Professional Documents

Culture Documents

M.M.A. welding electrode for Martensitic stainless steels

Uploaded by

cwiksjOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M.M.A. welding electrode for Martensitic stainless steels

Uploaded by

cwiksjCopyright:

Available Formats

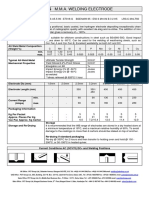

WB4102E M.M.A.

WELDING ELECTRODE

Classifications AWS A5.4-2006 E410-26 BSEN1600-97:E13 R 6 3

Rutile/basic coated, Martensitic stainless steel electrode made on mild steel core

Product Description wire, with metal powder additions to the coating. Having exceptional deslag and arc

stability, this electrode produces a recovery of 140%.

WB4102E is suitable for the welding of high strength Martensitic (12%Cr, type 410)

Applications stainless steels. Developed primary for CA-15 & BS410C21 castings.

Typical applications:- hydrocrackers, reaction vessels, valves bodies and turbine

sections.

All-Weld Metal Composition

(Weight %) C Mn Si S P Mo Cr Ni Cu

min. 0.05 0.50 0.20 - - 0.2 11.0 0.30 -

max. 0.12 1.00 0.50 0.020 0.025 0.5 13.5 0.60 0.050

Typical All-Weld Metal Ultimate Tensile Strength N/mm² 610

Mechanical Properties Yield Stress/0.2% Proof Stress N/mm² 455

Elongation on 5D % 34

Impact Energy CV @ Joules -

stress relieved @ 740C / 1Hr

Electrode Dia (mm) 1.6mm 2.0mm 2.5mm 3.2mm 4.0mm 5.0mm 6.0mm

Electrode Length (mm) - - 350 350 350 350 -

min. - - 70 90 120 160 -

Current Range

(Amps) max. - - 110 140 180 220 -

Packaging Information

Kg Per Vac-Pac - - 2 2 2 2 -

Approx. Pieces Per Kg - - 36 17 11 7 -

Storage

Storage and Re-baking It is recommended that the WB range of electrodes are stored in a dry heated store at

a minimum temperature of 18C, and a maximum relative humidity of 60%. To avoid

damage to the coatings no more than 6 cartons should be staked on top of another.

Re-drying

Re-dry @ 350C for 2 hours and then transfer to holding oven and hold @ 100 -

200C, or 50-100C in heated quiver.

Current Conditions AC (OCV70) /DC + and Welding Positions

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- WB56S M.M.A. Welding Electrode for Offshore FabricationsDocument1 pageWB56S M.M.A. Welding Electrode for Offshore FabricationscwiksjNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- WB5525E MMA Welding Electrode Spec SheetDocument1 pageWB5525E MMA Welding Electrode Spec SheetcwiksjNo ratings yet

- All-position stainless steel electrode for difficult weldsDocument1 pageAll-position stainless steel electrode for difficult weldscwiksjNo ratings yet

- WB35S welding electrodeDocument1 pageWB35S welding electrodelathasri78No ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- WB56S M.M.A. welding electrode specificationsDocument1 pageWB56S M.M.A. welding electrode specificationslathasri78No ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- WB88SHR M.M.A. welding electrode propertiesDocument1 pageWB88SHR M.M.A. welding electrode propertieslathasri78No ratings yet

- All-Purpose Welding ElectrodeDocument1 pageAll-Purpose Welding ElectrodecwiksjNo ratings yet

- WB9009E M.M.A. Welding Electrode Product InformationDocument1 pageWB9009E M.M.A. Welding Electrode Product Informationlathasri78No ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78No ratings yet

- Join & Repair High-Carbon Steels with NiCr HLSDocument1 pageJoin & Repair High-Carbon Steels with NiCr HLSwalter091011No ratings yet

- Aisi 304Document2 pagesAisi 304Rohit100% (1)

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- COVERED ELECTRODES FOR MILD STEEL WELDINGDocument1 pageCOVERED ELECTRODES FOR MILD STEEL WELDINGKannan MurugesanNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- OK 67.60 Esab 309LcDocument1 pageOK 67.60 Esab 309LcSadashiva sahooNo ratings yet

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFtiele_barcelosNo ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDocument5 pagesHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızNo ratings yet

- Low alloy electrodes for welding high-strength steels with OK 75.75Document1 pageLow alloy electrodes for welding high-strength steels with OK 75.75corsini999No ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- High corrosion resistant stick electrode for duplex and lean duplex alloysDocument1 pageHigh corrosion resistant stick electrode for duplex and lean duplex alloyscristian popescuNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- Esab 309lmo Ok 67.68Document1 pageEsab 309lmo Ok 67.68Sadashiva sahooNo ratings yet

- E316L-17 Rutile electrode characteristicsDocument1 pageE316L-17 Rutile electrode characteristicsInaamNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- 3310 Aluminum Sheer Beam Load Cell: Vishay Tedea-HuntleighDocument3 pages3310 Aluminum Sheer Beam Load Cell: Vishay Tedea-Huntleighsweet boy play boyNo ratings yet

- ER-410NiMo MIG Wire Data SheetDocument2 pagesER-410NiMo MIG Wire Data SheetAnonymous skBAwexNo ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- α α α α CBH CBV Cbr-V / Cbr-H: AlphaDocument2 pagesα α α α CBH CBV Cbr-V / Cbr-H: AlphaCecep MarfuNo ratings yet

- Primacore MW 71Document2 pagesPrimacore MW 71rjan7peNo ratings yet

- Electrode Booklet F Web 21Document1 pageElectrode Booklet F Web 21satnamNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- ASM Material Data Sheet 304Document2 pagesASM Material Data Sheet 304.xNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageF For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationTolga UZUNERNo ratings yet

- NiCrFe alloy welding electrodeDocument1 pageNiCrFe alloy welding electrodeRoberto_PrrNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Exaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageExaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodessergio jose morales perazaNo ratings yet

- Hardfacing Wood Chipper KnivesDocument1 pageHardfacing Wood Chipper KnivescwiksjNo ratings yet

- N004 - Daiko Strip 625Document1 pageN004 - Daiko Strip 625cwiksjNo ratings yet

- Robo TiPTiG Data Sheet FinalDocument2 pagesRobo TiPTiG Data Sheet FinalcwiksjNo ratings yet

- Daikoflux 940 ESW cladding flux data sheetDocument1 pageDaikoflux 940 ESW cladding flux data sheetcwiksjNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- NiCrFe alloy welding electrodeDocument1 pageNiCrFe alloy welding electrodeRoberto_PrrNo ratings yet

- Carboklad Cr36 Data SheetDocument1 pageCarboklad Cr36 Data SheetcwiksjNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- A Max WearplateDocument1 pageA Max WearplatecwiksjNo ratings yet

- All-position stainless steel electrode for difficult weldsDocument1 pageAll-position stainless steel electrode for difficult weldscwiksjNo ratings yet

- Meeting Minutes Roberts RulesDocument1 pageMeeting Minutes Roberts RulessaeedNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- Superduplex Welding Procedure Specification (WPSDocument4 pagesSuperduplex Welding Procedure Specification (WPSClaudia Mms100% (3)

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- IN150 ProHeat 35 WaterCooled Induction System EnglishDocument4 pagesIN150 ProHeat 35 WaterCooled Induction System EnglishCARLOSNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- M.M.A. welding electrode for Martensitic stainless steelsDocument1 pageM.M.A. welding electrode for Martensitic stainless steelscwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- WB5525E MMA Welding Electrode Spec SheetDocument1 pageWB5525E MMA Welding Electrode Spec SheetcwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- All-Purpose Welding ElectrodeDocument1 pageAll-Purpose Welding ElectrodecwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Design Aeration XilenDocument180 pagesDesign Aeration XilenAlvaro HueteNo ratings yet

- Smart Tig Ac DC 200p LusqtoffDocument34 pagesSmart Tig Ac DC 200p LusqtoffgarvipNo ratings yet

- Surface Preparation Guide PDFDocument13 pagesSurface Preparation Guide PDFait.koufiNo ratings yet

- International Journal of Industrial ErgonomicsDocument8 pagesInternational Journal of Industrial ErgonomicsErick YamamotoNo ratings yet

- Tubo Estructural Castv3Document104 pagesTubo Estructural Castv3Efe KaranciNo ratings yet

- Doublepipe and Multipipe Heat ExchangerDocument21 pagesDoublepipe and Multipipe Heat Exchangerpec21102002No ratings yet

- PVC-U piping systems guideDocument2 pagesPVC-U piping systems guidePrincipal mamceNo ratings yet

- FabricatorDocument4 pagesFabricatorhitanshuNo ratings yet

- 11 Refractory Weld Studs Sunbelt Stud Welding CatalogDocument14 pages11 Refractory Weld Studs Sunbelt Stud Welding CatalogKotenguNo ratings yet

- Welding (Unit Iv)Document19 pagesWelding (Unit Iv)Susheel GuptaNo ratings yet

- Solar Panel CleanerDocument25 pagesSolar Panel CleanerE7011 BHAVYA PRATAP SINGHNo ratings yet

- Carried Out Magnetic Particle Inspection On Nozzle WeldsDocument9 pagesCarried Out Magnetic Particle Inspection On Nozzle WeldssheikbbaNo ratings yet

- AVK Catalog 2015Document48 pagesAVK Catalog 2015G.L. HuyettNo ratings yet

- Offres D'emploi Cadres Employes 20 Septembre 2019Document67 pagesOffres D'emploi Cadres Employes 20 Septembre 2019Stéphanie Océane NadjiNo ratings yet

- Determing Calculation For Repair of Storage TankDocument4 pagesDeterming Calculation For Repair of Storage TankHendra Yudistira100% (2)

- GTAW & TIG Welding Question BankDocument19 pagesGTAW & TIG Welding Question BankRamzi BEN AHMEDNo ratings yet

- Prem Fouress ReportDocument23 pagesPrem Fouress ReportNithish Chandrashekar100% (1)

- What Are Wormholes and How Can They Be PreventedDocument13 pagesWhat Are Wormholes and How Can They Be PreventedElvin MenlibaiNo ratings yet

- Catalog EWM Multimatrix 2014Document116 pagesCatalog EWM Multimatrix 2014Tiberiu FerenczNo ratings yet

- Datasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1Document92 pagesDatasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1szystNo ratings yet

- (PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduDocument4 pages(PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduKumar R100% (1)

- Tig 500 500W Ac DCDocument1 pageTig 500 500W Ac DCmohammed boriyawalaNo ratings yet

- Synopsis of Changes BPVC Sec I Ed2023Document92 pagesSynopsis of Changes BPVC Sec I Ed2023yathi sNo ratings yet

- 2 Aluminium Fusion Welding 2015Document21 pages2 Aluminium Fusion Welding 2015Tuyen Nguyen100% (1)

- Date Vehicle Project Reference Flow Chart History Prepared By: M.AbrilDocument3 pagesDate Vehicle Project Reference Flow Chart History Prepared By: M.AbrilEva SuárezNo ratings yet

- Lecture1 CSE 411Document62 pagesLecture1 CSE 411Sharon NaisoiNo ratings yet

- Hot Work ProcedureDocument6 pagesHot Work ProcedureSCOTTNo ratings yet

- LSS Catalogue enDocument68 pagesLSS Catalogue enArzu AliyevaNo ratings yet

- Auto Body Collision Dam Repr Br. 1 310B Auto Body Repr Br.2 310Q Auto Painter 410N en TS 3Document99 pagesAuto Body Collision Dam Repr Br. 1 310B Auto Body Repr Br.2 310Q Auto Painter 410N en TS 3RevownSadaNo ratings yet

- RO1 Compendium As of June 2013Document60 pagesRO1 Compendium As of June 2013Catherine NieverasNo ratings yet

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- New Paradigms in Environmental Biomonitoring Using PlantsFrom EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNo ratings yet

- Climate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysFrom EverandClimate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysNo ratings yet

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)

- Acting as if Tomorrow Matters: Accelerating the Transition to SustainabilityFrom EverandActing as if Tomorrow Matters: Accelerating the Transition to SustainabilityNo ratings yet