Professional Documents

Culture Documents

Lesson Plan: Veer Surendra Sai University of Technology

Uploaded by

santhi saranya0 ratings0% found this document useful (0 votes)

7 views2 pagesThis document outlines a lesson plan for a Tool and Die Design course taught over a semester. The course is divided into 4 modules that will be covered in 40 lectures over 16 weeks. Module 1 focuses on system design approaches and covers topics like interchangeability and standardization. Module 2 covers designing single-point cutting tools like form tools and broaches. Module 3 addresses forging die design. Module 4 examines jig and fixture design principles and problems. The course aims to provide students with knowledge of tool design fundamentals and skills to design various cutting, forging, and workholding tools.

Original Description:

Lesson 1526472023

Original Title

Lesson 1526472023

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines a lesson plan for a Tool and Die Design course taught over a semester. The course is divided into 4 modules that will be covered in 40 lectures over 16 weeks. Module 1 focuses on system design approaches and covers topics like interchangeability and standardization. Module 2 covers designing single-point cutting tools like form tools and broaches. Module 3 addresses forging die design. Module 4 examines jig and fixture design principles and problems. The course aims to provide students with knowledge of tool design fundamentals and skills to design various cutting, forging, and workholding tools.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesLesson Plan: Veer Surendra Sai University of Technology

Uploaded by

santhi saranyaThis document outlines a lesson plan for a Tool and Die Design course taught over a semester. The course is divided into 4 modules that will be covered in 40 lectures over 16 weeks. Module 1 focuses on system design approaches and covers topics like interchangeability and standardization. Module 2 covers designing single-point cutting tools like form tools and broaches. Module 3 addresses forging die design. Module 4 examines jig and fixture design principles and problems. The course aims to provide students with knowledge of tool design fundamentals and skills to design various cutting, forging, and workholding tools.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

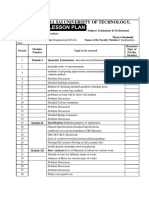

VEER SURENDRA SAI UNIVERSITY OF TECHNOLOGY

nd

LESSON PLAN

Semester >>2 Year >> 2016 Contact Hours per week >>4

(M.Tech)

Branch >>

Total Credit >>4

Sub: TOOL& DIE Production Engineering

DESIGN

TEACHER Dr.Pragyan Paramita Mohanty

Period Jan 2016-April 2016

Recommended Text book:

books >>

1. . Fundamentals of Tool Design: ASTME, PHI

2. 2. Metal Cutting Theory & Cutting Tool Design: Arshinov, MIR Pub.

3. 3. A Text Book of Production Engg.: P.C.Sharma, S.Chand & Co

4. 4. Tool Design: Donaldson, Le Cain, Goold, TMH

5. Fundamentals of Tool Engg. Design: Basu, Mukherjee, Mishra, Oxford &

IBH.

Sl. Lecture Topics to be covered No. of Classes

No. No.

MODULE-1

1 Lecture-01 Introduction to Tool Design

Lecture-02 System approach to production design: Elements of a product

2

manufacturing facility, materials selection 6

3 Lecture-03 System approach to production design: Interchangeability

5 Lecture-04 System approach to production design: standardization,

Lecture-05 System approach to production design: Use of new technology,

4

value engineering and analysis

6 Lecture-06 System approach to production design: Cost analysis.

MODULE-2

Lecture-06 Design of single-point cutting tools: Tool strength and rigidity

7 calculation, selection of tool angles, chip breakers, carbide, tipped

tools, High production cutting tools.

Lecture-07 Design of single-point cutting tools: Problems on single point

8

cutting tool i.e Tool strength and rigidity calculation. 14

Lecture-08 Design of single-point cutting tools: Problems on single point

9

cutting tool i.e Design of single point cutting tool.

10 Lecture-09 Design of single-point cutting tools: Introduction to Form Tools

Lecture-10 Form Tools: Types of form tools, method of determining the

11

profile of circular and flat form of tool, analytical

12 Lecture-11 Method of determining the profile of circular and flat form of tool

graphical method.

Lecture-12 Design of single-point cutting tools Problems on single point

13

cutting tool i.e Design of form tool(Graphical).

Lecture-13 Design of single-point cutting tools: Problems on single point

14

cutting tool i.e Design of form tool(Analytical).

15 Lecture-14 Problems practice

16 Lecture-15 Design of single-point cutting tools: Cutting process in broaching

Lecture-16 Design of single-point cutting tools: geometric elements of

17 broach teeth,

Lecture-17 Design of Internal & external surface broach, calculation of no. of

18

teeth, Rigidity, cutting force, power.

