Professional Documents

Culture Documents

DX 195 Servicing Checks: English

Uploaded by

ВЛАДИМИРOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DX 195 Servicing Checks: English

Uploaded by

ВЛАДИМИРCopyright:

Available Formats

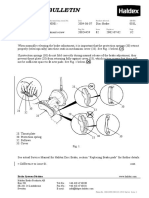

DX 195 Servicing Checks K604

2. INSPECTION OF GUIDE SLEEVE BOOTS

ENGLISH

Refer to the Figs 1 & 2 for inspection of the boots

Introduction Fig 1 Shows a view as seen on the trailer.

The caliper is a very compact unit. When installed on a vehicle it Fig 2 Is a close up of possible boot damage.

is not an easy task to visually inspect it in detail. Because of this

it is recommended that whenever the pads are removed for either

replacement or examination that the following procedure is

carried out.

Procedures to be carried out with the pads removed

1. Verify that the caliper will slide freely on the slide pins.

2. Inspect the slide pin boots for any possible damage.

3. Verification of Correct Operation of the Eccentric Cam.

4. Verify correct operation of the internal automatic adjuster.

1. VERIFICATION OF CORRECT CALIPER SLIDING FIG. 1

WARNING: This operation requires sliding of the caliper. Extreme care

should be taken to avoid trapping fingers.

Using hand force only, carefully slide the caliper fully inboard, (away

from the wheel). Do not actuate the brake caliper using air pressure or

use a lever of any description when performing this procedure. Use

care to avoid pinching fingers.

If the caliper does not slide using reasonable hand force then the

following action is required.

ACTION:

Repair Caliper using the Comprehensive Slide Pin Kit

Order Part Number DSB7 (Quantity 1)

FIG. 2

Shows possible boot damage.

If either of the slide pin boots are damaged.

ACTION:

Repair Caliper using the Comprehensive Slide Pin Kit

Order Part Number DSB7 (Quantity 1)

DX 195 Servicing Checks K604

3. VERIFICATION OF CORRECT OPERATION OF THE 4. VERIFICATION OF THE INTERNAL AUTOMATIC

ECCENTRIC CAM ADJUSTER OPERATION

The following checks need to be carried out with the pads The following checks need to be carried out with the pads

removed. removed.

1. Remove the R clip and clevis pin from the actuator clevis and 1. Remove the adjuster plug.

lever. (See Figure 3)

2. Position a 6mm allen key into the manual adjuster port and leave

in place. (See Figure 4).

FIG. 3

FIG. 4

2. Operate the eccentric shaft lever (by hand) fore and aft, checking

for smooth operation.

3. The function of the automatic adjuster device can now be

NOTE: the eccentric shaft is not spring loaded and will not return

checked using the wrench as an “indicator tool”.

on its own.

4. Operate the lever and eccentric (by hand) and observe the

3. The eccentric shaft should be free and smooth. If the movement

movement of the hexagon wrench.

feels rough or irregular, replace the caliper assembly.

5. The wrench should move when the lever is moved in one

direction and remain stationary when the lever is moved in the

Order Service Caliper: opposite direction.

15224836SR for LEFT Hand Brake 6. Continue with the fore and aft movement of the lever until at least

a full 360º rotation has been achieved by the wrench.

15224837SR for RIGHT Hand Brake

NOTE: During the check, be sure that the wrench does not interfere

with any other brake component as any contact and undue force could

cause damage to the mechanism.

7. If the wrench is not able to complete the full 360º rotation, the

caliper should be replaced.

Order Service Caliper:

15224836SR for LEFT Hand Brake

15224837SR for RIGHT Hand Brake

You might also like

- N7100 Cleaning Consumable Guide CG00002 291401Document20 pagesN7100 Cleaning Consumable Guide CG00002 291401Rafał Krzysztof KowalskiNo ratings yet

- Rear Toe Inspection/Adjustment Turning Angle InspectionDocument1 pageRear Toe Inspection/Adjustment Turning Angle InspectionsoftallNo ratings yet

- Harley-Davidson Custom Hand Lever KitDocument3 pagesHarley-Davidson Custom Hand Lever KitelvisandmickNo ratings yet

- Wheel Alignment and Balancing 2Document57 pagesWheel Alignment and Balancing 2Alan PeterNo ratings yet

