0% found this document useful (0 votes)

218 views9 pagesCNC Milling: 1, Setting The Vice

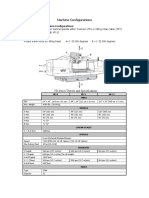

The document provides instructions for properly setting a vice on a CNC milling machine. It involves the following key steps:

1. Thoroughly clean the milling machine bed and vice to remove debris.

2. Use a parallel in the T-slot to initially align the vice. Then loosely clamp the vice and use a dial indicator to precisely clock the vice.

3. Tighten the vice clamps in a specific order to reduce distortion, and check the clocking again once tightened.

Uploaded by

Gundhi AsmoroCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

218 views9 pagesCNC Milling: 1, Setting The Vice

The document provides instructions for properly setting a vice on a CNC milling machine. It involves the following key steps:

1. Thoroughly clean the milling machine bed and vice to remove debris.

2. Use a parallel in the T-slot to initially align the vice. Then loosely clamp the vice and use a dial indicator to precisely clock the vice.

3. Tighten the vice clamps in a specific order to reduce distortion, and check the clocking again once tightened.

Uploaded by

Gundhi AsmoroCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd