Professional Documents

Culture Documents

Important - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line Loading

Uploaded by

Konstantinos SynodinosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Important - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line Loading

Uploaded by

Konstantinos SynodinosCopyright:

Available Formats

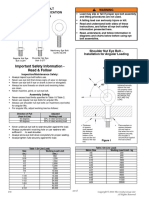

Important – Read and understand these instructions before using eye bolts.

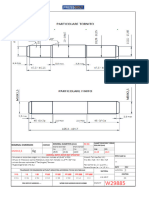

Regular Nut & Shoulder Nut Eye Bolt – Installation for In-Line Loading

RIGHT RIGHT RIGHT Tighten WRONG

hex nut

securely

against

More than One eye bolt load.

one eye bolt diameter of

diameter threads or

of threads, less, use (2)

only (1) nut nuts.

required.

Tap Depth:

2.5 x Diameter 2 x Diameter

(Minimum)

Tighten hex nut securely Tighten hex nut securely

against load. against load. One eye bolt diameter or less

Operating Safety

• Always stand clear of load. • Never exceed the capacity of the eye bolt–see Table 1 & 2.

• Always lift load with steady, even pull – do not jerk. • When using lifting slings of two or more legs, make sure

• Always apply load to eye bolt in the plane of the eye – not the loads in the legs are calculated using the angle from

at an angle. the vertical sling angle to the leg and properly size the

shoulder nut or machinery eye bolt for the angular load.

Accessories

WRONG After slings have Buckling may

Rigging

Do not reeve slings been properly occur if the

from one eye bolt attached to the eye load is not stiff

to another. This will bolts, apply force enough to resist

alter the load and slowly. Watch the the compressive

load carefully and forces which

angle of loading on Resultant Load be prepared to result from the

the eye bolt.

stop applying force angular loading.

if the load starts

buckling.

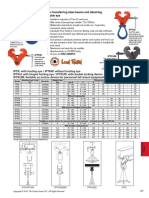

Machinery Eye Bolt - Installation for In-Line & Angular Loading

These eye bolts are primarily intended to be installed into

tapped holes. Table 3

Shim Thickness

1. After the loads on the eye bolts have been calculated, Required to Shim Thickness

select the proper size eye bolt for the job. Eye Bolt Change Rotation Eye Bolt Required to change

Size 90° Size Rotation 90°

For angular lifts, adjust working load as follows: (in.) (in.) (mm) (mm)

1/4 .0125 M6 .25

Direction of Pull Adjusted 5/16 .0139 M8 .31

(from In-Line) Working Load 3/8 .0156 M10 .38

45 degrees 30% of rated working load 1/2 .0192 M12 .44

90 degrees 25% of rated working load 5/8 .0227 M16 .50

3/4 .0250 M20 .62

2. Drill and tap the load to the correct sizes to a minimum 7/8 .0278 M24 .75

depth of one-half the eye bolt size beyond the shank length 1 .0312 M27 .75

of the machinery eye bolt. 1-1/8 .0357 M30 .88

1-1/4 .0357 M36 1.00

3. Thread the eye bolt into the load until the shoulder is flush

1-1/2 .0417 M42 1.13

and securely tightened against the load. 1-3/4 .0500 M48 1.25

4. If the plane of the machinery eye bolt is not aligned with 2 .0556 M64 1.50

the sling line, estimate the amount of unthreading rotation 2-1/2 .0625 — —

necessary to align the plane of the eye properly.

5. Remove the machinery eye bolt from the load and add Shim added to change

eye alignment 90˚.

shims (washers) of proper thickness to adjust the angle

of the plane of the eye to match the sling line. Use Table 3

to estimate the required shim thickness for the amount of

Minimum tap depth is

unthreading rotation required. basic shank length plus

one-half the nominal

eye bolt diameter.

Copyright © 2017 The Crosby Group LLC All Rights Reserved 201

You might also like

- Eye Bolts: Forged Eye Bolt Warning and Application InstructionsDocument5 pagesEye Bolts: Forged Eye Bolt Warning and Application InstructionsshamanthupadhyayaNo ratings yet

- Important Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings & Application InstructionsDocument1 pageImportant Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings & Application InstructionsKonstantinos SynodinosNo ratings yet

- Important Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings and Application InstructionsDocument2 pagesImportant Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings and Application InstructionsiLLeno 23No ratings yet

- Crosby Thimble Eye Bundle Clips Warning & Application InstructionsDocument1 pageCrosby Thimble Eye Bundle Clips Warning & Application InstructionsMareg Engenharia de SegurançaNo ratings yet

- Sulaiman SWMS RA - Rope Replacement - EL-1123Document5 pagesSulaiman SWMS RA - Rope Replacement - EL-1123ChaimaNo ratings yet

- Eye BoltsDocument5 pagesEye Boltsazteca14139445No ratings yet

- Shackle Marking InformationDocument7 pagesShackle Marking Informationmalborn100% (1)

- Engineering Bulletin - EB 99006: Proper Use of Eye Bolts and Hoist RingsDocument2 pagesEngineering Bulletin - EB 99006: Proper Use of Eye Bolts and Hoist RingsJean DuboisNo ratings yet

- Warning Wedge Socket Warnings and Application Instructions: Tail LengthDocument1 pageWarning Wedge Socket Warnings and Application Instructions: Tail Lengthmanglesh1No ratings yet

- Inspection and Maintenance Guidelines - ShacklesDocument5 pagesInspection and Maintenance Guidelines - ShacklesNomer AgcaoiliNo ratings yet

- Warning & Application Instructions Weld-On Pivoting Link Inspection / MaintenanceDocument1 pageWarning & Application Instructions Weld-On Pivoting Link Inspection / MaintenanceAlfonsus W.M.No ratings yet

- Hardlock AplicacionesDocument28 pagesHardlock AplicacionespauldanielmhNo ratings yet

- TSE Installation Manual Rev5Document2 pagesTSE Installation Manual Rev5eyya 007No ratings yet

- TI 07 006 DF AdjustmentDocument12 pagesTI 07 006 DF Adjustmenteko sunaryoNo ratings yet

- Mill Vise: InstructionsDocument1 pageMill Vise: InstructionsJF LuisNo ratings yet

- HLN Applications enDocument27 pagesHLN Applications enClint TcNo ratings yet

- Bearing Mounting Procedure: (Page 1 of 6)Document6 pagesBearing Mounting Procedure: (Page 1 of 6)JoséMiguelSánchezGNo ratings yet

- TVF Tranšėjos Apsaugų Surinkimo Instrukcija ENDocument12 pagesTVF Tranšėjos Apsaugų Surinkimo Instrukcija ENemat41No ratings yet

- Baby Jogger City Mini Stroller AssemblyDocument9 pagesBaby Jogger City Mini Stroller AssemblyTomNo ratings yet

- Ops-Core Step-In Visor User ManualDocument16 pagesOps-Core Step-In Visor User ManualJg GatdulaNo ratings yet

- Ballistic Pendulum 11229-00Document6 pagesBallistic Pendulum 11229-00oğuz hamurculuNo ratings yet

- Capocorda Crosby S-241Document1 pageCapocorda Crosby S-241cerfabioNo ratings yet

- Installation and Arrangement of Universal DrivelinesDocument4 pagesInstallation and Arrangement of Universal DrivelinesSrecko PantovicNo ratings yet

- Turbuckle InstallationDocument10 pagesTurbuckle Installationmoch ganafiaNo ratings yet

- Rigging GuidelinesDocument14 pagesRigging GuidelinesMalik AtikNo ratings yet

- Respectively .: SN Component Mode of FailureDocument1 pageRespectively .: SN Component Mode of FailureRamesh BammankattiNo ratings yet

- Instruction Manual For DODGE Setscrew, Eccentric Collar, D-Lok, H-E Series, E-Z Kleen, Ultra Kleen and Food Safe Mounted Ball BearingsDocument2 pagesInstruction Manual For DODGE Setscrew, Eccentric Collar, D-Lok, H-E Series, E-Z Kleen, Ultra Kleen and Food Safe Mounted Ball BearingsRichard VachonNo ratings yet

- Instructions TG8025 TG8030 TG8040Document1 pageInstructions TG8025 TG8030 TG8040KamKabNo ratings yet

- Pre-Starting Checks: Avertissement DangerDocument2 pagesPre-Starting Checks: Avertissement DangerAquino ArviNo ratings yet

- 600 Series Roller Bearings - Installation Manual - VNwhI8sDocument3 pages600 Series Roller Bearings - Installation Manual - VNwhI8skominthitsar7474No ratings yet

- RefrigeraçãoDocument6 pagesRefrigeraçãoozeas Vilela de moraisNo ratings yet

- Full Circle Releasing Spears: Instruction Manual 2100Document16 pagesFull Circle Releasing Spears: Instruction Manual 2100Rares PetreNo ratings yet

