Inspection and Maintenance Guidelines - Shackles Page 1 of 5

a Inspection and Maintenance Guidelines - Shackles

a presented by Hane Training, Inc.

a Shackles come in three basic types. They are:

1. Round Pin (Class I)

a 2. Screw Pin (Class II)

3. Bolt Type (Class III)

Many maintenance related

products are available to

you in our Products

Showcase

For other articles

related to this

topic visit our

Reference

Library. G-213 G-215 G-209 G-210

S-213 S-215 S-209 S-210

Round Pin (Class I) Screw Pin (Class II)

top

Need more

training?

We've got

information

about

maintenance

training and G-2130 G-2140 G-2150

trade shows S-2130 S-2140 S-2150

available to you

if you visit our Bolt Type (Class III)

Events Calendar.

Round Pin:

Used for tie downs, towing, suspension or lifting. These types are to

be used for in-line lifting ONLY.

top Screw Pin:

Same applications as round pin, plus can be side loaded. Also

Browse the . . . recommended for permanent installation where the load may be exposed

to vibration, cyclic loading or shock loading. Not to be used where the

Bookstore

load can slide across the pin, possibly causing the pin to rotate and

become disengaged.

where you'll find books WRONG! WRONG!

on predictive

maintenance.

http://maintenanceresources.com/referencelibrary/ezine/shackles.htm 8/11/2017

�Inspection and Maintenance Guidelines - Shackles Page 2 of 5

CORRECT!

Bolt Type:

Any application plus permanent or long term use where load slippage

may cause the pin to rotate.

Angle of Loading Reduction to Working Load Limit

45 degrees 30% reduction

90 degrees 50% reduction

Angle loads must be applied in the plane of the bow.

Use of Shackles

Shackles may be used to connect slings to lifting eyes or hooks.

When using lifting eyes:

http://maintenanceresources.com/referencelibrary/ezine/shackles.htm 8/11/2017

�Inspection and Maintenance Guidelines - Shackles Page 3 of 5

Load the shackle in-line with the center line of the

shackle for round pin shackles. Be careful to properly align

the shackles with the specific type of eyebolt that is being

used. If screw pin or bolt type shackles are being used with

an angular pull, reduced working load limits are required for

both the shackle and eyebolt.

When using on hooks:

Center the shackle pin in the saddle of the hook. Add

washers or spaces to the pin to insure proper centering.

When using two slings on a shackle, do not exceed a 120

degree included angle between the slings.

Add Washers to Center the Load

When two slings are used on a shackle, the load rating is based on the

load regardless of the included angle as long as it is less than 120

degrees.

Using Shackles:

• Use shackles for their intended purpose only

• Apply load slowly. DO NOT JERK!

http://maintenanceresources.com/referencelibrary/ezine/shackles.htm 8/11/2017

�Inspection and Maintenance Guidelines - Shackles Page 4 of 5

• Do not apply angular loads to round pin shackles

• De-rate screw pin and bolt type shackles when angular load is

applied

• Inspect shackles before using

• Do not heat or weld shackles

Inspection:

• Check distortions such as bends, twists and spread

• Check for peening, nicks and gouges

• Check for cracks or corrosion

• Check thread for damage

• Inspect for wear reduction of 5% or greater in the diameter of the

pin or bow

if any of these conditions exist, remove the shackle from service.

NEVER REPLACE A PIN WITH A BOLT OR ANY OTHER FASTENER!

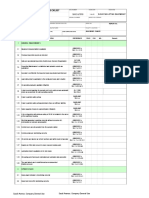

Examples of spread indicating shackle should be removed from

service.

WLL (TON) E MIN. E MAX.

1/3 .31 .44

1/2 .41 .53

3/4 .47 .59

1 .60 .72

1 1/2 .66 .78

2 .75 .88

3 1/4 1.00 1.12

4 3/4 1.19 1.31

6 1/2 1.38 1.50

8 1/2 1.63 1.75

9 1/2 1.75 1.88

12 1.97 2.09

13 1/2 2.13 2.38

http://maintenanceresources.com/referencelibrary/ezine/shackles.htm 8/11/2017

�Inspection and Maintenance Guidelines - Shackles Page 5 of 5

17 2.25 2.50

25 2.75 3.00

35 3.13 3.38

55 3.88 4.38

Dimensions are in inches

Bibliography:

Inspection and Maintenance Guidelines - Shackles

The Crosby Group - Revised May 1, 1992

This information is provided courtesy of Hane Training. For more

top

information on Hane's instructor-led training courses visit

www.hanetraining.com

If you have any comments about the article you have just read and you would like to share them

with us at Maintenance Resources, please feel free to email us by clicking on the email button

below.

Current Issue Archives E-mail Us

© Copyright 1999 Maintenance Resources, Inc.

http://maintenanceresources.com/referencelibrary/ezine/shackles.htm 8/11/2017