Professional Documents

Culture Documents

Amspec Techtalk Hydrogen Sulfide - h2s 4

Uploaded by

Javier Gomez TorregrosaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amspec Techtalk Hydrogen Sulfide - h2s 4

Uploaded by

Javier Gomez TorregrosaCopyright:

Available Formats

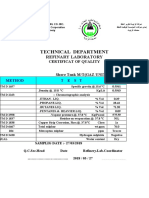

Technical Notes

# 022

Exceeding Expectations

Hydrogen Sulfide (H2S)

Hydrogen Sulfide (H2S) is a very dangerous, toxic, explosive, colorless and transparent gas which can be found

naturally in coal pits, sulfur springs, gas wells and as a product of decaying sulfur- containing organic matter. It is

also a by-product of crude and other petroleum products.

It can be generated during refining processes, and be released during handling, storage, and distribution. At very

low levels (0.0047 PPM), the gas has the characteristic smell of rotten eggs. If the concentration is between 10 –

50 PPM, H2S causes loss of smell, headaches, and dizziness. At concentrations above 300 PPM, exposure to H2S

may be fatal.

TESTING - H2S

These are the most common methods that AmSpec uses to determine Hydrogen Sulfide Content:

D5705 – Hydrogen Sulfide in the Vapor Phase above Residual Fuel Oils

D7621 (IP 570) – Hydrogen Sulfide in Fuel Oils – Rapid Liquid Phase Extraction Method

UOP 163 – Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric Titration

Method Products Scope Limitations

D5705 Residual Fuel 5 to 4000 PPM H2S Only applicable to liquids

with a viscosity of 5.5

mm2/s at 40OC to 50 mm2/s

at 100 OC

D7621 (IP 570) Marine Residual Fuels and 0.40 – 15.0 PPM H2S Only applicable to liquids

Blend Stocks with viscosities up to 3000

mm2/s at 50OC

UOP 163 Gasoline, Naphtha, Light 1.0 PPM H2S and above Only applicable to products

Cycle Oils, and Similar that are liquid at ambient

Distillates temperature

D5705 – A 1 liter H2S-inert glass test bottle is filled 50% with the fuel oil from a filled H2S-inert glass

sample bottle just prior to testing. In the test container, the vapor space above the fuel oil sample is

purged with nitrogen to displace air. The test container with sample is heated in an oven to 60°C, and

agitated on an orbital shaker at 220 RPM for 3 minutes. . A “length of stain” detector tube and hand

operated pump are used to measure the H2S concentration in the vapor phase of the test container.

If you would like to be removed from our distribution list or you require information on a certain subject, please let us know via return email.

Also, please be advised individual / group AmSpec laboratory / operational tours can be arranged upon request.

Please visit us on our website…www.amspecllc.com or contact us at (800) 286-2208

D7621 (IP 570) – A weighed test portion is introduced into a heated test vessel containing a diluent base oil.

Air is bubbled through the oil to extract the H2S gas. The H2S is passed, with the air, over a detector to

enable the H2S content of the air to be measured and the amount of H2S in the liquid phase to be calculated.

UOP 163 – The liquid hydrocarbon sample is weighed into isopropyl alcohol containing a small amount

of ammonium hydroxide. The solution is titrated potentiometrically with alcoholic silver nitrate using a

glass reference and silver-silver sulfide indicating electrode system.

** Please note below, Turnaround Time is defined as the actual length of time, on average, it takes to perform a

particular method once the sample has arrived and logged in the lab, and prepared for testing.

Method Phase Tested for H2S Turnaround Time

D5705 Vapor Phase 10 Minutes

D7621 (IP 570) Liquid Phase 30 Minutes

UOP 163 Liquid Phase 30 Minutes

Vapor Phase

The vapor headspace above the liquid that is generated by heating and shaking the sample as described

in the method.

Liquid Phase

The sample that is treated in accordance with the method.

Residual fuel oils that contain H2S in the liquid phase can result in hazardous vapor phase levels of H2S in

storage tank headspaces. The vapor phase levels can vary significantly according to the headspace

volume, fuel temperature and agitation. Measurement of H2S levels in the liquid phase provides a

useful indication of the residual fuel oil’s propensity to form high vapor phase levels, and lower levels in

the residual fuel oil will directly reduce risk of H2S exposure. The measurement of H2S in the liquid

phase is appropriate for product quality control, while the measurement of H2S in the vapor phase is

appropriate for health and safety purposes.

