Professional Documents

Culture Documents

Magazine: 1-1 Chute Guide

Uploaded by

Md. Hanif SanketOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magazine: 1-1 Chute Guide

Uploaded by

Md. Hanif SanketCopyright:

Available Formats

Chapter

4Qa Magazine

Introduction

Before adjusting the chute, ensure that the Bal-Con height, the stop position and the peg position have been

correctly adjusted. (Refer to Chapter 4La and 4Na)

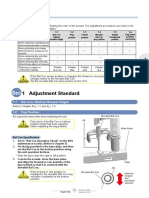

Sec 1 Adjustment Standard

1-1 Chute Guide

After adjusting the peg position, adjust the chute position.

Forward/Rear Direction 1

1. Set to “Chute Position Adjustment Mode” on the VOS maintenance screen. (Refer to Chapter 3 for Sec

further details.)

2. Align the peg with the chute position using the unit operation buttons, and close the chute.

As the magazine rotates simultaneously, be sure to take out the bobbin.

3. Loosen the bolt with a special wrench, and adjust the chute guide unit forward or backwards.

Peg tip

● When using a standard peg

Adjust the peg position so that its tip is at the front Bolt

end of the unit, touching the left and right side of

the chute guide. Chute

guide

Touches here

Special wrench

[Front end of unit] (included)

● When using a large peg (a peg size that

does not fit inside the chute guide)

When looking from the front end of the unit,

adjust the peg so that the tip of the peg is

positioned as shown in the diagram on the right:

A

[A (center of guide’s arc) = B (Contact point on the B Chute

guide arc for the unit’s procedure side)] guide

[Front end of unit]

Right/Left Direction

4. Return the peg to standby mode using the unit operation buttons, and close the chute.

5. When there is no peg, adjust the space between the left and the right chute guide to less than 1

mm using the left and the right bolts.

6. Adjust the chute guide so that the left and right side of the peg tip is even.

Bolt

Chute guide

0 to 1 mm

Peg tip

1 Doc No. P285

Chapter 4Qa Version 130401

Dimensions

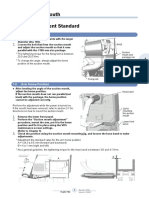

When removing the chute guide such as for maintenance, rotate the eccentric pin to adjust dimension C so that

the tip of the chute guide on the right and left side is even.

● Make sure that the chute is attached to the unit

- Adjust so that dimension C = 9.7 – 11.7 mm.

Eccentric pin 1

Sec

● Make sure that the chute is detached from the unit

- Adjust so that dimension C = 8.2 – 10.2 mm.

* When attached to the unit, the force of gravity will change the dimension to between 9.7 mm and 11.7 mm.

Chute guide

Inner side of the step

Adjust so that the tip of the chute guide on the right and left side is even. If the tip is not

even, it may lead to a chute error.

Make the chute guide even

[Good sample]

[Bad sample]

2 Doc No. P285

Chapter 4Qa Version 130401

Sec 2 Maintenance

2-1 Inspection & Lubrication

Frequency Item Guideline

Clean and lubricate the inside of the base, the lever and the latch slide

Magazine base * Extreme-pressure lithium-based grease with mineral oil and molybdenum

disulfide (wet type)

Yearly

Disassemble and lubricate the inside of the cylinder and packing parts

Magazine cutter * Use a maintenance tool

* Extreme-pressure lithium-based grease with mineral oil, NLGI No.2

Latch Lever Packing Cylinder

1

2

Sec

Slide sections

Inside of magazine base

2-2 Grease Injection into Cutter Cylinder

1. Using the grease gun provided, inject enough Grease gun

grease so that it fills up the front end of the

grease injection hose (length 12 cm).

Grease injection hose

2. Connect the grease filled hose to the air joint

provided.

Grease injection hose

Air joint

3. Pull off the magazine cutter air hose and

attach the air joint from step 2. Then, insert the Grease injection hose Joint for magazine

opposite end of the grease injection hose onto cutter

the joint for the magazine cutter.

* Removing the tensor box makes the lubrication

task easier to perform.

Magazine cutter

4. Turn on the air using the operation check cylinder

mode for the magazine cutter, and inject the

grease. (Refer to Chapter 3 for the check

mode.)

* You can lubricate the eject cutter cylinder following

the same procedure.

Air hose for Eject cutter cylinder

magazine cutter

3 Doc No. P285

Chapter 4Qa Version 120401

2-3 Tightening the Timing Belt

Turn and adjust the motor.

Ensure that the belt is not too slack or too taut. Malfunctions could occur if the tension is

out of the recommended range. (Recommended tension: When the bobbin length is 260

mm or less, the tension should be between 30.2 and 40.6 N. When the bobbin length is 261

mm or greater, the tension should be between 51.2 and 85.8 N)

[Opposite side]

Pull the

motor

bracket

2

Sec

Turn the motor

2-4 Yarn Guide Lever Assembly Method

If the yarn guide lever or the motor is removed, use the jig provided to re-assemble and mount it.

1. Position the unit casing so that it runs parallel to the yarn guide lever, and adjust it so that the gap

(A) between them is 1.5 mm.

2. Insert the jig pin into the lever hole.

3. Insert the jig all the way to the back of the case, and tighten the clamp bolt.

Jig

Runs parallel

A

Unit casing

Lever hole

Clamp bolt

4 Doc No. P285

Chapter 4Qa Version 141101

2-5 Precautions When Mounting the Magazine Cutter

• Apply locking adhesive to the bolt before mounting the cutter.

Since the cutter is ceramic, over-tightening the fixing bolt may cause the cutter to fracture

or break. (The recommended tightening torque is between 0.2 and 0.3 N•m)

• Be sure not to touch the cutter as it can cause injury.

Cutter

2/3

Sec

Bolt

Sec 3 Consumables

If the parts below are worn causing a failure or problem, replace the worn part or parts with a new one.

Bush

Timing belt

Packing

Washer (teflon)

5 Doc No. P285

Chapter 4Qa Version 141103

You might also like

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- 2012513单亮片英文说明书 -Ia User Manual for Sequin DeviceDocument5 pages2012513单亮片英文说明书 -Ia User Manual for Sequin DeviceMohamed NadirNo ratings yet

- CBM820 Service ManualDocument41 pagesCBM820 Service Manualhaithembs2017No ratings yet

- 119118-General 09 Tool GrindersDocument217 pages119118-General 09 Tool GrindersNathan RittenhouseNo ratings yet

- Manual 120726 Imc5050 Carton SealerDocument9 pagesManual 120726 Imc5050 Carton SealerTheodora StefanNo ratings yet

- GB 2-Speed Hammer Drill ManualDocument40 pagesGB 2-Speed Hammer Drill ManualAnonymous lSEnEklZ7No ratings yet

- Er Drilling Machine Operating Procedure Er 022Document4 pagesEr Drilling Machine Operating Procedure Er 022Ak PallNo ratings yet

- Transpol 2Document46 pagesTranspol 2MarcusrezendejuniorNo ratings yet

- Reciprocator Compact Single and MultiheadDocument14 pagesReciprocator Compact Single and MultiheadjoecentroneNo ratings yet

- Owner'S Manual 16" Stand Fan Model: SF-16T07: Read and Save These InstructionsDocument6 pagesOwner'S Manual 16" Stand Fan Model: SF-16T07: Read and Save These InstructionsKeziah SantosNo ratings yet

- Bottom Bracket Replacement - TDCMDocument16 pagesBottom Bracket Replacement - TDCMDenza_666No ratings yet

- DODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualDocument4 pagesDODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualALFONSO FERNANDEZ MULETNo ratings yet

- Universal Tool and Cutter Grinder Manual Low ResDocument16 pagesUniversal Tool and Cutter Grinder Manual Low ResDale Wade100% (1)

- Dive Scubapro D400 Maintenance ProcedureDocument5 pagesDive Scubapro D400 Maintenance ProceduremanonpomNo ratings yet

- Slide Cam Pulley: Instructions ManualDocument5 pagesSlide Cam Pulley: Instructions Manualhenrysaputra168No ratings yet

- Chum Saf-Xt ManualDocument8 pagesChum Saf-Xt Manualingrojas_No ratings yet

- AT520JK Users ManualDocument15 pagesAT520JK Users ManualgerezairNo ratings yet

- Manual XQ29-1.8 Power Tong - MotDocument27 pagesManual XQ29-1.8 Power Tong - MotPedro GilNo ratings yet

