Professional Documents

Culture Documents

Final Seminar Report

Uploaded by

HarishCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Seminar Report

Uploaded by

HarishCopyright:

Available Formats

FARMBOT

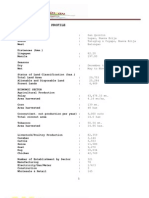

CONTENTS

1. ABSTRACT …………………………………………………2

2. INTRODUCTION ……………………………………………3

3. OBJECTIVES ………………………………………………..4

4. HISTORY ……………………………………………………5

5. FARMBOT GENESIS ……………………………………….6

a) TOOLS ……………………………………………...8

b) SOFTWARE ………………………………………...9

SOFTWARE CHALLAGES ………………11

c) HARDWARE………………………………………..12

6. FUTURE WORK …………………………………………….14

7. CONCLUSION ……………………………………………….15

8. REFERENCES ……………………………………………….16

Dept. of Mech. Engg., BITM, BALLARI Page 1

FARMBOT

ABSTRACT

The world’s population is growing and with that growth we must produce more

food. Due to the industrial and petrochemical revolutions, the agriculture industry has

kept up in food production, but only by compromising the soil, the environment, our

health, and the food production system itself. The increased production has largely come

from incremental changes in technology and economies of scale, but that trend is reaching

a plateau. Conventional agriculture methods are unsustainable and a paradigm shift is

needed.

Dept. of Mech. Engg., BITM, BALLARI Page 2

FARMBOT

INTRODUCTION

Agricultural automation using Farmbot is an attempt to reduce the burden

of maintaining a farm for small scale and large scale alike by automating the most

commonly performed tasks such as sowing of seeds, watering of plants and finally even

removing weeds or collecting root vegetables. In addition to all of the above the

architecture of Farmbot is modular i.e. there is a pick and place arm which is free to move

in circular and vertical direction, mounting this arm on a moving platform gives this

system freedom of movement along 3-axis.

Automation is the technique, method or system of operating or controlling a process by

highly automatic means, as by electronics devices, reducing human intervention to a

minimum.

Modular architecture refers to the design of any system composed of separate components

that can be connected together. The beauty of modular architecture is that you can replace

or add any one component (module) without affecting the rest of the system.

The area of digital electronics and intelligent systems, automation using robot has become

one of the fastest developing application-based technologies in the world. The

incorporation of the mobile communication technologies into the automation systems,

now allows the users to use mobile application on their phone to control their farms

(taken as example) from distance.

Dept. of Mech. Engg., BITM, BALLARI Page 3

FARMBOT

OBJECTIVES

The main objective of the system is to design and implement a scale model of a

cheap and open source agriculture automation system that conforms to principles of

Autonomous Robot Architectures (AuRa) mainly concentrating on modular structure,

centralized control. This system also proves as a base on which much more complex

systems might be designed.

The system uses Bluetooth for communication in this model for debugging purposes but

in real-time implementation this can be replaced by mobile GSM networks that require no

special modification on network infrastructure, or even no need for network infrastructure

at all. Here, Android mobile phone which acts as the server that bridges user and the

appliances the user wishes to control. This suitable for personal farming but in case of

large scale this can be easily replaced by a program for windows giving much more data

processing capabilities to the organization for further research and development. The

Android application is to be written in Java and the Android Development Kit SDK can

be used to rapid prototype a basic GUI that provides a convenient user interface to control

the system.

Dept. of Mech. Engg., BITM, BALLARI Page 4

FARMBOT

HISTORY

The FarmBot project was started in 2011 when Rory Aronson whilst studying

mechanical engineering at California Polytechnic State University.

Aronson attended and elective course in organic agriculture where he learned

about a tractor that used machine vision to detect and cover weeds which

removed the need for herbicides or manual labour , the tractor cost over $1

million USD.

In September 2013 Aronson published a white paper outlining the goals of the

project to "Grow a community that produces free and open-source hardware

plans, software, data, and documentation enabling everyone to build and

operate a farming machine."

The project is a response to the 60% increase food production needed due to

the growth in world population to between 7 - 9 billion by 2050 and the

potential of precision agriculture to reduce the environmental impacts of

farming by reducing water use, energy, transportation, petrochemicals and

time required to grow crops.

In March 2014 Aronson began working on the project full-time funded by a

grant from the Shuttle worth Foundation. Firmware developer Tim Evers and

software developer Rick Carlino later joined the project as core developers

and the open source community Farmbot.cc was created to support the

development of the project.

In March 2014 Rory Aronson created the company Farmbot.io to provide

hardware kits and software services and to serve as a funding source to

maintain the open source community. In 2014 and 2015 FarmBot was entered

into the Hackaday Prize where it became a finalist in 2015. Farmbot.io began

preorders of the first commercially available version of FarmBot, the FarmBot

Genesis, and the ninth iteration of the design in July 2016.

Dept. of Mech. Engg., BITM, BALLARI Page 5

FARMBOT

FARMBOT GENESIS

Capabilities

The FarmBot Genesis is able to plant over 30 different crops including potatoes,

peas, squash, artichokes and chard in an area of 2.9 meters × 1.4 meters with a

maximum plant height of 0.5 meters.

It can cultivate a variety of crops within same area at the same time and is able to

operate indoors, outdoors and covered areas.

It is estimated that the FarmBot Genesis produces 25% fewer carbon dioxide

emissions than standard US food production

FarmBot Genesis V0.9 CAD rendering.

FarmBot Genesis V0.7 prototype working outside

Dept. of Mech. Engg., BITM, BALLARI Page 6

FARMBOT

The Farmbot Genesis can perform almost all processes prior to harvesting

including sowing, mechanical weed control and watering.

It requires electricity, an internet connection and water supply which be provided

using off grid solutions including a water barrel to collect rain and a solar panel

and battery to provide electricity.

The FarmBot Genesis is able to gather data to take into account factors such as

age of the plant and local weather conditions from both local sensors and external

data from the internet.

FarmBot prototype watering for the first time

Dept. of Mech. Engg., BITM, BALLARI Page 7

FARMBOT

TOOLS

The FarmBot Genesis performs different tasks through automatically attaching

different tools to a universal tool mount, including a seed injector, a watering

nozzle and a tool to bury weeds.

The machine is able to weed the planted area using the weed suppressor using a

camera to identify weeds by comparing all plants in the area to the locations of

the planted seeds.

Dept. of Mech. Engg., BITM, BALLARI Page 8

FARMBOT

Software

The software for the FarmBot Genesis runs through a web interface allowing the

machine to be controlled on most internet enabled devices. The web app has the ability to

adjust different inputs including water, fertilizer and pesticide, seed spacing and

environmental factors including soil and weather conditions based on sensor readings,

location, and time of year. It is also able to build and schedule sequences by combining

and altering basic operations. The software is also able to manipulate data maps, real-time

logging and access an open plant data in the Open Farm database. All software is

available under the MIT license and is available on GitHub.

FarmBots are controlled and configured by a web application that is accessible from a

web browser on any device from any location.

FarmBot Genesis Web App on different devices.

Dept. of Mech. Engg., BITM, BALLARI Page 9

FARMBOT

FarmBot Genesis Farm Designer V7.

Dept. of Mech. Engg., BITM, BALLARI Page 10

FARMBOT

Software Challenges for the Farmbot Extensions

The design of the functional extensions aforementioned requires specific efforts from the

software engineering research community to address the underlying challenges. In this

section, we describe three of these main research challenges.

Designing resource aware software:

The design of a resource aware software requires an approach where the software will

adapt its functional and non-functional behavior dynamically according to the available

re-sources. The general problem for software engineering is therefore the automatic

optimization of resource usage for a software which requires seamless combination of

proactive and reactive adaptation of the software behavior. In the particular case of the

Farmbot system, we propose to investigate a smart resources manager that will schedule

tasks consuming these resources (network access, energy and water) based on both the

actual stocks and prevision of production. Leveraging the Farmbot access to weather

forecast and its embedded sensors, the embedded software will become aware of the

available resources and the prediction of resource productions. Taking into account a

specific model that will be built by monitoring its normal activity, the system will be able

to build a model of resource production and consumption to optimize the resource usage.

Designing domain specific optimization:

Optimizing food production and vegetable growing is not part of the expertise of a

computer scientist. Nevertheless, the software in charge of automating and optimizing the

Farmbot operations has to leverage this knowledge to both assist the user decision making

when choosing the seeds layout, and when automating the plant watering. The general

problem relates to the use of heterogeneous models and their combination in order to

optimize the operations of a software system which controls physical mechanisms (such

as Cyber Physical Systems, or Internet of Things devices). A particular instantiation of

this problem on the Farmbot system would be to leverage knowledge about multi crop

system, weather forecast, biomass growing and so on to optimize the layout of seeds and

their mutual benefit to optimize the food production.

Complex event detection through multi sensors stream analysis:

The automatic detection of mal-functions or disease is a very complex and challenging

task since it requires to crosscheck and match data coming from different sensors such as

humidity, images, and other chemical soil characteristics. Furthermore, the instantaneous

value of these sensors may not be sufficient to detect malfunctioning. The study of their

evolution over time will give significantly better results on such detection. The general

challenge for software engineering is therefore related to the ability to perform complex

relations and correlations between values produced by various sensors at different

locations and their evolution overtime. In the specific case of the Farmbot system, it

means correlating values from the evolution of the soil characteristics at various

locations, and image analysis to detect the size, holes in leafs and so on.

Dept. of Mech. Engg., BITM, BALLARI Page 11

FARMBOT

Hardware

The Farmbot Genesis is an open source hardware machine and is

designed around reproduce-ability and availability of components, it can be

created using common tools and processes meaning it is not reliant on a

single supplier.

The machine uses linear guides in the X, Y, and Z axis including the gantry

and custom flat connecting plates that can be fabricated with a number of

tools including water jet cutter, plasma cutter, laser cutter, CNC mill or

manually with a hacksaw and drill press .The FarmBot Genesis uses a belt

and pulley system including NEMA 17 stepper motors with rotary encoders,

GT2 belts and Open Builds v slot extrusions and wheels. Stainless

steel screws, t-nuts, washers, bearings, driveshaft and lead screw make the

machine weather and corrosion-resistant allowing long term operation in

outdoor environments.

Open Builds v slot wheels connecting plates, NEMA 17 stepper motor and

bolts which assemble to make the cross slide.

Farmbot is held together using 5mm aluminum plates.

Dept. of Mech. Engg., BITM, BALLARI Page 12

FARMBOT

Figure: A Farmbot prototype

Dept. of Mech. Engg., BITM, BALLARI Page 13

FARMBOT

FUTURE WORK

There is still much future scope for improving and upgrading the machine.

1. Multi-robot automated farming is yet to be implemented.

2. The passive modules need to be replaced by active modules and this can only happen

when power supply interface is designed from the place robotic interface.

3. Sensors have to be implemented to make the system more accurate.

4. The data obtained from the first generation systems have to undergo Machine Learning

to create truly intelligent systems and make them more efficient.

5. Newer modules must be designed that makes the system suitable for variety of farms.

6. Open-source frame work has to be written and successfully standardized to lead to

wide scale adoption of such modular systems.

7. Need an increase in technical know-how to operate the system.

Dept. of Mech. Engg., BITM, BALLARI Page 14

FARMBOT

CONCLUSION

The Farmbot system is a very interesting connected object which has a societal impact

through a paradigm shift for local food production. It also has many interests from a research

perspective in the software engineering community since it represents a fantastic experimental

case study for various open research problems in modern heterogeneous and distributed software

which interact directly with our physical environment.

In particular we draw in this paper several possible extensions of the Farmbot that raise

software engineering challenges, such as the design and integration of different domain-specie

languages, the composition of various kinds of models, and the computation of complex relations

and correlations from such a set of models.

Dept. of Mech. Engg., BITM, BALLARI Page 15

FARMBOT

REFERENCES

1. "Out in the Open: This FarmBot Makes Growing Food as Easy as Playing Farmville".

Retrieved 2016-08-01.

2. Jump up to:a b c d e f "FarmBot DIY agriculture robot promises to usher in the future of

farming". Retrieved 2016-08-01.

3. Jump up to:a b c d e f g h i j k l m "Details • FarmBot - Open-Source CNC Farming •

Hackaday.io". hackaday.io. Retrieved 2016-08-03.

4. Jump up to:a b c d e f g h i j "The FarmBot Genesis Brings Precision Agriculture to Your

Own Backyard". Retrieved 2016-08-02.

5. Jump up to:a b c d e "FarmBot Founder Aronson on Open Source Tech and Encouraging

Consumers to Farm - AgFunderNews". 2016-05-11. Retrieved 2016-08-02.

6. Jump up to:a b c d e says, Brian Despain (2016-06-02). "FarmBot is the world's first open

source CNC farming machine". Atmel Bits & Pieces. Retrieved 2016-08-02.

7. "The 2015 Hackaday Prize • Hackaday.io". hackaday.io. Retrieved 2016-08-23.

8. Jump up to:a b "FarmBot Genesis seeds, waters, and fertilizes your garden with life-giving

precision". Retrieved 2016-08-02.

9. Jump up to:a b "Old MacDonald Had A FarmBot, I/O, I/O, I/O". CleanTechnica.

Retrieved 2016-08-02.

10. Jump up to:a b c d e "Arduino Blog – FarmBot is an open-source CNC farming machine".

Retrieved 2016-08-02.

11. Carman, Ashley. "I bet Mesopotamian farmers didn't see FarmBot coming".

Retrieved 2016-08-02.

12. Jump up to:a b "FarmBot the Open Source Farming CNC Robot". Open Electronics.

Retrieved 2016-08-02.

13. "FarmBot Will 3D Print Your Crops and Email You When It Harvests Them".

Retrieved 2016-08-02.

Dept. of Mech. Engg., BITM, BALLARI Page 16

You might also like

- Farmbot SynopsisDocument10 pagesFarmbot SynopsisTanvi Khurana100% (2)

- Format For SRS Report - Part 2Document37 pagesFormat For SRS Report - Part 2Urvisha Parmar67% (15)

- Municipal Profile of Umingan, PangasinanDocument51 pagesMunicipal Profile of Umingan, PangasinanGina Lee Mingrajal Santos100% (1)

- Design and Fabrication of Smart Seed Sowing Robot: Materials Today: Proceedings August 2020Document6 pagesDesign and Fabrication of Smart Seed Sowing Robot: Materials Today: Proceedings August 2020Akmal HazimNo ratings yet

- Projects On Smart Agri-Food Systems: European CommissionDocument28 pagesProjects On Smart Agri-Food Systems: European Commissionhoussem rebouhNo ratings yet

- ResearchDocument7 pagesResearchMacoyNo ratings yet

- Robotics (Word)Document7 pagesRobotics (Word)MacoyNo ratings yet

- Ijcrt 194459 2Document7 pagesIjcrt 194459 2Ali HashmiNo ratings yet

- Solar Grass Cutter and Pesticides Spray RobotDocument23 pagesSolar Grass Cutter and Pesticides Spray RobotAkshay bypNo ratings yet

- Robotics(Word) - CopyDocument9 pagesRobotics(Word) - CopyMacoyNo ratings yet

- Agricultural Robot For Automatic Ploughing and SeedingDocument7 pagesAgricultural Robot For Automatic Ploughing and SeedingMadhusudhan N MNo ratings yet

- Robots Transform AgricultureDocument10 pagesRobots Transform AgricultureAbdurrahmanNo ratings yet

- Mechatronics Based Remote Controlled Agricultural RobotDocument11 pagesMechatronics Based Remote Controlled Agricultural RobotWARSE JournalsNo ratings yet

- Agriengineering 01 00029 v2 PDFDocument12 pagesAgriengineering 01 00029 v2 PDFAnshuman TagoreNo ratings yet

