Professional Documents

Culture Documents

ht8660b PDF

Uploaded by

gustavo enriquezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ht8660b PDF

Uploaded by

gustavo enriquezCopyright:

Available Formats

60-ton (45.

36 mt)

Hydraulic Truck Crane

• 35.5' – 110' (10.82 – 33.53 m)

4-section boom

• 28.5' – 51' (8.69 - 15.54 m)

two-piece offsettable fly

• 167' (50.90 m) maximum

tip height

• Interchangeable modular

counterweights

• Bent axis piston winches

• 15,519 lbs (7 039 kg)

maximum winch line pull

• 499 fpm (152.1 m/min)

maximum winch line speed

• Caterpillar C-11 365 hp

(272.2 kW) diesel engine

• ZF Astronic automated

transmission

• 60.7 mph (97.7 km/hr)

travel speed

• Front & rear axle

Raydan air ride

• Three lockable storage boxes

• "Stow 'n Go" steel

pontoons

This lean and mean

machine is built to

meet the toughest

road laws

• Drives like an automatic and has

the power of a manual transmission

• Air ride suspension on front and

rear axle

• Travels with full counterweight

Cruise in one load to

your next job site!

• Speeds up to 60.7 mph (97.7 km/hr) on the

highway, unmatched in the industry today

• Move it on the job site at 1.3 mph (2.0 km/hr) creep

speed at idle for maximum maneuverability.

• Caterpillar C-11 365 horsepower (272.2 kW) engine

with 1,350 ft lb (830 nm) of torque

• ZF Astronic automated transmission (no clutch

pedal) - 12 speeds forward, 2-speeds reverse

with two modes of operation: fully automatic

and semi-automatic

• Cruise control

• Three-stage engine compression brake

• Ether injection system - optional

Comfortable carrier cab

provides high visibility

• Ultra-Cab with fiberglass construction

• Dash-mounted comprehensive

instrumentation with backlit gauges

Raydan™ air-ride suspension front and • Sliding side and rear windows and roll up/down

rear provides a smooth ride and precise door window provides excellent ventilation

handling. Optional air-ride lift system • Fully adjustable air ride fabric seat

holds the rear suspension retracted while • Suspended pedals

the crane is on outriggers.

Hydraulic counterweight There are three standard

transfer/removal system locking storage boxes

with an optional fourth.

• Easily positions counterweight on carrier deck for

efficient axle load distribution.

Modular counterweights offer up

to four lifting combinations

Hammerhead boom nose allows the operator to

work at high boom angles without fouling wire rope.

4-section full power Lightweight nylon head

sheaves reduce weight

boom with attachment and increase capacity.

flexibility Quick reeve head

• 35.5' to 110' (10.8 - 33.5 m) machinery for fast,

• 167' (50.90 m) maximum easy line change

tip height with full Exclusive Amax mode (mode

attachment Optional auxiliary lift-

“A”) offers substantially

ing sheave requires

increased capacities. Standard mode (mode “B”)

only one person to

self-proportions all four sections equally.

install and does not

need to be removed

Optional 28.5' to 51' (8.7 - 15.5 m) when the attachment is

two-piece bi-fold lattice fly erected, regardless of

offset.

• Erection of two-piece (bi-fold) lattice fly is a one-person

operation — easy to erect & stow

• Exclusive design reduces side deflection when

lifting load Powerful &

• Also available: One-piece 28.5' (8.7 m)

lattice fly with lugs to allow addition of responsive

second section piston

• Attachments offset

to 2°, 20° and 40° winch

• Two-speed motor

with automatic

Counterweight transfer removal controls brake

located on each side of the upper structure • Grooved drums

minimize rope har-

monic motion and

improve spooling

• Optional auxiliary

two-speed winch

Winch viewing

Folding viewing mirror

Mechanical boom mirror for travel

angle indicator -

standard

Optional hoist drum

cable follower and

Optional

Innovative two-part paint coating technology, coupled optional third wrap

integrated air

with a pre-assembly paint process, provides the finest indicators

Large engine conditioning

quality coating system available today. doors allow for

easy access

Non-slip

surface

strips on

carrier deck

Carrier-mounted outrigger controls, located on each

side of the carrier, include an engine throttle-up switch

for fast outrigger deployment. For fine level adjusting of

the carrier, throttle can be taken down to idle.

Stow ‘n Go outrigger pontoons are quickly and easily

Full air, S-cam anti-lock (ABS) stored and secured for travel, eliminating the need to

brakes on all wheel ends with remove the pontoon each time the crane moves.

