Professional Documents

Culture Documents

Force and Position Control of An Hydraulic Press PDF

Force and Position Control of An Hydraulic Press PDF

Uploaded by

Daniel Felipe Verano CastilloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Force and Position Control of An Hydraulic Press PDF

Force and Position Control of An Hydraulic Press PDF

Uploaded by

Daniel Felipe Verano CastilloCopyright:

Available Formats

KRMILJENJE HIDRAVLIČNE STISKALNICE

Force and position control of a

hydraulic press

Željko ŠITUM

Abstract: The article reports on the design and control of a 50-kN hydraulic press that was made for educational

purposes as well as for an experimental verification of control algorithms. The press contains a servo-solenoid

pressure-control valve for regulating the pressure in the cylinder chamber and thus the force of the hydraulic

press. The press is equipped with a pressure sensor installed in the cylinder chamber for indirectly measuring the

pressing force. On the press it is also possible to measure the position of the upper plate by using a micro-pulse

linear transducer, which creates a precondition for the realization of a hybrid force/position-control algorithm.

The control algorithms and monitoring process are implemented on a real-time hardware board. They are pro-

grammed in the Matlab/Simulink program using the Real-Time Workshop tool for generating the C code and

building an executive program. The article also shows an industrial solution for hydraulic press control using a

programmable logic controller (PLC) as a control device. Based on the experimental results, it can be concluded

that electrically actuated control components supported by the appropriate computer programs make it possi-

ble to improve the characteristics of the hydraulic systems required in modern industrial plants.

Keywords: hydraulic press, force and position control, servo valve

1 Introduction [1]. Normally, due to its complexity, On the other hand, hydraulic presses

almost every advanced controller are generally slower than mechani-

Modern industry is looking for flex- must be implemented on a digital cal presses [2]; however, this disad-

ible solutions that will be able to computer. Such control systems that vantage is being overcome with the

provide some new characteristics of have electrically actuated valves can development of new valves with

hydraulic systems, such as the abil- respond to the complex demands higher flow capacities, smaller re-

ity of controlled motion, the possi- posed by today’s technology. sponse times and improved control

bility for continuous control of the capabilities. In these kinds of appli-

required values, simple data transfer Presses are one of the most com- cations, the ability of force-control

and signal processing, the possibility monly used machine tools in in- systems to follow-up varying refer-

of monitoring and process visualiza- dustry for the forming of different ence signals is often required for the

tion, etc. The rapid developments in materials. In the past, for the press- proper operation of the technologi-

microelectronics in recent years have ing tasks in industry, mechanical cal process. In addition, the task of

reduced the cost of computer equip- presses were more frequently used, the position control of the hydrau-

ment to a level acceptable for indus- but nowadays hydraulic presses take lic actuator is also very important.

trial applications, which has enabled precedence due to their numerous Therefore, a new quality and signifi-

the implementation of sophisticated advantages, such as: cant improvement in the functioning

control strategies in practice. There- - full force through the stroke, of the press can be obtained with a

fore, modern hydraulic systems have - moving parts that operate with simultaneous realization of position

evolved towards electronics and good lubrication, feedback, which is actually a hybrid

microprocessor-controlled electro- - force that can be programmed, control algorithm [3-5]. The hybrid

hydraulic components in order to - stroke that can be fully adjustable, force/position controller structure

achieve new control possibilities which contributes to the flexibility allows independent gains to be used

of application, for both the position and the force-

- safety features that can be pro- control task, allowing the different

Associate Professor, Ph.D Želj- grammed and incorporated into dynamics of each to be adjusted.

ko Šitum, University of Zagreb, the control algorithms, This paper describes the construc-

Faculty of Mechanical Enginee- - can be made for very large force tion of a hydraulic press and the im-

ring and Naval Architecture capacities. plementation of a control algorithm

314 Ventil 17 /2011/ 4

KRMILJENJE HIDRAVLIČNE STISKALNICE

for its force and position control. The the coefficients Kq and Kc represent controllers. The outputs from the

article also provides an example of the flow gain and the flow-pressure force and position controllers are

hydraulic press control using a pro- coefficient, respectively. summed, giving a control signal that

grammable logic controller (PLC) as is sent to the servo valve to satisfy

a control device, which could be ap- There are three effects that con- both the force and position refer-

plied in practice. tribute to the required flow rate ence commands.