- 2010 - 11 - 08 General GX120 - 160 - 200 Engine Adjustment InformatDocument1 page2010 - 11 - 08 General GX120 - 160 - 200 Engine Adjustment InformatstacybriandNo ratings yet

- E-COMPACT Installation Manual: A Table of ContentsDocument10 pagesE-COMPACT Installation Manual: A Table of ContentsCaptvik VikNo ratings yet

- HR5201CDocument60 pagesHR5201Cjokin mendiolaNo ratings yet

- ANGLE HEAD OPERATION GUIDEDocument7 pagesANGLE HEAD OPERATION GUIDEZira FitriNo ratings yet

- eTORK Digital Wrench InstructionsDocument8 pageseTORK Digital Wrench InstructionsJHON FREDY PEREZ ZAMUDIONo ratings yet

- TL 02006 Z Q Head ManualDocument9 pagesTL 02006 Z Q Head ManualMagno AguiarNo ratings yet

- Professional Tile Cutter Owner's ManualDocument8 pagesProfessional Tile Cutter Owner's Manualjairo yucraNo ratings yet

- Vernier Height Gauge: Applications and Features Part IdentificationDocument2 pagesVernier Height Gauge: Applications and Features Part IdentificationZain UlabideenNo ratings yet

- Dealer's Manual: (English)Document10 pagesDealer's Manual: (English)Rodney AtibulaNo ratings yet

- Instruction Manual: Aluminum Site-Rite Hand Benders AND Iron Site-Rite Hand BendersDocument28 pagesInstruction Manual: Aluminum Site-Rite Hand Benders AND Iron Site-Rite Hand BendersAymeeenNo ratings yet

- Ascensor l10 (Lej-Mm00202)Document11 pagesAscensor l10 (Lej-Mm00202)gui9871No ratings yet

- Pressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2Document2 pagesPressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2ossoskiNo ratings yet

- Cummins Engine Service Manual Cum S C Series PDFDocument8 pagesCummins Engine Service Manual Cum S C Series PDFAhmed Elsayed50% (2)

- ScaniaDocument6 pagesScaniaGustavo Paez100% (2)

- Preliminary Safety Guide for Suspension MaintenanceDocument11 pagesPreliminary Safety Guide for Suspension MaintenanceMarco CaggeseNo ratings yet

- VZH-1820 CatalogDocument5 pagesVZH-1820 CatalogVinhNo ratings yet

- Scott Bonnar 45 Operating InstructionsDocument8 pagesScott Bonnar 45 Operating InstructionsnickNo ratings yet

- Removing, Installing and Tensioning Toothed Belt: Special Tools and Workshop Equipment RequiredDocument12 pagesRemoving, Installing and Tensioning Toothed Belt: Special Tools and Workshop Equipment RequiredSigismund BeriaNo ratings yet

- ZMA2-52D InstructionsDocument10 pagesZMA2-52D InstructionsTuấn Ngô MinhNo ratings yet

- Broaching Operations Guide for Rotary BroachingDocument2 pagesBroaching Operations Guide for Rotary BroachingpeterNo ratings yet

- CouplingDocument4 pagesCouplingLuis Alberto Caballero AgueroNo ratings yet

- 035 - 319 - Technical Manual - Mechanical Units Bar End Commands - Campagnolo - Rev00 - 05 - 15Document6 pages035 - 319 - Technical Manual - Mechanical Units Bar End Commands - Campagnolo - Rev00 - 05 - 15theteamofthedragonflyNo ratings yet

- Hydraulic Sucker Rod Tong XQ29 2.6Document26 pagesHydraulic Sucker Rod Tong XQ29 2.6Ryan ZulkarnainNo ratings yet

- 15mmLinearMotion GuideDocument18 pages15mmLinearMotion GuideK R Rajeev KrishnanNo ratings yet

- 7l22a 2Document13 pages7l22a 2emmanuel_luna_85No ratings yet

- User's Manual for Hydraulic BreakersDocument34 pagesUser's Manual for Hydraulic BreakersClaudio VargasNo ratings yet

- DODGE® GRIP TIGHT Adapter Mount Ball BearingsDocument4 pagesDODGE® GRIP TIGHT Adapter Mount Ball BearingsDaNnIe09No ratings yet

- Adjusting valves and checking double rocker arms in D12D enginesDocument6 pagesAdjusting valves and checking double rocker arms in D12D enginesRicardo CostaNo ratings yet