- Manual de Instalação WarnerDocument8 pagesManual de Instalação WarnerЭлектроника EletroeletrônicaNo ratings yet

- Counterweight and Roller Removal Inspection and InstallationDocument7 pagesCounterweight and Roller Removal Inspection and InstallationAlma BravoNo ratings yet

- CRV Valve AdjustmentDocument7 pagesCRV Valve AdjustmentJamieNo ratings yet

- Gear Selector Control, Adjustment Volvo TransmissionDocument2 pagesGear Selector Control, Adjustment Volvo TransmissionHamilton MirandaNo ratings yet

- Freno Warner 1Document4 pagesFreno Warner 1javier castilloNo ratings yet

- Ots GRSH 250 00Document6 pagesOts GRSH 250 00ABC - Angela GomezNo ratings yet

- Windshield Wiper and Washer SystemsDocument22 pagesWindshield Wiper and Washer SystemsChristian MartinezNo ratings yet

- LT SK37U 03 Maintenance 37U 5th WheelDocument3 pagesLT SK37U 03 Maintenance 37U 5th WheelFernando Salamanca100% (1)

- 6 SteeringDocument63 pages6 SteeringAdrian MotocNo ratings yet

- DZS Series of Brakes Maintenance Instruction ManualDocument18 pagesDZS Series of Brakes Maintenance Instruction ManualCarlos Prieto100% (1)

- 5G Timing BeltDocument10 pages5G Timing Beltraúl_palomo_10% (1)

- Syncro Trak Service ManualDocument26 pagesSyncro Trak Service ManualMelina SbhNo ratings yet

- 035 - 319 - Technical Manual - Mechanical Units Bar End Commands - Campagnolo - Rev00 - 05 - 15Document6 pages035 - 319 - Technical Manual - Mechanical Units Bar End Commands - Campagnolo - Rev00 - 05 - 15theteamofthedragonflyNo ratings yet

- STC-EOS Samurai Transfer Case Cradle InstallationsDocument25 pagesSTC-EOS Samurai Transfer Case Cradle Installationsfm.gruianuNo ratings yet

- Formulas y Calculos de PerforacionDocument22 pagesFormulas y Calculos de Perforacionjairaso2950No ratings yet

- Full Tilt Feller PDFDocument13 pagesFull Tilt Feller PDFViniciusCamargosNo ratings yet

- Pajero Handbrake AdjustmentDocument1 pagePajero Handbrake AdjustmentNe TwentySixNo ratings yet

- Kalmar DRF 450 SuspensionDocument20 pagesKalmar DRF 450 Suspensiontuấn anh nguyễnNo ratings yet

- UD Ironers: Please Refer To Your Operating Manual For Detailed Maintenance ProceduresDocument13 pagesUD Ironers: Please Refer To Your Operating Manual For Detailed Maintenance Proceduresjhonatan ospina ojedaNo ratings yet

- 11 2E 后悬架Document15 pages11 2E 后悬架Alexander cesar neyra sotoNo ratings yet

- Signal Reverser For Railway SignalingDocument23 pagesSignal Reverser For Railway SignalingVikas Srivastav100% (1)

- Dixon ZTR 428-429 Technical DataDocument10 pagesDixon ZTR 428-429 Technical DatatecsbrainNo ratings yet

- VW, Audi 7-Speed DSG Clutch Installer & Remover: Item Description OEMDocument12 pagesVW, Audi 7-Speed DSG Clutch Installer & Remover: Item Description OEMAnonymous WzR5h9g8VNo ratings yet

- Slide Cam Pulley: Instructions ManualDocument5 pagesSlide Cam Pulley: Instructions Manualhenrysaputra168No ratings yet

- Instruction Manual AK-157Document10 pagesInstruction Manual AK-157Kalim KamNo ratings yet

- MIL ON WITH DTC P0741, P0744, P0746, P0776, P0841, P0965, P2857, P2858, P2859, AND/OR P285A STORED, and May Have Hesitation And/Or Lack of PowerDocument22 pagesMIL ON WITH DTC P0741, P0744, P0746, P0776, P0841, P0965, P2857, P2858, P2859, AND/OR P285A STORED, and May Have Hesitation And/Or Lack of Powerdamian berduscoNo ratings yet

- Service Manual Automatic Slack AdjusterDocument15 pagesService Manual Automatic Slack AdjusterEdho RidhoNo ratings yet