TREATMENTS - H2S Reduction Additives

The H2S content of fuels and crude oils can be reduced with chemical additives (such as “H2S

Scavengers”) during transport and blending operations to address safety and product quality concerns.

H2S Scavengers are widely used due to their ability to quickly and irreversibly react H2S into a safe non-

volatile sulfide molecule.

If you would like to be removed from our distribution list or you require information on a certain subject, please let us know via return email.

Also, please be advised individual / group AmSpec laboratory / operational tours can be arranged upon request.

Please visit us on our website…www.amspecllc.com or contact us at (800) 286-2208

The fast reaction of H2S Scavengers make them an excellent fit for treatments to reduce H2S during

vessel loading / discharges or tank transfers. The irreversible nature of a scavenger reaction is key to

ensure the continued safe handling of the treated fuel as it undergoes additional heating and/or

transportation.

There are multiple types of chemistries / products available that full under the “H2S Scavenger”

umbrella. The actual chemistry type used will depend on the particular oil being treated and its end use.

The most common H2S treatments occur in residual fuel oils and sour crude oils. In these cases, a

triazine-type chemistry is typically used to provide fast reactions at the lowest relative scavenger cost.

Some refineries request that a non-triazine scavenger be used for treated crude oil coming into their

facility due to potential corrosive salt formation in the crude distillation unit. In these cases, a glyoxal-

based scavenger may be a good solution to provide fast / irreversible H2S reduction and no refinery

impacts in terms of corrosive salt formation or nitrogen input to the naphtha hydrotreaters.

A wide variety of other specialized H2S scavengers are also available for naphtha, asphalt or sour water

applications.

HANDLING H2S

As previously mentioned, H2S has a very low odor threshold, with its smell being very

perceptible at concentrations below 1 part per million (ppm) in air. The odor increases as the

gas is more concentrated, with the strong rotten egg smell recognizable up to 30 ppm.

Above this level the gas is reported to have a sickeningly sweet odor up to around 100 ppm.

However, at concentrations above 100 ppm, a person’s ability to detect the gas is affected by

rapid temporary paralysis of the olfactory nerves in the nose, leading to loss of the sense of

smell. This means the gas can be present at dangerously high concentrations with no

perceivable odor.

H2S is classed as a chemical asphyxiant, similar to carbon monoxide and cyanide gases. It

inhibits cellular respiration and uptake of oxygen, causing biochemical suffocation.

AmSpec issues personal gas detectors to all employees who might encounter H2S. When

calibrated correctly and worn properly the detectors will ensure employee safety alerting them

to the presence of H2S. They are set to alarm at 10 ppm and must be worn close to the nose

and mouth to be effective.

Need more information? Feel free to contact the following AmSpec specialists

Testing … Jennifer Nesci … jnesci@amspecllc.com

Additives … Scott Hagstrom… scott.hagstrom@amspecllc.com

Inspection / handling … Jimmy Cormier … jimmy.cormier@amspecllc.com

If you would like to be removed from our distribution list or you require information on a certain subject, please let us know via return email.

Also, please be advised individual / group AmSpec laboratory / operational tours can be arranged upon request.

Please visit us on our website…www.amspecllc.com or contact us at (800) 286-2208

You might also like

- H2S Measurement MethodsDocument3 pagesH2S Measurement Methodssummiullah-zafar-1773No ratings yet

- Amspec Techtalk - Pona PianoDocument4 pagesAmspec Techtalk - Pona PianoAshutosh MishraNo ratings yet

- Astm D-3242Document5 pagesAstm D-3242Gabriella Evelyn LopesNo ratings yet

- Exceeding Expectations: Linear vs. Non-Linear That Is The QuestionDocument6 pagesExceeding Expectations: Linear vs. Non-Linear That Is The QuestionnarutorazNo ratings yet

- We're Going Global: The Impact of Product TemperatureDocument6 pagesWe're Going Global: The Impact of Product TemperaturebabushleshaNo ratings yet

- HM 49 - API MPMS Chapter 17.9 Vessel Experience Factor (VEF) - EIDocument2 pagesHM 49 - API MPMS Chapter 17.9 Vessel Experience Factor (VEF) - EIanNo ratings yet

