fine By-Products in The Construction Sector - Galetakis SoultanaDocument13 pagesA Review On The Utilization of Quarry and Ornamental Stone Industry Fine By-Products in The Construction Sector - Galetakis SoultanaEbrahim FlorisNo ratings yet

- VT-620/ 620S LM MS SealantDocument2 pagesVT-620/ 620S LM MS SealantditronzNo ratings yet

- Brochure HYDRAULIC Hose Quick Camlock Valve HIC India 04Document4 pagesBrochure HYDRAULIC Hose Quick Camlock Valve HIC India 04Tithi Kuldeep ChauhanNo ratings yet

- Comparative Analysis of River SandDocument5 pagesComparative Analysis of River SandMatt T100% (1)

- JBCC Priceindex September 2022Document7 pagesJBCC Priceindex September 2022kandy saidNo ratings yet

- As 5200.458-2008 Plumbing and Drainage Products Universal Plastic-Bodied Transition CouplingsDocument7 pagesAs 5200.458-2008 Plumbing and Drainage Products Universal Plastic-Bodied Transition CouplingsSAI Global - APACNo ratings yet

- Boqcomparativechart - 2023-05-27T100002.652Document10 pagesBoqcomparativechart - 2023-05-27T100002.652Abode ArtisanNo ratings yet