QL, which are contributions due to

2 Modelling and control the volume change, QV, due to the Using block-diagram rules, the over-

compression of the oil in the piston all transfer functions of the process

The mathematical model of the hy- chamber, Qc, and due to the leakage are obtained as follows [6]:

draulic system is obtained, first, from around the piston Q1. It is assumed

the model of the hydraulic valve dy- that these effects are additive, so we

namics, then by applying the flow may use this consideration to write

continuity through the orifice, then the following expression:

by analyzing the pressure behaviour

in the cylinder chambers, and, finally,

by applying Newton’s second law to

the actuator motion. In this appli- (3) (5)

cation a pressure-control valve was where xp is the position of the actua-

chosen because the emphasis is on tor, Ap is the average cross-sectional

the regulation of pressure, which is area of the piston, Vt is the total vol-

actually equivalent to the pressing ume of fluid under compression in

force. both chambers, β is the bulk modu-

lus of the operating oil and Ktc is the

The transfer function between the total leakage coefficient of the pis-

spool-valve position yv(s) and the in- (6)

ton, which includes the internal and

put voltage u(s) is typically a second- external leakage coefficient. where is the total

order term: flow-pressure coefficient.

The force balance equation for the

cylinder is given by: The control concept using a PID

controller with an anti-windup algo-

(1) (4) rithm for the press force control and

where kv is the proportional valve a fixed-gain PD controller for the

where m is the effective system mass,

gain, ωv is the natural frequency and press-position control is implemen-

b is the coefficient of viscous friction

ζv is the damping ratio. ted. Eventual conflicts between the

and ks is the elastic load stiffness.

two controllers are managed by me-

The relationship between the spool- ans of two gains, Cf and Cp, that can

Using equations (1)-(4) a block-di-

valve displacement, yv, and the load be used to determine the priority of

agram of the process can be con-

flow, QL, assuming turbulent flow the regulation and the contribution

structed. The control strategy, re-

through an orifice can be given as: of each signal in the total control si-

ferred to as hybrid force/position

control, is shown in Figure 1. With gnal on the valve.

this control technique the errors in

(2)

the force and position control loops 3 Experimental test setup

where ps is the supply pressure, are controlled by two independent

pL=p1–p2 is the load pressure and A schematic diagram and a photo

Figure 1. Hybrid force/position control system

Ventil 17 /2011/ 4 315

KRMILJENJE HIDRAVLIČNE STISKALNICE

Figure 2. Hydraulic press, a) schematic diagram, b) photo; 1–Cylinder, 2–Pressure sensor, 3–Micropulse linear trans-

ducer, 4–Solenoid 4/3 valve, 5–Servo valve, 6–Shut-off valve, 7–Solenoid 2/2 valve, 8–Throttling valve, 9–Manometer,

10–System pressure relief valve, 11–Ball check valve, 12–Pressure filter, 13–Return flow filter, 14–Three-phase electric

motor, 15–Hydraulic pump, 16–Electronic interface, 17–Electric rectifier, 18–PLC SIMATIC S7-1200, 19–Control computer

of the hydraulic press for control of a micro-pulse linear transducer (3), The data acquisition in the system is

the force and position are shown in manufactured by Balluff, type BTL5- handled by a National Instruments

