Professional Documents

Culture Documents

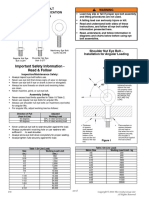

Important Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings & Application Instructions

Uploaded by

Konstantinos SynodinosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Important Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings & Application Instructions

Uploaded by

Konstantinos SynodinosCopyright:

Available Formats

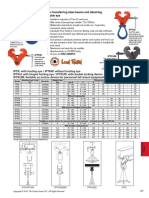

FORGED EYE BOLT

RIGGING ACCESSORIES

WARNING

WARNINGS & APPLICATION INSTRUCTIONS • Load may slip or fall if proper eye bolt assembly

and lifting procedures are not used.

• A falling load can seriously injure or kill.

• Read and understand these instructions, and

follow all eye bolt safety information presented

here.

• Read, understand, and follow information in

diagrams and charts below before using eye

bolt assemblies.

Machinery Eye Bolt

S-279 / M-279

Shoulder Nut Eye Bolt –

Regular Nut Eye Shoulder Nut Eye Installation for Angular Loading

Bolt G-291 Bolt G-277

Important Safety Information -

IN-LINE • The threaded shank

Read & Follow must protrude

through the load

Inspection/Maintenance Safety: sufficiently to allow

• Always inspect eye bolt before use. full engagement of

the nut.

• Never use eye bolt that shows signs of wear or damage.

• Never use eye bolt if eye or shank is bent or elongated.

• Always be sure threads on shank and receiving holes are clean. • If the eye bolt

• Never machine, grind, or cut eye bolt. protrudes so far

• Do not leave threaded end of macinery eye bolt in aluminum through the load that

the nut cannot be

loads for long periods of time as it may cause corrosion. tightened securely

against the load,

Assembly Safety: use properly sized

• Never exceed load limits specified in Table I & Table 2. washers to take up

• Never use regular nut eye bolts for angular lifts. the excess space

BETWEEN THE NUT

• Always use shoulder nut eye bolts (or machinery eye bolts) AND THE LOAD.

for angular lifts.

• For angular lifts, adjust working load as follows:

ANGLE FROM "IN-LINE" ADJUSTED WORKING LOAD LIMIT

5 degrees 100% of rated working load

15 degrees 80% of rated working load

30 degrees 65% of rated working load

45 degrees 30% of rated working load

• Thickness of spacers must • Place washers or spacers

90 degrees 25% of rated working load

exceed this distance between between nut and load so that

when the nut is tightened

• Never undercut eye bolt to seat shoulder against the load. the bottom of the load and

securely, the shoulder is

the last thread of the eye bolt.

• Always countersink receiving hole or use washers with secured flush against the

sufficient I.D. to seat shoulder. load surface.

• Always screw eye bolt down completely for proper seating. Figure 1

• Always tighten nuts securely against the load.

Table 1 (In-Line Load)

Size Working Load Limit Table 2 (In-Line Load)

(in.) (lbs.) Metric Size Working Load Limit - kg

1/4 650 m6 200

5/16 1,200 m8 400

3/8 1,550 m10 640

1/2 2,600 m12 1000

5/8 5,200 m16 1800

3/4 7,200 m20 2500

7/8 10,600 m24 4000

1 13,300 m27 5000

1-1/8 15,000 m30 6000

1-1/4 21,000 m36 8500

1-1/2 24,000 m42 14000

1-3/4 34,000 m48 17300

2 42,000 m64 29500

2-1/2 65,000

rev 8

200 Copyright © 2017 The Crosby Group LLC All Rights Reserved

You might also like

- Important Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings and Application InstructionsDocument2 pagesImportant Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings and Application InstructionsiLLeno 23No ratings yet

- Eye Bolts: Forged Eye Bolt Warning and Application InstructionsDocument5 pagesEye Bolts: Forged Eye Bolt Warning and Application InstructionsshamanthupadhyayaNo ratings yet

- Safe Use of Eyeblts Dlhonline PDFDocument2 pagesSafe Use of Eyeblts Dlhonline PDFMoetaz MohamedNo ratings yet

- Eyebolts SI 7.4Document2 pagesEyebolts SI 7.4reda mesbahNo ratings yet

- Instructions For The Safe Use Of: Eyebolts: The Information in This Leaflet Should Be Passed To The User of The EquipmentDocument2 pagesInstructions For The Safe Use Of: Eyebolts: The Information in This Leaflet Should Be Passed To The User of The EquipmentMontadhar SaeedNo ratings yet

- 3 (1) Leea Advice On Eyebolts PDFDocument2 pages3 (1) Leea Advice On Eyebolts PDFReda MashalNo ratings yet

