Professional Documents

Culture Documents

Boehler CN 13 4-MC - SW

Uploaded by

Sebastian AcostaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boehler CN 13 4-MC - SW

Uploaded by

Sebastian AcostaCopyright:

Available Formats

BÖHLER CN 13/4-MC

Metal cored wire, high alloyed, stainless

Classifications

EN ISO 17633-A EN ISO 17633-B AWS A5.9 AWS A5.22

T 13 4 M M12 2 TS 410NiMo-M M12 1 EC410NiMo (mod.) EC410NiMo (mod.)

Characteristics and typical fields of application

Metal cored wire for the fabrication and repair welding of hydro turbine components made of soft

martensitic 13 % Cr 4 % Ni alloyed steels and cast steels. BÖHLER CN 13/4-MC offers favourable

spray arc or pulsarc characteristics, minimum spatter formation, flat and smooth bead profiles,

excellent wetting behaviour and safe penetration. It is easy to operate in all welding positions.

Additionally, precise alloy adjustment ensure very good impact test results of the heat treated weld

metal. The hydrogen content is extra low (maximum 4 ml/100 g acc. to AWS conditions). Significant

gains in productivity can be realized by higher deposition rates and reduced post weld grinding

when compared to GMAW using solid wires.

Base materials

1.4317 GX4CrNi13-4, 1.4313 X3CrNiMo13-4, 1.4407 GX5CrNiMo13-4, 1.4414 GX4CrNiMo13-4

ACI Grade CA 6 NM

Typical analysis of all-weld metal (wt.-%)

C Si Mn Cr Ni Mo

wt.-% ≤ 0.025 0.7 0.9 12.0 4.6 0.6

Mechanical properties of all-weld metal

Condition Yield strength Tensile strength Elongation Impact work

R p0,2 Rm A (L 0 =5d 0 ) ISO-V KV J

MPa MPa % +20 °C –20 °C

a 760 (≥ 500) 900 (≥ 760) 16 (≥ 15) 65 60 (≥ 47)

a1 730 860 17 68 62 (≥ 47)

a annealed, 600°C / 2 h / furnace to 300 °C / air – shielding gas Argon + 2.5 % CO 2

a1 annealed, 580°C / 8 h / furnace to 300 °C / air – shielding gas Argon + 2.5 % CO 2

Operating data

Polarity: Shielding gases: ø (mm) Amps A Voltage V

DC ( + ) Argon + 2.5 % CO 2 1.2 130 – 370 16 – 38

1.6 250 – 550 22 – 40

Welding with conventional or pulsed power sources (preferably slightly trailing torch position,

angel appr. 80°). Recommended stick out 18 – 20 mm and length of arc 3 – 5 mm. Recommended

preheating and interpass temperatures in case of heavy wall thicknesses are 100 – 160 °C.

Maximum heat input 15 kJ / cm. Tempering at 580 – 620 °C.

Approvals

SEPROZ

All information provided is based upon careful investigation and intensive research. 03/2014

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- B - Boehler CN 25 9 CuT IG - TRDocument1 pageB - Boehler CN 25 9 CuT IG - TRalbertorebellatoNo ratings yet

- B Boehler CM 5-IG de en 5Document1 pageB Boehler CM 5-IG de en 5PT. CATUR MATRA NusantaraNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- B - Boehler FOX CM 9 KB - Se - en - 5Document1 pageB - Boehler FOX CM 9 KB - Se - en - 5misthahNo ratings yet

- 409Document2 pages409satish04No ratings yet

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- B - Boehler DMO-IG - Ss - en - 5 PDFDocument1 pageB - Boehler DMO-IG - Ss - en - 5 PDFDimitris NikouNo ratings yet

- MIP Bohler Welding Austria 364Document1 pageMIP Bohler Welding Austria 364c131508No ratings yet

- LINCOLN Nicromo 60-16Document2 pagesLINCOLN Nicromo 60-16AbdülHak ÖZkaraNo ratings yet

- B Boehler X 70-IG de en 5Document1 pageB Boehler X 70-IG de en 5Jorge RushNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- Boehler EAS 4 M-IG - Tig RodDocument1 pageBoehler EAS 4 M-IG - Tig RodbrayanNo ratings yet

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- Duplex UNS 32205Document1 pageDuplex UNS 32205Ercan YilmazNo ratings yet

