Professional Documents

Culture Documents

Estimate Brazing Alloys PDF

Estimate Brazing Alloys PDF

Uploaded by

habebe0 ratings0% found this document useful (0 votes)

15 views1 pageOriginal Title

Estimate Brazing Alloys.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 pageEstimate Brazing Alloys PDF

Estimate Brazing Alloys PDF

Uploaded by

habebeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

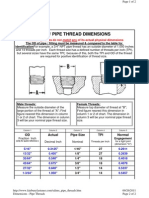

ESTIMATING AMOUNTS OF

PROCEDURES & TECHNICAL INFORMATION

BRAZING ALLOYS REQUIRED

1. Locate the tube diameter to be joined and the wire size to be used. Where

the row and the column intersect is the approximate length (in inches) of

alloy required per joint.

2. Multiply the length of the alloy needed per joint by the total number of joints.

3. To convert the total length to pounds or troy ounces, divide by the inches of

alloy/lb in row A or the inches of alloy/troy oz in row B.

.050”x Estimated

Tube 3/64” 1/16” 3/32” 1/8” Tip Acetylene

Diameter Wire Wire Wire Rod Size Use(C.F.H.)

1/4” 1 1/4” 3/4” 4 6-14

3/8” 1 1/2” 1” 4 6-14

1/2” 2” 1 1/2” 3/4” 7/8” 5 8-18

3/4” 3” 2” 1” 1 1/8” 5 8-18

1” 3” 1 1/2” 1 5/8” 6 10-20

1 1/4” 4” 2” 2 1/2” 6 10-20

1 1/2” 2 1/2” 2 3/4” 7 13-25

2” 3 3/4” 4 1/2” 8 16-32

2 1/2” 6” 7 1/2” 8 16-32

3” 10” 11 1/2” 9 20-37

3 1/2” 12” 13 3/4” 9 20-37

4” 14” 16” 10 24-42

6” 21” 23 3/4” 10 24-42

A 1900” 1068” 475” 513” in. of alloy/lb

B 118” 67” 29” in. of alloy/troy oz

A- Phos/copper/silver alloys. Dynaflow, Harris 15, etc.

B- Silver Brazing alloys, Safety-Silv 45, 56, etc.

The above figures are approximate and will vary depending on joint clearance, depth,

and operator technique.

www.harrisproductsgroup.com

You might also like

- API Spec 5CT IntroductionDocument37 pagesAPI Spec 5CT IntroductionChandrasekhar Sonar100% (2)

- NPT Thread DimensionsDocument1 pageNPT Thread DimensionsNeil Louis71% (7)

- V-Belt Size Chart PDFDocument1 pageV-Belt Size Chart PDFrachitmail100% (3)

- 10CVL 37 Survey Lab ManualDocument74 pages10CVL 37 Survey Lab ManualHarish T S Gowda78% (9)

- Sidecutters Manufactured by HensleyDocument8 pagesSidecutters Manufactured by Hensleyfernandoj100% (1)

- IV. Belts, Ropes and ChainsDocument54 pagesIV. Belts, Ropes and ChainsPrincessNo ratings yet

- 6m MoxonDocument4 pages6m MoxonwcantrellNo ratings yet

- 2-Meter Vertical Dipole ArrayDocument15 pages2-Meter Vertical Dipole ArrayJacky SinurayaNo ratings yet

- Astm A325 & A490 Bolts & NutsDocument6 pagesAstm A325 & A490 Bolts & NutsagusfitriyadiNo ratings yet

- NPT 2Document3 pagesNPT 2Mario Barbarić100% (1)

- En 12799 (2000) (E)Document8 pagesEn 12799 (2000) (E)Zeljko Ristic50% (2)

- En 12799 (2000) (E)Document8 pagesEn 12799 (2000) (E)Zeljko Ristic50% (2)