- Amspec Techtalk A Stands For API Gravity 4Document5 pagesAmspec Techtalk A Stands For API Gravity 4Sudea CadabaNo ratings yet

- Gasoline FAQ 1Document9 pagesGasoline FAQ 1Claudia MmsNo ratings yet

- Exceeding Expectations: Did You KnowDocument2 pagesExceeding Expectations: Did You KnownarutorazNo ratings yet

- GUNVOR Independent Inspection Requirements Rev - 6Document34 pagesGUNVOR Independent Inspection Requirements Rev - 6Bhagoo HatheyNo ratings yet

- Repeatability & Reproducibility of HFODocument5 pagesRepeatability & Reproducibility of HFOshishir4870No ratings yet

- Condensate MSDSDocument8 pagesCondensate MSDSDavid LincolnNo ratings yet

- Exceeding Expectations: Please Visit Us at Our Website or Contact Us at 800 286-2208Document3 pagesExceeding Expectations: Please Visit Us at Our Website or Contact Us at 800 286-2208Indra NainggolanNo ratings yet

- ISO 8217 - Test Methods Precision and InterpretationDocument4 pagesISO 8217 - Test Methods Precision and Interpretationhesigu14No ratings yet

- Gasses FixDocument44 pagesGasses Fixlistya_rNo ratings yet

- Table Astm d1250Document1 pageTable Astm d1250RomandonNo ratings yet

- ERAVAP M 78045Document199 pagesERAVAP M 78045Bozar TgtNo ratings yet

- Api 2540-2004 PDFDocument32 pagesApi 2540-2004 PDFamerNo ratings yet

- OCTFDocument30 pagesOCTFVidhyaNo ratings yet

- IFIA Test Question Book English - August 2010Document84 pagesIFIA Test Question Book English - August 2010Maksim Lemon Rutovic100% (2)

- SASO FDS 30127 2016 E Gasoline SpecDocument13 pagesSASO FDS 30127 2016 E Gasoline SpecZiauddeen NoorNo ratings yet

- Astm-D2106 2007 (2017)Document4 pagesAstm-D2106 2007 (2017)Manea GeorgeNo ratings yet

- Tanker Cargo Shortage and Contamination ClaimsDocument3 pagesTanker Cargo Shortage and Contamination ClaimsEtulan AduNo ratings yet

- Advice for Safe STS Operations in ChittagongDocument13 pagesAdvice for Safe STS Operations in Chittagonggnckptn100% (1)

- Voyage Estimating: Related NewsDocument11 pagesVoyage Estimating: Related NewsNikhil SalviNo ratings yet

- Cargo Operations Manual - Tankers TemplateDocument61 pagesCargo Operations Manual - Tankers TemplateMai Pham100% (1)

- P&I Claims Analysis Web PDFDocument76 pagesP&I Claims Analysis Web PDFMyo Htet LinnNo ratings yet

- Astm Calculation NotesDocument6 pagesAstm Calculation NotesThapliyal SanjayNo ratings yet

- Amspec Techtalk Trim Wedge Calculations 2Document5 pagesAmspec Techtalk Trim Wedge Calculations 2Gerald EdisonNo ratings yet

- Carefully Carrying Liquid Cargoes (38Document6 pagesCarefully Carrying Liquid Cargoes (38amrianoNo ratings yet

- Nordic Victory officer qualifications matrixDocument2 pagesNordic Victory officer qualifications matrixDarwin Nacion ManquiquisNo ratings yet

- UK P I Bunkers and BunkeringDocument48 pagesUK P I Bunkers and BunkeringGeorgios PapakostasNo ratings yet

- Interview HintsDocument4 pagesInterview HintsAgnes Llanes CruzNo ratings yet

- E23a ISGOTT Bunker ChklistDocument4 pagesE23a ISGOTT Bunker Chklistvic.barca2012100% (1)

- Manual Piston Cylinder Sampling For Volatile Crude Oils, Condensates, and Liquid Petroleum ProductsDocument14 pagesManual Piston Cylinder Sampling For Volatile Crude Oils, Condensates, and Liquid Petroleum ProductsjiandapaNo ratings yet

- DVLS VUV Analyzer Manual for ASTM D8071 AnalysisDocument22 pagesDVLS VUV Analyzer Manual for ASTM D8071 AnalysisDuy DangNo ratings yet