- L1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1Document1 pageL1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1cristian popescuNo ratings yet

- Böhler Nibas 625 PW-FD: DescriptionDocument1 pageBöhler Nibas 625 PW-FD: DescriptionBBalopesabbNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- Carbofil 3nimocr Oerlikon en TN130181Document1 pageCarbofil 3nimocr Oerlikon en TN130181rusf123No ratings yet

- Carbo 4370 Mpr-E307Document1 pageCarbo 4370 Mpr-E307ali torabiNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- 29102015000000B - Boehler CN 22 9 N-IG - TRDocument1 page29102015000000B - Boehler CN 22 9 N-IG - TRAnibal QuezadaNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- Datasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1Document3 pagesDatasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1szystNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- Product Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- Rod - Union I Crmo 910Document1 pageRod - Union I Crmo 910Rushita SolankiNo ratings yet

- Consumables For E911 Crmo Steel: En/Din AstmDocument3 pagesConsumables For E911 Crmo Steel: En/Din Astmmohamed AdelNo ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- Sandvik 254 Smo Tube and Pipe, Seamless: DatasheetDocument9 pagesSandvik 254 Smo Tube and Pipe, Seamless: DatasheetReadersmoNo ratings yet

- Cromarod Duplex B-1Document1 pageCromarod Duplex B-1Matija BušićNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- 1 Selectarc b90 FT Web AnglaisDocument1 page1 Selectarc b90 FT Web AnglaisfoxmancementNo ratings yet

- 02112015000000B - Boehler FOX EV 65 - CeDocument1 page02112015000000B - Boehler FOX EV 65 - CeMohamed AdelNo ratings yet

- Daiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireDocument1 pageDaiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireRhyan EdwinNo ratings yet

- Böhler CM 5-Ig: TIG Rod, High-Alloyed, Creep ResistantDocument1 pageBöhler CM 5-Ig: TIG Rod, High-Alloyed, Creep Resistantwesley59No ratings yet

- Avesta Tig 316-SiDocument1 pageAvesta Tig 316-SiMarco Andres Gonzalez SaavedraNo ratings yet

- Categorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBDocument1 pageCategorie GMAW-GTAW Massieve Draad Type Applications: C MN Si CR Ni Mo NBabhishekNo ratings yet

- Bohler S Eas 4 M-Ig: GTAW Rod, High-Alloyed, Chemical ResistantDocument1 pageBohler S Eas 4 M-Ig: GTAW Rod, High-Alloyed, Chemical Resistantjacob thangamNo ratings yet

- Boehler HL 75 T-MCDocument1 pageBoehler HL 75 T-MCBruno SantosNo ratings yet

- Boehler SKWAM-IG de en 5Document2 pagesBoehler SKWAM-IG de en 5Ivica MikolajNo ratings yet

- Ceweld - 316h TigDocument1 pageCeweld - 316h TigFilipe CordeiroNo ratings yet

- Ceweld - 316H TigDocument1 pageCeweld - 316H TigFilipe CordeiroNo ratings yet

- Diamondspark 54 MC: Seamless Cored WireDocument2 pagesDiamondspark 54 MC: Seamless Cored WireDavid RodriguesNo ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- Datasheet Sandvik 199l enDocument3 pagesDatasheet Sandvik 199l enpedro rojasNo ratings yet

- Duplex MetrodeDocument6 pagesDuplex Metrodeandresrojas25No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Composicion Quimica Gtd111: Mater. Process. Technol., Vol. 175, No. 1, Pp. 376-381, 2006Document2 pagesComposicion Quimica Gtd111: Mater. Process. Technol., Vol. 175, No. 1, Pp. 376-381, 2006Sebastian AcostaNo ratings yet

- W01-V03 Change View OptionsDocument107 pagesW01-V03 Change View Optionspritish chadhaNo ratings yet

- 3.1 Rating Plate: GAP 3501 DC and GAP 3501 DC USA: IdentificationDocument6 pages3.1 Rating Plate: GAP 3501 DC and GAP 3501 DC USA: IdentificationSebastian AcostaNo ratings yet

- Freeletics Rutina 15 SemanasDocument4 pagesFreeletics Rutina 15 SemanasSebastian AcostaNo ratings yet

- PDFDocument169 pagesPDFSebastian AcostaNo ratings yet

- Yellow Submarine (The Beatles) Imagine (John Lenon)Document2 pagesYellow Submarine (The Beatles) Imagine (John Lenon)Sebastian AcostaNo ratings yet

- Iq An DesignDocument395 pagesIq An DesignLê Trường LâmNo ratings yet

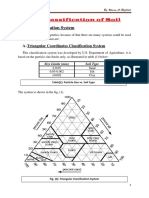

- 4 Classification of SoilDocument8 pages4 Classification of SoilPRAJWAL srNo ratings yet

- Waves Energy Part 2Document22 pagesWaves Energy Part 2api-271661638No ratings yet

- BN-20 Master Guide R3Document112 pagesBN-20 Master Guide R3Serge MaciaNo ratings yet

- Final Project Modified New (A Project Report On Customer Relaionship Managment With Reference To HyundaiDocument46 pagesFinal Project Modified New (A Project Report On Customer Relaionship Managment With Reference To Hyundairaghu100% (1)

- Steel DOS 1Document107 pagesSteel DOS 1MazharYasinNo ratings yet

- PB 579Document403 pagesPB 579Pilaf1No ratings yet

- m44 Complete PDFDocument9 pagesm44 Complete PDFGovardhan ReghuramNo ratings yet

- 6 - Curtain Fire Damper CatalogueDocument24 pages6 - Curtain Fire Damper CatalogueFloizel Anne Cruz - VictorinoNo ratings yet

- S12R Pta PDFDocument48 pagesS12R Pta PDFAbebe kebede75% (4)

- Verizon Wireless 4G LTE Mobile Hotspot MiFi 4510L ManualDocument88 pagesVerizon Wireless 4G LTE Mobile Hotspot MiFi 4510L ManualTravisNo ratings yet

- MVHRDocument4 pagesMVHRtexas_peteNo ratings yet

- BPP of Goods Receipt MIS-MMMDocument9 pagesBPP of Goods Receipt MIS-MMMmeddebyounesNo ratings yet

- EF132 BEE Lecture 2 & 3Document49 pagesEF132 BEE Lecture 2 & 3Anonymous gdLjDzNo ratings yet

- Proposal Report For CentrifugeDocument3 pagesProposal Report For CentrifugeDinesh KatochNo ratings yet

- 7250S Spec 1Document11 pages7250S Spec 1stephen prosserNo ratings yet

- Operation & Maintenance Manual: Vertical Shaft Impact CrusherDocument56 pagesOperation & Maintenance Manual: Vertical Shaft Impact CrusherSergeyNo ratings yet

- Conduit Fill RequirementsDocument3 pagesConduit Fill RequirementsManicontrolNo ratings yet

- Autronica Smoke DetectorDocument2 pagesAutronica Smoke DetectorbhavadasNo ratings yet

- Nle Mock 1 - PMC OfficialDocument205 pagesNle Mock 1 - PMC OfficialTauseef AfridiNo ratings yet

- OHR Bauma 2019 Press ReleaseDocument2 pagesOHR Bauma 2019 Press ReleaseM B RajpurohitNo ratings yet

- 2016 Kitchen ManualDocument93 pages2016 Kitchen ManualAdnan Ul HaqNo ratings yet

- 18 Seam IvDocument509 pages18 Seam IvFroilan Espinosa80% (5)

- Burnside ParkDocument8 pagesBurnside ParkAhmadinijadNo ratings yet

- Preprosthetic Surgery in The ElderlyDocument8 pagesPreprosthetic Surgery in The ElderlybkprosthoNo ratings yet

- Entry-Level QA TesterDocument3 pagesEntry-Level QA TesterNicasio AquinoNo ratings yet

- Smart Grid: Thin Film Solar CellsDocument5 pagesSmart Grid: Thin Film Solar CellsSHREYA SHARMA IET Lucknow StudentNo ratings yet

- Database Web Services Using Oracle9i JdeveloperDocument4 pagesDatabase Web Services Using Oracle9i Jdevelopertranhieu5959No ratings yet

- OWX50 Spec Sheet 1.3Document2 pagesOWX50 Spec Sheet 1.3simon.lctoddNo ratings yet

- Design of Engineering Materials: Stress-Strain DiagramDocument32 pagesDesign of Engineering Materials: Stress-Strain DiagramTRNADEWNo ratings yet