Professional Documents

Culture Documents

Mill Vise: Instructions

Uploaded by

JF LuisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mill Vise: Instructions

Uploaded by

JF LuisCopyright:

Available Formats

WEAR YOUR

SAFETY GLASSES

FORESIGHT IS BETTER

THAN NO SIGHT

READ INSTRUCTIONS

BEFORE OPERATING

Mill Vise

P/N 3551

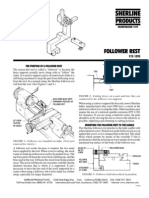

F1 NOTE: It is important to use the correct 5/8"

F2 long cap screw in the angle clamps. A shorter

screw will not engage enough threads in the

T-nut and a longer screw will damage the

Figure 1— F3 bottom of the table T-slots.

Pull-Down Feature

7 11

Adjustment Range:

Approximate Adjustment Slots 46° to 60° 6

Instructions 2

The advantages of this vise are obvious when

movement of the jaw is studied. (See Figure 10

1 and look at the bottom of your vise.) The 4

tightening force (F1) produces not only a force 3

against the part (F2), but also a force pulling

the jaw downward (F3). Therefore, angle “A” 9

must exceed 45° in order to make force F3

greater than F2. This keeps the movable jaw

8

from “tipping” back. Also note that extreme 1

clamping angles beyond 60° start to apply much Wrong

downward pressure but not much horizontal

force is directed to holding the part. Moving Right

10

the pull-down barrel to the proper slot keeps

the adjustment within the most effective

clamping range. Figure 2—

To clamp a part, place the jaw in approximate Holding A

5

position and start tightening the adjustment Work Piece

screw at an angle of 45° or greater. (The back face of the

movable jaw is machined at a 45° angle for reference.) If

the angle of the adjustment screw gets up to 60° or greater

Spacer

and you still haven't drawn down on the part, loosen up the

screw a little and move the pull-down barrel to the next Parts List

slot and retighten.

REF. NO. PART DESCRIPTION

Figure 2 shows the proper way to hold a part in the vise NO. REQ. NO.

(shown in black). If the part cannot be centered, use a

spacer to help keep the jaws parallel. This vise has been 1 1 35100 Vise body

designed to accurately hold objects being machined. It is 2 1 35020 Movable jaw

not recommended for use as a bench vise or for clamping 3 1 35030 Fixed jaw insert

parts in such a way and with such force as to adversely 4 1 35040 Movable jaw insert

affect its accuracy. 5 1 35120 Pull-down member

6 1 35060 Convex washer

Thank you, 7 2 35070 Flat head screw, 6-32 x 3/8" (2)

Sherline Products Inc. 8 2 30561 T-nut, 10-32 (2)

9 2 35580 Hold-down clamp (2)

NOTE: To keep the surface of your table from being marred, we recommend you take a 10 4 40330 SHC Screw, 10-32 x 5/8" (4)

file and slightly soften or deburr all the edges of the angle clamps that contact the table.

11 1 35130 SHC Screw, 10-32 x 1-5/8"

SHERLINE PRODUCTS INC. • 3235 Executive Ridge • Vista • California 92081-8527 • FAX: (760) 727-7857 7/26/17

Toll Free Order Line: (800) 541-0735 • International/Local/Tech. Assistance: (760) 727-5857 • Internet: www.sherline.com

You might also like

- Rodeo PDFDocument2,613 pagesRodeo PDFluigimasterNo ratings yet

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- Hino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine PartsDocument3 pagesHino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Partszakki ahmadNo ratings yet

- Pinout Ford Explorer 96Document7 pagesPinout Ford Explorer 96lervinjc100% (1)

- Hino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Parts, PDFDocument3 pagesHino J08C Engine Valve Adjustment Procedure, Valve Lash Clearance Specifications, Hino J08C Engine Parts, PDFArnold Mhlanga50% (2)

- AT520JK Users ManualDocument15 pagesAT520JK Users ManualgerezairNo ratings yet

- Singer U64A & U14B Overlock Service ManualDocument8 pagesSinger U64A & U14B Overlock Service ManualGinny Ross50% (2)

- Rotary BroachDocument2 pagesRotary BroachpeterNo ratings yet

- Shimano Nexus3 178 ManualDocument12 pagesShimano Nexus3 178 Manualgrazka20No ratings yet

- TL 02006 Z Q Head ManualDocument9 pagesTL 02006 Z Q Head ManualMagno AguiarNo ratings yet

- Electrical DictionaryDocument91 pagesElectrical DictionaryQudratullah EhsanNo ratings yet

- Bg101 User Manual1Document22 pagesBg101 User Manual1MikeNo ratings yet

- S791 M-38 6R5111121 Steering Gear PDFDocument173 pagesS791 M-38 6R5111121 Steering Gear PDFAndres Winchester MartinezNo ratings yet

- Dfs-230 Assault GliderDocument1 pageDfs-230 Assault GliderCARMEN JUANA CRUZ CONDEMAITANo ratings yet

- Dayton Arbor Presses Owners ManualDocument8 pagesDayton Arbor Presses Owners ManualBryan AceroNo ratings yet

- Starting Method of MotorsDocument9 pagesStarting Method of MotorsRanil FernandoNo ratings yet

- Testing and Commissioning of Current TransformerDocument16 pagesTesting and Commissioning of Current TransformerAdeel Zafar100% (1)

- Power Train Lh410Document96 pagesPower Train Lh410Karthii AjuNo ratings yet

- Wire Rope Discard CriteriaDocument14 pagesWire Rope Discard CriteriaDhanraj Patil100% (1)

- SSP403 2.0 TDI Engine With Common Rail PDFDocument68 pagesSSP403 2.0 TDI Engine With Common Rail PDFChengdong WuNo ratings yet

- Scheme Electrice VW Golf 4 2000Document57 pagesScheme Electrice VW Golf 4 2000flomar430100% (11)

- Parts Manual Keeway Fact 50 2tDocument61 pagesParts Manual Keeway Fact 50 2tSimon Albert100% (1)

- Kalmar DRF 450 SuspensionDocument20 pagesKalmar DRF 450 Suspensiontuấn anh nguyễnNo ratings yet

- Universal Auto Feed Reel Easy String Head: WarningDocument6 pagesUniversal Auto Feed Reel Easy String Head: WarningElena CMNo ratings yet

- Fast & Fluid Management: Punch Installation Manual HA480/HA680Document8 pagesFast & Fluid Management: Punch Installation Manual HA480/HA680Ray PutraNo ratings yet

- This Manual Should Only Be Used For Elite 3.5-21x50 & 4.5-30x50 Tactical Riflescopes With These Reticle DesignsDocument32 pagesThis Manual Should Only Be Used For Elite 3.5-21x50 & 4.5-30x50 Tactical Riflescopes With These Reticle DesignsEph EweNo ratings yet

- DELTA-P-VALVE MEP-4802-DPV - DatasheetDocument4 pagesDELTA-P-VALVE MEP-4802-DPV - Datasheetboukhalfa.oman.muscatNo ratings yet

- TSR-009 - EngDocument7 pagesTSR-009 - EngA2139No ratings yet

- DX 195 Servicing Checks: EnglishDocument2 pagesDX 195 Servicing Checks: EnglishВЛАДИМИРNo ratings yet

- MN4027 PDFDocument4 pagesMN4027 PDFAntonio Juan AntonioNo ratings yet

- 604 605 610 611 612 InstructionsDocument1 page604 605 610 611 612 InstructionsTaller PahrNo ratings yet

- Bearing Mounting Procedure: (Page 1 of 6)Document6 pagesBearing Mounting Procedure: (Page 1 of 6)JoséMiguelSánchezGNo ratings yet

- Luneta PrzesuwnaDocument3 pagesLuneta PrzesuwnaquarkqqNo ratings yet

- Manual Pulidora1Document34 pagesManual Pulidora1Warner BenavidesNo ratings yet

- Professional Series: PGP Installation: Arc Adjustments: Nozzle InstallationDocument2 pagesProfessional Series: PGP Installation: Arc Adjustments: Nozzle InstallationDaus AlexandruNo ratings yet

- Manual Qs Rc5Document1 pageManual Qs Rc5Director Tecnico AdministrativoNo ratings yet

- AllignmentDocument2 pagesAllignmentVishnu Vardhan . CNo ratings yet

- Avim101 PDFDocument2 pagesAvim101 PDFMahendra SinghNo ratings yet

- Installation and Arrangement of Universal DrivelinesDocument4 pagesInstallation and Arrangement of Universal DrivelinesSrecko PantovicNo ratings yet

