Professional Documents

Culture Documents

718 Stangard Egf (NV)

Uploaded by

Sandeep gangulyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

718 Stangard Egf (NV)

Uploaded by

Sandeep gangulyCopyright:

Available Formats

Technology licensed from

718 STANGARD EGF (NV)

Solvent Free Novolac Epoxy For Protecting Metal & Concrete Structures Against Aggressive

Acid’s, Alkalies & Industrial Chemicals Both Direct Spillage & Fumes

For protecting structures, both metallic & concrete, against aggressive industrial acids, alkalies & chemicals, as well as

their primary & secondary containment

Corrosive attack Tortous path

Unique resistance to 98% sulfuric & 33% hydrochloric acids: 180

days immersion - No Film Damage.

Withstands thermal shocks & high temperatures (100C

continuous & 140C intermittent).

High build -180 to 200 microns per coat, applicable on both

horizontal & vertical surfaces.

Resists higher concentrations of acids and solvents, where most

other coatings fail.

718 Stangard EGF NV contains glass and select inert flake reinforcement for dependability in maintaining their overlapping

structure. The flakes within the chemical resistant resin matrix provide an extremely low permeation rate, which greatly reduces

passage of ions through the coating.

Will protect both concrete & steel structures, against acid /alkaline /aggressive chemical fumes, as well as their intermittent

direct spillage.

Proprietary flyash-glass flake technology from IIT Bombay.

Excellent adhesion on both metal & concrete, combined with high tensile strength & very high flexural strength.

Excellent compatibility with RL 500PF, wet & rust tolerant primer, for long term protection of “Hand Prepared” metal

structures, against aggressive acid /alkaline fumes, as well as their intermittent direct contact.

Excellent compatibility with 755 (Dry) & 756 (Damp) concrete surface primers, for long term protection of concrete &

masonary structures, against aggressive acid /alkaline fumes as well as their intermittent direct contact.

STANVAC CHEMICALS (INDIA) LTD.

Corporate Office: 552, Sector-37, Pace City-II, Gurgaon, Haryana – 122001, India

Ph : +91-11-24647252, 24647199, 24638360, 24652337, 24649831 Fax : +91-11-24623826, 24633847

E-mail : sales@stanvac.com Web site : www.stanvac.com

Technology licensed from

Applications: Protecting steel, concrete, masonary structures against aggressive acidic /alkaline media, including 98% sulfuric

acid 33% hydrochloric acid… picking & electro plating metal treatment plants, petro chemical & fertilizer plants, refineries, pulp &

paper mills, waste water treatment plants, food processing plants…

Typical Properties

Property Value As per Specification

Color Grey

Specific Gravity 1.35 ± 0.05 gm/cc (Approx)

Mix Ratio by Weight 5:1

Pot Life @ 25C 25 - 30 min.

Coverage * (average) 0.75 – 0.80 kgs per sq mtr /2 coats /360-400 microns DFT

%NVM 100% ASTM D 2697

Cure Time 18-24 hrs

Cured Hardness (Shore D) >80 ASTM D 2240

Salt Spray test# >5000 hrs ASTM B 117

Abrasion resistance (mg/1000cycles) <50 mg ASTM D 4060

Tensile Strength >5000 psi ASTM D 638

%Elongation >3.0

Flexural strength >11600 psl ASTM D 790

Adhesive pull off strength# (on hand prepared mild steel) >1400 psl ASTM D 4541

Adhesive pull off strength# (on Concrete ) >600 psl (Concrete failure) ASTM D 4541

Recoat Time 6 - 8 hrs

Temperature Resistance (dry & wet) 100 C Under Standard Test Conditions Peak (140OC)

* Taking care of all genuine application wastages, actual working coverage will vary on Job area, Surface porosity, temp. etc.

#With recommended system

Recommended Systems

(A) For metal surfaces – external use (intermittent spillage)

System DFT / No of Coats Average Consumption

1. RL 500 PF primer 90-100 microns DFT /1 coat 0.180 to 0.200 ltr sq mtr

2. 718 EGF (NV) 360-400 microns DFT /2 coats 0.75-0.80 kgs per sq mtr

3. 725 PUTC (UV exposed areas only) 50-60 microns DFT /1 coat 0.180-0.200 kgs per sq mtr

(B) For concrete /masonary surfaces – external use (intermittent spillage)

System DFT / No of Coats Average Consumption

1. 755 (Dry) or 756 (Wet) 80-100 microns DFT /1 coat 0.250 kgs per sq mtr

2. 718 EGF NV 360-400 microns DFT 2 coats 0.75-0.80 kgs per sq mtr

3. 725 PUTC( UV exposed areas only) 50-60 microns /1coat 0.180-0.200 kgs per sq mtr

Imp: consumption datas are indicative – May vary according to surface conditions… May therefore be field verified.