- Manual AimpointDocument2 pagesManual AimpointMogos RobertNo ratings yet

- CNC Milling: 1, Setting The ViceDocument9 pagesCNC Milling: 1, Setting The ViceGundhi AsmoroNo ratings yet

- Crosby - Hoist RingDocument3 pagesCrosby - Hoist RingYADAGIRI REDDYNo ratings yet

- Warning: Crosby Swivel Hoist Ring Warning and Application InstructionsDocument3 pagesWarning: Crosby Swivel Hoist Ring Warning and Application InstructionsGianluca PiccinettiNo ratings yet

- Wave Springs CC2015Document32 pagesWave Springs CC2015Burak YılmazNo ratings yet

- (Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 120 129Document10 pages(Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 120 129Khaled RaafatNo ratings yet

- HLN Technical-Data enDocument24 pagesHLN Technical-Data enJayden BarnesNo ratings yet

- Wedge Socket Warning and Application InstructionsDocument1 pageWedge Socket Warning and Application InstructionsMinhKhuongHieuNo ratings yet

- Instructions For The Safe Use Of: Eyebolts: The Information in This Leaflet Should Be Passed To The User of The EquipmentDocument2 pagesInstructions For The Safe Use Of: Eyebolts: The Information in This Leaflet Should Be Passed To The User of The EquipmentMontadhar SaeedNo ratings yet

- Engineer The Lift!!: Applied Load Changes With Sling AngleDocument1 pageEngineer The Lift!!: Applied Load Changes With Sling AngleMohd FadliNo ratings yet

- Suspension 250XDocument7 pagesSuspension 250XErick EspinozaNo ratings yet

- Crosby Model Pl-N/O Hook Latch Kit: Warning Warnings and Application InstructionsDocument1 pageCrosby Model Pl-N/O Hook Latch Kit: Warning Warnings and Application InstructionsMareg Engenharia de SegurançaNo ratings yet

- Double E - Safety ChucksDocument6 pagesDouble E - Safety ChucksYanci JhoeNo ratings yet

- Safe Use of Eyeblts Dlhonline PDFDocument2 pagesSafe Use of Eyeblts Dlhonline PDFMoetaz MohamedNo ratings yet

- 3 (1) Leea Advice On Eyebolts PDFDocument2 pages3 (1) Leea Advice On Eyebolts PDFReda MashalNo ratings yet

- Grab For Angular Concrete Products WEZ: Site EquipmentDocument1 pageGrab For Angular Concrete Products WEZ: Site EquipmentMoldovan RoxanaNo ratings yet

- Quantel Optimis II Service Manual 51 60Document10 pagesQuantel Optimis II Service Manual 51 60Vladimir LevchenkoNo ratings yet

- 7400 Cem40 QSGDocument6 pages7400 Cem40 QSGsudhangshu_ghoseNo ratings yet

- Phorovist 200 Instruction Manual ENDocument28 pagesPhorovist 200 Instruction Manual ENTerrence JonesNo ratings yet

- Dial Indicators and Digital Indicators: Mounting A Dial IndicatorDocument1 pageDial Indicators and Digital Indicators: Mounting A Dial IndicatorozanNo ratings yet

- Adjustment Instructions: FunctionDocument4 pagesAdjustment Instructions: FunctionMohammedasifNo ratings yet

- MX Trax 5018 Owners ManualDocument9 pagesMX Trax 5018 Owners ManualSebastian CirnealaNo ratings yet

- Control Buttons Notes: Adjustment NutDocument2 pagesControl Buttons Notes: Adjustment Nutluca ardenziNo ratings yet

- Kalmar DRF 450 SuspensionDocument20 pagesKalmar DRF 450 Suspensiontuấn anh nguyễnNo ratings yet

- Austlift Catalogue EYE BOLTDocument10 pagesAustlift Catalogue EYE BOLTdoshi78No ratings yet

- Bolt Tensioning - E411 - GB PDFDocument2 pagesBolt Tensioning - E411 - GB PDF4jawwy markme026No ratings yet

- Synodinos Wire Rope SlingsDocument1 pageSynodinos Wire Rope SlingsKonstantinos SynodinosNo ratings yet

- Pewag Anchorage Points - Fall ProtectionDocument6 pagesPewag Anchorage Points - Fall ProtectionKonstantinos SynodinosNo ratings yet

- 26mm 8xK26 CertificateDocument2 pages26mm 8xK26 CertificateKonstantinos Synodinos100% (1)

- Crosby McKissick Snatch BLocks 2t To12tDocument1 pageCrosby McKissick Snatch BLocks 2t To12tKonstantinos SynodinosNo ratings yet

