Professional Documents

Culture Documents

YAWATA 7018: Classification Applications Characteristics Approvals

Uploaded by

Denny AgusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

YAWATA 7018: Classification Applications Characteristics Approvals

Uploaded by

Denny AgusCopyright:

Available Formats

YAWATA 7018 For 490 N/mm 2 High Tensile Strength Steel

Classification Approvals

AWS A 5.1 : E7018 ABS, BV, LR

JIS Z 3211 : E4918

Applications

Welding of 490 N/mm2 high tensile strength steels for ships, steel frames, bridges and

pressure vessels.

Characteristics

YAWATA 7018 is an iron powder low hydrogen type electrode containing a large amount of

iron powder in coating flux. Deposited metal gives excellent mechanical properties, crack

resistance and X-ray quality. Weldability is good and high welding efficiency is obtained.

Typical Chemical Composition of Deposited Metal (%)

C Si Mn P S

0.08 0.57 0.92 0.013 0.010

Typical Mechanical Properties of Deposited Metal

Tensile Strength Yield Strength Elongation Charpy 2V-notch

2

N/mm 2 (kgf/mm2 ) N/mm (kgf/mm2 ) % at -29℃ J (kgf.m)

530 (54) 460 (47) 33 110 (11.2)

Sizes & Recommended Current Range (AC or DC +)

Diameter/ Length (mm) 2.6/300 3.2/350 4.0/400 5.0/450

Welding Position Current (A)

F 70~100 100~140 150~200 190~240

V, OH 60~90 80~120 120~160 140~180

Guideline in Usage

1. Use dry electrodes only. Damp electrodes should be re-dried at 300~350℃ for 60

minutes before use.

2. Backstep method should be applied to prevent blowholes and pits at arc starting and arc

length should be kept as short as possible during welding.

3. All water, rust and oil in groove should be completely removed to prevent cracks and

blowholes.

Welding Positions

All positions, except vertical down

You might also like

- CSWIP 3.1 Hand OutDocument175 pagesCSWIP 3.1 Hand Outrony_lesbt100% (2)

- 0468-DSIC20-96P1-0005-001-B1 Padeye Load Test Comments 2020-05-28Document12 pages0468-DSIC20-96P1-0005-001-B1 Padeye Load Test Comments 2020-05-28Denny AgusNo ratings yet

- IACS requirements for materials and welding for gas tankersDocument247 pagesIACS requirements for materials and welding for gas tankersDenny AgusNo ratings yet

- Characterization of METHOCEL Cellulose Ethers by Aqueous SEC With Multiple DetectorsDocument11 pagesCharacterization of METHOCEL Cellulose Ethers by Aqueous SEC With Multiple DetectorsCastoriadisNo ratings yet

- IACS - REC - 20 NDT of Ship Hull Steel StructuresDocument11 pagesIACS - REC - 20 NDT of Ship Hull Steel Structuresalinor_tnNo ratings yet

- ANANYA-PTFE Coatings, Teflon Coating, Halar Coating, Xylan Coating Services, Corrosion Resistant Coatings, Non Stick CoatingDocument40 pagesANANYA-PTFE Coatings, Teflon Coating, Halar Coating, Xylan Coating Services, Corrosion Resistant Coatings, Non Stick CoatingAnanya CoatingsNo ratings yet

- POLYESTER FIBRE Manufacturing ProcessDocument4 pagesPOLYESTER FIBRE Manufacturing Processpraveen917No ratings yet

- Superhydrophobic Surface and ApplicationDocument28 pagesSuperhydrophobic Surface and ApplicationMaterials Research Institute100% (1)

- Hot Melt Adhesives - 2Document8 pagesHot Melt Adhesives - 2QUALITY CONTROL100% (1)

- MODEC Group confidential flange repair documentDocument11 pagesMODEC Group confidential flange repair documentDenny AgusNo ratings yet

- 45 Manufacturing ProcessDocument45 pages45 Manufacturing ProcessOtunba Olakunle Sunday AjayiNo ratings yet