- Warning & Application Instructions Weld-On Pivoting Link Inspection / MaintenanceDocument1 pageWarning & Application Instructions Weld-On Pivoting Link Inspection / MaintenanceAlfonsus W.M.No ratings yet

- Inspection and Maintenance Guidelines - ShacklesDocument5 pagesInspection and Maintenance Guidelines - ShacklesNomer AgcaoiliNo ratings yet

- Safe 01Document1 pageSafe 01Hidramarin TecnicoNo ratings yet

- Important - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingDocument1 pageImportant - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingKonstantinos SynodinosNo ratings yet

- Catalogo Llave de VarillaDocument38 pagesCatalogo Llave de VarillaWilson Cendales100% (1)

- Instructions For The Safe Use Of: ShacklesDocument2 pagesInstructions For The Safe Use Of: ShacklesAmeerUlHaqNo ratings yet

- Crosby Model Pl-N/O Hook Latch Kit: Warning Warnings and Application InstructionsDocument1 pageCrosby Model Pl-N/O Hook Latch Kit: Warning Warnings and Application InstructionsMareg Engenharia de SegurançaNo ratings yet

- Instructions For The Safe Use Of: ShacklesDocument2 pagesInstructions For The Safe Use Of: Shacklesreda mesbahNo ratings yet

- Crosby Instructions Chain Slings 1Document1 pageCrosby Instructions Chain Slings 1Konstantinos SynodinosNo ratings yet

- Crosby L-562A & L-320R ROV HOOKS Warning & Application Instructions WarningDocument2 pagesCrosby L-562A & L-320R ROV HOOKS Warning & Application Instructions WarningMareg Engenharia de SegurançaNo ratings yet

- Eye BoltsDocument5 pagesEye Boltsazteca14139445No ratings yet

- Shackles PDFDocument1 pageShackles PDFPrimelift Safety Resources LimitedNo ratings yet

- Monster WinchDocument16 pagesMonster WinchChristian VillaNo ratings yet

- QMF 123 Instructions For The Use of Wedge SocketsDocument2 pagesQMF 123 Instructions For The Use of Wedge Socketsmanglesh1No ratings yet

- Lifting Beams and Spreaders SI 8.3Document2 pagesLifting Beams and Spreaders SI 8.3reda mesbahNo ratings yet

- Warning Wedge Socket Warnings and Application Instructions: Tail LengthDocument1 pageWarning Wedge Socket Warnings and Application Instructions: Tail Lengthmanglesh1No ratings yet

- Instructions For The Safe Use Of: Beam ClampsDocument2 pagesInstructions For The Safe Use Of: Beam ClampsMontadhar SaeedNo ratings yet

- 2011 Vdo Installation Instructions en Viewline 85mm RudderDocument5 pages2011 Vdo Installation Instructions en Viewline 85mm RudderdikaNo ratings yet

- AIRS / R.RRFT$ M RN - : Owners ManualDocument24 pagesAIRS / R.RRFT$ M RN - : Owners ManualLesley RuseNo ratings yet

- Renfroe Pull Vert Susp ClampsDocument6 pagesRenfroe Pull Vert Susp ClampsMohamed FathyNo ratings yet

- Owner's guide PSW654 industrial winchesDocument20 pagesOwner's guide PSW654 industrial winchesRobert HollandNo ratings yet

- Installation Instructions: Viewline 52 MM: AmmeterDocument6 pagesInstallation Instructions: Viewline 52 MM: AmmeterSoloniainaNo ratings yet

- Civil Construction Safety GuidesDocument72 pagesCivil Construction Safety GuidesMALAYIL UNNINo ratings yet

- Installation Instructions: Viewline 52 MM: Operating Hours CounterDocument5 pagesInstallation Instructions: Viewline 52 MM: Operating Hours CounterJohn GarnetNo ratings yet

- Instructions For The Safe Use Of: Chain SlingsDocument2 pagesInstructions For The Safe Use Of: Chain SlingsMontadhar SaeedNo ratings yet

- Ball Screw Catalog PDFDocument379 pagesBall Screw Catalog PDFAmrita SenNo ratings yet

- Capocorda Crosby S-241Document1 pageCapocorda Crosby S-241cerfabioNo ratings yet

- Chuck Close's Portrait of Chuck OpenDocument44 pagesChuck Close's Portrait of Chuck Opensoluciones BiomedicasNo ratings yet

- Instructions For Safe Use ShacklesDocument2 pagesInstructions For Safe Use ShacklesNickNo ratings yet

- Husqvarna: Operator's ManualDocument18 pagesHusqvarna: Operator's ManualZepol MartinezNo ratings yet