Figure 2. The hydraulic cylinder (1) A11-M0300-P-S32, with an output DAQCard-6024E (for PCMCIA), whi-

that is used to actuate the press is voltage of 0 to 10 V and a resolution ch offers both a 12-bit analogue

a double-acting 300-mm-stroke cyl- of . With the installation of the input and an analogue output. The

inder with an 80-mm bore and a 60- displacement sensor in the system, control algorithms were developed

mm diameter rod. The control of the the preconditions for the realization in the Matlab/Simulink environment,

press force is accomplished using an of hybrid force/position-control al- supported by Real-Time Workshop

electro-hydraulic servo valve (5) de- gorithms are obtained. If the shut- (RTW) program for generating the C

signed for bypass operation, manu- off valve (6) is closed then the servo code and building a real-time appli-

factured by Schneider, model HVM valve is turned off, and then it can be cation. This control technique allows

025-005-1200-0, with a box-chop- shown the action of a press whose for continuous monitoring of the

per amplifier and ±10-V analogue motion is controlled using a clas- process variables, data acquisition

input signal. The maximum pressure sical solenoid 4/3 valve (4). Also, if and software solution for real-time

in the system is limited by a pres- the solenoid 2/2 valve (7) is closed, control. The command voltage to

sure relief valve (10) and the servo the oil flow is directed to a throt- the servo valve is sent via an analo-

valve actually reduces the pressure tling valve (8) and this changes the gue output and to the solenoid val-

in the system pressure line and the cylinder speed. Since the servo valve ves it is sent via digital outputs on

cylinder chamber. The servo valve is is installed in the system, particular the data-acquisition board.

installed in a bypass line, and with attention should be given to ensure

respect to the control signal enables the cleanliness of the oil, so a high- An industrial solution of the hydrau-

the oil flow to the tank, maintaining pressure filter (12) and a return flow lic press control is realized by using

the pressure in the cylinder cham- filter (13) are set in the hydraulic cir- a programmable logic controller

ber at a desired value. The hydraulic cuit. The hydraulic power is provided SIMATIC S7-1200, manufactured by

force applied to a rubber bumper by a hydraulic gear pump (15), mod- Siemens (18). The control program

is indirectly measured by a pres- el KV-1P from ViVoil, with a volumet- was built using SIMATIC WinCC flexi-

sure transducer (2), (Siemens type ric displacement of the pump of 2.6 ble software for programming the

7MF1564), with a measuring range cm3/rev and a maximum nominal controller and configuring the HMI

of 0 to 250 bar and an output sig- pressure of 25 MPa. The oil pump panel.

nal of 0 to 10 V, which is installed in is driven by a three-phase electrical

the cylinder chamber. In this system motor (14), 2.2 kW at 980 rpm. The considered system is actually

it is also possible to measure the one of three experimental electro-

displacement of the press by using -hydraulic systems that have been

316 Ventil 17 /2011/ 4

KRMILJENJE HIDRAVLIČNE STISKALNICE

Figure 3. Experimental results for hydraulic press control: a) pressure response for the step-reference signal, b) pres-

sure response for the sinusoidal reference signal, c) position response for the sinusoidal reference signal, d) hybrid

force/position control for the sinusoidal reference signal

made in the Laboratory for Automa- chamber is used. The major draw- into a comprehensive structure in

tion and Robotics at the University back of this measuring method is order to form a hybrid force/posi-

of Zagreb’s Faculty of Mechanical that the friction force of the hydrau- tion-control strategy. This control

Engineering and Naval Architecture. lic actuator remains outside the con- structure allows independent force

The modules are used for research trol loop. Using pressure feedback in and position controllers to be used

purposes in the field of hydraulic sy- the control algorithm allows us to for the implementation of both con-

stems control, as well as for training control the actuator force output. trol loops. In the force control loop

students [7-10]. The other two test Figure 3a) shows the pressure re- a PID controller with an anti-windup

systems are: the module for transla- sponse for a square-wave reference algorithm is implemented, while the

tional motion control and the modu- signal and the servo-valve control position control loop uses a PD con-

le for rotational motion control. The- signal. It can be seen that the control troller. The controllers were tuned