- Colour Subs F CMDocument70 pagesColour Subs F CMLucia OchovaNo ratings yet

- Industrial Training (Tarun Kumar) - Final ReprtDocument46 pagesIndustrial Training (Tarun Kumar) - Final ReprtSaumya GargNo ratings yet

- An Example: These Guidelines Applied To The Safe Automation of A Batch Polymerization ReactorDocument15 pagesAn Example: These Guidelines Applied To The Safe Automation of A Batch Polymerization ReactorIamsNo ratings yet

- PolytetrafluoroethyleneDocument27 pagesPolytetrafluoroethyleneTzuyu Chou100% (1)

- Solar Surface CoatingDocument7 pagesSolar Surface CoatingJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Modul 3.1Document336 pagesModul 3.1Denny AgusNo ratings yet

- PolyetheretherkeytoneDocument4 pagesPolyetheretherkeytoneGriffin BeemillerNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNo ratings yet

- OTE Zinc Plant Expansion by Outotec Direct Leachin PDFDocument12 pagesOTE Zinc Plant Expansion by Outotec Direct Leachin PDFZeus4321No ratings yet

- 9833 8648 01 - Pocket Guide To Tightening TechniqueDocument28 pages9833 8648 01 - Pocket Guide To Tightening TechniqueAnonymous FZs3yBHh7No ratings yet

- Flame Retardant PolyesterDocument14 pagesFlame Retardant PolyesterSENTHIL KUMAR100% (2)

- Nitrophos Fertilizer SpecificationDocument12 pagesNitrophos Fertilizer Specificationfahim khattak100% (1)

- ISO 5807 - 1985 (ENG) - Diagrama de Flujo (R2019)Document29 pagesISO 5807 - 1985 (ENG) - Diagrama de Flujo (R2019)YANET ALCANTARANo ratings yet

- L. A. Utracki (Auth.) - Commercial Polymer Blends-Springer US (1998) - 1Document669 pagesL. A. Utracki (Auth.) - Commercial Polymer Blends-Springer US (1998) - 1Đỗ NgânNo ratings yet

- Vinod Final Polyplex-1Document103 pagesVinod Final Polyplex-1Fan of carry minatiNo ratings yet

- Inakyd 3234 B-X-70Document1 pageInakyd 3234 B-X-70roybombomNo ratings yet

- Polyethylene Terephthalate (Pet) : HistoryDocument3 pagesPolyethylene Terephthalate (Pet) : HistoryMaleha SalimNo ratings yet

- En 1.0.0 BT Aerolock Rotary ValveDocument46 pagesEn 1.0.0 BT Aerolock Rotary ValveJose Marino Perez LazoNo ratings yet

- Eneral-Purpose Injection Moulding Grade: POKETONE Polymer M630ADocument2 pagesEneral-Purpose Injection Moulding Grade: POKETONE Polymer M630AmacNo ratings yet

- Stoving Paint MsdsDocument9 pagesStoving Paint MsdsrajangangarNo ratings yet

- 718 Stangard Egf (NV)Document5 pages718 Stangard Egf (NV)Sandeep gangulyNo ratings yet

- 04 PDFDocument24 pages04 PDFnamNo ratings yet

- Tyre Flap Specification AS35083SEP2016Document5 pagesTyre Flap Specification AS35083SEP2016Purchase and Stores Officer Contract Cell-IINo ratings yet

- Product Guide 2012Document16 pagesProduct Guide 2012Daniele BoscoNo ratings yet

- Impact of Petroleum Jelly on Ageing of Telephone WireDocument6 pagesImpact of Petroleum Jelly on Ageing of Telephone WireNavneet SinghNo ratings yet

- POY Spinning of Polyester - New Technologies To Improve ProductivityDocument8 pagesPOY Spinning of Polyester - New Technologies To Improve ProductivitySteve Jenkins100% (1)

- PellX 20 35 KW Pellet Burner Installation Manual US V1Document51 pagesPellX 20 35 KW Pellet Burner Installation Manual US V1António CruzNo ratings yet