STANVAC CHEMICALS (INDIA) LTD.

Corporate Office: 552, Sector-37, Pace City-II, Gurgaon, Haryana – 122001, India

Ph : +91-11-24647252, 24647199, 24638360, 24652337, 24649831 Fax : +91-11-24623826, 24633847

E-mail : sales@stanvac.com Web site : www.stanvac.com

Technology licensed from

Chemical Resistance

Chemical Fumes Spillage

Tri chloro ethylene Very Good Good

Ammonia Excellent Very Good

Cutting Oil NA Very Good

Gasoline (Unleaded) Excellent Good

Hydrochloric Acid 33% Excellent Very Good

Kerosene Excellent Very Good

Methyl Ethyl Ketone Excellent Good

Methylene Chloride Good Fair

Phosphoric Acid 10% Excellent Very Good

Potassium Hydroxide 20% Excellent Very Good

Sodium Chloride Brine Excellent Very Good

Sodium Hydroxide 10% Excellent Excellent

Sodium Hydroxide 30% Excellent Excellent

Sodium Hypochlorite Excellent Very Good

Sulfuric Acid10% Excellent Excellent

Sulfuric Acid 50% Excellent Excellent

Sulfuric acid 98% Excellent Excellent

Trisodium Phosphate NA Very Good

Xylene Excellent Good

Benzene Very Good Good

Mineral Spirits Excellent Excellent

Nitric Acid 10% Very Good Good

Potassium Hydroxide 30% Excellent Excellent

Toluene Good Good

Immersion Resistance : One Coat of Primer+2 Coats of 718 Stangard EGF (NV)

Chemical 24 hrs 7day’s 30 day’s 90 day’s 180 day’s

Sodium Hydroxide 20% R R R R R

Sulphuric Acid(98%) R RD RD RD RD R= Resistant to prolonged contact

Sulphuric Acid(30%) R R R R R T= Temporarily resistant

Hydrochloric acid(33%) R RD RD RD RD C= Breakdown of coating

Phosphoric acid (30%) R R R R R D= Discolouration of coating

Xylene+IPA(1:1) R R R R R

Nitric Acid (10%) R RD RD C C

Methyl ethyl ketone R R R R R

Methylene chloride A C C C C

Gasoline R R R R R

Diesel R R R R R

Water R R R R R

Ammonia 10% R R R R R

Hydraulic fluids R R R RD RD

(7day cure at 25°C and 50% relative humidity.)

STANVAC CHEMICALS (INDIA) LTD.

Corporate Office: 552, Sector-37, Pace City-II, Gurgaon, Haryana – 122001, India

Ph : +91-11-24647252, 24647199, 24638360, 24652337, 24649831 Fax : +91-11-24623826, 24633847

E-mail : sales@stanvac.com Web site : www.stanvac.com

Technology licensed from

Surface Preparation

1. Metal surfaces external use : ST 2 /ST 3 + RL 500PF Primer or SA 2.5 blasting.

Ensure surfaces are clean & dry

Primer : RL 500 PF /701 HP prime.

2. Metal Surfaces immersion use : SA 3.0 blasting mandatory

Primer :RL 500PF /701 HP prime.

3. Concrete /masonry : Apply only to clean, dry and sound concrete, masonary

substrates that are free of all coatings, sealers, curing

compounds, oils, greases or any other contaminants.

Primer : 755 /756.

New concrete should be cured a minimum of 28 day

Concrete that has been contaminated with chemicals or other foreign matter must be neutralized or removed.

Remove any laitance or weak surface layers.

Ideally concrete should have a minimum surface tensile strength of at least 300 PSI per ASTM D-4541.

Surface profile shall be CSP-3 to CSP-5 meeting ICRI (International Concrete Repair Institute) standard guideline #03732

for coating concrete, producing a profile equal to 60-grit sand paper or coarser. Prepare surface by mechanical means to

achieve this desired profile.