se modules have the characteristics system follows the reference trajec- manually in order to achieve fast and

of general electro-hydraulic systems, tory with a small error and shows a smooth responses to the sinusoidal

which are commonly used in indu- good dynamic behaviour. The exper- inputs in both the force and position

strial plants. iment was also made for a sinusoidal control loop. The controller gains

reference signal and the results are are set to the values: Kpf = 20, Kif =

4 Experimental results shown in Figure 3b). Thereafter, the 2 and Kdf = 0.5 for the force control

following experiment was made for loop and Kpx=120 and Kdx = 0.1 for

Experiments were first made for the the position control of the hydraulic the position control loop. The force

regulation of the force achieved with press, and the results are shown in gain is set to the value of Cf=1.7 and

the control of the cylinder pressure. Figure 3c). Once these two control the position gain is set to the value

To realize the control loop a pressure schemes had been proven sepa- of Cp=1.2, and they determine the

transducer installed in the cylinder rately, it was then merged together contribution of the control signal

Ventil 17 /2011/ 4 317

KRMILJENJE HIDRAVLIČNE STISKALNICE

Figure 4. Simulink model for hybrid force/position control

applied to the servo valve. In Figure Experiments were also performed there is also an alarm table, which

3d) the experimental results of the using a PLC SIMATIC S7-1200 as a gives the operator some important

hybrid force/position control for a si- control device. Most hydraulic pres- states in the process.

nusoidal reference signal are shown. ses used in industry working in an

open-loop and are usually operated 5 Conclusion

The Simulink/Real Time Workshop manually or by using a control devi-

(RTW) model used to perform the ce such as a PLC. Figure 5 shows the The hydraulic circuit and instrumen-

process control is shown in Figure 4. HMI (human machine interface) that tation of the hydraulic press, the

The host PC with the RTW tool gene- was built using the WinCC flexible simplified modelling of the system

rates an ANSI C code automatically software tool for the hydraulic press for computer control, the design

and enables a ‘hardware in the loop control. Using the HMI is intuitive, and implementation of the com-

feature’ that has an ability to execu- with a graphic and textual display, puter program for hybrid position/

te the Simulink model in real-time trends and alarms and it can perform force control have been presented.

using an interface data-acquisition real-time control and monitoring of The control program was made

(DAQ) card. In this way it is possible the process. The HMI has the ability in Matlab/Simulink, while C code

to use the DAQ inputs and outputs to display the amount of achieved was generated using the Real-Time

as sources and sinks in the Simulink cylinder position and pressure. The Workshop program, making possi-

model. By activating various switches reference pressure can be directly ble the realization of digital control

in the developed program, it is pos- changed, and there is a graphical algorithms. The tuned controllers

sible to choose the appropriate ope- representation of the pressure chan- derived for the independent force

rating mode, type of reference signal ges over time. Below the graphical and position schemes gave satis-

and form of data storage. display of the pressure condition factory results in terms of trajectory

318 Ventil 17 /2011/ 4

KRMILJENJE HIDRAVLIČNE STISKALNICE

Figure 5. HMI interface for the hydraulic press control

tracking with an acceptable level of Clegg, A.C., Edwards, I.: Hybrid trol Principle to an Electrohy-

control error. Experiments were also position/ force control of a hy- draulic Velocity Servomechani-

performed using a PLC as a typical draulic underwater manipula- sm, 7th Int. Fluid Power Conf.

control device used in an industrial tor, IEE Proc. of Control Theory (7th IFK), Aachen, Germany, 22-

environment. Based on the experi- Application, Vol. 143, No. 2., pp. 24 March, Vol. 2 - Workshop,

mental results it can be concluded 145–151, (1996). pp. 379-390, (2010).