- BR3 002 ManualDocument10 pagesBR3 002 ManualEric LempkeNo ratings yet

- Section: Illustrated Sourcebook Mechanical ComponentsDocument22 pagesSection: Illustrated Sourcebook Mechanical ComponentsscubazNo ratings yet

- TI 07 006 DF AdjustmentDocument12 pagesTI 07 006 DF Adjustmenteko sunaryoNo ratings yet

- SD91 MG Manual enDocument1 pageSD91 MG Manual enAimielNo ratings yet

- Crosman 1077 Series Manual EN ES-minDocument2 pagesCrosman 1077 Series Manual EN ES-minPiluni MehakNo ratings yet

- Freno Warner 1Document4 pagesFreno Warner 1javier castilloNo ratings yet

- TSE Installation Manual Rev5Document2 pagesTSE Installation Manual Rev5eyya 007No ratings yet

- Ballistic Pendulum 11229-00Document6 pagesBallistic Pendulum 11229-00oğuz hamurculuNo ratings yet

- Safetyjoint PDFDocument1 pageSafetyjoint PDFYves-donald MakoumbouNo ratings yet

- Table Saw: Assembly ManualDocument10 pagesTable Saw: Assembly Manualkimba worthNo ratings yet

- GBC USP13 ManualDocument17 pagesGBC USP13 ManualAlvaroSNo ratings yet

- Owner'S Manual 16" Stand Fan Model: SF-16T07: Read and Save These InstructionsDocument6 pagesOwner'S Manual 16" Stand Fan Model: SF-16T07: Read and Save These InstructionsKeziah SantosNo ratings yet

- Type CMR, Instalacion.Document4 pagesType CMR, Instalacion.Mario MarquezNo ratings yet

- Installation and Arrangement of Universal DrivelinesDocument6 pagesInstallation and Arrangement of Universal DrivelinesPrateek KesarwaniNo ratings yet

- Pre-Starting Checks: Avertissement DangerDocument2 pagesPre-Starting Checks: Avertissement DangerAquino ArviNo ratings yet

- Manual - Rotary 3 Speed HubsDocument2 pagesManual - Rotary 3 Speed Hubsbostin011No ratings yet

- 999-998-423 - 425 InstructionsDocument4 pages999-998-423 - 425 InstructionsKimba WorthNo ratings yet

- J Max User Manual 20210819Document1 pageJ Max User Manual 20210819pd4h8ggmh9No ratings yet

- Data Sheet Gh505 Cutler HammerDocument4 pagesData Sheet Gh505 Cutler HammerMauro MiguelNo ratings yet

- Brunton Axis Transit Instruction Manual: Every Angle, Every DirectionDocument16 pagesBrunton Axis Transit Instruction Manual: Every Angle, Every DirectionEdilberNo ratings yet

- 600 Series Roller Bearings - Installation Manual - VNwhI8sDocument3 pages600 Series Roller Bearings - Installation Manual - VNwhI8skominthitsar7474No ratings yet

- Instruction Sheet: Flexwell Waveguide Flaring and Connector AssemblyDocument2 pagesInstruction Sheet: Flexwell Waveguide Flaring and Connector AssemblysamiNo ratings yet

- Anexo 03 Instructivo Instalación Herraje de Suspensión OPGW - ADSSDocument4 pagesAnexo 03 Instructivo Instalación Herraje de Suspensión OPGW - ADSSDidier solanoNo ratings yet

- Important - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingDocument1 pageImportant - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingKonstantinos SynodinosNo ratings yet

- FSA bb30Document3 pagesFSA bb30odeiviNo ratings yet

- Magazine: 1-1 Chute GuideDocument5 pagesMagazine: 1-1 Chute GuideMd. Hanif SanketNo ratings yet

- Notice HK1820Document32 pagesNotice HK1820Keys SyekNo ratings yet

- Safety Precautions: Assembling The CraneDocument1 pageSafety Precautions: Assembling The CraneNotnow CalmNo ratings yet

- Chum Saf-Xt ManualDocument8 pagesChum Saf-Xt Manualingrojas_No ratings yet

- 428 - 20191202121748 - Singer Stitch Sew Quick User ManualDocument3 pages428 - 20191202121748 - Singer Stitch Sew Quick User ManualVlade NaumovskiNo ratings yet