Optional daytime automatic slack adjusters Pontoon storage space is also available on rear fenders

running lights Aluminum wheels and radial and side access ladders.

tires with chrome and stainless

wheel accents The Confined Area Lifting

Capacities (CALC) system

Optional integrated air provides three outrigger

Self-storing fifth

Large west coast- conditioning (not a positions:

outrigger pontoon

style rear viewing roof-mounted system) • full retraction

mirrors • intermediate extension

• full extension

Outrigger pins eliminate

guesswork by automatically

positioning outriggers at

midpoint position.

The operator’s cab is Integral rated capacity limiter

roomier and quieter than The Microguard aids the operator in safe and efficient

operation by continuously monitoring boom length, boom

traditional cabs angle, head height, radius of load, machine configuration,

allowed load, actual load and percent of allowed load.

• Six-way adjustable fabric seat with An exclusive feature is the

lift-up armrest (which deactivates Operator Defined Area

control functions when raised) Alarm. By setting two

• Armrest mounted, responsive dual axis points, the operator creates

hydraulic controllers an imaginary vertical plane

• Bubble level sight level mounted on to maintain a safe working

side console distance from nearby obsta-

• Ducted air through automotive-style cles. Should the operator

directional vents attempt to operate the crane

• Sliding right side, rear windows and beyond the plane, the RCL

swing-up roof window will sound an alarm.

• Single foot pedal boom telescope control

• Automotive-style windshield The Microguard

• Corner-post-mounted, backlit gauges also features:

• Large, sweeping electric wipers

• Improved access time

• Dashless design

• Radio frequency shielding

• Engine-dependant warm water heating

• Large liquid crystal alpha-numeric display

with defroster

• Total system override capabilities to provide for

rigging requirements

• Optional graphic display bar, positioned near the top of

the windshield for optimum viewing during crane opera-

Superior accessibility tion alerts the operator of the current lift capacity

Access to the operator’s cab and engine through a series of green, yellow and red lights.

compartment is superb with strategically-

located ladders and steps. The pull-out

CabWalk™ slides out from its secured travel When you invest in a Link-Belt

position underneath the operator’s cab

to give the operator a platform to stand on crane, you invest in a legacy of

for easy entry and exit from the cab.

outstanding customer support

Distributor support personnel

Factory-trained technicians are specifically tested to

establish proficiency in all aspects of crane diagnostics

and repair.

Factory product support team

Supporting your trained distributor personnel are

experienced factory advisors with comprehensive

records and technical libraries that stand ready to

resolve any crane service issue.

Parts Distribution Center

72,000 sq. ft. Parts Distribution Center

averages an over 90% parts availability

rate.

eParts

Link-Belt’s online computer

system links our distributors

worldwide so customers

can order genuine Link-

Belt parts 24 hours a

day, 7 days a week.

Link-Belt Preferred

Link-Belt’s customer web site provides instant access to a

comprehensive library of all parts, service and operator

manuals plus other technical and sales information.

Lexington, Kentucky

www.linkbelt.com

® Link-Belt is a registered trademark. Copyright 2005.

All rights reserved. We reserve the right to change designs

and specifications at any time.

Litho in U.S.A. 11/05 #4316

FOR MORE INFORMATION, CONTACT YOUR AUTHORIZED LINK-BELT DISTRIBUTOR:

You might also like

- Here: Toyota 1g Fe Engine Service Manual PDFDocument2 pagesHere: Toyota 1g Fe Engine Service Manual PDFrodrigo diaz salas67% (3)

- 2007 Harley Davidson Street Bob 66490 PDFDocument119 pages2007 Harley Davidson Street Bob 66490 PDFThömpsöñ Témbö IñfìnìtèNo ratings yet

- MM Case Study On Audi and HarleyDocument22 pagesMM Case Study On Audi and HarleyKiran YadavNo ratings yet

- Old Cars Express July 2017Document74 pagesOld Cars Express July 2017unhinged17No ratings yet

- How To Use BMW EDocument16 pagesHow To Use BMW EReza VaraminiNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Anura Trading House: Item Wise Price ListDocument25 pagesAnura Trading House: Item Wise Price ListNuwan Dias100% (1)

- Grove Tms900eDocument36 pagesGrove Tms900eJaime Flórez0% (1)

- 2020 Ford F 150 Owners Manual Version3 - Om - EN US - 04 - 2020 PDFDocument625 pages2020 Ford F 150 Owners Manual Version3 - Om - EN US - 04 - 2020 PDFHuawei ITMOVP7P8No ratings yet