- Fast & Fluid Management: Punch Installation Manual HA480/HA680Document8 pagesFast & Fluid Management: Punch Installation Manual HA480/HA680Ray PutraNo ratings yet

- Drill Grinder Instructions 0CECFEC7086BDDocument8 pagesDrill Grinder Instructions 0CECFEC7086BDMIGUEL ANGEL GARCIA BARAJASNo ratings yet

- Brunton Axis Transit Instruction Manual: Every Angle, Every DirectionDocument16 pagesBrunton Axis Transit Instruction Manual: Every Angle, Every DirectionEdilberNo ratings yet

- Woodpecker Plungelift™ Installation Instructions: Step 1Document2 pagesWoodpecker Plungelift™ Installation Instructions: Step 1MarcosPauloGrilloNo ratings yet

- Service Buletin 07-2965DDocument29 pagesService Buletin 07-2965DAgustinus KNo ratings yet

- Operation Manual: Model Xq114/6B Hydraulic Power Tong PartsDocument33 pagesOperation Manual: Model Xq114/6B Hydraulic Power Tong PartsJohan PorrasNo ratings yet

- Shop Manual: Mega Sc750 Sidecar EngineDocument26 pagesShop Manual: Mega Sc750 Sidecar EngineDaniel HughesNo ratings yet

- Formulas y Calculos de PerforacionDocument22 pagesFormulas y Calculos de Perforacionjairaso2950No ratings yet

- Akses Manual Mesin BarudanDocument45 pagesAkses Manual Mesin BarudanSektor VNo ratings yet

- Torque WrenchDocument12 pagesTorque WrenchJonathan TedriaNo ratings yet

- BR3 007 ManualDocument5 pagesBR3 007 ManualRodrigo Jechéla BarriosNo ratings yet

- ME432STI Service Manual - Pages.1 24Document24 pagesME432STI Service Manual - Pages.1 24Paul MartinNo ratings yet

- VosDocument86 pagesVosMd. Hanif SanketNo ratings yet

- 1-1 Bal-Con / Balloon Breaker Height 1-2 Peg PositionDocument5 pages1-1 Bal-Con / Balloon Breaker Height 1-2 Peg PositionMd. Hanif SanketNo ratings yet

- Adjust compressed air and winding parts on packaging machineDocument10 pagesAdjust compressed air and winding parts on packaging machineMd. Hanif SanketNo ratings yet

- PC Sensor: WarningDocument2 pagesPC Sensor: WarningMd. Hanif SanketNo ratings yet

- Uster Quantum ClearerDocument16 pagesUster Quantum Clearerraheem umer77% (13)

- Drum 1 Adjustment Standard: 1-1 Removing & Mounting The DrumDocument4 pagesDrum 1 Adjustment Standard: 1-1 Removing & Mounting The DrumMd. Hanif SanketNo ratings yet

- Upper Yarn Sensor 1 Adjustment Standard: 1-1 VOS SettingsDocument2 pagesUpper Yarn Sensor 1 Adjustment Standard: 1-1 VOS SettingsMd. Hanif SanketNo ratings yet

- PROCESS CONER II Maintenance GuideDocument24 pagesPROCESS CONER II Maintenance GuideMd. Hanif SanketNo ratings yet

- Re-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionDocument4 pagesRe-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionMd. Hanif SanketNo ratings yet

- Suction Mouth 1 Adjustment Standard: 1-1 ParallelismDocument4 pagesSuction Mouth 1 Adjustment Standard: 1-1 ParallelismMd. Hanif SanketNo ratings yet

- Air SplicerDocument11 pagesAir SplicerMd. Hanif SanketNo ratings yet

- Magazine Conveyor 1 Adjustment StandardDocument4 pagesMagazine Conveyor 1 Adjustment StandardMd. Hanif SanketNo ratings yet

- Lohillty 400 Commonwealth Drive Warrendale, Pa 15096: Rockwell International/Rocketdyne Division Canoga Park, CaliforniaDocument12 pagesLohillty 400 Commonwealth Drive Warrendale, Pa 15096: Rockwell International/Rocketdyne Division Canoga Park, CaliforniasmhosNo ratings yet

- Jaw Build 2010 April Rev2Document94 pagesJaw Build 2010 April Rev2defiunikasungtiNo ratings yet