- Distillation Curve of Fuel SamplesDocument4 pagesDistillation Curve of Fuel SamplesRais Alfiansyah TaufiqNo ratings yet

- A Masters Guide To Using Fuel Oil Onboard ShipsDocument74 pagesA Masters Guide To Using Fuel Oil Onboard ShipsPatetico Pianto LupoNo ratings yet

- Instructions To Maritime Cook Islands Inspector: Part A: General InformationDocument11 pagesInstructions To Maritime Cook Islands Inspector: Part A: General InformationMariyath Muraleedharan KiranNo ratings yet

- Petroleum Measurement Selected Pages ASTM TablesDocument43 pagesPetroleum Measurement Selected Pages ASTM Tablesnatarajchittur100% (1)

- Tank Cleaning To Methanol Standards Wall Wash Test RequirementsDocument1 pageTank Cleaning To Methanol Standards Wall Wash Test Requirementsdassi99100% (3)

- Oil Gas Sampling SystemsDocument8 pagesOil Gas Sampling SystemsCarlos JuárezNo ratings yet

- 16 - Upgrading Olefins For Gasoline BlendingDocument21 pages16 - Upgrading Olefins For Gasoline BlendingAbhimanyu SharmaNo ratings yet

- Sweet Crude CompositionDocument278 pagesSweet Crude Compositionthermo_engineerNo ratings yet

- LPG tanker cargo grade change and drydock preparation procedureDocument3 pagesLPG tanker cargo grade change and drydock preparation procedureAlice Mano JiamaNo ratings yet

- Amendments To Singapore Standard Code of Practice For BunkeringDocument10 pagesAmendments To Singapore Standard Code of Practice For Bunkeringbrain_ringNo ratings yet

- WWW Sevensurveyor Com Wedge FormulaDocument14 pagesWWW Sevensurveyor Com Wedge FormulaSurya Putra JayaNo ratings yet

- Types of Marine Insurance: Group 1Document18 pagesTypes of Marine Insurance: Group 1ayaNo ratings yet

- Shrinkage Loses Resulting From Liquid Hydrocarbon BlendingDocument6 pagesShrinkage Loses Resulting From Liquid Hydrocarbon BlendingManuel AguilarNo ratings yet

- Oil LossesDocument12 pagesOil Lossesrenkli100% (2)

- Crude OilDocument5 pagesCrude OilSyed Bakhtyar AhmedNo ratings yet

- Fuel Quality Testing: Instruction ManualDocument31 pagesFuel Quality Testing: Instruction Manualch3g44100% (1)

- ASTM D5191 - Jtvo9242Document5 pagesASTM D5191 - Jtvo9242Nayth Andres GalazNo ratings yet

- Modern Chemical TankersDocument41 pagesModern Chemical TankersHtoo Htoo Kyaw100% (1)

- Wedge Formula DESKTOP BH644DPDocument2 pagesWedge Formula DESKTOP BH644DPMed Amine RessadNo ratings yet

- Ibc CHPT17 PDFDocument15 pagesIbc CHPT17 PDFKanwalahsan2017gmail.com Kanwalahsan2017gmail.comNo ratings yet

- D1686 - 10 Standard Test Method For Color of Solid Aro PDFDocument3 pagesD1686 - 10 Standard Test Method For Color of Solid Aro PDFJacques Blueq100% (1)

- Fuel Field ManualDocument26 pagesFuel Field ManualFREDIELABRADORNo ratings yet

- Hydrogen Sulfide in PetroleumDocument28 pagesHydrogen Sulfide in PetroleumRamon Iglesias100% (1)

- 2.6 Scavengers O2 H2S Bruce Adams PDFDocument67 pages2.6 Scavengers O2 H2S Bruce Adams PDFJoel Siegel100% (1)

- Ajax E-565 Gas Engine Flyer PDFDocument2 pagesAjax E-565 Gas Engine Flyer PDFgustavoespinosamNo ratings yet

- Berkine BasinDocument3 pagesBerkine Basinkadrawi100% (1)

- 2018 04 HPDocument149 pages2018 04 HPVS2712No ratings yet

- Anandha Rajan.rDocument5 pagesAnandha Rajan.rjohn MNo ratings yet

- Chemguard C306-MS-C 3% AFFF Concentrate: DescriptionDocument2 pagesChemguard C306-MS-C 3% AFFF Concentrate: DescriptionChyeAmshariYumanNo ratings yet