- E-AK200-HDX Rev 03Document82 pagesE-AK200-HDX Rev 03Douglas SilvaNo ratings yet

- Tomei Manual EnglishDocument5 pagesTomei Manual EnglishMuaiyad AL-baluchi100% (1)

- STRiDA Owner's Manual - EnglishDocument30 pagesSTRiDA Owner's Manual - EnglishMalo Malo MaloNo ratings yet

- STRiDA Foldable Bicycles Owner's Manual PDFDocument30 pagesSTRiDA Foldable Bicycles Owner's Manual PDFCharles WestNo ratings yet

- Volvo D12Document5 pagesVolvo D12ANH LÊ0% (1)

- 11 1964 CH-ClutchDocument4 pages11 1964 CH-ClutchJose LaproviteraNo ratings yet

- Ac Motor Repair: N35ZDR, N45ZR (C264) N30ZDR, N35-40ZR (D470) N30ZDRS, N35-40ZRS (A265)Document14 pagesAc Motor Repair: N35ZDR, N45ZR (C264) N30ZDR, N35-40ZR (D470) N30ZDRS, N35-40ZRS (A265)Linde ForkliftNo ratings yet

- MC 10174415 0001 PDFDocument22 pagesMC 10174415 0001 PDFgerbin gaytan riveraNo ratings yet

- CF1711 - Trocador AtcDocument24 pagesCF1711 - Trocador Atcmec04162No ratings yet

- Tilt Steering Column: A: RemovalDocument4 pagesTilt Steering Column: A: RemovalmiguelNo ratings yet

- HR5201CDocument60 pagesHR5201Cjokin mendiolaNo ratings yet

- 3gr-Fse-Em6-Drive BeltDocument3 pages3gr-Fse-Em6-Drive BeltHuỳnh Minh ĐứcNo ratings yet

- 4WNA & 4WFA Winch Operations ManualDocument14 pages4WNA & 4WFA Winch Operations Manualsukri arjunaNo ratings yet

- Multi ToolDocument33 pagesMulti ToolAnonymous 8kyF72100% (2)

- Windshield Wipers and WashersDocument6 pagesWindshield Wipers and WashersPelis CloneNo ratings yet

- Instruction Manual For Multi Head Drilling Machine LZD12-17Document22 pagesInstruction Manual For Multi Head Drilling Machine LZD12-17tommy.noelNo ratings yet

- Mitsubishi LT2-2230 Instruction ManualDocument32 pagesMitsubishi LT2-2230 Instruction ManualCarlos Alonso Alarcón CórdobaNo ratings yet

- MSA5TCD97L3455Document4 pagesMSA5TCD97L3455Mudflap CalizayaNo ratings yet

- En 03-04-1117689 Daily-Check-Logbook TOPlift-L GLOBALlift-R V01R03 De-EnDocument3 pagesEn 03-04-1117689 Daily-Check-Logbook TOPlift-L GLOBALlift-R V01R03 De-EnHABIBINo ratings yet

- Alignment of TwoDocument15 pagesAlignment of TwoquintanacalzadillasjaimeNo ratings yet

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocument10 pagesWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNo ratings yet

- 11 1963 CH-ClutchDocument3 pages11 1963 CH-ClutchJose LaproviteraNo ratings yet

- Yamaha YZFR6X Service Manual 2008 (235-434)Document200 pagesYamaha YZFR6X Service Manual 2008 (235-434)Harold CruzNo ratings yet

- 90 MM 1Document6 pages90 MM 1Pedro PgNo ratings yet

- 453 BicsDocument7 pages453 BicsJesseNo ratings yet

- Ducati - ST4s - Scottoiler Vsystem - English3-9-2014Document1 pageDucati - ST4s - Scottoiler Vsystem - English3-9-2014Simon HesterNo ratings yet

- Tsm00042-Steering Actuator AlignmentDocument5 pagesTsm00042-Steering Actuator AlignmentCristian Elías Cruces CaamañoNo ratings yet

- User's Manual Hydraulic BreakerDocument34 pagesUser's Manual Hydraulic BreakerClaudio VargasNo ratings yet

- Part Number Update: Bendix Tappet Boot Kit UpdateDocument1 pagePart Number Update: Bendix Tappet Boot Kit UpdateВЛАДИМИРNo ratings yet