- Crosby Instructions Chain Slings 1Document1 pageCrosby Instructions Chain Slings 1Konstantinos SynodinosNo ratings yet

- Closed Spelter SocketsDocument2 pagesClosed Spelter SocketsKonstantinos SynodinosNo ratings yet

- Dyform 8 PI: High Performance Crane Ropes BenefitsDocument2 pagesDyform 8 PI: High Performance Crane Ropes BenefitsKonstantinos SynodinosNo ratings yet

- For Transferring Steel Beams and Attaching Tackle Eye: IptkuDocument1 pageFor Transferring Steel Beams and Attaching Tackle Eye: IptkuKonstantinos SynodinosNo ratings yet

- Crosby Grade 100 SHUR-LOC Handle Hooks: Shur-Loc Handle Swivel Hook With Bearing Shur-Loc Handle Eye HookDocument1 pageCrosby Grade 100 SHUR-LOC Handle Hooks: Shur-Loc Handle Swivel Hook With Bearing Shur-Loc Handle Eye HookKonstantinos SynodinosNo ratings yet

- Threaded Rod M33 (3.5) 10.9Document4 pagesThreaded Rod M33 (3.5) 10.9Konstantinos SynodinosNo ratings yet

- Horizontal Clamps Horizontal Clamps: For Horizontal Lift and Transfer With Pretension SystemDocument1 pageHorizontal Clamps Horizontal Clamps: For Horizontal Lift and Transfer With Pretension SystemKonstantinos SynodinosNo ratings yet

- Ropeblock - Snatch Blocks S Series With Hook - MetricDocument1 pageRopeblock - Snatch Blocks S Series With Hook - MetricKonstantinos SynodinosNo ratings yet

- G-209 / S-209 Screw Pin Anchor ShacklesDocument1 pageG-209 / S-209 Screw Pin Anchor Shacklesaizzi1989No ratings yet

- Pewag SVW - SVSW - SvsuwDocument1 pagePewag SVW - SVSW - SvsuwKonstantinos SynodinosNo ratings yet

- Crosby Grade 100 Clevis Sling Hooks: J AA R LDocument1 pageCrosby Grade 100 Clevis Sling Hooks: J AA R LKonstantinos SynodinosNo ratings yet

- 05 Snatch Block (Ts150)Document1 page05 Snatch Block (Ts150)Konstantinos SynodinosNo ratings yet

- All Breaking Loads Are in Metric Tonnes. To Maximize The Benefits of The Improved Strength of The Chain, Only Use Compatible Trawlex FittingsDocument1 pageAll Breaking Loads Are in Metric Tonnes. To Maximize The Benefits of The Improved Strength of The Chain, Only Use Compatible Trawlex FittingsKonstantinos SynodinosNo ratings yet

- To Remove Lifting Point: Table 1 Working Load Limit 4:1 (T) UNC Bolt Size (In.) Effective Thread Projection Length (In.)Document1 pageTo Remove Lifting Point: Table 1 Working Load Limit 4:1 (T) UNC Bolt Size (In.) Effective Thread Projection Length (In.)Konstantinos SynodinosNo ratings yet

- Diepa X53 K: Ordinary Lay Non-Rotation Resistant Wire RopeDocument1 pageDiepa X53 K: Ordinary Lay Non-Rotation Resistant Wire RopeKonstantinos SynodinosNo ratings yet

- Crosby Slide-Loc Lifting Point: Warnings & Application Instructions WarningDocument1 pageCrosby Slide-Loc Lifting Point: Warnings & Application Instructions WarningKonstantinos SynodinosNo ratings yet

- Crosby Grade 100 Foundry Hooks: A-1359 Clevis Foundry HookDocument1 pageCrosby Grade 100 Foundry Hooks: A-1359 Clevis Foundry HookKonstantinos SynodinosNo ratings yet

- Product Sheet HDTP 13.03.2019Document1 pageProduct Sheet HDTP 13.03.2019Konstantinos SynodinosNo ratings yet

- Western Manila Rope Blocks Western Standard Steel BlocksDocument1 pageWestern Manila Rope Blocks Western Standard Steel BlocksKonstantinos SynodinosNo ratings yet

- Western Manila Rope Blocks Western Standard Steel BlocksDocument1 pageWestern Manila Rope Blocks Western Standard Steel BlocksKonstantinos SynodinosNo ratings yet

- Product Sheet HDTP 13.03.2019Document1 pageProduct Sheet HDTP 13.03.2019Konstantinos SynodinosNo ratings yet

- Type H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestDocument2 pagesType H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestKonstantinos SynodinosNo ratings yet

- Type H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestDocument2 pagesType H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestKonstantinos SynodinosNo ratings yet

- HG 226Document1 pageHG 226Konstantinos SynodinosNo ratings yet

- Hexagon Fits Bolts With Long Thread DIN 609: DescriptionDocument2 pagesHexagon Fits Bolts With Long Thread DIN 609: DescriptionVasant bhoknalNo ratings yet

- Action Impact Sockets en PDFDocument46 pagesAction Impact Sockets en PDFRichkyIrawanNo ratings yet

- Round Bend U-Bolts: 8%Row6Shflàfdwlrqv U-Bolts & 2 Nuts U-Bolts, Plates & 2 NutsDocument5 pagesRound Bend U-Bolts: 8%Row6Shflàfdwlrqv U-Bolts & 2 Nuts U-Bolts, Plates & 2 NutsRaging Red HippoNo ratings yet

- M Etric Threads: Max L Product InternaDocument2 pagesM Etric Threads: Max L Product InternajimboNo ratings yet

- Dash SizingDocument2 pagesDash SizingPraveen KumarNo ratings yet

- Ballscrew Product SpecificationsDocument30 pagesBallscrew Product SpecificationsrogeriofcrealNo ratings yet

- b1 20 1Document31 pagesb1 20 1Gustavo FamaNo ratings yet

- 24 U Bone Screw Management PDFDocument28 pages24 U Bone Screw Management PDFEduardo BernardinoNo ratings yet

- Ansi Screw Clearance HolesDocument1 pageAnsi Screw Clearance HoleswilliaqNo ratings yet

- Threaded Rod ManufacturersDocument1 pageThreaded Rod ManufacturersBd WireNo ratings yet

- Winner Hydraulics - Price List: Index and Part Number Interchange ListDocument23 pagesWinner Hydraulics - Price List: Index and Part Number Interchange ListSHANENo ratings yet

- Is 5624Document9 pagesIs 5624jselwyn1980No ratings yet

- Longxing CatálogoDocument36 pagesLongxing CatálogoFabián Armijos100% (1)

- Tabella 6÷17B Asme B1.1 2003Document15 pagesTabella 6÷17B Asme B1.1 2003Ru MonNo ratings yet

- Ab at InventoryDocument32 pagesAb at InventoryecirecirNo ratings yet

- A PresentationDocument57 pagesA Presentationmadan023No ratings yet

- VW 60432Document10 pagesVW 60432Israel FidelesNo ratings yet

- 1963 Supplement To Screw-Thread Standards For Federal Services Parts I, II, & IIIDocument132 pages1963 Supplement To Screw-Thread Standards For Federal Services Parts I, II, & IIIBigboydNo ratings yet

- Bhel Po ListDocument2 pagesBhel Po ListaamanwatkarNo ratings yet

- Essential Home Gym: Assembly ManualDocument8 pagesEssential Home Gym: Assembly ManualJuan Casado LlanezaNo ratings yet

- Single Bolt Capacity To EN 1993-1-8: Bolts Diameters, Hole Sizes and AreasDocument17 pagesSingle Bolt Capacity To EN 1993-1-8: Bolts Diameters, Hole Sizes and AreasabhijitNo ratings yet

- Pumpen Einbau Pump Installation 99707781757 From No / Up To NoDocument2 pagesPumpen Einbau Pump Installation 99707781757 From No / Up To NoweldsaidiNo ratings yet

- Bracket Assy CP - Ph2Document3 pagesBracket Assy CP - Ph2cristian nahuelcuraNo ratings yet

- Nominal Dimension: 18,28 18,25 General Notes When Not SpecifiedDocument1 pageNominal Dimension: 18,28 18,25 General Notes When Not SpecifiedDaniele Fazio MusicNo ratings yet

- Thread Chart PDFDocument9 pagesThread Chart PDFKathirrasu100% (1)

- Asme B18.16.6Document1 pageAsme B18.16.6Mario FonsecaNo ratings yet

- Uscts08 320Document1 pageUscts08 320Srinivasan RadhaNo ratings yet

- Despiece FI 30Document51 pagesDespiece FI 30juandesevillaNo ratings yet

- Thread Pitch ChartDocument2 pagesThread Pitch ChartChoon Wei WongNo ratings yet

- Bolt Depot - Pilot Hole Sizes For Wood ScrewsDocument2 pagesBolt Depot - Pilot Hole Sizes For Wood ScrewsarqmemofirsNo ratings yet