Professional Documents

Culture Documents

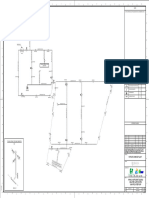

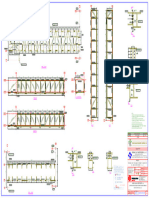

Section Thro. Offtake: Steel Ladder Details

Section Thro. Offtake: Steel Ladder Details

Uploaded by

Justus OtungaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section Thro. Offtake: Steel Ladder Details

Section Thro. Offtake: Steel Ladder Details

Uploaded by

Justus OtungaCopyright:

Available Formats

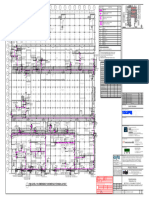

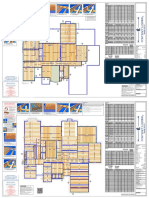

Location Bar mark Bar dia.

Total Length Cut length Total Sketch of bar

mm No. A(mm) B(mm) mm length m shape

P1 Y10 4 503 100 603 2412

Floor Slab

P2 4 1378 100 1478 5912

P3 4 2145 100 2245 8980

P4 4 3076 100 3176 12704

50

50mmx25mm reducer

P5 4 3409 100 3509 14036 varies

25mm nipple P6 4 3688 100 3788 15152

P1 to P17

P7 4 3924 100 4024 16096

25mm socket P8 4 4126 100 4226 16904

P9 4 4297 100 4397 17588

2 NoY8 P20

25mm flange P10 4 4441 100 4541 18164

25mm x 900 P11 4 4561 100 4661 18644

25mm

Max. water level P12 4 4612 100 4712 18848

offtake pipe

P13 4 4658 100 4758 19032

300

P14 4 4735 100 4835 19340

3 No.Y8 P20

25mm socket P15 4 4792 100 4892 19568

32mm dia. GI pipe 250

250

P16 4 4829 100 4929 19716

300

80mm dia. overflow pipe P17 4 4848 100 4948 19792

4No.Y8 P20

2,165

P18 1 12878 600 13478 13478

300

3082

2,750 P19 1 13980 600 14580 14580

R20mm welded

2No.Y8 P20

Walling P20 Y8 29 13430 600 14030 406870

to pipes

SECTION THRO. OFFTAKE

300

25mm plastering with water proof

P21 4 1008 100 1108

cement SCALE 1: 25 Roof P22 Y10 4 1880 100 1980 36876

300

25mm floor screed with water proof 225 dia varies

P23 4 2424 100 2524 37308

cement

20mm x 15mm bondex joint P24 4 2835 100 2935 37308

STEEL LADDER DETAILS 80mm x50mm reducing socket

P25 4 3165 100 3265 38044

SCALE 1:50 P20

200mm RC slab 50mm nipple P26 4 3437 100 3537 38336

50mm blinding P27 4 3666 100 3766 38612

400

50mm socket

P28 4 3857 100 3957 38836

200mm well compacted

P29 4 4017 100 4117 39024

100 100 hardcore

200 50 225 2,800 225 50 200 P30 4 4149 100 4249 39172

50

P31 4 4256 100 4356 39284

50mm 9000

3,950 P32 4 4340 100 4440 39360

scour pipe P33 4 4402 100 4502 39396 P44

50mm flange

CROSS SECTION P34 4 4443 100 4543 435450

250

P35 4 4463 100 4563 232240

SCALE 1: 25

P36 Y8 4 28695 100 - 344340

50mm x 90o bend

P37 1 12878 600 13478 13478

50mm socket

SECTION THRO SCOUR PIPE P38 Y8 36 1360 100 1460 52560

SCALE 1: 25 manhole

cover

P41 R8 4 9553 100 9653 38612

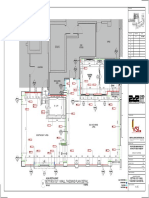

NOTES

1. HARDCORE

-Layer thickness shall be determined by the engineer but not less than 200mm

2. MASONRY WALL

25mm ball -Shall not be connected to either the floor slab nor the roof slab. The wall supporting area of the floor slab as

valve well as the top of the wall shall be trowel finished and be painted with 3 coats of bituminous paint.

-The masonry wall shall be built of good quality local building stones or concrete blocks, the size of the stone

600mm x 600mm manhole with

25mm IPS shall be : width not less than 150mm and 225mm respectively for 150mm and 225mm thick walling.

framed steel plate cover

inlet pipe : length between 200mm and 300mm

: height not more than 225mm

-Wall stone is to be soaked for 24 hours in water before laying.

-All sand used must be clean and sharp and free from all earth clay vegetable and other deleterious matter.

3. CONCRETE

-Concrete class 20/20 (mixture 1:2:4) for floor slab, roof slab as well as concrete blocks concrete class Q

Y12 @ 150mm c/c (mixture 1:3:6) for blinding.

Y10 150mm c/c

bothways P21 to P35 32mm dia.GI pipe stands with R20 -All ballast for concrete to be broken from sound rock to a maximum size of 20mm. It must pass through a

bothways P1 to P12

welded at 300mm c/c fabricated 22mm mesh screen and should be evenly graded to 6mm size so that approx. 50% is retained on a 13mm mesh

ladder (internal only) and not less than 15% passes 10mm mesh.

4. REINFORCEMENT

0

93

-Minimum concrete cover of reinforcement 25mm

5. FLOOR SLAB

50mm dia. vent pipe -Of the tank must be 350mm if the tank is sited on black cotton soil or similar soil conditions. The reinforcement

must be diameter 20mm bars c/c 200mm on the top and diameter 10mm bars c/c 200mm on the bottom

(crosswise).

6. CONSTRUCTION JOINTS

TYPICAL SECTION THRO

-Are not permitted, the slab must be casted at one time.

INLET PIPE 7. FORMWORK

SCALE 1:25 -For the roof slab must have a camber of 50mm at the centre

8. EXTERIOR SURFACE

15

0

-Of the tank shall receive one coat of cement wash

1,

ROOF SLAB SHOWING

30

9. INTERIOR SURFACE

0

16G steel plate with

1,

100mm dia. scour pipe

-Of the tank shall be plastered thickness 25mm in 3 no coats with a mortar mixture of 1:2 (cement :sand). To

REINFORCEMENT

00

paneled 16G 25mm

0

square hollow section lockablemanhole 1,300 obtain a water proof plastering, pudlo cement shall be added.

SCALE 1: 25 cover

with frame 150 1,000 150 RIFT VALLEY WATER WORKS

15

0

DEVELOPMENT AGENCY

Outlet and Scour Valve Chamber GL HEADQUARTER

150

Control Valve 150mm thick masonry

walling

10m3 GROUND MASONRY

1,000

FLOOR SLAB SHOWING 50mm dia. outlet pipe

STORAGE TANK

REINFORCEMENT AND PIPING ARRANGEMENT 80mm dia. scour pipe

100x350mm strip foundation Gravel

SCALE 1: 25

Scale : As shown

100

100 150 1,000 150 100 FIGURED DIMENSIONS ONLY TO BE TAKEN FROM

350 800 350 THIS DRAWING

1,500 Surveyed Date:

Designed Paul G. Muhuhe Date:June 2019

SECTION THRO VALVE Drawn Paul G. Muhuhe Date:June 2019

CHAMBER Checked C.M.Murage Date:June 2019

SCALE 1:50

DRG. No. RVWWDA/HQ/STD/T/01/2019

You might also like

- Land Use Change of Urban Wetlands in Davao City by EnP Lemuel ManaloDocument21 pagesLand Use Change of Urban Wetlands in Davao City by EnP Lemuel ManaloLemuel Manalo100% (2)

- Detail of Quantity of Hume Pipe Culvert Single ROW Input Detail For Quantity of Hume Pipe Culvert at Various LocationsDocument1 pageDetail of Quantity of Hume Pipe Culvert Single ROW Input Detail For Quantity of Hume Pipe Culvert at Various LocationsAjay Kumar GuptaNo ratings yet

- Plano Chasis Vm330Document1 pagePlano Chasis Vm330D FernandezNo ratings yet

- U P PU U P X0204 (KL.15) EURO 4/5 EURO 4/5 EURO 4/5: Chassis para Ônibus, Bm. 382.15Document1 pageU P PU U P X0204 (KL.15) EURO 4/5 EURO 4/5 EURO 4/5: Chassis para Ônibus, Bm. 382.15Bruno SilvaNo ratings yet

- Printed Wiring Board: MAIN Unit (Side A)Document6 pagesPrinted Wiring Board: MAIN Unit (Side A)Nazim MetiNo ratings yet

- 3372 Ecg B01 DWG K 01 005 Ifc 0Document1 page3372 Ecg B01 DWG K 01 005 Ifc 0mohammad faragNo ratings yet

- 08 SwitchgearDocument12 pages08 SwitchgearMuhammad AsifNo ratings yet

- Auditorium Seating Plan PDFDocument1 pageAuditorium Seating Plan PDFAravindNo ratings yet

- Areal Rainfall EstimationDocument1 pageAreal Rainfall EstimationJohnoricks Ace Camarillo CatlingNo ratings yet

- T00 O00c01 Ari 04 ZZ SDW Ar 05001Document1 pageT00 O00c01 Ari 04 ZZ SDW Ar 05001muhammadibraheem5017No ratings yet

- Notes: Piping & Instrument Diagram Osbl Fire Water System Main Fire Water PumpDocument1 pageNotes: Piping & Instrument Diagram Osbl Fire Water System Main Fire Water PumpHadi SuagungNo ratings yet

- C42C Yop F26 Hy 1ya 4303 - 7Document1 pageC42C Yop F26 Hy 1ya 4303 - 7mirandayulisra287No ratings yet

- P30 Pro (VOG-Lxx .HL2VOGUEM - PCB LayoutDocument2 pagesP30 Pro (VOG-Lxx .HL2VOGUEM - PCB Layouttotem xpressNo ratings yet

- Foundation SectionDocument1 pageFoundation SectionShreyansh JainNo ratings yet

- Planos-Tramo-I Final de EjecucionDocument6 pagesPlanos-Tramo-I Final de EjecucionDiego RuizNo ratings yet

- TroubleshootingDocument24 pagesTroubleshootingjbelope52No ratings yet

- T.y.bms Sem-Vi Oct.19 Choice Based Human Resource - HRM in Global Prespective Pd-16 Oct.19 Pc-74861Document2 pagesT.y.bms Sem-Vi Oct.19 Choice Based Human Resource - HRM in Global Prespective Pd-16 Oct.19 Pc-74861Gaurav GhareNo ratings yet

- Pad Footings Quantity Take Off: Footing DetailsDocument1 pagePad Footings Quantity Take Off: Footing DetailsVincent MutambirwaNo ratings yet

- Second Floor Beam DetailingDocument1 pageSecond Floor Beam DetailingSri Rama ChandNo ratings yet

- Pilares Que Nacen en NIVEL 0.0 y Mueren en NIVEL 3.0 Hormigón: H-21 Acero en Barras: AH-420 Acero en Estribos: AH-420Document1 pagePilares Que Nacen en NIVEL 0.0 y Mueren en NIVEL 3.0 Hormigón: H-21 Acero en Barras: AH-420 Acero en Estribos: AH-420Edwin Henrry Tarifa MercierNo ratings yet

- Eng Est L16 012 - R1Document1 pageEng Est L16 012 - R1Gustavo AbreuNo ratings yet

- Drawing4 ModelDocument1 pageDrawing4 ModelKaran KumarNo ratings yet

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- Mountain Residence Poverh 3Document1 pageMountain Residence Poverh 3crazyproff1911No ratings yet

- Wall Detail 1Document1 pageWall Detail 1LMN ArchitectNo ratings yet

- Mountain Residence Poverh 10Document1 pageMountain Residence Poverh 10crazyproff1911No ratings yet

- Módulo CPCDocument1 pageMódulo CPCBruno SilvaNo ratings yet

- Design and TD For MBR Dubai HillsDocument1 pageDesign and TD For MBR Dubai HillszfrlNo ratings yet

- 07Document34 pages07ESRANo ratings yet

- Master-Lokasi 25.8.2022Document1 pageMaster-Lokasi 25.8.2022naimparmal3No ratings yet

- Foundation Layout: Agami EngineeringDocument1 pageFoundation Layout: Agami EngineeringNimish PrabhukhanolkarNo ratings yet

- ETE MurosDocument1 pageETE MurosLuanaGuimarãesNo ratings yet

- OR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE EDocument1 pageOR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE EAhmed SolankiNo ratings yet

- OR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE FDocument1 pageOR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE FAhmed SolankiNo ratings yet

- Layout MTL - Sin LogoDocument1 pageLayout MTL - Sin LogoFer Cristopher PvelaNo ratings yet

- Focus: All Devices and Components To Match Base Built System Make and ModelDocument1 pageFocus: All Devices and Components To Match Base Built System Make and ModelArun UdayabhanuNo ratings yet

- First Floor-Daimond 0°Document1 pageFirst Floor-Daimond 0°tarique1370No ratings yet

- SAILOR 6004 Control Panel: Installation GuideDocument2 pagesSAILOR 6004 Control Panel: Installation GuideRomeish KelaartNo ratings yet

- MODELO Projeto DadosDocument1 pageMODELO Projeto DadosWilson PicininNo ratings yet

- A545 730 81 41 02052 - Rev 0 PDFDocument2 pagesA545 730 81 41 02052 - Rev 0 PDFFaizan Ullah KhanNo ratings yet

- Torano-Maki DP-3510/3520/4510/4520/6010/6020: Service Modes (For Copier)Document2 pagesTorano-Maki DP-3510/3520/4510/4520/6010/6020: Service Modes (For Copier)asdrefNo ratings yet

- T5 B2 LayoutDocument1 pageT5 B2 Layoutsatyam.pulkam7490No ratings yet

- Section 1: Key PlanDocument1 pageSection 1: Key Planalezandro del rossiNo ratings yet

- Soshnick Residence - Production LayoutDocument3 pagesSoshnick Residence - Production Layoutmauricio mejiaNo ratings yet

- Proceso de Plano General: PersonalizadoDocument1 pageProceso de Plano General: PersonalizadoAntonio Mijail Briceño LiñanNo ratings yet

- GRGRGDocument3 pagesGRGRGSenthilmurugan KumaresanNo ratings yet

- Furminator v. Rolf C. Hagen Et. Al.Document9 pagesFurminator v. Rolf C. Hagen Et. Al.PriorSmartNo ratings yet

- Balcon C1Document1 pageBalcon C1Laura GeorgianaNo ratings yet

- HW4 - Shfrytezimi NentokesorDocument2 pagesHW4 - Shfrytezimi NentokesorGzim IbishiNo ratings yet

- Road The PDFDocument2 pagesRoad The PDFTiery guitareNo ratings yet

- S-105-Third Floor.BDocument1 pageS-105-Third Floor.BNimish PrabhukhanolkarNo ratings yet

- Electrical Power Generator - Agregati - Electrolux Macedonia - ELITE - IVECODocument2 pagesElectrical Power Generator - Agregati - Electrolux Macedonia - ELITE - IVECOIgor MatijevićNo ratings yet

- Kel. Pisangcandi Kec. Sukun: Jl. MentengDocument1 pageKel. Pisangcandi Kec. Sukun: Jl. Mentengarpan gugstiawanNo ratings yet

- Wa0641437 0002 0000Document1 pageWa0641437 0002 0000BenjaminNo ratings yet

- DZZSM00237-0 SFDL2 TM Eng 1st 0422 PDFDocument2 pagesDZZSM00237-0 SFDL2 TM Eng 1st 0422 PDFasdrefNo ratings yet

- Pop 44860 106 - Rev1Document2 pagesPop 44860 106 - Rev1Muhammad NURMANNo ratings yet

- Revisions: Research in MotionDocument2 pagesRevisions: Research in Motionzulkafli othmanNo ratings yet

- Pacific Adventure Deck PlanDocument1 pagePacific Adventure Deck PlanMrKrish GamingNo ratings yet

- Foundation Layout: Agami EngineeringDocument1 pageFoundation Layout: Agami EngineeringNimish PrabhukhanolkarNo ratings yet

- Plan +16405 D - D: Semac & Partners L.L.CDocument1 pagePlan +16405 D - D: Semac & Partners L.L.CDhina karanNo ratings yet

- C-1CO15 - COLUMNA - Rev 1Document1 pageC-1CO15 - COLUMNA - Rev 1LEONCIO RIVERA GALINDONo ratings yet

- 275291Document40 pages275291Justus OtungaNo ratings yet

- Tender DocumentDocument67 pagesTender DocumentJustus OtungaNo ratings yet

- Project Schedule Critical Path and GanttDocument21 pagesProject Schedule Critical Path and GanttJustus OtungaNo ratings yet

- Longitudinal Section: Rift Valley Water Services Board Muhonia Turasha Water ProjectDocument1 pageLongitudinal Section: Rift Valley Water Services Board Muhonia Turasha Water ProjectJustus OtungaNo ratings yet

- Longitudinal Section: Rift Valley Water Services BoardDocument1 pageLongitudinal Section: Rift Valley Water Services BoardJustus OtungaNo ratings yet

- KureswoDocument89 pagesKureswoJustus OtungaNo ratings yet

- Rift Valley Water Works Development Agency: Tender Document ForDocument152 pagesRift Valley Water Works Development Agency: Tender Document ForJustus OtungaNo ratings yet

- Clarification 1 and Addendum 1 - Kgn-gogo-08-2019-Tender For Construction of Social Hall at Gogo Power Station.Document1 pageClarification 1 and Addendum 1 - Kgn-gogo-08-2019-Tender For Construction of Social Hall at Gogo Power Station.Justus OtungaNo ratings yet

- Water WorksDocument161 pagesWater WorksJustus OtungaNo ratings yet

- Call For Applications - Students PDFDocument4 pagesCall For Applications - Students PDFJustus OtungaNo ratings yet

- Tender Notice For KureswoDocument1 pageTender Notice For KureswoJustus OtungaNo ratings yet

- DownloadDocument192 pagesDownloadJustus OtungaNo ratings yet

- Lab Report of Newton RingsDocument1 pageLab Report of Newton RingsJustus OtungaNo ratings yet

- DownloadDocument192 pagesDownloadJustus OtungaNo ratings yet

- Cosmotic Surgical Center Business PlanDocument37 pagesCosmotic Surgical Center Business PlanRamchandra Cv100% (1)

- SVT International Scope of Services AnsichtDocument2 pagesSVT International Scope of Services AnsichtIvan HandjievNo ratings yet

- Largo & Allegro: Air CompressorsDocument12 pagesLargo & Allegro: Air Compressorsdan 117No ratings yet

- Analysis of Fires and Firefighting Operations On Container Vessels 5e3d66a0382a7-81-95Document15 pagesAnalysis of Fires and Firefighting Operations On Container Vessels 5e3d66a0382a7-81-95alin grecuNo ratings yet

- Ketamine ZhaoPDocument12 pagesKetamine ZhaoPSutanMudaNo ratings yet

- Lostgears Fargo July 302008Document3 pagesLostgears Fargo July 302008lostgearsNo ratings yet

- Simple Easy Daily Mantras For All Above 40 MantrasDocument45 pagesSimple Easy Daily Mantras For All Above 40 MantrasDr Naresh ChawhanNo ratings yet

- End of Year Tercero Eso BilDocument4 pagesEnd of Year Tercero Eso BilCLEMENTE GARCIA RAFAEL DARIONo ratings yet

- Common Disk-Shaped Tablets A Tablet Is A Mixture of ActiveDocument8 pagesCommon Disk-Shaped Tablets A Tablet Is A Mixture of Activenasser9876No ratings yet

- STO Ship Management CaseDocument20 pagesSTO Ship Management Casepradyum kumarNo ratings yet

- Uttarakhand Power Corporation Limited: Released Connections BetweenDocument27 pagesUttarakhand Power Corporation Limited: Released Connections BetweenAshwani SharmaNo ratings yet

- AGM Minutes 2019Document5 pagesAGM Minutes 2019nomadNo ratings yet

- Key Words: Dikaka, Cham, Cremation, Tradition, Bury, Tomb, DeathDocument16 pagesKey Words: Dikaka, Cham, Cremation, Tradition, Bury, Tomb, DeathJurgoi Saleh Jnr.No ratings yet

- Some Major Plant Toxicities of The Western United StatesDocument8 pagesSome Major Plant Toxicities of The Western United StatesFlaviu TabaranNo ratings yet

- Chemical Reaction Engineering (CRE) Is TheDocument61 pagesChemical Reaction Engineering (CRE) Is TheHairunnisaNo ratings yet

- Brands You Trust.: CRANE® REVO® - Pneumatic Rack and Pinion ActuatorsDocument12 pagesBrands You Trust.: CRANE® REVO® - Pneumatic Rack and Pinion ActuatorsYamil Diaz SantosNo ratings yet

- Short Coursework: Literary Devices of PoemDocument13 pagesShort Coursework: Literary Devices of Poemrhijau_3No ratings yet

- Christmas CrackerDocument1 pageChristmas CrackerPaulo SantosNo ratings yet

- Aurinio L50 L30 Brochure en TXM WEBDocument9 pagesAurinio L50 L30 Brochure en TXM WEBfikNo ratings yet

- Revised 1st Year Degree Syllabus of TitDocument28 pagesRevised 1st Year Degree Syllabus of TitGhagniSinghaniaNo ratings yet

- St. Jude 2023 OKC Floor and Elevation PlanDocument3 pagesSt. Jude 2023 OKC Floor and Elevation PlanOKCFOXNo ratings yet

- June 2019 MS - Component 1 WJEC Geography (A) GCSEDocument17 pagesJune 2019 MS - Component 1 WJEC Geography (A) GCSERiskyRoadzNo ratings yet

- Nadsat GlossaryDocument5 pagesNadsat GlossaryWilson MullenNo ratings yet

- CE6405 Soil MechanicsDocument13 pagesCE6405 Soil MechanicsshanmugamNo ratings yet

- Example DWOP AgendaDocument1 pageExample DWOP Agendagman_g2000100% (1)

- Annual Report 2020 21Document268 pagesAnnual Report 2020 21David haughesNo ratings yet

- Q E R RDocument3 pagesQ E R Rsadam gebiNo ratings yet

- M7025cat Milpower Ysmetronics M7025-10aDocument5 pagesM7025cat Milpower Ysmetronics M7025-10abhutaniseNo ratings yet