- SM Db22 Haldex Eng A4Document103 pagesSM Db22 Haldex Eng A4sasa oljacaNo ratings yet

- BW1114 New ADB-0408Document2 pagesBW1114 New ADB-0408ВЛАДИМИРNo ratings yet

- Modulx Service Parts Catalog: Air Disc BrakesDocument12 pagesModulx Service Parts Catalog: Air Disc BrakesВЛАДИМИРNo ratings yet

- HALDEX mk4Document86 pagesHALDEX mk4ВЛАДИМИРNo ratings yet

- Haldex Modul The Disc Brake For Heavy Commercial VehiclesDocument8 pagesHaldex Modul The Disc Brake For Heavy Commercial VehiclesВЛАДИМИРNo ratings yet

- The Brakes Must Be Able To Manage All Possible Situations!Document38 pagesThe Brakes Must Be Able To Manage All Possible Situations!ВЛАДИМИРNo ratings yet

- Haldex Disc Brake DB22 Service Manual: Innovative Vehicle TechnologyDocument93 pagesHaldex Disc Brake DB22 Service Manual: Innovative Vehicle TechnologyВЛАДИМИРNo ratings yet

- CS9i Low Mount Suspension Assembly Parts ListDocument3 pagesCS9i Low Mount Suspension Assembly Parts ListВЛАДИМИРNo ratings yet

- CS9i Top Mount Suspension Assembly Parts ListDocument3 pagesCS9i Top Mount Suspension Assembly Parts ListВЛАДИМИРNo ratings yet

- SM Db22 Haldex Eng A4Document103 pagesSM Db22 Haldex Eng A4sasa oljacaNo ratings yet

- Service Bulletin: Issued by Introduction From Serial No. Date Product AffectedDocument2 pagesService Bulletin: Issued by Introduction From Serial No. Date Product AffectedВЛАДИМИРNo ratings yet

- Volvo RC Caliper Brochure V11 Single Pages 1476178707Document12 pagesVolvo RC Caliper Brochure V11 Single Pages 1476178707ВЛАДИМИРNo ratings yet

- Bepco Lucas BookDocument17 pagesBepco Lucas BookВЛАДИМИРNo ratings yet

- Bepco Lucas BookDocument17 pagesBepco Lucas BookВЛАДИМИРNo ratings yet

- DX175Document84 pagesDX175ВЛАДИМИРNo ratings yet

- Hydraulic Dry Disc Brakes: Parts CatalogDocument16 pagesHydraulic Dry Disc Brakes: Parts CatalogВЛАДИМИРNo ratings yet

- Parts View Parts Kits Bulletin KPS 001 0313 Rev2Document30 pagesParts View Parts Kits Bulletin KPS 001 0313 Rev2ВЛАДИМИРNo ratings yet

- Hydraulic Brake Product Catalog: Distributed byDocument1,533 pagesHydraulic Brake Product Catalog: Distributed byMiroslav MilosevskiNo ratings yet

- Volvo RC Caliper Brochure V11 Single Pages 1476178707Document12 pagesVolvo RC Caliper Brochure V11 Single Pages 1476178707ВЛАДИМИРNo ratings yet

- SAC CAM Drum Brake Service Diagnosis: Manual No. 0359Document38 pagesSAC CAM Drum Brake Service Diagnosis: Manual No. 0359ВЛАДИМИРNo ratings yet

- Wheel Brake Z Cam Rear0Document3 pagesWheel Brake Z Cam Rear0ВЛАДИМИРNo ratings yet

- Z-CAM KatalogDocument9 pagesZ-CAM KatalogВЛАДИМИРNo ratings yet

- Warning: Understanding MGM BrakesDocument8 pagesWarning: Understanding MGM BrakesВЛАДИМИРNo ratings yet

- MC2007 007Document147 pagesMC2007 007ВЛАДИМИРNo ratings yet

- Meritor Inc. Simplex Air Cam Drum Brake: Maintenance Manual No. Mm-0267Document90 pagesMeritor Inc. Simplex Air Cam Drum Brake: Maintenance Manual No. Mm-0267ВЛАДИМИРNo ratings yet

- MC2007 007Document147 pagesMC2007 007ВЛАДИМИРNo ratings yet

- Air Disc Service ChambersDocument2 pagesAir Disc Service ChambersВЛАДИМИРNo ratings yet