- Wheel Loader Specifications: Service Weight 13.7 T - 14,5 T Engine Output 130 KW Loading Buckets 2.3 - 6.0 MDocument10 pagesWheel Loader Specifications: Service Weight 13.7 T - 14,5 T Engine Output 130 KW Loading Buckets 2.3 - 6.0 MIbrahim AwadNo ratings yet

- Operating Manual: Clean AheadDocument200 pagesOperating Manual: Clean AheadLucyan IonescuNo ratings yet

- Clutch Controol p360Document15 pagesClutch Controol p360andi maryantoNo ratings yet

- Sany SRC885 LiteratureDocument24 pagesSany SRC885 LiteratureYudhi AntonioNo ratings yet

- Htc-8675 Seriesii 75tDocument62 pagesHtc-8675 Seriesii 75tvikramchowdary100% (1)

- 4HP20 Bodyvalve Explode ViewDocument5 pages4HP20 Bodyvalve Explode ViewCarlota SilvaNo ratings yet

- T500 - Parts Book - 12261-228 - 09-01-2002Document206 pagesT500 - Parts Book - 12261-228 - 09-01-2002gustavo enriquez67% (3)

- RT 500 Series: Rough Terrain CranesDocument16 pagesRT 500 Series: Rough Terrain Cranesmain powerNo ratings yet

- Grove TMS 9000e 90 Ton Grove PDFDocument28 pagesGrove TMS 9000e 90 Ton Grove PDFkhalid shadhanNo ratings yet

- Linkbelt HTC11100 SpecDocument16 pagesLinkbelt HTC11100 SpecDaniel Cáceres TrujilloNo ratings yet

- Unit 4 General Test: Listen To The Conversations. Then Choose The Word or Phrase That Correctly Completes Each SentenceDocument5 pagesUnit 4 General Test: Listen To The Conversations. Then Choose The Word or Phrase That Correctly Completes Each SentenceAngel Cardenas0% (2)

- Link Belt HTC 8640Document48 pagesLink Belt HTC 8640saul dussanNo ratings yet

- HTC-8660 60TDocument16 pagesHTC-8660 60TMIchael TaczaNo ratings yet

- 67-Wa100m-7 Venss05000 1407Document12 pages67-Wa100m-7 Venss05000 1407ediNo ratings yet

- Brouchure 1 HTC8640 PT - DakDocument6 pagesBrouchure 1 HTC8640 PT - DakNordiscNo ratings yet

- TMS9000e 0208Document20 pagesTMS9000e 0208Juan ReyesNo ratings yet

- National Boom Trucks Spec 15a5fcDocument4 pagesNational Boom Trucks Spec 15a5fccubarro1234No ratings yet

- Link Belt ATC 3200Document6 pagesLink Belt ATC 3200msdk00No ratings yet

- WP contentuploads201401HSL 218 - 110T PDFDocument60 pagesWP contentuploads201401HSL 218 - 110T PDFsundar_kiruthiNo ratings yet

- V3sh7djz0s7gj4b3grove Tms900e 90-Ton Hydraulic Truck Crane NetworkDocument36 pagesV3sh7djz0s7gj4b3grove Tms900e 90-Ton Hydraulic Truck Crane NetworkRobin ChaRiNo ratings yet

- Documentos Link Belt 2024Document38 pagesDocumentos Link Belt 2024Nicolas GeremíasNo ratings yet

- ManitowocMLC300 FPCflyerCONEXPODocument4 pagesManitowocMLC300 FPCflyerCONEXPOJorge VillalobosNo ratings yet

- Rt530e 2 - PG 1 PDFDocument16 pagesRt530e 2 - PG 1 PDFNavarro NayraNo ratings yet

- The Industry's Most Innovative Solution To Big Rough Terrain Cranes Maneuverability and Transportability!Document8 pagesThe Industry's Most Innovative Solution To Big Rough Terrain Cranes Maneuverability and Transportability!eduardoNo ratings yet

- 6eaee Grue Mobile 110t Grove Tms9000eDocument28 pages6eaee Grue Mobile 110t Grove Tms9000eSoufiane KadarNo ratings yet

- Grua Hidraulica Telescopica Grove - Tms9000e-SmDocument36 pagesGrua Hidraulica Telescopica Grove - Tms9000e-SmXavier Alexis Cortes VillalobosNo ratings yet

- HYLAB Series Lattice Boom Truck Crane 200-Ton (181.5 MT)Document6 pagesHYLAB Series Lattice Boom Truck Crane 200-Ton (181.5 MT)jonny david martinez perezNo ratings yet

- KomatsuDocument16 pagesKomatsuGeorge BowenNo ratings yet

- ETV 114n 116n 118n 120nDocument6 pagesETV 114n 116n 118n 120nganteng deweNo ratings yet

- DL300A EspecificacionesDocument20 pagesDL300A EspecificacionesRuiz D. AntonioNo ratings yet

- Bobcat R-Series LoadersDocument6 pagesBobcat R-Series LoadersАндрей ТретьяковNo ratings yet

- 248 Hylab HSL SeriesDocument2 pages248 Hylab HSL SeriesSokjo0ker17No ratings yet

- Hydrostatic Vibratory Plate: A Trusted CompactorDocument2 pagesHydrostatic Vibratory Plate: A Trusted Compactorhamdi galipNo ratings yet

- Mecalac Ahlmann As 210Document8 pagesMecalac Ahlmann As 210ForomaquinasNo ratings yet

- HTC-86 HTC-8670: Long BoomDocument4 pagesHTC-86 HTC-8670: Long BoomNoeGonzalezNo ratings yet

- Dlupeizrdtzqtw2jgrove Tms700e Truck Crane Network PDFDocument24 pagesDlupeizrdtzqtw2jgrove Tms700e Truck Crane Network PDFJesus SuarezNo ratings yet

- PC Wa200pz 6Document24 pagesPC Wa200pz 6CopemaqNo ratings yet

- Asphalt PaverDocument16 pagesAsphalt Paverzae nurdinNo ratings yet

- PC Wa250pz 6Document24 pagesPC Wa250pz 6CopemaqNo ratings yet

- Tabla de Carga PH10Document16 pagesTabla de Carga PH10Wilson SotoNo ratings yet

- Https WWW - Ale-Heavylift - Com Wp-Content Uploads 2014 01 EQUIPMENT-DATA-SHEET-SPT-Nicolas PDFDocument1 pageHttps WWW - Ale-Heavylift - Com Wp-Content Uploads 2014 01 EQUIPMENT-DATA-SHEET-SPT-Nicolas PDFRyan LeeNo ratings yet

- Komatsu Heavy Equipment2Document12 pagesKomatsu Heavy Equipment2Christoper NavaNo ratings yet

- Rigid Backhoe Loader: 74 KW / 99,2 HP at 2.200 RPM 8.070 KGDocument12 pagesRigid Backhoe Loader: 74 KW / 99,2 HP at 2.200 RPM 8.070 KGvitaliyNo ratings yet

- WB93R-5 Wess004510 1701Document12 pagesWB93R-5 Wess004510 1701email sharingNo ratings yet

- Specifications: Standard EquipmentDocument12 pagesSpecifications: Standard EquipmentBart JohnNo ratings yet

- Engine Rated Power: 340 KW (460 PS) Operating Weight ZAXIS800: 73 900 77 400 KG Backhoe Bucket 3.8 MDocument11 pagesEngine Rated Power: 340 KW (460 PS) Operating Weight ZAXIS800: 73 900 77 400 KG Backhoe Bucket 3.8 MKevin DaveNo ratings yet

- Yt3tshpnzufrkqm8grove Rt530e-2 30-Ton Rough Terrain Crane NetworkDocument16 pagesYt3tshpnzufrkqm8grove Rt530e-2 30-Ton Rough Terrain Crane Networkoscar albertoNo ratings yet

- RT700EDocument16 pagesRT700EPedro FranciaNo ratings yet

- 45t Grove Rt600e PGDocument16 pages45t Grove Rt600e PGMohd FadliNo ratings yet

- ZW310 3.4-4.2 Cum PDFDocument11 pagesZW310 3.4-4.2 Cum PDFSriram NambiNo ratings yet

- Series 1216 Data SheetDocument2 pagesSeries 1216 Data SheetSenthilKumarNo ratings yet

- PK 165002 Tec7 enDocument16 pagesPK 165002 Tec7 enSofean AbojaradehNo ratings yet

- LS87 Onesheet-WebDocument2 pagesLS87 Onesheet-WebAlexandre De Paula SilvaNo ratings yet

- Cke1350 1F1Document12 pagesCke1350 1F1AndriNo ratings yet

- Lattice Crawler - PictureDocument6 pagesLattice Crawler - PictureMohamed FathyNo ratings yet

- As 210e Englisch 3 2015 PDFDocument8 pagesAs 210e Englisch 3 2015 PDFVandersonOrtolaniNo ratings yet