Lecture-18 Design of single-point cutting tools: Problems on single point

19 cutting tool i.e Design of broach tool.

Lecture-19 Design of single-point cutting tools: Problems on single point

20 cutting tool i.e Design of broach tool.

21 Lecture-20 Problems practice

MODULE-3

22 Lecture-22 Inroduction to Forging Design

23 Lecture-23 Forging Design-Allowances, Forging process,

24 Lecture-24 Forging die design, Drop forging Dies and auxiliary tools,

25 Lecture-25 Upset forging. Die block design

Lecture-26 Punch design, punch support, stop, pilot, stripper, knockout, blanking & 10

26 piercing die design

27 Lecture 27 Design for sheet metal works: Press working-shearing action

Lecture 28 Center of pressure, clearance, cutting force

28

Lecture 29 Progressive & compound die design, Drawing dies, metal flow, Blank

29 diameter, Drawing force.

30 Lecture 30 Forging Design : Problems on single point cutting tool

31 Lecture 31 Class Test on Module-III

Module-4

31 Lecture 31 Introduction

32 Lecture 32 Jigs & Fixture design: 10

33 Lecture 33 Locating & clamping, principles of location

34 Lecture-34 Clamping, devices, materials for locating & clamping elements

35 Lecture-35 Design principles: Design of Drilling Jig

36 Lecture-36 Design principles: Design of Milling fixtures.

37 Lecture-37 Problems on Jig

Lecture-38 Problems on Fixtures

38

39 Lecture-39 Class Test on Module-IV

40 Lecture-40 Old question paper discussion

Signature of Teacher

You might also like

- Absolute Beginners Guide To Lathe ThreadingDocument15 pagesAbsolute Beginners Guide To Lathe ThreadingRandy Wilson95% (21)

- Micro Machine Shop Mods EtcDocument488 pagesMicro Machine Shop Mods Etcsbarnett38@100% (4)

- Bolt and Nut Lathe MachineDocument34 pagesBolt and Nut Lathe MachineIxora My0% (2)

- N. K. Mehta - Metal Cutting and Design of Cutting Tools, Jigs & fixtures-McGraw Hill Education (India) (2015) PDFDocument452 pagesN. K. Mehta - Metal Cutting and Design of Cutting Tools, Jigs & fixtures-McGraw Hill Education (India) (2015) PDFSumair100% (2)

- Manufacturing ProcessDocument1 pageManufacturing ProcessRonald Reagon20% (5)

- LatheDocument127 pagesLatheneelesh singh75% (4)

- Production Engineering: Jig and Tool DesignFrom EverandProduction Engineering: Jig and Tool DesignRating: 4 out of 5 stars4/5 (9)

- Machine ToolDocument23 pagesMachine ToolMohammad Anaitullah HassanNo ratings yet

- Theory of Metal CuttingDocument10 pagesTheory of Metal CuttingHxn BhattiNo ratings yet

- Machine Shop TheoryDocument25 pagesMachine Shop TheoryNiño Vince VallespinNo ratings yet

- Grinding Your Own Lathe ToolsDocument9 pagesGrinding Your Own Lathe ToolsredneckrepairsNo ratings yet

- CNC Cutting Tool Live Monitoring and Cost ReductionDocument10 pagesCNC Cutting Tool Live Monitoring and Cost ReductionKodali Rithvik0% (2)

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- ME 2207 - Manufacturing Technology 1 - Lab ManualDocument57 pagesME 2207 - Manufacturing Technology 1 - Lab ManualMohan Prasad.M71% (17)

- Fabrication of Quick Change Tool Post PDFDocument2 pagesFabrication of Quick Change Tool Post PDFBetty0% (1)

- Manufacturing Technology NotesDocument97 pagesManufacturing Technology Notesswap1983No ratings yet

- ch21 Fundamentals of MachiningDocument25 pagesch21 Fundamentals of MachiningBaatar Zorigt100% (1)

- MP405 Tool EngineeringDocument2 pagesMP405 Tool EngineeringAbhay SajeevNo ratings yet

- Tool EngineeringDocument3 pagesTool EngineeringAmirDeshmukhNo ratings yet

- Manufacturing Process Lab IiiDocument5 pagesManufacturing Process Lab IiiMuhammad Bilal SahiNo ratings yet

- Tool Engineering PDFDocument3 pagesTool Engineering PDFEr Nikunj Miyani100% (3)

- Topics For Tool and Die Design 2Document15 pagesTopics For Tool and Die Design 2Jose Lapera Jr.No ratings yet

- 2nd Sem PDM SyllabusDocument11 pages2nd Sem PDM SyllabusVinay AlagundiNo ratings yet

- Manufacturing Processes UTA026Document9 pagesManufacturing Processes UTA026Tania CENo ratings yet

- Lecture 1 Introduction To Design of Machine ElementsDocument25 pagesLecture 1 Introduction To Design of Machine ElementsHaider AliNo ratings yet

- Vishwakarma Institute of Technology: Issue 05: Rev No. 0: Dt. 13/03/15 Course Plan FormatDocument3 pagesVishwakarma Institute of Technology: Issue 05: Rev No. 0: Dt. 13/03/15 Course Plan FormatKunalNo ratings yet

- Syllabus DFM Latest PDFDocument1 pageSyllabus DFM Latest PDFNAVEEN KUMAR S NNo ratings yet

- Machine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurDocument16 pagesMachine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurDeekshaomarNo ratings yet

- Nptel: Design For Manufacture and Assembly (DFMA) For Industrial Design - Web CourseDocument3 pagesNptel: Design For Manufacture and Assembly (DFMA) For Industrial Design - Web CourseglobalhodmechNo ratings yet

- r05010302 Engineering MechanicsDocument39 pagesr05010302 Engineering Mechanicsdassault megecNo ratings yet

- 15mec243 - Tool Design: VII Semester - Elective Mechanical EngineeringDocument17 pages15mec243 - Tool Design: VII Semester - Elective Mechanical Engineeringvignesh100% (1)

- Gujarat Technological University Automobile Engineering (02) /mechanical EngineeringDocument3 pagesGujarat Technological University Automobile Engineering (02) /mechanical EngineeringRavi SidhpuriaNo ratings yet

- Subject Production Techology SyllabusDocument3 pagesSubject Production Techology SyllabusbmdbmdbmdNo ratings yet

- UG Syllabus B.tech 1stDocument12 pagesUG Syllabus B.tech 1stRaunak GuptaNo ratings yet

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909Document3 pagesGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909ShahinNo ratings yet

- Product Design and Development SyllabusDocument7 pagesProduct Design and Development Syllabusharshottam2977No ratings yet

- Lesson Plan Subject Name-Tool Design Branch - Production Engineering Subject Code - BPE 2604 Semester - 6Document2 pagesLesson Plan Subject Name-Tool Design Branch - Production Engineering Subject Code - BPE 2604 Semester - 6Raja RamachandranNo ratings yet

- Production Design & Production ToolingDocument1 pageProduction Design & Production ToolingAnonymous 37UeMkrENo ratings yet

- Workshop Laboratory Manual PDFDocument95 pagesWorkshop Laboratory Manual PDFPradipta PaulNo ratings yet

- Design of Machine Members - Syllabus PDFDocument3 pagesDesign of Machine Members - Syllabus PDFVAIBHAV TIWARINo ratings yet

- Tool and Fixture Design For UsersDocument15 pagesTool and Fixture Design For UsersRahul KatnaNo ratings yet

- Metal Cutting and Tool DesignDocument3 pagesMetal Cutting and Tool DesignHemanth YadaNo ratings yet

- Nptel: Design For Manufacturing - Web CourseDocument3 pagesNptel: Design For Manufacturing - Web CourseChinnadurai LakshmananNo ratings yet

- Single Point Cutting ToolDocument22 pagesSingle Point Cutting ToolMeer UmarNo ratings yet

- MCMT Course File Doc 30th Juky2016 Unit 1 2 and 3,4Document91 pagesMCMT Course File Doc 30th Juky2016 Unit 1 2 and 3,4Pilla SireeshaNo ratings yet

- MFT-2 .Two Marks With KeyDocument13 pagesMFT-2 .Two Marks With KeySujith KumarNo ratings yet

- Production Technology PDFDocument2 pagesProduction Technology PDFRamana Kumar NarsipuramNo ratings yet

- DesignofJigsFixturesPressTools GKV PDFDocument19 pagesDesignofJigsFixturesPressTools GKV PDFniharika kadiriNo ratings yet

- Design of Jigs, Fixtures and Press Tools: Muruganandam Arunachalam Vijayaraghavan G.KDocument19 pagesDesign of Jigs, Fixtures and Press Tools: Muruganandam Arunachalam Vijayaraghavan G.Kchaitanya kulkarniNo ratings yet

