Professional Documents

Culture Documents

Jurnal Terpadu 1

Uploaded by

imronmasfruriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jurnal Terpadu 1

Uploaded by

imronmasfruriCopyright:

Available Formats

Feasibility Studies with the Aim of Developing a Bilateral Offset Credit

Mechanism FY2011

Studies for Project Development and Organization

CO2 Emission Reduction in Power

Plant by Steam Tube Dryer (STD)

New Energy and Industrial Technology Development Organization (NEDO)

Tsukishima Kikai Co., Ltd.

Sojitz Corporation

CO2 Emission Reduction in Power

Plant by Steam Tube Dryer (STD)

Tsukishima Kikai Co., Ltd.

Sojitz Corporation

Study Background

Indonesia has abundant Low Rank Coal (LRC) reserves such as lignite

and sub-bituminous coal, and the number of LRC power plant is

expanding but LRC power generation efficiency is low due to its low

calorific value caused by high moisture content.

Therefore, pre-drying of LRC is expected to improve power generation

efficiency and decrease CO2 emission. STD, Indirect heating dryer is

expected to be suitable for this system, because low pressure steam

and low value energy generated in power generation can be utilized.

Target

• Confirming applicability of coal drying technology for Indonesian LRC

• Clarifying the potential to reduce CO2 emissions by reducing moisture in

LRC, utilizing Japanese high efficiency coal drying technology

• Developing a methodology of CO2 reduction and MRV with a combination of

reliable simulator, Coal Quality Evaluation System (C-Quens).

• Promotion of Steam Tube Dryer (STD) in Indonesian Market

Copyright © Tsukishima Kikai Co., Ltd. & Sojitz Corporation 2012

3

Configuration of

Tsukishima Kikai (TSK)’s Steam Tube Dryer (STD)

Configuration of TSK’s Steam Tube Dryer

① STD is an indirect heating dryer, in which Low Rank Coal Carrier Gas

Main body (Shell)

low pressure steam can be utilized as heating source.

:Steam drain can be recycled as boiler feed water. Heating tubes

② Easy to scale-up, suitable for large capacity.

Exhaust Gas

:500t/h capacity, Coal moisture is 10 to 6% after pre-drying.

③ Simple configuration. One year continuous operation Steam

is available.

:Reliable operation is suitable for power generation unit

④ Minimal exhaust gas from STD allows less capacity for

exhaust gas treatment.

Dried Coal Drain

:Safer operation with lower oxygen concentration Steam Tube Dryer Application for Power Plant

in exhaust gas.

Exhaust Gas

(Low Rank Coal)

LP Steam

Abundant Track Records & Proven Technology LRC

Tsukishima Kikai Co., Ltd.(TSK) has supplied

more than 500 sets of STD for various applications. Steam

Turbine

Electricity

STD

Condenser

Dried Coal

Boiler

BFW

(Boiler Feed Water)

Commercial Drying plant for coking coal & thermal coal

Copyright © Tsukishima Kikai Co., Ltd. & Sojitz Corporation 2012

4

Drying Test & Combustion Test

Content

Drying test and Combustion Test of Indonesian Low Rank Coal were

already executed by Pilot Plant at Indonesia.

Result

STD can achieve the appropriate drying speed without coal properties

change during drying process.

It was confirmed that STD is highly applicable to dry for Indonesian LRC

and the dried coal has good combustion characteristics.

60 120

50 100

Coal Temperature [℃]

Coal Moisture [%]

40 80

30 60

20 40

10 20

0 0

0.0 0.5 1.0 1.5 2.0 2.5 3.0

Heating area of Pilot test machine[m2]

Pilot plant for Drying test Pilot plant for Combustion test Drying curve

Copyright © Tsukishima Kikai Co., Ltd. & Sojitz Corporation 2012

5

Coal Quality Evaluation System (C-Quens)

“Coal Quality Evaluation System (C-Quens)” developed by Gifu

University was used in this study to verify the potential of

reduction of CO2 emission by reducing low rank coal moisture.

Overview

• C-Quens is a simulation software which originally designed for

determining performance of coal power plant with coal plant condition

and coal analysis data.

• C-Quens’s outputs are not only CO2 emission but also coal usage,

efficiency, ash quality and so on. (Simulates coal supply volume to

minimize electricity generation cost, negative impacts on the

environment, operational troubles on plan, etc)

• Abundant track records in Japan

- 23 coal power plants -

(Tohoku Electric Power Co., Chubu Electric Power Co., J-Power,

Okinawa Electric Power Co., Cugoku Electric Power Co. and Kobe

Steel., LTD ) The details are given in

the MRV pages

Copyright © Tsukishima Kikai Co., Ltd. & Sojitz Corporation 2012

6

Application of C-Quens for MRV Tool

Current Operation ACM0011

Key Parameters &

& Monitoring • Consolidated baseline methodology

Formulas Defined

Practice in for fuel switching from coal and/or

in Methodologies of petroleum fuels to natural gas in

Rembang Power

CDM existing power plants for electricity

Plant generation

Assume dried

coal i/o

natural gas

STD Installation Case

(C-QUENS)

New MRV Tool

For Rembang Power Plant, including Data Input Table

for Monitoring Items Automatic Calculation for

Emission Reduction Reporting format for Verification

Copyright © Tsukishima Kikai Co., Ltd. & Sojitz Corporation 2012

7

Result of CO2 Reduction from C-Quens simulation

Subroutine of boiler efficiency decreased by

steam extraction

• Steam Extraction (0.72 Mpa (G), 30 t/h)

C-Quens

Condition

• Moisture Content : 35wt%(without STD)→25wt%(with STD)

• Electricity Generation : 315MW×2plants

• Capacity Factor : 85%

Result

[ Annual CO2 Reduction ]

Baseline Emission Project Emission Leakage Emission

2,104,860 t-CO2/y - 2,091,176 t-CO2/y - 0 t-CO2/y = 27,368 t-CO2/y

×2plants ×2plants ×2plants

Copyright © Tsukishima Kikai Co., Ltd. & Sojitz Corporation 2012

8

Cash Flow Analysis

LRC Supplier Japanese Side

PJ Scheme for Cash Flow Analysis Syndicate

ERPA Loan Private

LRC

Supply Bank

Government of

• PLN establishes a SPC which owns and operates STD. Loan

Indonesia JBIC

STD

• Dried coal made by STD is supplied to Rembang Operator

(MOF)

Investment

Power Plant. SPC procures LRC and sells dried coal to (SPC)

Dried Coal Supply

PLN’s

Subsidiary

PLN under the supply agreement. Power supply (PPA)

• CAPEX is covered by PLN’s equity and JBIC’s Export STD Rembang Power Plant PLN

credit. Power Supply

Land Lease

Condition

• STD Cost • Finance (JBIC Export Credit)

Machinery: US$ 36.6 M, Installation: US$ 23.4 M Percentage STD Cost ×85%

(The remaining 15% is a down payment as equity portion)

• Coal Price (Jan 2012) Ratio JBIC: 60%, Private Bank: 40%

Period 2y (Construction Phase) + 10y (Operation Phase)

Indexes form HBA FOB Price Interest JBIC: CIRR (affected by market) + Risk Premium (1.32%)

Eco Coal (Moisture: 35wt%) 56.94 [US$/ton] Private Bank: Libor 6M (affected by market) + Spread (1.5%)

Eco Coal (Moisture: 25wt%) 74.11 [US$/ton] MOF: 1%

Private Upfront Fee (Private Bank Portion×1%) + NEXI Cost

Bank’s Fee

Results

Credit Price (EUR/CO2-ton) 8 9 9.5 10 10.5 11 12

Project IRR (%) 5.30 5.35 5.38 5.40 5.43 5.45 5.51

Equity IRR (%) 6.47 6.57 6.62 6.67 6.72 6.78 6.88

NPV (US$ , Million) 3.96 4.33 4.51 4.70 4.89 5.07 5.44

Pay Back Period (Years) 16 16 16 16 16 16 16

Copyright © Tsukishima Kikai Co., Ltd. & Sojitz Corporation 2012

9

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Prologue: Managerial Accounting and The Business EnvironmentDocument156 pagesPrologue: Managerial Accounting and The Business EnvironmentMarcus MonocayNo ratings yet

- Solvent Acid ClayDocument8 pagesSolvent Acid ClayimronmasfruriNo ratings yet

- Solvent Acid ClayDocument8 pagesSolvent Acid ClayimronmasfruriNo ratings yet

- Math10 q2 Week1 Module1 Polynomial-Functions For-ReproductionDocument32 pagesMath10 q2 Week1 Module1 Polynomial-Functions For-ReproductionChaz grant borromeo89% (9)

