Professional Documents

Culture Documents

Böhler Eas 2 PW-FD

Uploaded by

HAKANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Böhler Eas 2 PW-FD

Uploaded by

HAKANCopyright:

Available Formats

BÖHLER EAS 2 PW-FD

Flux cored wire, high-alloyed, stainless

Classifications

EN ISO 17633-A EN ISO 17633-B AWS A5.22

T 19 9 L P M21 1 TS308L-F M21 (C1) 1 E308LT1-4

T 19 9 L P C1 1 E308LT1-1

Characteristics and typical fields of application

Rutile strip alloyed flux cored welding wire with fast freezing slag providing excellent positional

operating characteristics and fast travel speeds. It is easy to use and operates with a powerful

penetrating spray arc transfer, minimum spatter formation and self releasing slag.

This flux cored welding wire offers many economical and quality advantages over solid wire pulse

arc welding. High deposition rates and productivity gains are easily achievable. Additional cost

effective benefits are offered through use of less expensive shielding gases (Argon + 15 – 25 %

CO 2 or 100 % CO 2 ), good wetting characteristics (less grinding), little temper discoloration & bead

oxidation (less pickling expenses), easy operation and safe penetration (reduces the risk of weld

defects and associated repair work costs), and smooth and clean weld finish (less post weld work).

Due to its characteristics mainly for positional welding and service temperatures between –196 °C

to- +350 °C. For down hand & horizontal welding positions (1G, 1F, 2F) our flux cored wire

BÖHLER EAS 2-FD should be preferred.

Base materials

1.4306 X2CrNi19-11, 1.4301 X5CrNi18-10, 1.4311 X2CrNiN18-10, 1.4312 GX10CrNi18-8,

1.4541 X6CrNiTi18-10, 1.4546 X5CrNiNb18-10, 1.4550 X6CrNiNb18-10

AISI 304, 304L, 304LN, 302, 321, 347; ASTM A157 Gr. C9, A320 Gr. B8C or D

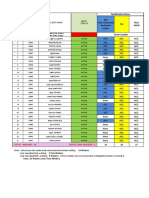

Typical analysis of all-weld metal (wt.-%)

C Si Mn Cr Ni

wt.-% 0.03 0.7 1.5 19.8 10.5

Mechanical properties of all-weld metal

Condition Yield strength Tensile strength Elongation Impact work

R p0,2 Rm A (L 0 =5d 0 ) ISO-V KV J

MPa MPa % +20 °C –196 °C

u 380 (≥ 320) 560 (≥ 520) 40 (≥ 35) 70 40 (≥ 32)

u untreated, as welded – shielding gas Ar + 18 % CO 2

Operating data

Polarity: Shielding gases: Redrying: ø (mm) Amps A Voltage V

DC ( + ) Argon + possible 1.2 100 – 220 20 – 31

15 – 25 % CO 2 150 °C / 24 h 1.6 175 – 260 21 – 29

100 % CO 2

Welding with standard GMAW-facilities possible, slightly trailing torch position (angel appr. 80°), slight

weaving is recommended for positional welding; when using 100 % CO 2 as shielding gas it is necessary to

increase the voltage by 2 V; the gas flow should be 15 – 18 l/min

Approvals

TÜV (09117.), DB (43.014.23), CWB (E308LT1-1(4)), GL (4550S (C1,M21)), SEPROZ, CE

All information provided is based upon careful investigation and intensive research. 03/2014

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Bohler Ti 52Document1 pageBohler Ti 52Anonymous nKOyHbNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Böhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileDocument1 pageBöhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileRaviTeja BhamidiNo ratings yet

- UNION ER90S-B3 TIG rodDocument1 pageUNION ER90S-B3 TIG rodbrayanNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- B_Boehler-CN-25-9-CuT-IG_trDocument1 pageB_Boehler-CN-25-9-CuT-IG_tralbertorebellatoNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Boehler EAS 4 M-IG - Tig RodDocument1 pageBoehler EAS 4 M-IG - Tig RodbrayanNo ratings yet

- Boehler HL 75 T-MCDocument1 pageBoehler HL 75 T-MCBruno SantosNo ratings yet

- B - Boehler EMK 6 - de - en - 5 PDFDocument1 pageB - Boehler EMK 6 - de - en - 5 PDFburakNo ratings yet

- Böhler Er 70 S-2Document1 pageBöhler Er 70 S-2brayanNo ratings yet

- E316L-17 Rutile electrode characteristicsDocument1 pageE316L-17 Rutile electrode characteristicsInaamNo ratings yet