Moisture vapor transmission should be 3 pounds or less per 1,000 square feet over a 24 hour time period, as confirmed

through a calcium chloride test, as per ASTM E-1907. Quantitative relative humidity (RH) testing, ASTM F-2170, should

confirm concrete RH results <75%. Alternatively concrete surface should pass “plastic sheet Test” (ASTM D 4263)

All surface irregularities, cracks, expansion joints and control joints should be properly addressed prior to application.

Please use 750 Stanfloor repair, /762 /766 SL screed, as required for surface levelling.

Outgassing may occur due to the porosity of some concrete surfaces. To reduce the effect of out gassing, the primer and

coating should be applied when the temperature of the concrete substrate is dropping. This usually occurs in the evening;

however, the concrete substrate temperature should be measured with a surface thermometer for verification. Double

priming will greatly reduce the effects of out gassing by additionally filling the pores in the concrete

Mixing Instructions

It is strongly recommended that full units be mixed, or else proper weighing & mixing should be carried out

1. Add part 'B' into part 'A'.

2. Mix thoroughly with screwdriver or similar tool (continuously scrape material away from sides and bottom of container)

until uniform.

3. If required, adjust the consistency of the mixture by adding requisite quantity of Stangard 7000 diluent and mix well.

4. Large batch mixing: Use a propeller-type Jiffy Mixer on an electric drill. Mix until homogenous.

STANVAC CHEMICALS (INDIA) LTD.

Corporate Office: 552, Sector-37, Pace City-II, Gurgaon, Haryana – 122001, India

Ph : +91-11-24647252, 24647199, 24638360, 24652337, 24649831 Fax : +91-11-24623826, 24633847

E-mail : sales@stanvac.com Web site : www.stanvac.com

Technology licensed from

Clean-up - Clean – Up tools & equipment before coating dries & cured with Stangard-1000 diluent. Clean hands and skin

immediately with soap and water, Industrial hand cleaner, or denatured alcohol.

Shelf life – Although the product undergoes no chemical changes even during very long storage, some rise in viscosity and some

settling may occur after storage for more than one year and it would be advisable to conduct a small quantity trial when the

material is to be used after one year from the date of manufacture.

Warranty: M/S Stanvac will replace any material found to be with manufacturing defect. Because the storage, handling and

application of this material is beyond our control, we can accept no liability for the results obtained

Important Notification

The information, and, in particular, the recommendations relating to the application and end-use of STANVAC products, are given

in good faith based on M/s Stanvac current knowledge and experience of the products when properly stored ,handled and applied

under normal conditions.

STANVAC CHEMICALS (INDIA) LTD.

Corporate Office: 552, Sector-37, Pace City-II, Gurgaon, Haryana – 122001, India

Ph : +91-11-24647252, 24647199, 24638360, 24652337, 24649831 Fax : +91-11-24623826, 24633847

E-mail : sales@stanvac.com Web site : www.stanvac.com Revised on: 07/01/2014

You might also like

- Organic Syntheses Collective Volume 5Document1,162 pagesOrganic Syntheses Collective Volume 5caltexas100% (4)

- Conjugate Acid Base Pairs: Name - Chem Worksheet 19-2Document2 pagesConjugate Acid Base Pairs: Name - Chem Worksheet 19-2Taylor Delancey100% (2)

- An AP beginner’s manual: Easy synthesis and safety tips for acetone peroxydeDocument6 pagesAn AP beginner’s manual: Easy synthesis and safety tips for acetone peroxydealahwalakbadNo ratings yet

- Fused and Sintered AluminaDocument7 pagesFused and Sintered AluminaSaragadam DilsriNo ratings yet

- Specification HGRM-30 GRADEDocument1 pageSpecification HGRM-30 GRADESanjayNo ratings yet

- Astm C909Document4 pagesAstm C909deivisbtsNo ratings yet

- Damage of Refractory Bricks Lined in Cement Rotary Kiln: Technical Research Laboratory, Mino Yogyo Co. LTD., JapanDocument10 pagesDamage of Refractory Bricks Lined in Cement Rotary Kiln: Technical Research Laboratory, Mino Yogyo Co. LTD., JapanPham tony1604No ratings yet

- Float Glass RefractoryDocument4 pagesFloat Glass RefractorySans SenNo ratings yet

- How fiber addition affects properties of low cement castablesDocument4 pagesHow fiber addition affects properties of low cement castablesAndrian Hadiana100% (1)

- Cement Plant CorrosionDocument7 pagesCement Plant CorrosionHemlata ChandelNo ratings yet

- 3 Strategies For Reducing Cement KilnDocument14 pages3 Strategies For Reducing Cement Kilnorientanjali7066100% (1)

- Alsiflex®-1260 Blankets - Technical Data Sheet - English PDFDocument2 pagesAlsiflex®-1260 Blankets - Technical Data Sheet - English PDFTanmay GorNo ratings yet

- Calcined ClayDocument4 pagesCalcined ClaynaikNo ratings yet

- Determination of Free Silica in Limestone and Kiln FeedDocument1 pageDetermination of Free Silica in Limestone and Kiln FeedavisgopNo ratings yet

- Casting MethodDocument15 pagesCasting MethodGabriela Maira Sanches VolpiNo ratings yet

- Calcination ProcessDocument82 pagesCalcination ProcessMayur ChhagNo ratings yet

- Effect of Limestone Aggregate Absorption on Concrete Strength and Slump LossDocument4 pagesEffect of Limestone Aggregate Absorption on Concrete Strength and Slump LossAman SahadeoNo ratings yet

- Bricks and Shapes 2Document6 pagesBricks and Shapes 2nay den100% (1)

- The Calcination of Kaolin ClayDocument7 pagesThe Calcination of Kaolin ClaytaghdirimNo ratings yet

- Cement Production Technology PapersDocument0 pagesCement Production Technology PapersBruno Vilas BoasNo ratings yet

- Refractory Mortars Datasheet - JM 2600, Blakite, Blakite V, JM 3300Document2 pagesRefractory Mortars Datasheet - JM 2600, Blakite, Blakite V, JM 3300didapopescuNo ratings yet

- COMPRIT F50G-6 gunning mixDocument2 pagesCOMPRIT F50G-6 gunning mixNic RicNo ratings yet

- Application Procedure ROCKHARD-90Document4 pagesApplication Procedure ROCKHARD-90JCSNo ratings yet

- Furan C - Product Information Sheet PDFDocument2 pagesFuran C - Product Information Sheet PDFAnuradhaPatraNo ratings yet

- Kirloskar Corrocoat GFC CaseStudyDocument35 pagesKirloskar Corrocoat GFC CaseStudyAbhishek SharmaNo ratings yet

- Corrosion in Cement Plants Caused by Acid GasesDocument5 pagesCorrosion in Cement Plants Caused by Acid GasesAnonymous NxpnI6jCNo ratings yet

- Molding Training PresentationDocument30 pagesMolding Training PresentationVinesh RJNo ratings yet

- Awst 11 07Document8 pagesAwst 11 07Herd ImanNo ratings yet

- Dokumen - Tips - Castables and Refractories For Cement Dri Sponge Iron Kiln CoolerDocument8 pagesDokumen - Tips - Castables and Refractories For Cement Dri Sponge Iron Kiln CoolerjulianoducaNo ratings yet

- SSC JE Study Material Building MaterialsDocument10 pagesSSC JE Study Material Building MaterialsMohd aslamNo ratings yet

- How Mixing Affects The Rheology of Refractory Castables - Part IIDocument25 pagesHow Mixing Affects The Rheology of Refractory Castables - Part IIVinh Do ThanhNo ratings yet

- Introducing the KALTEK cold ladle lining system improves casting qualityDocument4 pagesIntroducing the KALTEK cold ladle lining system improves casting qualityMar CarreonNo ratings yet

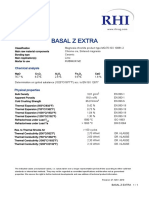

- Basal Z Extra: Chemical AnalysisDocument1 pageBasal Z Extra: Chemical Analysismahreza189No ratings yet

- Ankerfix Rp10 Stahl Flow Control Iso enDocument1 pageAnkerfix Rp10 Stahl Flow Control Iso enthinhbntNo ratings yet

- New Additive Packages For Self-Flowing High-Alumina and MgO Based Refractory CastablesDocument6 pagesNew Additive Packages For Self-Flowing High-Alumina and MgO Based Refractory CastablespetemberNo ratings yet