that modern hydraulic presses offer [5] Sun, P., Gracio, J.J., Ferreira, J.A.: [10] Šitum, Ž., Milić, V., Žilić, T., Essert,

good performance, efficiency and Control System of a mini hy- M.: Design, Construction and

reliability; they are well adapted to draulic press for evaluating Computer Control of a Hydrau-

different requirements of pressing, springback in sheet metal for- lic Press, The 12th Scandinavi-

which is enabled by using modern ming, Journal of Materials Pro- an Conference on Fluid Power,

microprocessor technology, new cessing Technology, Vol. 176, May 18-20, Tampere, Finland,

fast-acting valves and digital control pp. 55–61, (2006). Vol. 3, pp. 93-103, (2011).

theory. [6] Choux, M., Hovland, G.: Design

of a Hydraulic Servo System for

References Robotic Manipulation, Proc. of

the 5th FPNI Ph.D Symposium,

[1] Murrenhoff, H.: Trends in Valve Krakow, 1-5 July, pp. 391–400,

Development, O+P Ölhydraulik (2008).

und Pneumatik, Vol. 46, Nr. 4., [7] Šitum, Ž., Bačanek, M.: Hydrau-

pp. 1-36, (2003). lic System Control Using Pro-

[2] Smith, D.: Hydraulic Presses, portional Valve, Transactions

Smith & Associates, www.smi- of FAMENA, Vol. 29, No. 2; pp.

thassoc.com/ copyrighted-whi- 23–34, (2005).

te-papers/papers/C07.pdf, Mo- [8] Šitum, Ž., Essert, M, Žilić, T., Mi-

nroe, Michigan, pp.1-20, (1993). lić, V.: Design and Construction

[3] Nguyen, Q.H., Ha, Q.P., Rye, D.C., of Hydraulic Servomechanisms

Durrant-Whytel, H.F.: Force/ for Position, Velocity and Force

Position Tracking for Electro- Control, CD–ROM Proc. of the

hydraulic Systems of a Robotic 8th ASEE Global Colloquium on

Excavator, Proc. of the 39th IEEE Engineering Education, Buda-

Conf. on Decision and Control, pest, Hungary, 12-15 October,

Dec. 12-15, Sydney, Australia, GC-2009-62, (2009).

pp. 5224–5229, (2000). [9] Šitum, Ž., Milić, V., Essert, M.:

[4] Dunnigan, M.W., Lane, D.M., Throttling and Volumetric Con-

Ventil 17 /2011/ 4 319

KRMILJENJE HIDRAVLIČNE STISKALNICE

Regulacija sile in položaja na hidravlični stiskalnici

Razširjeni povzetek

V prispevku je prikazan postopek projektiranja in regulacije hidravlične stiskalnice (50 kN), izdelane tako za izobra-

ževanje kot tudi za eksperimentalno verifikacijo krmilnih algoritmov. Za regulacijo delovnega tlaka v hidravličnem

valju in posledično pritisne sile hidravlične stiskalnice služi tlačni servoventil. Stiskalnica za posredno merjenje priti-

sne sile je opremljena s tlačnim senzorjem, nameščenim direktno v komori hidravličnega valja. Stiskalnica omogoča

tudi merjenje položaja batnice hidravličnega valja in posledično zgornje potisne plošče z uporabo mikropulznega

merilnika pomika, kar je tudi pogoj za realizacijo hibridnega krmilnega algoritma (sila/položaj). Prispevek najprej

prikazuje matematični model za hidravlično stiskalnico, upoštevaje dinamiko servoventila, kontinuiteto hidravličnih

tokov skozi zožitve, tlačne spremembe v komorah hidravličnega valja ter drugi Newtonov zakon za gibajoče se dele

stiskalnice. Na podlagi matematičnega modela je bil izdelan blokovni diagram krmilnega sistema (slika 1). Nato sta

bili določeni še prenosni funkciji za hibridni (sila/pomik) krmilni sistem. Slika 2a prikazuje funkcijsko shemo, slika 2b

pa fotografijo hidravlične stiskalnice. Glavni sestavni deli stiskalnice (sliki 2a in 2b) so: 1 – hidravlični valj, 2 – tlačni

senzor, 3 – mikropulzni linearni merilnik pomika, 4 – elektromagnetni 4/3-potni ventil, 5 – servoventil, 6 – krogelni

zapirni ventil, 7 – elektromagnetni 2/2-potni ventil, 8 – dušilni ventil, 9 – manometer, 10 – varnostni ventil, 11 – proti-

povratni ventil, 12 – tlačni filter, 13 – povratni filter, 14 – trifazni elektromotor, 15 – hidravlična črpalka, 16 – električna

krmilna omarica, 17 – električni usmernik, 18 – programabilni logični krmilnik (PLC) SIMATIC S7-1200, uporabljen pri

industrijski rešitvi krmiljenja in nadzora delovanja hidravlične stiskalnice, 19 – krmilno-nadzorni računalnik.

Krmilni algoritmi in nadzorni procesi se izvajajo istočasno, izvršeni so s pomočjo realnočasovne (ang. ''real-time'')

računalniške opreme. Krmilni in nadzorni algoritmi so izdelani v programskem paketu Matlab/Simulink z uporabo

orodij za istočasno (ang. ''real-time'') generiranje C-kode in izdelavo strojnega programa, ki krmili in nadzira delo-

vanja hidravlične stiskalnice. Prispevek prikazuje tudi industrijsko rešitev krmiljenja hidravlične stiskalnice z uporabo

programabilnega logičnega krmilnika (PLC) kot krmilne naprave.

V prispevku so najprej prikazani eksperimentalni rezultati regulacije sile preko krmiljenja in nadzora tlaka v hidra-

vličnem valju. Največji problem teh meritev je, da sila trenja znotraj hidravličnega valja ostaja zunaj krmilne zanke.

Uporaba povratne zanke za tlak v krmilno-nadzornem algoritmu nam omogoča krmiljenje izhodne sile stiskalnice. V

prispevku predstavljeni rezultati meritev prikazujejo tlačne odzive na pravokotni (slika 3a) in sinusni (slika 3b) vhodni

krmilni signal servoventila. Naslednji rezultati meritev (slika 3c) se nanašajo na odzive pomika batnice hidravličnega

valja na sinusni vhodni krmilni signal servoventila. Zadnji predstavljeni rezultati meritev prikazujejo odzive hidravlič-

ne stiskalnice pri hibridnem krmiljenju (sila/pomik). Vsi predstavljeni rezultati kažejo na dobro dinamično odzivnost

hidravlične stiskalnice in potrjujejo možnost uporabe v sodobnih industrijskih napravah. Slika 4 prikazuje blokovni

diagram krmilno-nadzornega programa, izdelanega v programskem paketu Simulink za hibridno krmiljenje sile in

položaja batnice hidravličnega valja stiskalnice. Preizkusi so bili najprej izvedeni s pomočjo krmilno-zajemne kartice

DAQCard-6024E proizvajalca National Instruments. Nato so se vsi preizkusi izvedli še na krmilniku PLC SIMATIC

S7-1200, izdelanem za industrijske namene. Slika 5 prikazuje vmesnik HMI (ang. human machine interface), ki je bil

izdelan s pomočjo fleksibilnega programskega orodja WinCC in je namenjen za sodobno industrijsko krmiljenje in

nadzor hidravlične stiskalnice.

Na osnovi eksperimentalnih rezultatov lahko zaključimo, da električno gnane sestavine, podprte z ustreznimi raču-

nalniškimi programi, omogočajo izboljšave delovnih karakteristik, izkoristkov in zanesljivosti hidravličnih sistemov,

uporabljanih v sodobnih industrijskih proizvodnjah.

Ključne besede: hidravlična stiskalnica, regulacija sile in položaja, servoventil

Acknowledgements

The author acknowledges the financial support of the research project “Energy optimal control of fluid power

and electromechanical systems” funded by the Ministry of Science, Education and Sports of the Republic of

Croatia.