- Classifications: For Atmospheric Corrosion Resisting SteelDocument1 pageClassifications: For Atmospheric Corrosion Resisting Steelhuynh thanh truongNo ratings yet

- High corrosion resistant stick electrode for duplex and lean duplex alloysDocument1 pageHigh corrosion resistant stick electrode for duplex and lean duplex alloyscristian popescuNo ratings yet

- Böhler SG 2: Solid Wire, UnalloyedDocument1 pageBöhler SG 2: Solid Wire, Unalloyedrombi aritonangNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- CHT81 Ni 1Document1 pageCHT81 Ni 1ImmalatulhusnaNo ratings yet

- Avesta Tig 316-SiDocument1 pageAvesta Tig 316-SiMarco Andres Gonzalez SaavedraNo ratings yet

- EMK 6 - DatasheetDocument1 pageEMK 6 - Datasheetronaldb322No ratings yet

- 29102015000000B - Boehler CN 22 9 N-IG - TRDocument1 page29102015000000B - Boehler CN 22 9 N-IG - TRAnibal QuezadaNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014HoangNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014Yousab CreatorNo ratings yet

- Copper-Coated Solid Wire for Universal Welding ApplicationsDocument1 pageCopper-Coated Solid Wire for Universal Welding ApplicationsInaamNo ratings yet

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- Product Data Sheet for OK AristoRod 12.50Document2 pagesProduct Data Sheet for OK AristoRod 12.50João GuilhermeNo ratings yet

- High-alloyed TIG rod for heat resistant steelsDocument1 pageHigh-alloyed TIG rod for heat resistant steelsSerhii MishchenkoNo ratings yet

- L1 8581 en Diamondspark 44 BC CU03100F 3379759 ENDocument1 pageL1 8581 en Diamondspark 44 BC CU03100F 3379759 ENRaviTeja BhamidiNo ratings yet

- Technical data sheet for rutile flux cored welding wireDocument1 pageTechnical data sheet for rutile flux cored welding wireawNo ratings yet

- DATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Document2 pagesDATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Dries VandezandeNo ratings yet

- MIP Bohler Welding Austria 63Document1 pageMIP Bohler Welding Austria 63thod3rNo ratings yet

- 2 Fcaw-AllDocument51 pages2 Fcaw-AllAhmad ShaheenNo ratings yet

- B Boehler X 70-IG de en 5Document1 pageB Boehler X 70-IG de en 5Jorge RushNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)Document1 pageClassifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)felipeNo ratings yet

- Sandvik 19.9.L Welding Wire DatasheetDocument3 pagesSandvik 19.9.L Welding Wire Datasheetpedro rojasNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- 02112015000000B_Boehler FOX EASN 25 M_ceDocument1 page02112015000000B_Boehler FOX EASN 25 M_ceABNo ratings yet

- Manual Metal-Arc Welding Product Data SheetDocument2 pagesManual Metal-Arc Welding Product Data SheetC7 TGNo ratings yet

- B Boehler Ti 80 T-FD Fde en 5Document1 pageB Boehler Ti 80 T-FD Fde en 5Valentin Hernández TrianoNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- Böhler NiCu1 Ti T-FD wire for corrosion resistant steel weldingDocument1 pageBöhler NiCu1 Ti T-FD wire for corrosion resistant steel weldingbrayanNo ratings yet

- Standards Approvals & Certificates: Rmrs Ce DNV-GL LR Classnk Tuv BV Abs Rina TL DBDocument2 pagesStandards Approvals & Certificates: Rmrs Ce DNV-GL LR Classnk Tuv BV Abs Rina TL DBKhaled GamalNo ratings yet

- High-alloyed GTAW rod for welding duplex steelsDocument1 pageHigh-alloyed GTAW rod for welding duplex steelsErcan YilmazNo ratings yet

- Böhler CM 5-IG solid wire for high-temperature steel weldingDocument1 pageBöhler CM 5-IG solid wire for high-temperature steel weldingPT. CATUR MATRA NusantaraNo ratings yet

- B - Boehler DMO-IG - Ss - en - 5 PDFDocument1 pageB - Boehler DMO-IG - Ss - en - 5 PDFDimitris NikouNo ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- Filcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- Kms-308Lsi: Gmaw Solid Wire For Stainless SteelDocument1 pageKms-308Lsi: Gmaw Solid Wire For Stainless SteelStefanoTampieriNo ratings yet

- MIP Bohler Welding Austria 62Document1 pageMIP Bohler Welding Austria 62Pradeepta MohantyNo ratings yet

- Shield - Bright 2209 FCAW (!)Document2 pagesShield - Bright 2209 FCAW (!)rajNo ratings yet

- CV TemplateDocument4 pagesCV TemplateHAKANNo ratings yet

- CV Template-01Document4 pagesCV Template-01HAKANNo ratings yet

- Pde-Cvc-0970-Ec-00001 - 000 - 00 - Tehnical Descriprion - Road DesignDocument19 pagesPde-Cvc-0970-Ec-00001 - 000 - 00 - Tehnical Descriprion - Road DesignHAKANNo ratings yet

- Road Schedule Concept.v2Document1 pageRoad Schedule Concept.v2HAKANNo ratings yet

- Road Construction-DME - QC - CIVIL - RMA - 0001 - Approved AC2Document30 pagesRoad Construction-DME - QC - CIVIL - RMA - 0001 - Approved AC2HAKANNo ratings yet

- HIL0480 (EFOR) - Mesh Sertifikası PDFDocument2 pagesHIL0480 (EFOR) - Mesh Sertifikası PDFHAKANNo ratings yet

- CPR 520 Doroport Alesd Rev 2020 En-RevDocument1 pageCPR 520 Doroport Alesd Rev 2020 En-RevHAKANNo ratings yet

- MoM TemplateDocument2 pagesMoM TemplateHAKANNo ratings yet

- rs0021 RMX OradeaDocument3 pagesrs0021 RMX OradeaHAKANNo ratings yet

- 49 Dop Doroport TB 25 Ae v3 Feb 21 En-RevDocument1 page49 Dop Doroport TB 25 Ae v3 Feb 21 En-RevHAKANNo ratings yet

- Road Works - ChecklistDocument3 pagesRoad Works - ChecklistHAKAN100% (1)

- Map of Roads 5-7Document1 pageMap of Roads 5-7HAKANNo ratings yet

- EF-2019-012-5671D005-000 Rev06 - As-Built PDFDocument1 pageEF-2019-012-5671D005-000 Rev06 - As-Built PDFHAKANNo ratings yet

- 16.11.2021 - Method Statement - Road WorksDocument17 pages16.11.2021 - Method Statement - Road WorksHAKANNo ratings yet

- CU-0845 - Survey of Platforms LevelDocument4 pagesCU-0845 - Survey of Platforms LevelHAKANNo ratings yet

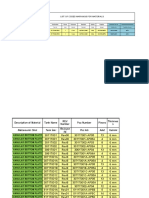

- NO Welder Id Welder Name: Team LeaderDocument1 pageNO Welder Id Welder Name: Team LeaderHAKANNo ratings yet

- Detecting Harmful Phases in Duplex SteelDocument9 pagesDetecting Harmful Phases in Duplex SteelutreshwarmiskinNo ratings yet

- List of Coded Markings For Materials (Eksik sertifikaANNULAR-BOTTOM-RING) - 8.09.2020Document17 pagesList of Coded Markings For Materials (Eksik sertifikaANNULAR-BOTTOM-RING) - 8.09.2020HAKANNo ratings yet

- Insulation (ROOF) Insulation (SHELL) : R L) D H)Document6 pagesInsulation (ROOF) Insulation (SHELL) : R L) D H)HAKANNo ratings yet

- Polyol ProjectDocument1 pagePolyol ProjectHAKANNo ratings yet

- Rti Brochure Process Manual - Na - en PDFDocument189 pagesRti Brochure Process Manual - Na - en PDFHAKANNo ratings yet

- İş Programı Montaj Planlaması-Rev01Document1 pageİş Programı Montaj Planlaması-Rev01HAKANNo ratings yet

- WPS & PQRDocument84 pagesWPS & PQRjoseph.maquez24100% (4)

- RFIDocument1 pageRFIHAKANNo ratings yet

- Api Ast Subcommittee: Impact: Minimal 620 Appendix X-Duplex Stainless Steel Storage Tanks X.1 ScopeDocument14 pagesApi Ast Subcommittee: Impact: Minimal 620 Appendix X-Duplex Stainless Steel Storage Tanks X.1 ScopeHAKANNo ratings yet

- 8 WeldingofduplexstainlesssteelsDocument39 pages8 WeldingofduplexstainlesssteelsHAKANNo ratings yet

- RFIDocument1 pageRFIHAKANNo ratings yet

- Approximate RT Calculation For API 650 TankDocument2 pagesApproximate RT Calculation For API 650 Tankjayaarnav100% (6)

- POLYOLWELDGAS 01rev 02Document1 pagePOLYOLWELDGAS 01rev 02HAKANNo ratings yet

- Pre Int Sample Unit PDFDocument12 pagesPre Int Sample Unit PDFHAKANNo ratings yet