- Umf Vs Delta PDocument22 pagesUmf Vs Delta PimronmasfruriNo ratings yet

- K 103 ContentDocument24 pagesK 103 ContentAixa BerchiNo ratings yet

- 4-Catalytic Pyrolysis of Waste Plastic Into Liquid Fuel PDFDocument5 pages4-Catalytic Pyrolysis of Waste Plastic Into Liquid Fuel PDFFaisal MumtazNo ratings yet

- Ethanol N BiodieselDocument81 pagesEthanol N BiodieselimronmasfruriNo ratings yet

- Empty Fruit Bunch (EFB) Gasification in An Entrained Ow Gasification SystemDocument8 pagesEmpty Fruit Bunch (EFB) Gasification in An Entrained Ow Gasification SystemimronmasfruriNo ratings yet

- H Vs QDocument71 pagesH Vs QimronmasfruriNo ratings yet

- Refining Biofeedstock Innovations PDFDocument6 pagesRefining Biofeedstock Innovations PDFMaximiliano TaubeNo ratings yet

- 1 s2.0 S1364032112003036 MainDocument9 pages1 s2.0 S1364032112003036 MainAnil KunworNo ratings yet

- Current and Future Power Generation Technologies Pathways To Reducing The Cost of Carbon Capture For Coal Fueled Power Plants PDFDocument17 pagesCurrent and Future Power Generation Technologies Pathways To Reducing The Cost of Carbon Capture For Coal Fueled Power Plants PDFimronmasfruriNo ratings yet

- Bio Friends Inc.: Company InformationDocument8 pagesBio Friends Inc.: Company InformationimronmasfruriNo ratings yet

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- Lube Oil Re-Refining TechnologyDocument25 pagesLube Oil Re-Refining TechnologySunil BhosaleNo ratings yet

- Lube Oil Re-Refining TechnologyDocument25 pagesLube Oil Re-Refining TechnologySunil BhosaleNo ratings yet

- Biogas Industrial: User ManualDocument59 pagesBiogas Industrial: User ManualimronmasfruriNo ratings yet

- Biogas CaptureDocument44 pagesBiogas CaptureimronmasfruriNo ratings yet

- Book CementDocument242 pagesBook Cementproscoke100% (1)

- ASTM Recycling & RerefiningDocument5 pagesASTM Recycling & RerefiningimronmasfruriNo ratings yet

- Komposisi Waste Oil DLLDocument8 pagesKomposisi Waste Oil DLLimronmasfruriNo ratings yet

- NaOH Untuk Used OilDocument9 pagesNaOH Untuk Used OilimronmasfruriNo ratings yet

- Re-Refining of Automotive Lubricating Oil Using Wiped Film EvaporatorDocument4 pagesRe-Refining of Automotive Lubricating Oil Using Wiped Film EvaporatorimronmasfruriNo ratings yet

- Compare WFE TFE Dan Vacuum - OKDocument5 pagesCompare WFE TFE Dan Vacuum - OKimronmasfruriNo ratings yet

- Lube Oil Re-Refining TechnologyDocument25 pagesLube Oil Re-Refining TechnologySunil BhosaleNo ratings yet

- Re Refining of Used Lubricating Oil PDFDocument4 pagesRe Refining of Used Lubricating Oil PDFArpan BiswasNo ratings yet

- Lube Oil Re-Refining TechnologyDocument25 pagesLube Oil Re-Refining TechnologySunil BhosaleNo ratings yet

- Thin Fil EvapDocument13 pagesThin Fil EvapimronmasfruriNo ratings yet

- Modern RecoveryDocument5 pagesModern RecoveryimronmasfruriNo ratings yet

- Olis EngDocument74 pagesOlis EngBoulos NassarNo ratings yet

- Phy Interface Pci Express Sata Usb31 Architectures Ver43 PDFDocument99 pagesPhy Interface Pci Express Sata Usb31 Architectures Ver43 PDFRaj Shekhar ReddyNo ratings yet

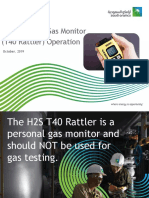

- H2S Personal Gas MonitorDocument14 pagesH2S Personal Gas Monitormaher mansiNo ratings yet

- Survey Questionnaire 3 - Student EngagementDocument2 pagesSurvey Questionnaire 3 - Student EngagementDAN MARK CAMINGAWANNo ratings yet

- W01-Introduction To Materials Modeling and SimulationDocument30 pagesW01-Introduction To Materials Modeling and SimulationMuco İboNo ratings yet

- AWS Abbreviations Oxyfuel Cutting - OFC Oxyacetylene Cutting - OFC-A Oxyfuel Cutting - Process and Fuel GasesDocument8 pagesAWS Abbreviations Oxyfuel Cutting - OFC Oxyacetylene Cutting - OFC-A Oxyfuel Cutting - Process and Fuel GasesahmedNo ratings yet

- Turkey GO (896-22)Document1 pageTurkey GO (896-22)shrabon001No ratings yet

- Dallas Symphony Orchestra 2009 Annual ReportDocument14 pagesDallas Symphony Orchestra 2009 Annual ReportCharlie StephensonNo ratings yet

- Barotac Nuevo POP PDFDocument10 pagesBarotac Nuevo POP PDFJason Barrios PortadaNo ratings yet

- Chapter 5 - Societies To Social NetworksDocument11 pagesChapter 5 - Societies To Social NetworksSumeet KumarNo ratings yet

- Chilis Allergen Vegetarian GenericDocument6 pagesChilis Allergen Vegetarian Genericsuresh jkNo ratings yet

- Agrasar Lecture and Demonstration Programme On Water, Food and Climate ChangeDocument20 pagesAgrasar Lecture and Demonstration Programme On Water, Food and Climate ChangeMinatiBindhaniNo ratings yet

- Wilkerson Case Study FinalDocument5 pagesWilkerson Case Study Finalmayer_oferNo ratings yet

- Avila-Flores Etal 2017 - The Use of The DPSIR Framework To Estimate Impacts of Urbanization On Mangroves of La Paz BCSDocument13 pagesAvila-Flores Etal 2017 - The Use of The DPSIR Framework To Estimate Impacts of Urbanization On Mangroves of La Paz BCSKriistian Rene QuintanaNo ratings yet

- Autodesk 2016 Product Keys 1Document3 pagesAutodesk 2016 Product Keys 1EfrEn QuingAtuñaNo ratings yet

- Cheats BFG Doom 3Document5 pagesCheats BFG Doom 3screw_x3No ratings yet

- Theory of Multiple Intelligences and WhyDocument7 pagesTheory of Multiple Intelligences and WhyEveNo ratings yet

- Nitotile GroutDocument2 pagesNitotile GroutBalasubramanian AnanthNo ratings yet

- Cancer Registry Standard Operating ProceduresDocument3 pagesCancer Registry Standard Operating ProceduresAnan AghbarNo ratings yet

- 2course Codes For 1 SEMESTER S.Y. 2021-2022: GE 2/ GE 1: Readings in The PhilippineDocument10 pages2course Codes For 1 SEMESTER S.Y. 2021-2022: GE 2/ GE 1: Readings in The PhilippineRexson Dela Cruz TagubaNo ratings yet

- Design Guide For Overhead CranesDocument3 pagesDesign Guide For Overhead CranesralluinNo ratings yet

- Adding Rows Dynamically in A Table Using Interactive Adobe FormsDocument5 pagesAdding Rows Dynamically in A Table Using Interactive Adobe Formsbharath_sajjaNo ratings yet

- Bba-Mq Tias 2023-24Document2 pagesBba-Mq Tias 2023-24Chris PresleyNo ratings yet

- Reading 40 Introduction To Industry and Company AnalysisDocument23 pagesReading 40 Introduction To Industry and Company AnalysisNeerajNo ratings yet

- AutoCad 2012 ReadmeDocument2 pagesAutoCad 2012 Readmema_basith50% (2)

- Primax Solar Energy CatalogueDocument49 pagesPrimax Solar Energy CatalogueSalman Ali QureshiNo ratings yet

- Regulatory Guide 1.71Document5 pagesRegulatory Guide 1.71Siis IngenieriaNo ratings yet

- XDM-100 IOM SDH A00 4-5 enDocument334 pagesXDM-100 IOM SDH A00 4-5 endilipgulatiNo ratings yet

- File Handling in Python PDFDocument25 pagesFile Handling in Python PDFNileshNo ratings yet