- Design of Jigs, Fixtures and Press Tools: Muruganandam Arunachalam Vijayaraghavan G.KDocument19 pagesDesign of Jigs, Fixtures and Press Tools: Muruganandam Arunachalam Vijayaraghavan G.Kniharika kadiriNo ratings yet

- Me Vtu DFM Syllabus CBCS SchemeDocument2 pagesMe Vtu DFM Syllabus CBCS SchemeNitheeshNo ratings yet

- Machine Design NotesDocument349 pagesMachine Design NotesAkshay More100% (1)

- Week 1 - Introduction - March 2021Document6 pagesWeek 1 - Introduction - March 2021Porkkodi SugumaranNo ratings yet

- Chapter 1 - Tool-Design MethodsDocument15 pagesChapter 1 - Tool-Design Methodsdawit solomonNo ratings yet

- Course OverviewDocument14 pagesCourse OverviewVinayaka G PNo ratings yet

- Manufacturing Engineering - IDocument3 pagesManufacturing Engineering - Ias2faasbujsacNo ratings yet

- PROJECT REVIEW 1 FinalDocument23 pagesPROJECT REVIEW 1 FinalNani DatrikaNo ratings yet

- Institute of Engineering & Technology, Devi Ahilya University, Indore, (M.P.), India. (Scheme Effective From July 2015)Document2 pagesInstitute of Engineering & Technology, Devi Ahilya University, Indore, (M.P.), India. (Scheme Effective From July 2015)Rohan NewaskarNo ratings yet

- ME6402 SCAD MSM by EasyEngineering - Net 2Document101 pagesME6402 SCAD MSM by EasyEngineering - Net 2Akash PrasanthNo ratings yet

- Production Processes and MetrologyDocument3 pagesProduction Processes and MetrologymaheshNo ratings yet

- Bmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lDocument3 pagesBmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lKrijayNo ratings yet

- ME6402 MT II by WWW - Learnengineering.inDocument102 pagesME6402 MT II by WWW - Learnengineering.inVikram C KNo ratings yet

- 1ET1010603 - Machine Design IIDocument3 pages1ET1010603 - Machine Design IIPatel SarkarNo ratings yet

- Theory of Metal Cutting KTU SyllabusDocument3 pagesTheory of Metal Cutting KTU SyllabusAron PanickerNo ratings yet

- JigsDocument5 pagesJigsTamilSelvanSoundararajNo ratings yet

- Mec445:Tool Design: Course ObjectivesDocument1 pageMec445:Tool Design: Course ObjectivesSunil SharmaNo ratings yet

- 3141908Document3 pages3141908kk bhattNo ratings yet

- ME MT Lecture NotesDocument135 pagesME MT Lecture NotesIts meNo ratings yet

- MCMT SyllabusDocument3 pagesMCMT SyllabusshahazadNo ratings yet

- Engineering Graphics2Document7 pagesEngineering Graphics2ILAYAPERUMAL KNo ratings yet

- Plagiarism - ReportDocument42 pagesPlagiarism - ReportJerick HernandezNo ratings yet

- Lesson Plan mp2Document2 pagesLesson Plan mp2Saravanan RajendranNo ratings yet

- Course Code: CH1106 Course Title: Introduction To Biochemical Principles Semester: Course Time: Jan - MayDocument4 pagesCourse Code: CH1106 Course Title: Introduction To Biochemical Principles Semester: Course Time: Jan - Maysanthi saranyaNo ratings yet

- Btech VI Sem 15ce347e PDFDocument3 pagesBtech VI Sem 15ce347e PDFsanthi saranyaNo ratings yet

- BT1001 Biology For Engineers 2 PDFDocument2 pagesBT1001 Biology For Engineers 2 PDFsanthi saranyaNo ratings yet

- Btech Vi Sem 15ce347eDocument2 pagesBtech Vi Sem 15ce347esanthi saranyaNo ratings yet

- Introduction To Biochemical Principles 2013 2014Document4 pagesIntroduction To Biochemical Principles 2013 2014santhi saranyaNo ratings yet

- BT1001 Biology For Engineers1Document3 pagesBT1001 Biology For Engineers1santhi saranyaNo ratings yet

- Department of Automobile Engineering Course PlanDocument4 pagesDepartment of Automobile Engineering Course Plansanthi saranyaNo ratings yet