- Heap Leaching With OxygenDocument6 pagesHeap Leaching With OxygenArief RHNo ratings yet

- Bock PDFDocument147 pagesBock PDFjuliaNo ratings yet

- Environmental EngineeringDocument5 pagesEnvironmental EngineeringOktrian SinathryaNo ratings yet

- Difference Between - Hogging - Sagging, Pipe - Tubes, IBR - Non IBR Boiler, Cold End - Hot End Corrosion - ASKPOWERPLANTDocument16 pagesDifference Between - Hogging - Sagging, Pipe - Tubes, IBR - Non IBR Boiler, Cold End - Hot End Corrosion - ASKPOWERPLANTRaju MaityNo ratings yet

- Waterproofing 2022Document8 pagesWaterproofing 2022VR RajNo ratings yet

- Sample Paper-01 Chemistry (Theory) Class – XIDocument4 pagesSample Paper-01 Chemistry (Theory) Class – XISarthakNo ratings yet

- Activated Charcoal Adsorption of Acetic AcidDocument9 pagesActivated Charcoal Adsorption of Acetic AcidNkugwa Mark William67% (3)

- Wang 2006 J. Electrochem. Soc. 153 C357Document9 pagesWang 2006 J. Electrochem. Soc. 153 C357Santiago EdingerNo ratings yet

- To Do List (Msa)Document17 pagesTo Do List (Msa)Muhammad Umer RanaNo ratings yet

- Cambridge IGCSE: Chemistry 0620/21Document16 pagesCambridge IGCSE: Chemistry 0620/21Mina AbdouNo ratings yet

- Verde de Malaquita - Sigma Aldrich-115942-EnDocument2 pagesVerde de Malaquita - Sigma Aldrich-115942-EnDiegoNo ratings yet

- AMMONIA PROCESS SIMULATIONDocument8 pagesAMMONIA PROCESS SIMULATIONChecoCastilloNo ratings yet

- Asme Section Viii Div.1Document87 pagesAsme Section Viii Div.1balu100% (7)

- Dumas Method LabDocument5 pagesDumas Method LabJohn JosephNo ratings yet

- Riverside Dilemma (Extra Credit)Document7 pagesRiverside Dilemma (Extra Credit)Odaro Osayimwen0% (2)

- Honeycomb Kevlar 49 (Hexcel)Document3 pagesHoneycomb Kevlar 49 (Hexcel)Julia GarciaNo ratings yet

- Gas Reticulation Project Group 8Document13 pagesGas Reticulation Project Group 8Mohd Hafiz50% (2)

- Restriction Mapping GuideDocument4 pagesRestriction Mapping GuideWency Joy ObreroNo ratings yet

- Affect of Cooking On Quality of PulsesDocument14 pagesAffect of Cooking On Quality of PulsesBotany Department100% (1)

- Environmental Pollution Upsc Notes 90 PDFDocument6 pagesEnvironmental Pollution Upsc Notes 90 PDFSumit ChauhanNo ratings yet

- Hydrobromic Acid (48% Solution in Water) : General & Use: Flammability and ExplosivityDocument2 pagesHydrobromic Acid (48% Solution in Water) : General & Use: Flammability and ExplosivityGustavo SoaresNo ratings yet

- Final Thermodynamics Project ReportDocument18 pagesFinal Thermodynamics Project ReportAnil YarlagaddaNo ratings yet

- ASTM D36D36M Standart Test Method For Softening Point of Bitumen (Ring and Ball Apparatus)Document5 pagesASTM D36D36M Standart Test Method For Softening Point of Bitumen (Ring and Ball Apparatus)Yeison GarciaNo ratings yet

- Welding Defect PhotoDocument14 pagesWelding Defect Photo0502raviNo ratings yet

- Effect of The Use of Ceramic Filters in Steel CastingDocument6 pagesEffect of The Use of Ceramic Filters in Steel CastingJavier Escalante VillanuevaNo ratings yet

- SULIT Marking SchemeDocument11 pagesSULIT Marking SchemeZaiton RoslanNo ratings yet

- Solar Oven Challenge ReportDocument7 pagesSolar Oven Challenge Reportapi-311233754No ratings yet

- ExperimentalDocument5 pagesExperimentalbabuNo ratings yet

- Measuring Active Ingredients in Aspirin with TitrationDocument14 pagesMeasuring Active Ingredients in Aspirin with TitrationAnonno DipNo ratings yet

- PowerSafe VM - Range SummaryDocument2 pagesPowerSafe VM - Range Summarydwi krisnaNo ratings yet