- Project Report PDFDocument33 pagesProject Report PDFGAUTAM KUMAR BHATTACHARYANo ratings yet

- Fly Ash BricksDocument13 pagesFly Ash BricksPrabhat RaiNo ratings yet

- Tri-ACT® 1820: Safety Data SheetDocument13 pagesTri-ACT® 1820: Safety Data SheetEDUARDONo ratings yet

- 3025 51Document8 pages3025 51rambinodNo ratings yet

- Sulphate Resisting Portland Cement PS 612 1989Document7 pagesSulphate Resisting Portland Cement PS 612 1989ehtisham zaibNo ratings yet

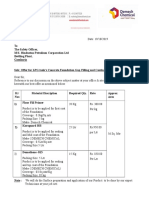

- Offer For HPCLDocument2 pagesOffer For HPCLhello tumNo ratings yet

- SUPRAL - S60 Per Blocchi (Equivalente RESISTAL S60) PDFDocument1 pageSUPRAL - S60 Per Blocchi (Equivalente RESISTAL S60) PDFgiuseppe.timpone1No ratings yet

- Lecture # 04: Chemistry of Cement Manufacturin GDocument89 pagesLecture # 04: Chemistry of Cement Manufacturin Gmurtaza mustafaNo ratings yet

- SAN & ABS Polymers GuideDocument9 pagesSAN & ABS Polymers GuideSdkmega HhNo ratings yet

- Mix Design CalculationDocument8 pagesMix Design CalculationEr Digvijay SinghNo ratings yet

- Failure Analysis of Refractory Anchors of A PowerDocument8 pagesFailure Analysis of Refractory Anchors of A PowerVinh Do ThanhNo ratings yet

- Cements, Chemically Resistant: 1. 2. Types of Cement 2.1. Cements Containing Inorganic BindersDocument8 pagesCements, Chemically Resistant: 1. 2. Types of Cement 2.1. Cements Containing Inorganic BindersjaimeNo ratings yet

- Blast Furnace Slag Weathering StudyDocument8 pagesBlast Furnace Slag Weathering StudyARNALDO BATTAGIN100% (3)

- Rev0 - Repair-Instructions PDFDocument8 pagesRev0 - Repair-Instructions PDFZantar AbdelhaqNo ratings yet

- Rubber Research Institute Testing FeeDocument15 pagesRubber Research Institute Testing FeemoumonaNo ratings yet

- API936 Effective Sheet-2020 PDFDocument2 pagesAPI936 Effective Sheet-2020 PDFmalleshNo ratings yet

- Refractory Lining of Blast Furnace PDFDocument11 pagesRefractory Lining of Blast Furnace PDFceng el samiuNo ratings yet

- Pds Tabcast 94Document1 pagePds Tabcast 94AmitNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, MoDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, Mobaskaran ayyapparajNo ratings yet

- Analysis of Portland CementDocument4 pagesAnalysis of Portland CementDipmalya Basak33% (3)

- Urcast Shac Ev 0 3 CLDocument1 pageUrcast Shac Ev 0 3 CLmahreza189No ratings yet

- Characterization of Silica Fume and Its Effects On Concrete PropertiesDocument49 pagesCharacterization of Silica Fume and Its Effects On Concrete PropertiessultanNo ratings yet

- Free Lime Determination ClinkerDocument2 pagesFree Lime Determination ClinkerfoxmancementNo ratings yet

- PDF ST Nanobond e - 04 2019.en.22Document8 pagesPDF ST Nanobond e - 04 2019.en.22Henry Sunarko100% (1)

- Ash Handling CatalogueDocument8 pagesAsh Handling CatalogueVaijayanti JoshiNo ratings yet

- Handbook of Vinyl FormulatingFrom EverandHandbook of Vinyl FormulatingRichard F GrossmanRating: 3 out of 5 stars3/5 (1)

- LH 104Document1 pageLH 104Sandeep gangulyNo ratings yet

- General Characteristics:: Wearresist Technologies Pvt. LTDDocument1 pageGeneral Characteristics:: Wearresist Technologies Pvt. LTDSandeep gangulyNo ratings yet

- Application of Brushable Ceramic Coating and Superior Metal For Pipe SupportDocument2 pagesApplication of Brushable Ceramic Coating and Superior Metal For Pipe SupportSandeep gangulyNo ratings yet