- Lesson1499214383 PDFDocument2 pagesLesson1499214383 PDFsanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla: Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla: Lesson Plansanthi saranyaNo ratings yet

- Department of Automobile Engineering Course PlanDocument4 pagesDepartment of Automobile Engineering Course Plansanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaNo ratings yet

- BT1001 Biology For Engineers PDFDocument2 pagesBT1001 Biology For Engineers PDFsanthi saranyaNo ratings yet

- Department of Automobile Engineering Course PlanDocument4 pagesDepartment of Automobile Engineering Course Plansanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla: Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla: Lesson Plansanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla: Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla: Lesson Plansanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla: Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla: Lesson Plansanthi saranyaNo ratings yet

- Ar 15203 History of Architecture I (3-0-0-0) CR-03Document2 pagesAr 15203 History of Architecture I (3-0-0-0) CR-03santhi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaNo ratings yet

- Ar 15201 Building Materials Ii (3-0-0-0) CR-03Document3 pagesAr 15201 Building Materials Ii (3-0-0-0) CR-03santhi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaNo ratings yet

- Lesson Plan: Veer Surendra Sai University of Technology, BurlaDocument2 pagesLesson Plan: Veer Surendra Sai University of Technology, Burlasanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaNo ratings yet

- Lesson Plan: Veer Surendra Sai University of Technology, BurlaDocument2 pagesLesson Plan: Veer Surendra Sai University of Technology, Burlasanthi saranyaNo ratings yet

- Veer Surendra Sai University of Technology, Burla: Quantity Estimation: Introduction, Definitions & Terms UsedDocument2 pagesVeer Surendra Sai University of Technology, Burla: Quantity Estimation: Introduction, Definitions & Terms Usedsanthi saranyaNo ratings yet

- 2 1 Theory of Metal Cutting Q A For StudentDocument8 pages2 1 Theory of Metal Cutting Q A For Studentmyidprince100% (2)

- Tool Bit - WikipediaDocument31 pagesTool Bit - WikipediaDavejohn AleviadoNo ratings yet

- Advanced Metal Cutting Technology (MAT-514 A) Patr 1Document25 pagesAdvanced Metal Cutting Technology (MAT-514 A) Patr 1Bizuayehu Tadesse100% (1)

- CH 23Document61 pagesCH 23Anonymous 9yhXGZVNo ratings yet

- SPR MAN 4 14 ET Operating ManualDocument24 pagesSPR MAN 4 14 ET Operating ManualJason WeeksNo ratings yet

- Assignment ADocument2 pagesAssignment AMemer PointNo ratings yet

- Unit 8 PDFDocument43 pagesUnit 8 PDFAnurag RanaNo ratings yet

- Tool Engineering LabDocument23 pagesTool Engineering LabAnonymous YaJlLHYNo ratings yet

- Shaper, Slotter and Planer Machines: Department of Mechanical Engineering SSETDocument27 pagesShaper, Slotter and Planer Machines: Department of Mechanical Engineering SSETsree_guruNo ratings yet

- MP IiDocument51 pagesMP IiMarthandeNo ratings yet

- Secondary or Machining ProcessDocument49 pagesSecondary or Machining ProcessHar QuinNo ratings yet

- Mech 4sem MT IIDocument147 pagesMech 4sem MT IITheVagabond HarshalNo ratings yet

- Evaluation of Painted or Coated Specimens Subjected To Corrosive EnvironmentsDocument4 pagesEvaluation of Painted or Coated Specimens Subjected To Corrosive EnvironmentsRafael Tournier VianaNo ratings yet

- Technology of Machine ToolsDocument42 pagesTechnology of Machine ToolsAnibal DazaNo ratings yet

- Static and Fatigue Analysis of Lathe Spindle For Maximum Cutting ForceDocument7 pagesStatic and Fatigue Analysis of Lathe Spindle For Maximum Cutting Forcefitria ramadhaniNo ratings yet

- Development of A Cutting Tool For Composites With Thermoplastic MatrixDocument6 pagesDevelopment of A Cutting Tool For Composites With Thermoplastic MatrixEge menNo ratings yet

- O5. Study-Of-Various-Angles-Of-Cutting-Tools-Single-And-Multi-PointDocument7 pagesO5. Study-Of-Various-Angles-Of-Cutting-Tools-Single-And-Multi-PointHridoyNo ratings yet

- Turner Question and Answer Bank 2014 PDFDocument88 pagesTurner Question and Answer Bank 2014 PDFBhanupratap MallickNo ratings yet