- Applying Technologies of Robotics in FarmingDocument8 pagesApplying Technologies of Robotics in FarmingjackNo ratings yet

- Applsci 12 04335 v2Document13 pagesApplsci 12 04335 v2Syed Muhammad AlamNo ratings yet

- IoT Based Precision Agriculture Using AgribotDocument4 pagesIoT Based Precision Agriculture Using AgribotGRD JournalsNo ratings yet

- Android-powered agricultural robot automates seeding & plowingDocument11 pagesAndroid-powered agricultural robot automates seeding & plowingVijaylakshmiNo ratings yet

- A Review: Autonomous Agribot For Smart Farming: Ashish Lalwani, Mrunmai Bhide, S. K. ShahDocument4 pagesA Review: Autonomous Agribot For Smart Farming: Ashish Lalwani, Mrunmai Bhide, S. K. ShahSona BhatNo ratings yet

- I. Current Automation Related To Agriculture: A. Autonomous and Robotic LabourDocument3 pagesI. Current Automation Related To Agriculture: A. Autonomous and Robotic LabourHaseel BuenavistaNo ratings yet

- Agricultural Robotics Is The Logical Proliferation of Automation Technology Into Bio Systems Such As AgricultureDocument3 pagesAgricultural Robotics Is The Logical Proliferation of Automation Technology Into Bio Systems Such As AgricultureAnonymous utfuIcnNo ratings yet

- 373-Текст статті-562-1-10-20200517Document7 pages373-Текст статті-562-1-10-20200517keyloggerfree45No ratings yet

- IEEEDocument5 pagesIEEEKavipriyaNo ratings yet

- Automatic Multipurpose Agribot Using Arduino Mega and GPS Module ReceiverDocument9 pagesAutomatic Multipurpose Agribot Using Arduino Mega and GPS Module ReceiverInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review On Multipurpose Agriculture RobotDocument8 pagesReview On Multipurpose Agriculture RobotIJRASETPublicationsNo ratings yet

- Paper 69-Design and Development of Autonomous Pesticide SprayerDocument7 pagesPaper 69-Design and Development of Autonomous Pesticide SprayerMoez MizouNo ratings yet

- Solar Powered Seed Sowing and Fertilizer Spraying Robot With Wireless ControlDocument4 pagesSolar Powered Seed Sowing and Fertilizer Spraying Robot With Wireless ControlNavneet singhNo ratings yet

- Multipurpose Autonomous Agricultural Robot017Document4 pagesMultipurpose Autonomous Agricultural Robot017Noureldin SharabyNo ratings yet

- Low Cost Agribot For Precision Farming Focused Spraying On Agri-LandDocument5 pagesLow Cost Agribot For Precision Farming Focused Spraying On Agri-LandInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 1.1 Overview: A.I.T.M Varanasi 1Document40 pages1.1 Overview: A.I.T.M Varanasi 1Aamir AmeenNo ratings yet

- FINAL YEAR PROJECT PROPOSAL (Review)Document15 pagesFINAL YEAR PROJECT PROPOSAL (Review)MusTaFa QuReShiNo ratings yet

- 08 - Laboratory in Computer LabDocument7 pages08 - Laboratory in Computer LabGabriel Michael AblayNo ratings yet

- Plant leaf disease and agri bot systemDocument26 pagesPlant leaf disease and agri bot systemDreamer JayaNo ratings yet

- FY ResearchPaperDocument11 pagesFY ResearchPapergopika bmNo ratings yet

- Autonomous Solar Powered Mini Excavator Robot For Agricultural PlantingDocument9 pagesAutonomous Solar Powered Mini Excavator Robot For Agricultural PlantingRonna Mae AmayaNo ratings yet

- Mate AssDocument12 pagesMate AssTolosa TafeseNo ratings yet

- Design and Fabrication of A Multipurpose Agriculture RobotDocument10 pagesDesign and Fabrication of A Multipurpose Agriculture RobotIJRASETPublicationsNo ratings yet

- Solar Powered Multifunctional Agricultural Robot: International Research Journal of Engineering and Technology (IRJET)Document4 pagesSolar Powered Multifunctional Agricultural Robot: International Research Journal of Engineering and Technology (IRJET)Chetangouda PatilNo ratings yet

- Drone For Precision Agriculture Using IoTDocument5 pagesDrone For Precision Agriculture Using IoTRudresh RakeshNo ratings yet

- SynopsisDocument7 pagesSynopsisSachin joshiNo ratings yet

- Finished Essay Farmtrx 1Document6 pagesFinished Essay Farmtrx 1api-542121636No ratings yet

- Base Paper - RequiredDocument7 pagesBase Paper - RequiredteekamNo ratings yet

- Application of Robotics for Advancement in Agriculture using IoTDocument9 pagesApplication of Robotics for Advancement in Agriculture using IoTAruna ParekhNo ratings yet

- Robotic Vehicle For Seed Planting and Weeding ApplicationsDocument4 pagesRobotic Vehicle For Seed Planting and Weeding ApplicationsIJIRSTNo ratings yet

- About: Figure 1: Google Earth Image of Greenhouses Figure 2: Inside A Greenhouse FarmDocument2 pagesAbout: Figure 1: Google Earth Image of Greenhouses Figure 2: Inside A Greenhouse FarmazanNo ratings yet

- Design And) Abrication of A Solar Powered2021Document8 pagesDesign And) Abrication of A Solar Powered2021Noureldin SharabyNo ratings yet

- PSG College of Technology Robotic Applications & FunctionsDocument14 pagesPSG College of Technology Robotic Applications & Functionsharita sakkaravarthiNo ratings yet

- Agri Digging and Seeding RobotDocument9 pagesAgri Digging and Seeding RobotMectrosoft Creative technologyNo ratings yet

- Assignment On Robotics &automation Assignment: Submitted byDocument4 pagesAssignment On Robotics &automation Assignment: Submitted byHrishikesh PradhanNo ratings yet

- Smartphone Operated Multifunctional Farming VehicleDocument6 pagesSmartphone Operated Multifunctional Farming VehicleVIVA-TECH IJRINo ratings yet

- On Gis ApplicationDocument11 pagesOn Gis Applicationraj kumarNo ratings yet

- Agricultural RobotsDocument3 pagesAgricultural RobotsVictor OuruNo ratings yet

- Mobibush A Cloud Enabled Mobile App For FarmersDocument2 pagesMobibush A Cloud Enabled Mobile App For FarmersEditor IJRITCCNo ratings yet

- AI Boosts Agricultural ProductivityDocument12 pagesAI Boosts Agricultural ProductivityRass SeyoumNo ratings yet

- A Technical Seminar Report 443Document31 pagesA Technical Seminar Report 443Gayathri YaddalaNo ratings yet

- Format For SRS Report Part 2 PDFDocument37 pagesFormat For SRS Report Part 2 PDFmohitNo ratings yet

- Modelling of AGRO-BOTDocument3 pagesModelling of AGRO-BOTInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Autonomous Pesticide Sprayer Robot: Abstract-The Management of Pest Insects Is The CriticalDocument7 pagesAutonomous Pesticide Sprayer Robot: Abstract-The Management of Pest Insects Is The CriticalPranay SudhanNo ratings yet

- Smart Forming PDFDocument16 pagesSmart Forming PDFsonam singhNo ratings yet

- Guide on Digital Agricultural Extension and Advisory Services: Use of Smartphone Applications by Smallholder FarmersFrom EverandGuide on Digital Agricultural Extension and Advisory Services: Use of Smartphone Applications by Smallholder FarmersNo ratings yet

- Written Report Maneco FinalDocument31 pagesWritten Report Maneco FinalKymicah DesiertoNo ratings yet

- 144-WARA AD 2.1 To AD 2.24 AIRAC AIP AMDT 125 26 JAN 23Document9 pages144-WARA AD 2.1 To AD 2.24 AIRAC AIP AMDT 125 26 JAN 23latsar kusumoNo ratings yet

- Wiz107sr User Manual en v1.0Document29 pagesWiz107sr User Manual en v1.0Pauli Correa ArriagadaNo ratings yet

- ACFCS Certification BrochureDocument7 pagesACFCS Certification Brochurebeena pandeyNo ratings yet

- NOC Hardware Management SO.P. Derricks FormattedDocument3 pagesNOC Hardware Management SO.P. Derricks Formattedapi-27532183No ratings yet

- Police Report Hearing RightsDocument7 pagesPolice Report Hearing RightsYatn BangadNo ratings yet

- Director Infrastructure Technology Data Center in Atlanta GA Resume Thiron BarrDocument4 pagesDirector Infrastructure Technology Data Center in Atlanta GA Resume Thiron BarrThironBarrNo ratings yet

- High-Energy Fuels For Cruise MissilesDocument4 pagesHigh-Energy Fuels For Cruise Missilesgrindormh53No ratings yet

- Nursing Grand Rounds Reviewer PDFDocument17 pagesNursing Grand Rounds Reviewer PDFAlyssa Jade GolezNo ratings yet

- Research On HIBADocument9 pagesResearch On HIBAPixel GeekNo ratings yet

- Dhaka Epz Factory List & List of Inspected Factories by EIMS For AllianceDocument12 pagesDhaka Epz Factory List & List of Inspected Factories by EIMS For Alliancearman chowdhury100% (4)

- Nitro - Quiz 3 Ged102-A13Document3 pagesNitro - Quiz 3 Ged102-A13Eliezer NitroNo ratings yet

- Unit 8 Grammar Short Test 1 A+B Impulse 2Document1 pageUnit 8 Grammar Short Test 1 A+B Impulse 2karpiarzagnieszka1No ratings yet

- Global CityDocument3 pagesGlobal Citycr lamigoNo ratings yet

- Modern History Notes (Sample Notes For JPSC Mains Exam)Document21 pagesModern History Notes (Sample Notes For JPSC Mains Exam)Ijhar AhmadNo ratings yet

- The Stolen EaglesDocument12 pagesThe Stolen EaglesJavier Horacio FernandezNo ratings yet

- Tle 6 Ict Q4 M9Document16 pagesTle 6 Ict Q4 M9Christ Khayzee R. BacalsoNo ratings yet

- What Is A Human Resources Strategy?Document8 pagesWhat Is A Human Resources Strategy?abdallah abdNo ratings yet

- 20 5880100Document2 pages20 5880100'Theodora GeorgianaNo ratings yet

- Hedonomics: Bridging Decision Research With Happiness ResearchDocument20 pagesHedonomics: Bridging Decision Research With Happiness ResearchgumelarNo ratings yet

- TABS 6SellSheetDocument4 pagesTABS 6SellSheetHernando MontenegroNo ratings yet

- GATE Previous Year Solved Papers CSDocument152 pagesGATE Previous Year Solved Papers CSNagaraja Rao100% (1)

- Normalization Castuera BSCS2CDocument8 pagesNormalization Castuera BSCS2CRichard, Jr. CastueraNo ratings yet

- The King's Avatar - A Compilatio - Butterfly BlueDocument8,647 pagesThe King's Avatar - A Compilatio - Butterfly BlueDarka gamesNo ratings yet

- Shrimp Aquaculture in Sarangani BayDocument5 pagesShrimp Aquaculture in Sarangani BayronanvillagonzaloNo ratings yet

- Cylinder PDFDocument22 pagesCylinder PDFhossein soltanipourNo ratings yet

- Improved Line Maze Solving Algorithm For PDFDocument2 pagesImproved Line Maze Solving Algorithm For PDFRaja Joko MusridhoNo ratings yet

- Binders For: Architectural CoatingsDocument8 pagesBinders For: Architectural CoatingsAPEX SON100% (1)

- IT144052 Bauhn Wifi Extender Manual PDFDocument56 pagesIT144052 Bauhn Wifi Extender Manual PDFEdmark AldeaNo ratings yet