- The Hanau Spring-Bow Hanau Spring-Bow L'arc Facial Flexible de Marque Hanau L'arco-Spring Hanau Arco A Resorte Spring-Bow de HanauDocument52 pagesThe Hanau Spring-Bow Hanau Spring-Bow L'arc Facial Flexible de Marque Hanau L'arco-Spring Hanau Arco A Resorte Spring-Bow de HanauVivek ShankarNo ratings yet

- 1620F End Mill Louis Belet Cutting Tools Watchmaking Jura Swiss Vendlincourt ENDocument1 page1620F End Mill Louis Belet Cutting Tools Watchmaking Jura Swiss Vendlincourt ENJF LuisNo ratings yet

- TittleDocument1 pageTittleJF LuisNo ratings yet

- FC262 Need WantDocument2 pagesFC262 Need WantJF LuisNo ratings yet

- Making Minature ChainDocument5 pagesMaking Minature ChainJF LuisNo ratings yet

- Liposomal Sulforaphane: Supplement FactsDocument1 pageLiposomal Sulforaphane: Supplement FactsJF LuisNo ratings yet

- 4 HydraulicsDocument51 pages4 Hydraulicsalexis aguirre espejoNo ratings yet

- Pump Unit KFA en KFAS EngDocument45 pagesPump Unit KFA en KFAS EngkujkojaNo ratings yet

- (TDB) 2021 Fan Coil Unit For Europe (Water, 50Hz) - Ver.1.1 - 211116Document34 pages(TDB) 2021 Fan Coil Unit For Europe (Water, 50Hz) - Ver.1.1 - 211116LNo ratings yet

- Europa Operators Handbook English (Olympus Euro 6)Document80 pagesEuropa Operators Handbook English (Olympus Euro 6)Przemysław PastuchaNo ratings yet

- Airflow Meters Measure The Amount of Air Going Into The Engine This Is Used by The Ecu To Control The Amount of Fuel Used by The EngineDocument30 pagesAirflow Meters Measure The Amount of Air Going Into The Engine This Is Used by The Ecu To Control The Amount of Fuel Used by The EngineJohn Gary WalfordNo ratings yet

- Siemens Containerized SubstationDocument10 pagesSiemens Containerized SubstationMaithunNo ratings yet

- MCT68ME Installation Manual: Roger Access Control SystemDocument2 pagesMCT68ME Installation Manual: Roger Access Control SystemMarkoNo ratings yet

- 3054 Finding Top Center Position For No. 1 PistonDocument15 pages3054 Finding Top Center Position For No. 1 Pistonhenry lavieraNo ratings yet

- Experiment - 1: Aim: Apparatus: Components: TheoryDocument8 pagesExperiment - 1: Aim: Apparatus: Components: TheoryDeepmalaNo ratings yet

- Lot Id Lot Number Package Device Group Cust Device Cust Id Wafer Size Orientation QtyDocument10 pagesLot Id Lot Number Package Device Group Cust Device Cust Id Wafer Size Orientation QtyamirulamirNo ratings yet

- SRX712M: 12" Two-Way Stage Monitor/ Utility SpeakerDocument2 pagesSRX712M: 12" Two-Way Stage Monitor/ Utility SpeakerRafael Tinajero RaflesNo ratings yet

- Dragonfly Express Gettingstarted ManualDocument2 pagesDragonfly Express Gettingstarted ManualjorgeS_No ratings yet

- Minus 1 Bars - Minus 0.1: Nikuni KTM25F & 25N Circuit Diagram 00185Document1 pageMinus 1 Bars - Minus 0.1: Nikuni KTM25F & 25N Circuit Diagram 00185wacsii ccasullaNo ratings yet

- Error en Tarjeta de RedDocument1 pageError en Tarjeta de RedElvira RodNo ratings yet

- Static Transfer Switch Installation PDFDocument69 pagesStatic Transfer Switch Installation PDFemmanuel beckleyNo ratings yet

- #4-c Eliminator AEBDocument7 pages#4-c Eliminator AEBBrandon Manrique GonzalesNo ratings yet

- Chapter 1 DescDocument22 pagesChapter 1 DescshambhoiNo ratings yet

- SP36-M Oa-Presence-Tn - ManualDocument2 pagesSP36-M Oa-Presence-Tn - Manualdavidmontesgarci92No ratings yet