- Astm F1498Document13 pagesAstm F1498Hernando Andrés Ramírez GilNo ratings yet

- Basic Dimensions, American National Standard Taper Pipe Threads, NPT, (ANSI B2.1-1968)Document2 pagesBasic Dimensions, American National Standard Taper Pipe Threads, NPT, (ANSI B2.1-1968)Adrian Petrascu100% (1)

- Making A Fast Pulse Induction Mono CoilDocument8 pagesMaking A Fast Pulse Induction Mono CoilMusta Nicolae100% (2)

- LBF Rail CraneRailSystemsDocument25 pagesLBF Rail CraneRailSystemsIrving OroNo ratings yet

- AMICO - Grating Stair Tread SectionDocument12 pagesAMICO - Grating Stair Tread SectionwijayanataNo ratings yet

- AutoCAD VBA ProgrammingDocument59 pagesAutoCAD VBA ProgrammingZeljko Ristic100% (2)

- Connections in GeneralDocument10 pagesConnections in GeneralLes SzalaiNo ratings yet

- EN ISO 13585 (2012) (E) CodifiedDocument7 pagesEN ISO 13585 (2012) (E) CodifiedZeljko Ristic0% (2)

- Holes and Slots, Standard SizesDocument3 pagesHoles and Slots, Standard SizesStephen KokoNo ratings yet

- Pipe Thread DiameterDocument3 pagesPipe Thread DiameterNabil RamehNo ratings yet

- Available Standards Presentation by TWI 21.10.2010Document52 pagesAvailable Standards Presentation by TWI 21.10.2010Zeljko RisticNo ratings yet

- Estimate Brazing AlloysDocument1 pageEstimate Brazing AlloysAhmed GomaaNo ratings yet

- Brazing Filler WireDocument1 pageBrazing Filler WireElizabeth SpenceNo ratings yet

- Vertical Rev HDocument10 pagesVertical Rev HMiguel OyarzabalNo ratings yet

- Table 7-14a Bolt Shear Plane ConditionsDocument1 pageTable 7-14a Bolt Shear Plane ConditionsHRCNo ratings yet

- Xdims Pipe ThreadsDocument2 pagesXdims Pipe ThreadsamevaluacionesNo ratings yet

- Imperial Inch Dowels To BS1804Document1 pageImperial Inch Dowels To BS1804Marco Antonio OrtizNo ratings yet

- V-Belt Size ChartDocument1 pageV-Belt Size ChartColNo ratings yet

- How To Read V-Belt CodeDocument1 pageHow To Read V-Belt CodeSunarto100% (1)

- V-Belt Size Chart PDFDocument1 pageV-Belt Size Chart PDFAdham Abd El KareemNo ratings yet

- Costing 6E and 6GDocument2 pagesCosting 6E and 6GJohnson ArellanoNo ratings yet

- (Inches) Inches MM InchesDocument1 page(Inches) Inches MM InchesRajesh J BharadwajNo ratings yet

- Assignment Chapter 5Document1 pageAssignment Chapter 5amirahNo ratings yet

- Peso de CablesDocument5 pagesPeso de Cablesrlexl6darvNo ratings yet

- Disclosure To Promote The Right To InformationDocument34 pagesDisclosure To Promote The Right To InformationKashyap PatelNo ratings yet

- NPT ThreadDocument3 pagesNPT ThreadaniruddhkrsharmaNo ratings yet

- PIPE THREAD DimensionDocument2 pagesPIPE THREAD DimensionAriel AnascoNo ratings yet

- Topics - Deign of A Mechanical System - ME 881Document9 pagesTopics - Deign of A Mechanical System - ME 881Aamir AhmedNo ratings yet

- Machine ShopDocument6 pagesMachine ShopEjNo ratings yet

- Material List ChiltronDocument2 pagesMaterial List ChiltronPepe GuaraNo ratings yet

- Aluminum Portable Antenna 40 Meter HF BandDocument15 pagesAluminum Portable Antenna 40 Meter HF BandihendrajayaNo ratings yet

