0% found this document useful (0 votes)

548 views7 pagesWSM West Salem Machinery

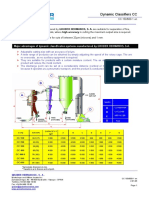

This document provides information about West Salem Machinery (WSM), a leading manufacturer of size reduction and recycling machinery. It describes several types of machines they offer, including horizontal and vertical feed grinders, hammermills, low RPM grinders, and screens. For each machine type, it lists example materials that can be processed and provides details and videos. WSM offers a full range of grinding, shredding, and milling machines in different sizes and configurations to best suit various applications.

Uploaded by

mostafa sherifCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

548 views7 pagesWSM West Salem Machinery

This document provides information about West Salem Machinery (WSM), a leading manufacturer of size reduction and recycling machinery. It describes several types of machines they offer, including horizontal and vertical feed grinders, hammermills, low RPM grinders, and screens. For each machine type, it lists example materials that can be processed and provides details and videos. WSM offers a full range of grinding, shredding, and milling machines in different sizes and configurations to best suit various applications.

Uploaded by

mostafa sherifCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd