Professional Documents

Culture Documents

Horizontal Clamps Horizontal Clamps: For Horizontal Lift and Transfer With Pretension System

Uploaded by

Konstantinos SynodinosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Horizontal Clamps Horizontal Clamps: For Horizontal Lift and Transfer With Pretension System

Uploaded by

Konstantinos SynodinosCopyright:

Available Formats

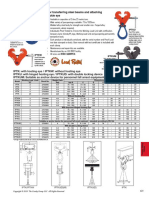

Horizontal Clamps

CROSBY LIFTING CLAMPS

E

L

A D

C

F

G

®

IPHNM10 IPH10

The IPHNM10 horizontal lifting clamps have a The IPH10 horizontal lifting clamps with spring

pretension feature that allows the user to attach loaded tension have a pretension feature that

the clamps to the material for horizontal lifting and allows the user to attach the clamps to the

transfer of non-sagging material. To be used where material for horizontal lifting and transfer of

material surface must not be damaged. These non-sagging material. These clamps must be

clamps must be used in pairs or more. used in pairs or more.

For horizontal lift and transfer with pretension system

• Available in capacities of .5 thru 12 metric tons. • Each product is individually serialized, with the serial number and Proof

• Jaw openings available: 0 to 120mm. Load test date stamped on body. User manual with test certificate is

• Welded alloy steel body for strength and smaller size. Forged alloy included with each clamp.

components, where required. • Maintenance and repair kits are available.

• Individually Proof Tested to 2 times the Working Load Limit with certification • Manufactured by an ISO 9001 facility.

• Company name (CrosbyIP), logo, Working Load Limit and jaw • All sizes are RFID EQUIPPED.

opening permanently stamped on body.

Model IPHNM10

Working Load IPHNM10 Weight Dimensions

Limit Stock Each (mm)

Model (Per Pair) (t)* No. (kg) Jaw A B C D E F G H J K L

IPHNM10 .5 2703287 4.0 0 - 20 81 22 82 16 101 160 74 12 60 4

IPHNM10 1 2703288 7.0 0 - 35 93 30 92 16 103 164 74 12 60 7

IPHNM10 2 2703290 15.0 0 - 30 139 30 131 22 166 245 100 20 74 9

IPHNM10J 2 2703291 16.0 30 - 60 169 30 131 22 166 245 100 20 74 9

* Design Factor based on EN 13155 and ASME B30.20.

Model IPH10 and IPH10J: With Spring Loaded Tension, Magnets and Handle

Working Load Dimensions

Limit IPH10 Weight Each (mm)

Model (Per Pair) (t)* Stock No. (kg) Jaw A B C E F G H J K L

IPH10 .5+ 2703297 1.8 0 - 20 86 12 16 103 150 60 12 27 4

IPH10 1+ 2703298 2.5 0 - 35 100 16 16 103 150 60 12 31 7

IPH10 2 2703522 5.5 0 - 60 117 16 22 109 256 110 20 40 9

IPH10 3 2703523 7.5 0 - 60 117 20 26 109 266 120 20 48 11

IPH10 4.5 2703524 10.5 0 - 60 132 25 30 104 280 130 20 48 12

IPH10 6 2703525 13.0 0 - 60 143 25 36 123 320 130 20 48 14

IPH10 9 2703526 18.5 0 - 60 157 30 43 133 330 140 25 62 16

IPH10 12 2703527 21.5 0 - 60 172 30 47 141 353 150 25 62 17

With larger jaw opening #

IPH10J 3 2703533 18.0 60 - 120 177 20 26 109 266 120 20 48 9

IPH10J 4.5 2703534 24.0 60 - 120 192 25 30 104 280 130 20 48 11

IPH10J 6 2703535 30.0 60 - 120 203 25 36 123 320 130 20 48 12

IPH10J 9 2703536 41.0 60 - 120 217 30 43 133 330 140 25 62 14

IPH10J 12 2703537 41.0 60 - 120 232 30 47 141 353 150 25 62 16

* Design Factor based on EN 13155 and ASME B30.20. + No handle or magnets. # Larger Working Load Limits available.

414 Copyright © 2019 The Crosby Group LLC All Rights Reserved

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Alien Bestiary PDFDocument450 pagesAlien Bestiary PDFDũng Lê100% (13)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Synodinos Wire Rope SlingsDocument1 pageSynodinos Wire Rope SlingsKonstantinos SynodinosNo ratings yet

- Pewag Anchorage Points - Fall ProtectionDocument6 pagesPewag Anchorage Points - Fall ProtectionKonstantinos SynodinosNo ratings yet

- 26mm 8xK26 CertificateDocument2 pages26mm 8xK26 CertificateKonstantinos Synodinos100% (1)

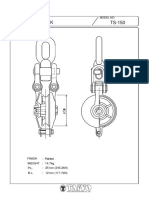

- Crosby McKissick Snatch BLocks 2t To12tDocument1 pageCrosby McKissick Snatch BLocks 2t To12tKonstantinos SynodinosNo ratings yet

- Crosby Instructions Chain Slings 1Document1 pageCrosby Instructions Chain Slings 1Konstantinos SynodinosNo ratings yet

- Closed Spelter SocketsDocument2 pagesClosed Spelter SocketsKonstantinos SynodinosNo ratings yet

- Dyform 8 PI: High Performance Crane Ropes BenefitsDocument2 pagesDyform 8 PI: High Performance Crane Ropes BenefitsKonstantinos SynodinosNo ratings yet

- Ropeblock - Snatch Blocks S Series With Hook - MetricDocument1 pageRopeblock - Snatch Blocks S Series With Hook - MetricKonstantinos SynodinosNo ratings yet

- Crosby Grade 100 SHUR-LOC Handle Hooks: Shur-Loc Handle Swivel Hook With Bearing Shur-Loc Handle Eye HookDocument1 pageCrosby Grade 100 SHUR-LOC Handle Hooks: Shur-Loc Handle Swivel Hook With Bearing Shur-Loc Handle Eye HookKonstantinos SynodinosNo ratings yet

- Threaded Rod M33 (3.5) 10.9Document4 pagesThreaded Rod M33 (3.5) 10.9Konstantinos SynodinosNo ratings yet

- For Transferring Steel Beams and Attaching Tackle Eye: IptkuDocument1 pageFor Transferring Steel Beams and Attaching Tackle Eye: IptkuKonstantinos SynodinosNo ratings yet

- Pewag SVW - SVSW - SvsuwDocument1 pagePewag SVW - SVSW - SvsuwKonstantinos SynodinosNo ratings yet

- G-209 / S-209 Screw Pin Anchor ShacklesDocument1 pageG-209 / S-209 Screw Pin Anchor Shacklesaizzi1989No ratings yet

- Crosby Grade 100 Clevis Sling Hooks: J AA R LDocument1 pageCrosby Grade 100 Clevis Sling Hooks: J AA R LKonstantinos SynodinosNo ratings yet

- Diepa X53 K: Ordinary Lay Non-Rotation Resistant Wire RopeDocument1 pageDiepa X53 K: Ordinary Lay Non-Rotation Resistant Wire RopeKonstantinos SynodinosNo ratings yet

- 05 Snatch Block (Ts150)Document1 page05 Snatch Block (Ts150)Konstantinos SynodinosNo ratings yet

- Crosby Grade 100 Foundry Hooks: A-1359 Clevis Foundry HookDocument1 pageCrosby Grade 100 Foundry Hooks: A-1359 Clevis Foundry HookKonstantinos SynodinosNo ratings yet

- To Remove Lifting Point: Table 1 Working Load Limit 4:1 (T) UNC Bolt Size (In.) Effective Thread Projection Length (In.)Document1 pageTo Remove Lifting Point: Table 1 Working Load Limit 4:1 (T) UNC Bolt Size (In.) Effective Thread Projection Length (In.)Konstantinos SynodinosNo ratings yet

- All Breaking Loads Are in Metric Tonnes. To Maximize The Benefits of The Improved Strength of The Chain, Only Use Compatible Trawlex FittingsDocument1 pageAll Breaking Loads Are in Metric Tonnes. To Maximize The Benefits of The Improved Strength of The Chain, Only Use Compatible Trawlex FittingsKonstantinos SynodinosNo ratings yet

- Crosby Slide-Loc Lifting Point: Warnings & Application Instructions WarningDocument1 pageCrosby Slide-Loc Lifting Point: Warnings & Application Instructions WarningKonstantinos SynodinosNo ratings yet

- Important - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingDocument1 pageImportant - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingKonstantinos SynodinosNo ratings yet

- Important Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings & Application InstructionsDocument1 pageImportant Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings & Application InstructionsKonstantinos SynodinosNo ratings yet

- Product Sheet HDTP 13.03.2019Document1 pageProduct Sheet HDTP 13.03.2019Konstantinos SynodinosNo ratings yet

- Western Manila Rope Blocks Western Standard Steel BlocksDocument1 pageWestern Manila Rope Blocks Western Standard Steel BlocksKonstantinos SynodinosNo ratings yet

- Western Manila Rope Blocks Western Standard Steel BlocksDocument1 pageWestern Manila Rope Blocks Western Standard Steel BlocksKonstantinos SynodinosNo ratings yet

- Product Sheet HDTP 13.03.2019Document1 pageProduct Sheet HDTP 13.03.2019Konstantinos SynodinosNo ratings yet

- Type H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestDocument2 pagesType H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestKonstantinos SynodinosNo ratings yet

- Type H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestDocument2 pagesType H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestKonstantinos SynodinosNo ratings yet

- HG 226Document1 pageHG 226Konstantinos SynodinosNo ratings yet

- Research ProposalDocument2 pagesResearch Proposalsmh9662No ratings yet

- معالجات ستاذ يزنDocument11 pagesمعالجات ستاذ يزنammerNo ratings yet

- Securing Your Organization From Modern Ransomware: Ransomware Attacks Are Now A Team EffortDocument11 pagesSecuring Your Organization From Modern Ransomware: Ransomware Attacks Are Now A Team EfforttiagouebemoraisNo ratings yet

- Initial 2Document6 pagesInitial 2Asad HoseinyNo ratings yet

- Shrutiand SmritiDocument9 pagesShrutiand SmritiAntara MitraNo ratings yet

- Pke - End Sleeves - Cembre (1) - AKBAR TRADING EST - SAUDI ARABIADocument2 pagesPke - End Sleeves - Cembre (1) - AKBAR TRADING EST - SAUDI ARABIAGIBUNo ratings yet

- 02 Photogrammetry - Vertical PhotoDocument37 pages02 Photogrammetry - Vertical PhotoAhmed ElsaidNo ratings yet

- Fire Master Mirine PlusDocument3 pagesFire Master Mirine PlusCarlos BarriosNo ratings yet

- Aurora National High School: Report On AttendanceDocument2 pagesAurora National High School: Report On AttendanceLimuel CaringalNo ratings yet

- Miri Datalogger FlyerDocument1 pageMiri Datalogger FlyerernestoveigaNo ratings yet

- With Pneumatic and Electric Actuators: Datasheet 448001 EnglishDocument7 pagesWith Pneumatic and Electric Actuators: Datasheet 448001 EnglishPinak ProjectsNo ratings yet

- How To Plant Thoughts in Her Mind Ross Jeffries: TranscriptDocument12 pagesHow To Plant Thoughts in Her Mind Ross Jeffries: TranscriptAlcajNo ratings yet

- Certified Vendors As of 6 17 22Document18 pagesCertified Vendors As of 6 17 22Harry ConnerNo ratings yet

- Chemistry Bridging Course Lecture NotesDocument3 pagesChemistry Bridging Course Lecture NotesNNo ratings yet

- Major06 QP DLP NEET2019 (Pmtcorner - In) PDFDocument40 pagesMajor06 QP DLP NEET2019 (Pmtcorner - In) PDFMegha HazarikaNo ratings yet

- 2.HVT Terminacion InstrDocument18 pages2.HVT Terminacion Instrelectrica3No ratings yet

- Plot Elements - DisneyDocument23 pagesPlot Elements - DisneyssssssNo ratings yet

- Saes TABLEDocument13 pagesSaes TABLERiyaz BasheerNo ratings yet

- Sample CISSP ResumeDocument4 pagesSample CISSP ResumeAskia MappNo ratings yet

- The Explanatory GapDocument2 pagesThe Explanatory GapPapuna ChivadzeNo ratings yet

- Screen 2014 Uricchio 119 27Document9 pagesScreen 2014 Uricchio 119 27NazishTazeemNo ratings yet

- h4 History of India Ad 1526 - Ad 1707Document2 pagesh4 History of India Ad 1526 - Ad 1707Baddela ReddyNo ratings yet

- Renaissance RapierDocument66 pagesRenaissance Rapierrshpr100% (1)

- 02 - Consumerism Then and NowDocument28 pages02 - Consumerism Then and NowGeorge TsangNo ratings yet

- 5.1 CompleteDocument11 pages5.1 Completenyanmoemyat2010No ratings yet

- Dharmakirti On Pratyaksa PDFDocument14 pagesDharmakirti On Pratyaksa PDFonlineyyk100% (1)

- Āyāt Al-Aḥkām, Ayat Al-AhkamDocument6 pagesĀyāt Al-Aḥkām, Ayat Al-AhkamRasoul NamaziNo ratings yet

- Sheet - PDF 3Document4 pagesSheet - PDF 3Nazar JabbarNo ratings yet

- Table of Contents and Company Profile of JPCOM CARES STAC5Document4 pagesTable of Contents and Company Profile of JPCOM CARES STAC5Ch Ma100% (1)