- Selection of Gas CompressorsDocument5 pagesSelection of Gas CompressorsstreamtNo ratings yet

- Fluidization behaviour of gas-liquid systemsDocument11 pagesFluidization behaviour of gas-liquid systemsمروان الشباليNo ratings yet

- Dynamic Compaction AnalysisDocument14 pagesDynamic Compaction AnalysisJack DoverNo ratings yet

- Pump Efficiency For Single Stage Centrifugal PumpsDocument8 pagesPump Efficiency For Single Stage Centrifugal PumpsPerrobast100% (1)

- B 502 - 02 - QjuwmgDocument3 pagesB 502 - 02 - QjuwmghamidharvardNo ratings yet

- Actuators and DC MotorDocument48 pagesActuators and DC MotorAvinash BaldiNo ratings yet

- Chapter 9b PlasticityDocument86 pagesChapter 9b PlasticityRajeshNo ratings yet

- Manthani BhupaapalliDocument144 pagesManthani BhupaapalliLambu SampathNo ratings yet

- PA427 Spare Parts QuotationDocument2 pagesPA427 Spare Parts QuotationAsaithambi TNo ratings yet

- Chapter 16: Drying - Grain Drying, Types of Drying, Types of Dryers, Importance of DryingDocument10 pagesChapter 16: Drying - Grain Drying, Types of Drying, Types of Dryers, Importance of Drying9567592146No ratings yet

- MT Duct 40/33 Hdpe: 2009 3020 5021 6001 5015 4005 TranDocument2 pagesMT Duct 40/33 Hdpe: 2009 3020 5021 6001 5015 4005 TranDerrick Kojo SenyoNo ratings yet

- HVAC Load Analysis for Hospital de Contingencia San AntonioDocument17 pagesHVAC Load Analysis for Hospital de Contingencia San AntonioIsaac Sthidf Sanchez CabezasNo ratings yet

- Final Exam MA and MBDocument6 pagesFinal Exam MA and MBعبدالله حامد الرفاعيNo ratings yet

- 01-PT11-Intro2Turbomachines (Compatibility Mode) PDFDocument72 pages01-PT11-Intro2Turbomachines (Compatibility Mode) PDFShantanu GaikwadNo ratings yet

- Hydraulic Circuits Lab ReportDocument13 pagesHydraulic Circuits Lab ReportklashincoviskyNo ratings yet

- Support Detail PDFDocument139 pagesSupport Detail PDFSumanNo ratings yet

- Paper of Adrian BejanDocument21 pagesPaper of Adrian BejanshamoonjamshedNo ratings yet

- Quick Change Connectors: JK 201 Nipples (Special Mold Plug)Document2 pagesQuick Change Connectors: JK 201 Nipples (Special Mold Plug)Anilabc VermaxyzNo ratings yet

- Protection and Switchgear by U.A.Bakshi and M.V.Bakshi PDFDocument389 pagesProtection and Switchgear by U.A.Bakshi and M.V.Bakshi PDFRutuja patilNo ratings yet

- Fem1d CDocument10 pagesFem1d CManda Ramesh BabuNo ratings yet

- Schneider GV2 Motor Circuit BreakerDocument19 pagesSchneider GV2 Motor Circuit BreakeruuraydinNo ratings yet

- Chaypy V NotchDocument5 pagesChaypy V NotchGherNo ratings yet

- AMT 214 Reviewer (Oral)Document2 pagesAMT 214 Reviewer (Oral)Edjayde GodinezNo ratings yet

- CFD Pro 14.5 L08 IntroCFD CFXDocument27 pagesCFD Pro 14.5 L08 IntroCFD CFXMahir SoyerNo ratings yet

- Ssangyong Rexton BrochureDocument32 pagesSsangyong Rexton BrochureJuan de las heras calvoNo ratings yet

- TPE - 322302 - AFABQQEFWB - Cipta MandiriDocument5 pagesTPE - 322302 - AFABQQEFWB - Cipta MandiriTrisna RamadhanNo ratings yet

- D180TIER2 GB PDFDocument417 pagesD180TIER2 GB PDFkrzysztofNo ratings yet

- Week Three Homework Problems: Fundamentals of ! Fluid PowerDocument2 pagesWeek Three Homework Problems: Fundamentals of ! Fluid PowerjtorerocNo ratings yet