- Crosby Thimble Eye Bundle Clips Warning & Application InstructionsDocument1 pageCrosby Thimble Eye Bundle Clips Warning & Application InstructionsMareg Engenharia de SegurançaNo ratings yet

- Um 5xz0a 006 EngDocument1 pageUm 5xz0a 006 EngNick BoldingNo ratings yet

- Installation Instructions: Viewline 52 MMDocument6 pagesInstallation Instructions: Viewline 52 MMMaksim Panfilov100% (1)

- EN - AuV Hoist Wheel 2017Document16 pagesEN - AuV Hoist Wheel 2017ArdamitNo ratings yet

- Manual Esmeril Black & Decker BT3600 6Document9 pagesManual Esmeril Black & Decker BT3600 6Argenis MarinNo ratings yet

- S-4320 Hook Latch Kit Warning: 121 All Rights ReservedDocument1 pageS-4320 Hook Latch Kit Warning: 121 All Rights ReservedMinhKhuongHieuNo ratings yet

- Assemble Layher Hoist WheelDocument16 pagesAssemble Layher Hoist WheelEmmanuel CardosoNo ratings yet

- Crosby Model PL Hook Latch Kit: Warnings and Application InstructionsDocument1 pageCrosby Model PL Hook Latch Kit: Warnings and Application InstructionsMareg Engenharia de SegurançaNo ratings yet

- Crosby Weld-On Hooks: Warning and Application Instructions WarningDocument2 pagesCrosby Weld-On Hooks: Warning and Application Instructions WarningMoisesNo ratings yet

- Ii:Rrftsmrn'I: Owner's ManualDocument8 pagesIi:Rrftsmrn'I: Owner's ManualAnuta CosminNo ratings yet

- Wedge Socket Warning and Application InstructionsDocument1 pageWedge Socket Warning and Application InstructionsMinhKhuongHieuNo ratings yet

- Prensa Hidraulico - RidgidDocument12 pagesPrensa Hidraulico - RidgidEduardo PardinhoNo ratings yet

- Crrftsmrn°: Operator's ManualDocument32 pagesCrrftsmrn°: Operator's ManualaNo ratings yet

- Rigging HardwareDocument18 pagesRigging HardwareARULSELVAN MURUGESANNo ratings yet

- SWP ChainsawOperationDocument2 pagesSWP ChainsawOperationELVY FLORINA THOMASNo ratings yet

- Wire Rope Slings SI 2.3Document2 pagesWire Rope Slings SI 2.3reda mesbahNo ratings yet

- Crosby - Hoist RingDocument3 pagesCrosby - Hoist RingYADAGIRI REDDYNo ratings yet

- Instruction Manual For DODGE Setscrew, Eccentric Collar, D-Lok, H-E Series, E-Z Kleen, Ultra Kleen and Food Safe Mounted Ball BearingsDocument2 pagesInstruction Manual For DODGE Setscrew, Eccentric Collar, D-Lok, H-E Series, E-Z Kleen, Ultra Kleen and Food Safe Mounted Ball BearingsRichard VachonNo ratings yet

- ' - : - Airs/ CRRFT$ Ivlrn: Owner'SDocument33 pages' - : - Airs/ CRRFT$ Ivlrn: Owner'SsNo ratings yet

- Turbuckle InstallationDocument10 pagesTurbuckle Installationmoch ganafiaNo ratings yet

- Floor Jack: Operators ManualDocument8 pagesFloor Jack: Operators ManualAlain DefoeNo ratings yet

- Crosby McKissick Snatch BLocks 2t To12tDocument1 pageCrosby McKissick Snatch BLocks 2t To12tKonstantinos SynodinosNo ratings yet

- Crosby Instructions Chain Slings 1Document1 pageCrosby Instructions Chain Slings 1Konstantinos SynodinosNo ratings yet

- Pewag Anchorage Points - Fall ProtectionDocument6 pagesPewag Anchorage Points - Fall ProtectionKonstantinos SynodinosNo ratings yet

- Synodinos Wire Rope SlingsDocument1 pageSynodinos Wire Rope SlingsKonstantinos SynodinosNo ratings yet

- 26mm 8xK26 CertificateDocument2 pages26mm 8xK26 CertificateKonstantinos Synodinos100% (1)

- Dyform 8 PI: High Performance Crane Ropes BenefitsDocument2 pagesDyform 8 PI: High Performance Crane Ropes BenefitsKonstantinos SynodinosNo ratings yet

- For Transferring Steel Beams and Attaching Tackle Eye: IptkuDocument1 pageFor Transferring Steel Beams and Attaching Tackle Eye: IptkuKonstantinos SynodinosNo ratings yet

- G-209 / S-209 Screw Pin Anchor ShacklesDocument1 pageG-209 / S-209 Screw Pin Anchor Shacklesaizzi1989No ratings yet

- Closed Spelter SocketsDocument2 pagesClosed Spelter SocketsKonstantinos SynodinosNo ratings yet

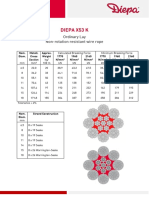

- Diepa X53 K: Ordinary Lay Non-Rotation Resistant Wire RopeDocument1 pageDiepa X53 K: Ordinary Lay Non-Rotation Resistant Wire RopeKonstantinos SynodinosNo ratings yet

- Threaded Rod M33 (3.5) 10.9Document4 pagesThreaded Rod M33 (3.5) 10.9Konstantinos SynodinosNo ratings yet

- Crosby Grade 100 SHUR-LOC Handle Hooks: Shur-Loc Handle Swivel Hook With Bearing Shur-Loc Handle Eye HookDocument1 pageCrosby Grade 100 SHUR-LOC Handle Hooks: Shur-Loc Handle Swivel Hook With Bearing Shur-Loc Handle Eye HookKonstantinos SynodinosNo ratings yet

- Crosby Slide-Loc Lifting Point: Warnings & Application Instructions WarningDocument1 pageCrosby Slide-Loc Lifting Point: Warnings & Application Instructions WarningKonstantinos SynodinosNo ratings yet

- Horizontal Clamps Horizontal Clamps: For Horizontal Lift and Transfer With Pretension SystemDocument1 pageHorizontal Clamps Horizontal Clamps: For Horizontal Lift and Transfer With Pretension SystemKonstantinos SynodinosNo ratings yet

- Pewag SVW - SVSW - SvsuwDocument1 pagePewag SVW - SVSW - SvsuwKonstantinos SynodinosNo ratings yet

- Crosby Grade 100 Clevis Sling Hooks: J AA R LDocument1 pageCrosby Grade 100 Clevis Sling Hooks: J AA R LKonstantinos SynodinosNo ratings yet

- Ropeblock - Snatch Blocks S Series With Hook - MetricDocument1 pageRopeblock - Snatch Blocks S Series With Hook - MetricKonstantinos SynodinosNo ratings yet

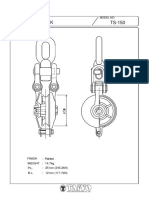

- 05 Snatch Block (Ts150)Document1 page05 Snatch Block (Ts150)Konstantinos SynodinosNo ratings yet

- Important - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingDocument1 pageImportant - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingKonstantinos SynodinosNo ratings yet

- To Remove Lifting Point: Table 1 Working Load Limit 4:1 (T) UNC Bolt Size (In.) Effective Thread Projection Length (In.)Document1 pageTo Remove Lifting Point: Table 1 Working Load Limit 4:1 (T) UNC Bolt Size (In.) Effective Thread Projection Length (In.)Konstantinos SynodinosNo ratings yet

- All Breaking Loads Are in Metric Tonnes. To Maximize The Benefits of The Improved Strength of The Chain, Only Use Compatible Trawlex FittingsDocument1 pageAll Breaking Loads Are in Metric Tonnes. To Maximize The Benefits of The Improved Strength of The Chain, Only Use Compatible Trawlex FittingsKonstantinos SynodinosNo ratings yet

- Product Sheet HDTP 13.03.2019Document1 pageProduct Sheet HDTP 13.03.2019Konstantinos SynodinosNo ratings yet

- Crosby Grade 100 Foundry Hooks: A-1359 Clevis Foundry HookDocument1 pageCrosby Grade 100 Foundry Hooks: A-1359 Clevis Foundry HookKonstantinos SynodinosNo ratings yet

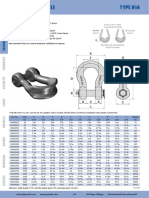

- Type H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestDocument2 pagesType H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestKonstantinos SynodinosNo ratings yet

- Western Manila Rope Blocks Western Standard Steel BlocksDocument1 pageWestern Manila Rope Blocks Western Standard Steel BlocksKonstantinos SynodinosNo ratings yet

- Western Manila Rope Blocks Western Standard Steel BlocksDocument1 pageWestern Manila Rope Blocks Western Standard Steel BlocksKonstantinos SynodinosNo ratings yet

- HG 226Document1 pageHG 226Konstantinos SynodinosNo ratings yet

- Product Sheet HDTP 13.03.2019Document1 pageProduct Sheet HDTP 13.03.2019Konstantinos SynodinosNo ratings yet

- Type H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestDocument2 pagesType H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestKonstantinos SynodinosNo ratings yet

- Grade 5. Unit 15Document6 pagesGrade 5. Unit 15Đình ThuậnNo ratings yet

- Opening SpeechDocument1 pageOpening SpeechTaniușa SavaNo ratings yet

- English Try Out UN 1 2008/2009Document4 pagesEnglish Try Out UN 1 2008/2009Cepiana Abas100% (10)

- Nanotechnology Presentation Covers Medicine, Electronics and EnergyDocument13 pagesNanotechnology Presentation Covers Medicine, Electronics and EnergypravinfoodNo ratings yet

- Honey & Bee Product Recipes: November 2007Document29 pagesHoney & Bee Product Recipes: November 2007Kyra ThomasNo ratings yet

- Measuring Instruments Temperature GuideDocument52 pagesMeasuring Instruments Temperature GuidemohammedhanafyNo ratings yet

- SKF Frecuently Questions With AnswersDocument16 pagesSKF Frecuently Questions With AnswersCarlos AlcantaraNo ratings yet

- Discover the training secrets of legendary bodybuildersDocument129 pagesDiscover the training secrets of legendary bodybuildersfatmir100% (7)

- Jadwal Oral Presentation Peserta FIT-VIIIDocument26 pagesJadwal Oral Presentation Peserta FIT-VIIIKlinik FellitaNo ratings yet

- Medical Power PointDocument124 pagesMedical Power PointPhysiology by Dr Raghuveer75% (4)

- Tapping Volcanic Energy for Human UseDocument9 pagesTapping Volcanic Energy for Human UseThartson Oliveros MagdadaroNo ratings yet

- Joule Gym Marketing Plan for Female-Only Fitness CenterDocument23 pagesJoule Gym Marketing Plan for Female-Only Fitness CenterJeremy BadalNo ratings yet

- Duconmix CRP 400Document2 pagesDuconmix CRP 400FounTech612No ratings yet

- DLL - MAPEH 4 - Q4 - W8 - New@edumaymay@lauramos@angieDocument8 pagesDLL - MAPEH 4 - Q4 - W8 - New@edumaymay@lauramos@angieDonna Lyn Domdom PadriqueNo ratings yet

- VBAC Parents Guide v2 April 2019Document110 pagesVBAC Parents Guide v2 April 2019The VBAC Link100% (4)

- 11 Chapter 7Document14 pages11 Chapter 7ParthaSarathyNo ratings yet

- Subway 2009Document12 pagesSubway 2009sparklers_mNo ratings yet

- BC-5300 Preventive Maintenance Kit ManualDocument8 pagesBC-5300 Preventive Maintenance Kit ManualAbdel MUNDENNo ratings yet

- NanocatalysisDocument9 pagesNanocatalysisNouran ElbadawiNo ratings yet

- Cronidur 30: Maximum Demand by Maximum Demand by Corrosive Stress WearDocument24 pagesCronidur 30: Maximum Demand by Maximum Demand by Corrosive Stress WearVlad PopescuNo ratings yet

- ETR - Part C - Course SyllabusDocument26 pagesETR - Part C - Course SyllabusDon JubacNo ratings yet

- Performance Evaluation of Sewage Treatment Plants (STPS) in Multistoried BuildingsDocument6 pagesPerformance Evaluation of Sewage Treatment Plants (STPS) in Multistoried BuildingsAnonymous iTzCnMNo ratings yet

- Heat Transfer Surfaces Guide PDFDocument8 pagesHeat Transfer Surfaces Guide PDFJohan ConradieNo ratings yet

- Smart medical system monitors dementia patients' medicationDocument9 pagesSmart medical system monitors dementia patients' medicationKresnaNo ratings yet

- ELCO Brochure FGR (ENG) 1.2Document16 pagesELCO Brochure FGR (ENG) 1.2Mohd Bismillah AnsariNo ratings yet

- Curriculum DesignDocument20 pagesCurriculum DesignRose Glaire Alaine TabraNo ratings yet

- Recommended Abma & Asme Boiler Water Limits Drum Operating Pressure (Psig) SteamDocument9 pagesRecommended Abma & Asme Boiler Water Limits Drum Operating Pressure (Psig) Steammaoc4vnNo ratings yet

- Group 3Document11 pagesGroup 3Sharp MIER TVNo ratings yet

- Detox 101Document31 pagesDetox 101Botoşanu Diana-LarisaNo ratings yet

- MYK Grout Card 2Document2 pagesMYK Grout Card 2Abdul Raheem SyedNo ratings yet