- Polybutadiene Coagents Improve Elastomer Properties for Wire and CableDocument19 pagesPolybutadiene Coagents Improve Elastomer Properties for Wire and CableVivek RainaNo ratings yet

- Internship Report 2019Document78 pagesInternship Report 2019M Hamza Nadeem AnjumNo ratings yet

- Zytel-All in One Extrusion ProcessesDocument10 pagesZytel-All in One Extrusion ProcessesYiğit IlgazNo ratings yet

- Tds Uk 905tx (Urethane Thinner A) v1Document1 pageTds Uk 905tx (Urethane Thinner A) v1HAFIDZ100% (1)

- A 976 - 13 PDFDocument5 pagesA 976 - 13 PDFflpNo ratings yet

- Research Advances in Bonding Agents For Composite PropellantsDocument11 pagesResearch Advances in Bonding Agents For Composite PropellantsspetNo ratings yet

- Encor367 - en o Ucar 367 ArkemaDocument2 pagesEncor367 - en o Ucar 367 ArkemaAlvaro Hernandez VidalNo ratings yet

- Chemical Blowing Agents: Providing Production, Economic and Physical Improvements To A Wide Range of PolymersDocument6 pagesChemical Blowing Agents: Providing Production, Economic and Physical Improvements To A Wide Range of Polymersphillynovita100% (1)

- Seminar ReportDocument19 pagesSeminar Reportvivekr84100% (1)

- Thermal Strap PaperDocument7 pagesThermal Strap PaperSuraj_73No ratings yet

- Bio-Based Composites Made From Agrowaste: Lucas Whale & Suviti ChariDocument38 pagesBio-Based Composites Made From Agrowaste: Lucas Whale & Suviti CharisuvicNo ratings yet

- Installation Instruction For Conventional Castables PDFDocument2 pagesInstallation Instruction For Conventional Castables PDFakv_bhelNo ratings yet

- Metallocene PolypropyleneDocument3 pagesMetallocene PolypropyleneDianne Aicie ArellanoNo ratings yet

- Manufacturing End Uses: Riaz-Ul-Haq 060820-054Document12 pagesManufacturing End Uses: Riaz-Ul-Haq 060820-054Kasra GolbanNo ratings yet

- Reduce Styrene Migration from UP ResinsDocument2 pagesReduce Styrene Migration from UP Resinsgunawan refiadi0% (1)

- Reactol 1717 EDocument1 pageReactol 1717 EbuninaNo ratings yet

- SAN & ABS Polymers GuideDocument9 pagesSAN & ABS Polymers GuideSdkmega HhNo ratings yet

- YUKOL 5613 Polyol Flexible Foam PropertiesDocument2 pagesYUKOL 5613 Polyol Flexible Foam PropertiesCarlos SiuNo ratings yet

- Brake Pads Compendium CompressedDocument230 pagesBrake Pads Compendium CompressedThillai RajanNo ratings yet

- Selecting AdhesivesDocument17 pagesSelecting AdhesivesPubg fansNo ratings yet

- Trelleborg Users Chart 2011Document13 pagesTrelleborg Users Chart 2011hemontoyNo ratings yet

- Proper storage and handling of spandex yarnDocument4 pagesProper storage and handling of spandex yarnKasra Golban100% (1)

- Ethylene Glycol versus Propylene Glycol Heat Transfer PropertiesDocument5 pagesEthylene Glycol versus Propylene Glycol Heat Transfer PropertiesPråveen SågittåŕiúśNo ratings yet

- Derakane 451-400Document5 pagesDerakane 451-400Pecel LeleNo ratings yet

- Natural Ageing of Rubber - RP Brown and T Butler - 2000 - RAPRADocument178 pagesNatural Ageing of Rubber - RP Brown and T Butler - 2000 - RAPRALeonel RochaNo ratings yet

- Api05 Huntsman Construction PaperDocument7 pagesApi05 Huntsman Construction PaperdNo ratings yet

- Formulation of Ash Based Dish Wash Bars and Their Studies On Bacteria Removal EfficiencyDocument8 pagesFormulation of Ash Based Dish Wash Bars and Their Studies On Bacteria Removal EfficiencyabubekerNo ratings yet