- Bolts FastenerDocument20 pagesBolts FastenerUpadrasta HarishNo ratings yet

- Strain Gauge Installation ExamplesDocument5 pagesStrain Gauge Installation ExamplesJaya DiNo ratings yet

- Graseras AlemitesDocument37 pagesGraseras Alemitesjoroma58No ratings yet

- Machine Design ProblemsDocument1 pageMachine Design ProblemsNeo GarceraNo ratings yet

- Cable Support WeatherproofingDocument15 pagesCable Support WeatherproofingwangjinshanNo ratings yet

- 70cm Quadruple QuadDocument5 pages70cm Quadruple QuadJosé Antonio Miranda100% (1)

- BOQ - Tubes and Fitting For Transmitters, Control Vlaves and Analyzers S/N DescriptionDocument2 pagesBOQ - Tubes and Fitting For Transmitters, Control Vlaves and Analyzers S/N DescriptionSobhy GendykhelaNo ratings yet

- Estimated Costs For Livestock Fencing: Barbed Wire FenceDocument4 pagesEstimated Costs For Livestock Fencing: Barbed Wire FenceSantosh PolNo ratings yet

- NPT ThreadsDocument4 pagesNPT ThreadssatphoenixNo ratings yet

- 2762 - Material For Wire Rope Slings and Top Bull RingDocument13 pages2762 - Material For Wire Rope Slings and Top Bull RingKaushik SenguptaNo ratings yet

- NPT Vs BSP PipeDocument1 pageNPT Vs BSP PipeAnonymous is1oAmNo ratings yet

- A 820 - A 820M - 04 PDFDocument4 pagesA 820 - A 820M - 04 PDFoscargon19No ratings yet

- F 765 - 93 R98 - RJC2NQ - PDFDocument6 pagesF 765 - 93 R98 - RJC2NQ - PDFRománBarciaVazquezNo ratings yet

- Percentage Wall Reduction Is The Most FrequentlyDocument4 pagesPercentage Wall Reduction Is The Most Frequentlysanketpavi21No ratings yet

- 300# Stud and Nut ChartDocument1 page300# Stud and Nut ChartMahesh KumarNo ratings yet

- Drilling Engineering: PETE 203Document48 pagesDrilling Engineering: PETE 203sereptNo ratings yet

- Grundfosliterature 1580Document268 pagesGrundfosliterature 1580Zeljko RisticNo ratings yet

- Iso 9459-5Document61 pagesIso 9459-5Zeljko Ristic100% (3)

- SDH WP3 D31 D32 - August2012Document152 pagesSDH WP3 D31 D32 - August2012Zeljko RisticNo ratings yet

- Dynaflow Vs Stay Silv 15Document2 pagesDynaflow Vs Stay Silv 15Zeljko RisticNo ratings yet

- Technical Information No. 13 - Use of Copper-Phosphourus Brazing Alloys On Low Alloyed Copper Materials Containing IronDocument14 pagesTechnical Information No. 13 - Use of Copper-Phosphourus Brazing Alloys On Low Alloyed Copper Materials Containing IronZeljko RisticNo ratings yet

- Mikrotherm en LQDocument8 pagesMikrotherm en LQZeljko RisticNo ratings yet

- Decl of Conf KTM512Document1 pageDecl of Conf KTM512Zeljko RisticNo ratings yet

- Energo System CenovnikDocument1 pageEnergo System CenovnikZeljko RisticNo ratings yet

- Dijagram V-DP (Zaporni Ventil)Document8 pagesDijagram V-DP (Zaporni Ventil)Zeljko RisticNo ratings yet

- Excel Link 3 User GuideDocument88 pagesExcel Link 3 User GuideZeljko RisticNo ratings yet

- Dijagram V-DP (Hvatac Necistoce)Document4 pagesDijagram V-DP (Hvatac Necistoce)Zeljko RisticNo ratings yet