- grt8120 FlyerDocument2 pagesgrt8120 FlyerRicardo Mendez AsencioNo ratings yet

- Spacemaster SX: Electric Wire Rope Hoists Electric Wire Rope HoistsDocument6 pagesSpacemaster SX: Electric Wire Rope Hoists Electric Wire Rope Hoistssarexcuca2010No ratings yet

- Panoramic: P 101.10 HM P 80.9 HM P 65.14 HM P 45.18 HMDocument12 pagesPanoramic: P 101.10 HM P 80.9 HM P 65.14 HM P 45.18 HMСвятослав ВороновNo ratings yet

- The Industry's Most Innovative Solution To Big Rough Terrain Cranes Maneuverability and Transportability!Document8 pagesThe Industry's Most Innovative Solution To Big Rough Terrain Cranes Maneuverability and Transportability!salman KhanNo ratings yet

- Cke1800 PDFDocument4 pagesCke1800 PDFlechinhNo ratings yet

- 30 Ton Terex T 230 Specs and Load Chart Rev 5 - 06 - DLDocument16 pages30 Ton Terex T 230 Specs and Load Chart Rev 5 - 06 - DLDimi Jeri TriNo ratings yet

- Product Guide: FeaturesDocument24 pagesProduct Guide: FeaturesHoward HoacNo ratings yet

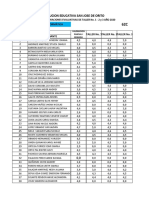

- Reporte Notas Tecnologia e Informatica 6.2CDocument2 pagesReporte Notas Tecnologia e Informatica 6.2Cgustavo enriquezNo ratings yet

- Notas Parciales Grado 6-2cDocument2 pagesNotas Parciales Grado 6-2cgustavo enriquezNo ratings yet

- HT 8660 TDocument32 pagesHT 8660 Tgustavo enriquezNo ratings yet

- ENGINE 541.9 in MODELS 950, 952, 953, 954Document1 pageENGINE 541.9 in MODELS 950, 952, 953, 954محمد يونسNo ratings yet

- MKP - 5 Laporan Bulanan Peralatan Equipment & KendaraanDocument1 pageMKP - 5 Laporan Bulanan Peralatan Equipment & KendaraanFajar NugrohoNo ratings yet

- Technical Service Information 12-45Document2 pagesTechnical Service Information 12-45Planta Damiana2No ratings yet

- REHS6121 - Commissioning Procedure For The 793F, 793F Tier 4, and The 793F CMD Off-Highway TruckDocument136 pagesREHS6121 - Commissioning Procedure For The 793F, 793F Tier 4, and The 793F CMD Off-Highway TruckAnderson Oliveira SilvaNo ratings yet

- Asas ONLINE JuniDocument90 pagesAsas ONLINE Junirina meilaniNo ratings yet

- Especificaciones Camber Caster VariosDocument8 pagesEspecificaciones Camber Caster VariosJose Antonio Jimenez HernandezNo ratings yet

- Dreamsol Oil Recommendation Chart - July 2021Document3 pagesDreamsol Oil Recommendation Chart - July 2021kiranNo ratings yet

- Manual Opeação 416bDocument10 pagesManual Opeação 416bSilvanio Rosa QueirozNo ratings yet

- BMW Motorrad Vision DC Roadster enDocument6 pagesBMW Motorrad Vision DC Roadster enAixer Alexander PadronNo ratings yet

- DJ Alagendran Automobiles Private LimitedDocument4 pagesDJ Alagendran Automobiles Private LimitedDJ Automobiles MarketingNo ratings yet

- F&B Approval FormatDocument2 pagesF&B Approval FormatJammieNo ratings yet

- Pyga Industries Katalog 2013Document12 pagesPyga Industries Katalog 2013Timothy JacksonNo ratings yet

- Field Studies IIDocument24 pagesField Studies IImaduvatsNo ratings yet

- Brochure A35F A40FDocument24 pagesBrochure A35F A40FRezhaNo ratings yet

- TSK Crane Service CatalougeDocument158 pagesTSK Crane Service Catalougewadius100% (2)

- Sip - DeepDocument73 pagesSip - DeepKartikey KumarNo ratings yet

- 2012 Model Vin Codes: Vehicle Identification NumberDocument1 page2012 Model Vin Codes: Vehicle Identification NumberFRANCISCO JAVIER SALDIVIA SALDIVIANo ratings yet

- Shinko Reach10 30 PDFDocument12 pagesShinko Reach10 30 PDFThiên PhúcNo ratings yet

- W210 Schematics 2of2Document30 pagesW210 Schematics 2of2mahmoud magdy100% (1)