- UR W11 Rev7 Apr 2008Document36 pagesUR W11 Rev7 Apr 2008Denny AgusNo ratings yet

- t11 Berger Polyurethane Varnish - 2475Document2 pagest11 Berger Polyurethane Varnish - 2475Denny AgusNo ratings yet

- Hi Pon50 01PolyurethaneTopCoat - TDSDocument4 pagesHi Pon50 01PolyurethaneTopCoat - TDSDenny AgusNo ratings yet

- 510T WebsiteDocument253 pages510T WebsiteJafian VernandkNo ratings yet

- BW FinishOne+Passivator+630 EN 2022 GL 152 PreviewDocument2 pagesBW FinishOne+Passivator+630 EN 2022 GL 152 PreviewDenny AgusNo ratings yet

- Uw 11-MaterialDocument18 pagesUw 11-MaterialDenny AgusNo ratings yet

- REGULAR VERIFICATION REPORT (UT CALIBRATION BLOCKDocument3 pagesREGULAR VERIFICATION REPORT (UT CALIBRATION BLOCKDenny AgusNo ratings yet

- Avesta-Pickling-Gel-122 AU Vers 8 410122Document10 pagesAvesta-Pickling-Gel-122 AU Vers 8 410122Denny AgusNo ratings yet

- SDS (Redox Heavy Duty Cleaner) 2018 R1Document7 pagesSDS (Redox Heavy Duty Cleaner) 2018 R1Denny AgusNo ratings yet

- W28 welding procedure qualification testsDocument13 pagesW28 welding procedure qualification testsDenny AgusNo ratings yet

- NK - P3497 204 01 R0Document1 pageNK - P3497 204 01 R0Denny AgusNo ratings yet

- Action Plan Housekeeping 7009Document3 pagesAction Plan Housekeeping 7009Denny AgusNo ratings yet

- Ansi B16 150Document1 pageAnsi B16 150Anonymous 5odj1IcNo ratings yet

- Table 1 - Database Codes OverviewDocument3 pagesTable 1 - Database Codes OverviewMuthu Srinivasan Muthu SelvamNo ratings yet

- B16.47 Series A Class 150 Weld Neck & Blind Flange DimensionsDocument1 pageB16.47 Series A Class 150 Weld Neck & Blind Flange DimensionsDenny AgusNo ratings yet

- B16.47 Series A Class 150 Weld Neck & Blind Flange DimensionsDocument1 pageB16.47 Series A Class 150 Weld Neck & Blind Flange DimensionsKashif MirzaNo ratings yet

- Vendor GuidelinesDocument5 pagesVendor GuidelinesDenny AgusNo ratings yet

- Table 1 - Database Codes OverviewDocument3 pagesTable 1 - Database Codes OverviewMuthu Srinivasan Muthu SelvamNo ratings yet

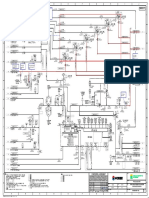

- 0468-MI20-90DP-1561-001 Hydro Test Markup PIDDocument1 page0468-MI20-90DP-1561-001 Hydro Test Markup PIDDenny AgusNo ratings yet

- BP Block 31 - Survey Scope A - Hull Gauging SB82289 Client BP Date 1/22/2020 Revision 0 Project Name Project NumberDocument4 pagesBP Block 31 - Survey Scope A - Hull Gauging SB82289 Client BP Date 1/22/2020 Revision 0 Project Name Project NumberDenny AgusNo ratings yet

- 0468 Asom20 00TQ 0001 001 BDocument14 pages0468 Asom20 00TQ 0001 001 BDenny AgusNo ratings yet

- 01.CV & Dokumen Ahmad Dani EMAIL2Document51 pages01.CV & Dokumen Ahmad Dani EMAIL2Denny AgusNo ratings yet

- 01.CV & Dokumen Ahmad Dani EMAIL2Document51 pages01.CV & Dokumen Ahmad Dani EMAIL2Denny AgusNo ratings yet