- LH 106Document1 pageLH 106Sandeep gangulyNo ratings yet

- Hishiko TIG welding electrode for hardfacing applicationsDocument1 pageHishiko TIG welding electrode for hardfacing applicationsSandeep gangulyNo ratings yet

- Koroglass 1000Document3 pagesKoroglass 1000Sandeep gangulyNo ratings yet

- Ral Colour CardDocument2 pagesRal Colour CardSandeep gangulyNo ratings yet

- Diffusaloy 6180Document1 pageDiffusaloy 6180gauravsphNo ratings yet

- Water Treatment Program Manual: 6 Revision, March 2010Document104 pagesWater Treatment Program Manual: 6 Revision, March 2010Sunny OoiNo ratings yet

- Chapter 11Document22 pagesChapter 11Anna AradiNo ratings yet

- Ascorbic Acid PDFDocument7 pagesAscorbic Acid PDFM Ahya KNo ratings yet

- Understanding Acid and Alkaline PropertiesDocument27 pagesUnderstanding Acid and Alkaline PropertiesShahrul HisyamNo ratings yet

- BONDERITE C NE 10466 en - USDocument2 pagesBONDERITE C NE 10466 en - USankarthik11No ratings yet

- Kami Export - Fuels & Alkanes 1 QP PDFDocument11 pagesKami Export - Fuels & Alkanes 1 QP PDFHanaOmarNo ratings yet

- PH DRIFTDocument2 pagesPH DRIFTUtsav DalalNo ratings yet

- Lab ManualDocument16 pagesLab Manualchiranjeev rathoreNo ratings yet

- Dynamic Soil Systems Part ADocument7 pagesDynamic Soil Systems Part AIshwaranSivaNo ratings yet

- Ammonia Destruction in The Reaction Furnace - Optimized Gas TreatingDocument9 pagesAmmonia Destruction in The Reaction Furnace - Optimized Gas TreatingAlejandro PedezertNo ratings yet

- Green Road Trial Sem 3 2022 QuastionDocument8 pagesGreen Road Trial Sem 3 2022 QuastionKeertana SubramaniamNo ratings yet

- Acids Bases Salts Neutralization Reactions (39Document6 pagesAcids Bases Salts Neutralization Reactions (39HONEY YOYONo ratings yet

- 1956-1957 Sodium MetabisulfiteDocument2 pages1956-1957 Sodium MetabisulfiteChibao VoNo ratings yet

- Derivative Analysis of Potentiometric Titration Data To Obtain Protonation ConstantsDocument6 pagesDerivative Analysis of Potentiometric Titration Data To Obtain Protonation ConstantsMaría José CárdenasNo ratings yet

- CHM Flio HAHA FAILDocument26 pagesCHM Flio HAHA FAILLoi Reng TeckNo ratings yet

- Lecture 3 - PhenolDocument34 pagesLecture 3 - PhenolQutaiba IbrahimNo ratings yet

- Acid-Base-Property-If-Water 1Document10 pagesAcid-Base-Property-If-Water 1Robelle Grace M. CulaNo ratings yet

- Salt hydrolysis pH calculationDocument34 pagesSalt hydrolysis pH calculationSalim Sanjaya100% (1)

- Acid - Base BalanceDocument13 pagesAcid - Base Balanceadam yassineNo ratings yet

- Non-aqueous acid-base titration methodsDocument27 pagesNon-aqueous acid-base titration methodsRitwik DasNo ratings yet

- Aspirin and SoapDocument4 pagesAspirin and SoapyeeeyyyNo ratings yet

- Lix® ReagentDocument47 pagesLix® Reagentzaqwsxcde123100% (6)

- Stoichiometry PracticeDocument4 pagesStoichiometry Practicejana gomezNo ratings yet

- P-block elements propertiesDocument21 pagesP-block elements propertiesSaurabh PatilNo ratings yet

- Understanding Entropy and Equilibrium ReactionsDocument62 pagesUnderstanding Entropy and Equilibrium ReactionsYoNo ratings yet

- Chemical Nomenclature Workbook - Guided Memorization PDFDocument47 pagesChemical Nomenclature Workbook - Guided Memorization PDFViviana MărgăritNo ratings yet

- Buffer and Buffer Capacity Activity ExplainedDocument2 pagesBuffer and Buffer Capacity Activity ExplainedValenzuela Allene GraceNo ratings yet