- Meritor Continuous Wear Sensors - EN - WebDocument6 pagesMeritor Continuous Wear Sensors - EN - WebВЛАДИМИРNo ratings yet

- British Birds 10 LondDocument376 pagesBritish Birds 10 Londcassy98No ratings yet

- Acute Leukemia The Scientist's Perspective and ChallengeDocument438 pagesAcute Leukemia The Scientist's Perspective and ChallengemedskyqqNo ratings yet

- II. Put The Verbs in The Correct FormsDocument3 pagesII. Put The Verbs in The Correct FormsNguyễn Bích DiệpNo ratings yet

- 506 Koch-Glitsch PDFDocument11 pages506 Koch-Glitsch PDFNoman Abu-FarhaNo ratings yet

- Alem Ketema Proposal NewDocument25 pagesAlem Ketema Proposal NewLeulNo ratings yet

- Invitation of Nomination For The Rajiv Gandhi Wildlife Conservation Award For The Year 2011&2012Document2 pagesInvitation of Nomination For The Rajiv Gandhi Wildlife Conservation Award For The Year 2011&2012Naresh KadyanNo ratings yet

- Daftar Harga Toko Jeremy LengkapDocument2 pagesDaftar Harga Toko Jeremy LengkapSiswadi PaluNo ratings yet

- Eureka Math Grade 2 Module 3 Parent Tip Sheet 1Document2 pagesEureka Math Grade 2 Module 3 Parent Tip Sheet 1api-324573119No ratings yet

- Technical and Business WritingDocument3 pagesTechnical and Business WritingMuhammad FaisalNo ratings yet

- Template Remarks For IIDocument18 pagesTemplate Remarks For IIjasleeneceNo ratings yet

- ABS Electrical System Tiba 2Document8 pagesABS Electrical System Tiba 2ﺍﻟﻄﺎﺋﺮ ﺍﻟﺤﺰﻳﻦNo ratings yet

- Cs Fujitsu SAP Reference Book IPDFDocument63 pagesCs Fujitsu SAP Reference Book IPDFVijay MindfireNo ratings yet

- Manuscript PDFDocument50 pagesManuscript PDFMartina Mae Benig GinoNo ratings yet

- Andromeda: Druid 3 Warborn06Document5 pagesAndromeda: Druid 3 Warborn06AlanNo ratings yet

- What Is An EcosystemDocument42 pagesWhat Is An Ecosystemjoniel05No ratings yet

- Modular ResumeDocument1 pageModular ResumeedisontNo ratings yet

- D15 Hybrid P1 QPDocument6 pagesD15 Hybrid P1 QPShaameswary AnnadoraiNo ratings yet

- Introduction To Pharmacology by ZebDocument31 pagesIntroduction To Pharmacology by ZebSanam MalikNo ratings yet

- Cutler Hammer Dry Type TransformerDocument220 pagesCutler Hammer Dry Type TransformernprajanNo ratings yet

- Practical Applications of Electrical ConductorsDocument12 pagesPractical Applications of Electrical ConductorsHans De Keulenaer100% (5)

- T Rex PumpDocument4 pagesT Rex PumpWong DaNo ratings yet

- Altura Architect & Interior Design BriefDocument56 pagesAltura Architect & Interior Design BriefDave WongNo ratings yet

- 1000 KilosDocument20 pages1000 KilosAbdullah hayreddinNo ratings yet

- Korea Times - Korean-EnglishDocument313 pagesKorea Times - Korean-EnglishgyeryongNo ratings yet

- Things You Can Do at Burnham ParkDocument2 pagesThings You Can Do at Burnham ParkBcpo TeuNo ratings yet

- Snowflake ScarfDocument2 pagesSnowflake ScarfAmalia BratuNo ratings yet

- Corporate Valuation WhartonDocument6 pagesCorporate Valuation Whartonebrahimnejad64No ratings yet

- Advanced Statistical Approaches To Quality: INSE 6220 - Week 4Document44 pagesAdvanced Statistical Approaches To Quality: INSE 6220 - Week 4picalaNo ratings yet

- Chapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsDocument27 pagesChapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsEdwin ChuenNo ratings yet

- Accounting System (Compatibility Mode) PDFDocument10 pagesAccounting System (Compatibility Mode) PDFAftab AlamNo ratings yet