The author would like to thank Mr. Ž. Ban and Mr. S. Ban from HI-KON for the design and construction of the

experimental setup.

320 Ventil 17 /2011/ 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- EmpoTech - Q2 M1 - Rich and Content Interactivity of Web 2.0 and The Use of ICT For Social ChangeDocument16 pagesEmpoTech - Q2 M1 - Rich and Content Interactivity of Web 2.0 and The Use of ICT For Social ChangeKennedy Fieldad Vagay100% (7)

- HAZOP On Startup N ShutdownDocument9 pagesHAZOP On Startup N ShutdownmmudassaraliNo ratings yet

- Clariant TLP Brosch 2Document22 pagesClariant TLP Brosch 2mutazsalihNo ratings yet

- Example (Pty) LTD: Asset Set-UpDocument25 pagesExample (Pty) LTD: Asset Set-UpMichaelszAndreyNo ratings yet

- 1 - CBM 25 (2011) 2030Document6 pages1 - CBM 25 (2011) 2030mutazsalihNo ratings yet

- Certificari SalamanderDocument1 pageCertificari SalamandermutazsalihNo ratings yet

- Boral4Builders No7Document14 pagesBoral4Builders No7mutazsalihNo ratings yet

- de Zig Ner TechDocument4 pagesde Zig Ner TechmutazsalihNo ratings yet

- ConnexDocument6 pagesConnexmutazsalihNo ratings yet

- Hydrapave Bro LRDocument4 pagesHydrapave Bro LRmutazsalihNo ratings yet

- 5P02729B4B 10.06 WebDocument8 pages5P02729B4B 10.06 WebmutazsalihNo ratings yet

- Colori Dec Brochure SingleDocument4 pagesColori Dec Brochure SinglemutazsalihNo ratings yet

- Brick Cleaning SheetDocument1 pageBrick Cleaning SheetmutazsalihNo ratings yet

- BrickInfo-2 LRDocument1 pageBrickInfo-2 LRmutazsalihNo ratings yet

- BrickInfo-1 LRDocument2 pagesBrickInfo-1 LRmutazsalihNo ratings yet

- DL Bricks SampleFly LRDocument1 pageDL Bricks SampleFly LRmutazsalihNo ratings yet

- TieDownMaxi 2pp FA LRDocument2 pagesTieDownMaxi 2pp FA LRmutazsalihNo ratings yet

- Oxide Colours: Build Something GreatDocument6 pagesOxide Colours: Build Something GreatmutazsalihNo ratings yet

- 05073CairoCornBro v6Document2 pages05073CairoCornBro v6mutazsalihNo ratings yet

- Concrete Visual Enhancing Articimo Exposed BDocument4 pagesConcrete Visual Enhancing Articimo Exposed BmutazsalihNo ratings yet

- SydneyBro v3Document2 pagesSydneyBro v3mutazsalihNo ratings yet

- Spec Release: Form Release For Use With Concrete Form LinersDocument4 pagesSpec Release: Form Release For Use With Concrete Form LinersmutazsalihNo ratings yet

- Spec Release: Form Release For Use With Concrete Form LinersDocument1 pageSpec Release: Form Release For Use With Concrete Form LinersmutazsalihNo ratings yet

- BLST N Ecch RTDocument4 pagesBLST N Ecch RTmutazsalihNo ratings yet

- Ma8351 Discrete MathematicsDocument2 pagesMa8351 Discrete MathematicsSurya SuryaNo ratings yet

- ns2 Basics Manual1Document19 pagesns2 Basics Manual1THANGARAJTNo ratings yet

- Dev ListDocument8 pagesDev ListPăun MihaiNo ratings yet

- Jesse P Ravensbergen ResumeDocument1 pageJesse P Ravensbergen Resumeapi-209670575No ratings yet

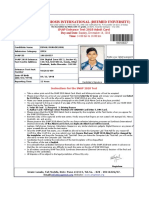

- Symbiosis International (Deemed University) : SNAP Entrance Test 2018 Admit CardDocument1 pageSymbiosis International (Deemed University) : SNAP Entrance Test 2018 Admit CardKunal KhandelwalNo ratings yet

- Voice Activated Home Automation Using Arduino: Software Requirements SpecificationDocument6 pagesVoice Activated Home Automation Using Arduino: Software Requirements SpecificationNaveed AnwarNo ratings yet

- CS101 Solved File For Final Term MCQS 1 To 45 LecturesDocument130 pagesCS101 Solved File For Final Term MCQS 1 To 45 LecturesHisan Mehmood64% (28)

- NAME: Param Shah ID: Vu4f2021119 Div: A: Expirnment No: 11 AimDocument3 pagesNAME: Param Shah ID: Vu4f2021119 Div: A: Expirnment No: 11 AimsayalitekeNo ratings yet

- The Five Principles of Showing Your Weakness - Bill SchmalfeldtDocument14 pagesThe Five Principles of Showing Your Weakness - Bill SchmalfeldtPaulKrendlerNo ratings yet

- Mock Test 1 BPS 5 To 15 Jobs (Sarwaich Encyclopedia - 03093934147)Document12 pagesMock Test 1 BPS 5 To 15 Jobs (Sarwaich Encyclopedia - 03093934147)zahid hussain BrohiNo ratings yet

- ECS401U Main FINALDocument34 pagesECS401U Main FINALka hoNo ratings yet

- SAP Transport Workflow 20090912Document20 pagesSAP Transport Workflow 20090912Rajagopalan MuthukrishnanNo ratings yet

- Words Unit 5 - Secrets (Speakout Advanced) Lesson 5.1.family SecretsDocument6 pagesWords Unit 5 - Secrets (Speakout Advanced) Lesson 5.1.family SecretsolegmnNo ratings yet

- Thermoelectric Fridge: Using TEC Peltier Module & SolarDocument26 pagesThermoelectric Fridge: Using TEC Peltier Module & Solaravinash naikNo ratings yet

- Week#9 Class Slides Quantitative AnalysisDocument28 pagesWeek#9 Class Slides Quantitative AnalysistssfzrNo ratings yet

- Learning Centre ProposalDocument12 pagesLearning Centre ProposalKshitiz SharmaNo ratings yet

- Service Manual: Ic-F3 Ic-F3s Ic-F4 Ic-F4sDocument52 pagesService Manual: Ic-F3 Ic-F3s Ic-F4 Ic-F4sbaykasifNo ratings yet

- BIDV1112 Av 00Document637 pagesBIDV1112 Av 00Shaun Joe KurianNo ratings yet

- Intro To Frame GrabbersDocument45 pagesIntro To Frame GrabberswrwerNo ratings yet

- Intel OpenCL SDK User GuideDocument38 pagesIntel OpenCL SDK User GuideArhakhan Theanjharak OrshagkNo ratings yet

- ĐỀ THI HỌC SINH GIỎI LỚP 12 NĂM HỌC 2018Document87 pagesĐỀ THI HỌC SINH GIỎI LỚP 12 NĂM HỌC 2018Nguyễn Văn Tiến DũngNo ratings yet

- Smart Attendance Face Recognision Using Machine Learning 2Document27 pagesSmart Attendance Face Recognision Using Machine Learning 2Murtaza BurhaniNo ratings yet

- Ewan Ptact 5 2 8Document6 pagesEwan Ptact 5 2 8Muhammad HudzaifahNo ratings yet

- PDC - Bit Bank 20122017Document29 pagesPDC - Bit Bank 20122017VigneshNo ratings yet

- Read Me!Document2 pagesRead Me!r6ty56y6y5No ratings yet

- CAD/CAM Important QuestionsDocument3 pagesCAD/CAM Important Questionsivs yeswanthNo ratings yet

- Presentation On OPMDocument81 pagesPresentation On OPMAnush_MakamNo ratings yet