- Canusa Pipeline Repair Products Installation GuideDocument2 pagesCanusa Pipeline Repair Products Installation GuideLewoski100% (1)

- NCA Petrol and Diesel Price InvestigationDocument43 pagesNCA Petrol and Diesel Price Investigationcimon999No ratings yet

- Project Guide B32 - 40A 2018Document145 pagesProject Guide B32 - 40A 2018Guilherme Henrique FilhoNo ratings yet

- 3lpe CoatingDocument30 pages3lpe CoatingMohan Kumar SNo ratings yet

- Chapter 1 - Part 1 Introduction To Organic ChemistryDocument43 pagesChapter 1 - Part 1 Introduction To Organic ChemistryqilahmazlanNo ratings yet

- Planetary Hydraulic Winch Instruction ManualDocument31 pagesPlanetary Hydraulic Winch Instruction Manualadrianram1No ratings yet

- EE TherajaDocument54 pagesEE TherajaJun RyNo ratings yet

- PegDocument1 pagePegAxel Mahya AvichenaNo ratings yet

- Legend SymbolsDocument21 pagesLegend SymbolsFaJar FieLdenNo ratings yet

- Workover Programme - Tubing Change OutDocument11 pagesWorkover Programme - Tubing Change OutE_Amr_SorourNo ratings yet

- Working up tar, pitch, asphalt, bitumen and producing pyroligneous acidDocument4 pagesWorking up tar, pitch, asphalt, bitumen and producing pyroligneous acidbehnamNo ratings yet

- Identify A Particular Cable and Not The Colour. in This Instance, The Cables Will Be Numbered at Each End Close To TheDocument2 pagesIdentify A Particular Cable and Not The Colour. in This Instance, The Cables Will Be Numbered at Each End Close To Themsimic57No ratings yet

- Bomba Hidrualica Brigg&Straton 356447Document32 pagesBomba Hidrualica Brigg&Straton 356447Guatemalan1979No ratings yet

- شهادة غاز L - P - GASDocument1 pageشهادة غاز L - P - GASMohamed NedalNo ratings yet

- Flamethrower - Plans - Mad - AbeDocument4 pagesFlamethrower - Plans - Mad - AbeJosé Roberto Romeiro Abrahão100% (1)

- 11062015XL38J3Q0Annexure documentofEIADocument368 pages11062015XL38J3Q0Annexure documentofEIAeastNo ratings yet

- Crucible Furnace Some More PDFDocument2 pagesCrucible Furnace Some More PDFikhlas amalNo ratings yet

- 0981-0172 - I9 - 201806 (Operator Manual)Document122 pages0981-0172 - I9 - 201806 (Operator Manual)Tan AkumaNo ratings yet

- Jawa-20 Owners Handbook PDFDocument18 pagesJawa-20 Owners Handbook PDFAnonymous AdOp46XOkNo ratings yet

- Energy Consumption Calculation ToolDocument4 pagesEnergy Consumption Calculation Toolhafidz bandungNo ratings yet

- Summary of Immiscible WAG at Tapis FieldDocument2 pagesSummary of Immiscible WAG at Tapis FieldUmmu Mus'abNo ratings yet

- Cleaning Pin Tubes Procedure PDFDocument3 pagesCleaning Pin Tubes Procedure PDFAarón Díaz100% (1)

- Himanshu Singh Turbocharger-SeminarDocument20 pagesHimanshu Singh Turbocharger-SeminarHimanshu SinghNo ratings yet

- Ccru SlidesDocument47 pagesCcru SlidesManish KalraNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- Advanced Computer-Aided Fixture DesignFrom EverandAdvanced Computer-Aided Fixture DesignRating: 5 out of 5 stars5/5 (1)

- Introduction to Fly-By-Wire Flight Control SystemsFrom EverandIntroduction to Fly-By-Wire Flight Control SystemsRating: 5 out of 5 stars5/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Quantum Mechanics 3: Wavefunctions, Superposition, & Virtual ParticlesFrom EverandQuantum Mechanics 3: Wavefunctions, Superposition, & Virtual ParticlesNo ratings yet

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet