Professional Documents

Culture Documents

Piston Manufacturing Process

Piston Manufacturing Process

Uploaded by

hannah marvilla0 ratings0% found this document useful (0 votes)

4 views3 pagesPiston Manufacturing Process

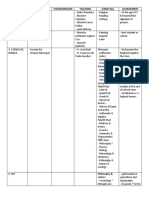

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPiston Manufacturing Process

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views3 pagesPiston Manufacturing Process

Piston Manufacturing Process

Uploaded by

hannah marvillaPiston Manufacturing Process

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Piston manufacturing process

1. 1. PISTON MANUFACTURING PROCESS PRESENTED BY, KOWSHIGAN S V

2. 2. Pistons The piston's primary responsibility is to take thermal energy created by the

ignition of fuel and air, and transform it into linear motion. Linear motion acts on the

crankshaft journal and becomes rotary motion.

3. 3. A typical piston illustrating the various parts and the names.

4. 4. Piston Heads (Crown) • Domed • Flat Top • Recessed (valve reliefs) • Dished

5. 5. A domed piston with valve reliefs or valve pockets. A Flat Top piston A Flat Top piston

with valve reliefs or valve pockets. A Dished piston with valve reliefs or valve pockets.

6. 6. Piston Skirts Moly Graphite A low-friction moly coating on the skirt of this piston helps

prevent piston scuffing when the engine is cold.

7. 7. Piston Composition @ Process

8. 8. Piston Composition @ Process Aluminum - cast Pour aluminum into a mold Light-

weight economical Some silicone added General usage Brittle Somewhat

unpredictable expansion qualities

9. 9. Piston Composition @ Process

10. 10. Aluminum - Forged Can be made lighter weight (smaller) than cast because it’s

stronger Can withstand abuse Newer designs have predictable expansion qualities

Silicon & Nickel added Greater piston to wall clearance

11. 11. Notice the temperature difference between a forged piston and a cast piston.

12. 12. Piston diameter being measured using a micrometer.

13. 13. Compression Ring Composition • Pearlitic • Nodular Iron • Ductile Iron – flexible • Cast

Iron • Chromium - .0004” - durable • Molybdenum – reduced scuffing • Chrome-moly

14. 14. Piston Rings • Compression • Oil – usually unidirectional Ring expander

15. 15. • The preferred material for compression rings is a low- alloyed, heat-treated nodular cast

iron (KV1/GOE 52). • This material is characterized by a high bending strength of min. 1300

MPa and a high modulus of elasticity attributable to a martensitic microstructure and

spherulitic graphite structure.

16. 16. •In the 2nd groove, alloyed grey cast irons are used in a heat-treated condition. •Besides

having a high bending strength and modulus of elasticity, an increased hardness of 320 to

470 HB is produced in order to obtain the required wear resistance in the uncoated condition.

•The demand for high wear strength is also met by the use of a tempered, alloyed cast iron

(GOE 44). This has the benefit of a high bending strength of min. 800 MPa and high modulus

of elasticity. •The good wear resistance results from the combination of a fine-pearlitic matrix

structure and finely dispersed, precipitated secondary carbides. • Unalloyed grey cast iron is

used for 2-piece oil rings in the 3rd groove. • These ring materials (STD / GOE 12, GOE 13)

are characterized by a fine-lamellar graphite structure in a pearlitic matrix and have good

conformability due to a relatively low modulus of elasticity.

17. 17. •Reduced width piston rings in gasoline engines to match reductions in the overall height

of pistons, and increasing combustion pressures in diesel engines call for materials with

increased strength characteristics. •These challenges are met by the use of high-chromium

alloyed steels and spring steels. •The greater durability under increased stresses is

demonstrated by the improved fatigue strength manifested as form stability in a comparison

of S/N curves for different piston ring materials (spherulitic, heat-treated cast iron versus

heat-treated 18% chromium steel). •The wear resistance derives from finely distributed

chromium carbides of the type M23C6 and M7C3 embedded in the tempered martensite

matrix. •For improved wear resistance these steels are mainly used in a nitrided condition or

with a peripheral coating. •The steels mentioned are used chiefly as compression ring

materials for gasoline engines and truck diesel engines as well as for the steel rails and

expander-spacers of oil control rings and for 2-piece profiled steel oil rings.

18. 18. Pearlitic Rings • Pearlite is a two-phased, lamellar (or layered) structure composed of

alternating layers of alpha-ferrite (88 wt%) and cementite (12%) that occurs in some steels

and cast irons. • The eutectoid composition of Austenite is approximately 0.8% carbon ; steel

with less carbon content will contain a corresponding proportion of relatively pure ferrite

crystallites that do not participate in the eutectoid reaction and cannot transform into pearlite.

• The appearance of pearlite under the microscope resembles mother of pearl (also a

lamellar structure), from which it takes its name.

19. 19. Nodular (ductile) Iron • Ductile iron, also called ductile cast iron, spheroidal graphite iron,

nodular cast iron, is a type of cast iron invented in 1943 by Keith Millis. • While most varieties

of cast iron are brittle, ductile iron is much more flexible and elastic, due to its nodular

graphite inclusions.

20. 20. Chromium rings • Chromium is a steely-gray, lustrous, hard metal that takes a high polish

and has a high melting point. • It is odourless, tasteless, and malleable.

21. 21. Chromium facing can be seen on the right side of the sectional view of the piston ring.

22. 22. Molybdenum Rings • Molybdenum • It has the sixth-highest melting point of any element,

and for this reason it is often used in high-strength steel alloys. • Molybdenum was

discovered in 1778 by Carl Wilhelm Scheele and first isolated in 1781 by Peter Jacob Hjelm

23. 23. Molybdenum facing can be seen on the right side of the sectional view of the piston ring.

TECH TIP

24. 24. This typical three-piece oil control ring uses a hump- type stainless steel spacer-

expander. The expander separates the two steel rails and presses them against the cylinder

wall.

25. 25. Ring Gaps • Ring gap must be checked prior to engine assembly • Loose • Tight • Butt

gap • Gapless?

26. 26. The gapless ring overlaps, while the conventional ring design uses a gap. Frequently

Asked Question

27. 27. Gapless Ring

28. 28. Combustion chamber pressure forces the ring against the cylinder wall and the bottom of

the ring groove. These are the two sealing surfaces that the top ring must be able to seal for

maximum engine power.

29. 29. The piston rings must have the specified side and back clearance. Fitting Piston Rings

30. 30. The rectangular and the barrel face are the most commonly used top compression rings

because they provide the best seal.

31. 31. The taper face ring provides good oil control by scraping the cylinder wall. If this design

ring were accidentally installed upside down, the tapered face would pump oil into the

combustion chamber.

32. 32. Torsional twist rings provide better compression sealing and oil control than regular taper

face rings.

33. 33. Cutting Rings

34. 34. Cylinder liner • A cylinder liner is a cylindrical part to be fitted into an engine block to form

a cylinder. • It is one of the most important functional parts to make up the interior of an

engine. • This is called Cylinder liner in Japan, but some countries (or companies) call this

Cylinder sleeve. • These are main functions of Cylinder Liners.

35. 35. Properties of an cylinder liner The cylinder liner, serving as the inner wall of a cylinder,

forms a sliding surface for the piston rings while retaining the lubricant within. The most

important function of cylinder liners is the excellent characteristic as sliding surface and

these four necessary points. • High anti-galling properties • Less wear on the cylinder liner

itself • Less wear on the partner piston ring • Less consumption of lubricant

36. 36. Cylinder liners manufacturing process • Centrifugal casting or rotocasting is a casting

technique that is typically used to cast thin-walled cylinders. • It is used to cast such

materials as metal, glass, and concrete. • It is noted for the high quality of the results

attainable, particularly for precise control of their metallurgy and crystal structure. • Unlike

most other casting techniques, centrifugal casting is chiefly used to manufacture stock

materials in standard sizes for further machining, rather than shaped parts tailored to a

particular end-use.

37. 37. Materials which can be casted in centrifugal casting • Typical materials that can be cast

with this process are iron, steel, stainless steels, glass, and alloys of aluminum, copper and

nickel. Two materials can be cast together by introducing a second material during the

process.

38. 38. Applications of centrifugal castings • Concrete pipe and form Typical parts made by this

process are pipes, flywheels, cylinder liners and other parts that are axi-symmetric. • It is

notably used to cast cylinder liners and sleeve valves for piston engines, parts which could

not be reliably manufactured otherwise.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5809)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bullying Research PaperDocument50 pagesBullying Research Paperhannah marvilla85% (13)

- Application For Certificate of Occupancy CEBU CityDocument1 pageApplication For Certificate of Occupancy CEBU Cityhannah marvillaNo ratings yet

- Orphanage ThesisDocument15 pagesOrphanage Thesishannah marvilla0% (1)

- DSWD Residential Facilities Design StandardsDocument14 pagesDSWD Residential Facilities Design Standardshannah marvilla100% (1)

- Modul E 10:: Social Relationship in Middle and Late AdolescenceDocument10 pagesModul E 10:: Social Relationship in Middle and Late Adolescencehannah marvillaNo ratings yet

- Innovative Building Systems For Sustaina PDFDocument18 pagesInnovative Building Systems For Sustaina PDFhannah marvillaNo ratings yet

- Rizal's EducationDocument2 pagesRizal's Educationhannah marvillaNo ratings yet

- EET Ldren: STR CHIDocument22 pagesEET Ldren: STR CHIhannah marvillaNo ratings yet

- Towards Great ArchitectureDocument14 pagesTowards Great Architecturehannah marvillaNo ratings yet

- Republic Act 8368Document1 pageRepublic Act 8368hannah marvillaNo ratings yet

- Betrework Worku PDFDocument85 pagesBetrework Worku PDFOrtho DocNo ratings yet

- Materials Science and Engineering ComposDocument98 pagesMaterials Science and Engineering Compos26. Prita R. SabillaNo ratings yet

- Abbreviations AllDocument21 pagesAbbreviations AllnanduNo ratings yet

- Sample Problems in Quality Control 1Document17 pagesSample Problems in Quality Control 1Jaica Mangurali TumulakNo ratings yet

- 1126-17 Scanvent Type 2317 GFC Rev 1Document13 pages1126-17 Scanvent Type 2317 GFC Rev 1Ivaylo IvanovNo ratings yet

- KORADO KonvektoriDocument100 pagesKORADO KonvektoriRaske89No ratings yet

- VB12 Reagent KitDocument7 pagesVB12 Reagent KitaymanepocketNo ratings yet

- Solubility of Budesonide, Hydrocortisone, and Prednisolone in Ethanol + Water Mixtures at 298.2 KDocument90 pagesSolubility of Budesonide, Hydrocortisone, and Prednisolone in Ethanol + Water Mixtures at 298.2 KsekahaNo ratings yet

- Vegan - Vegetarian Recipe Book How Mary and Frank and Friends EatDocument8 pagesVegan - Vegetarian Recipe Book How Mary and Frank and Friends EatIura CealaNo ratings yet

- Fuel Used in Power PlantsDocument55 pagesFuel Used in Power PlantsOsaid HaqNo ratings yet

- GCR 2016 - Bilingual 62 106Document45 pagesGCR 2016 - Bilingual 62 106ChethanNo ratings yet

- Paliparan National High SchoolDocument22 pagesPaliparan National High SchoolLeeanah Delovino CruzNo ratings yet

- Pre PSPM Set 1 (SK015)Document13 pagesPre PSPM Set 1 (SK015).....No ratings yet

- 5 AlcoholDocument10 pages5 AlcoholfadhlinamNo ratings yet

- Poly (Acrylic Acid)Document10 pagesPoly (Acrylic Acid)Rashid WattooNo ratings yet

- BCE (Module - II)Document34 pagesBCE (Module - II)PARTHA SARATHI PANDANo ratings yet

- Echem WKST KeyDocument7 pagesEchem WKST KeyNurul Hana OmarNo ratings yet

- Mahendra College of Engineering: Communication and Soft Skills Laboratory BasedDocument54 pagesMahendra College of Engineering: Communication and Soft Skills Laboratory BasedSathish PrinceNo ratings yet

- Advantages PCP For Offshore ApplicationDocument4 pagesAdvantages PCP For Offshore ApplicationDwi Hermanto SetiawanNo ratings yet

- Polycoat Announce New Product For WaterproofingDocument2 pagesPolycoat Announce New Product For WaterproofingpolycoatNo ratings yet

- PRINSIP DALAM PEMBERIAN OBAT PPTDocument28 pagesPRINSIP DALAM PEMBERIAN OBAT PPTMohammad AdhinNo ratings yet

- 4th Sem SyllabusDocument20 pages4th Sem Syllabusmohd ameerNo ratings yet

- Aspen Guidelines Parenteral NutritionDocument34 pagesAspen Guidelines Parenteral NutritionKamilo ÁlvarezNo ratings yet

- Hazard Class Pattern of Sprinkler Sprinkler Size Nominal Orifice Less ThanDocument5 pagesHazard Class Pattern of Sprinkler Sprinkler Size Nominal Orifice Less ThanRavi ShankarNo ratings yet

- CMA-106H PF-500/US-521H Tgs-2Cmh: Technical ReportDocument5 pagesCMA-106H PF-500/US-521H Tgs-2Cmh: Technical ReportAshishNo ratings yet

- #5class-8 (Cordova) Chapter-6 SCIENCE Coal and PetroleumDocument2 pages#5class-8 (Cordova) Chapter-6 SCIENCE Coal and PetroleumVivek PatidarNo ratings yet

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocument13 pagesASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplNo ratings yet

- Master's Thesis: Zhejiang Sci-Tech UniversityDocument82 pagesMaster's Thesis: Zhejiang Sci-Tech UniversityEvariste UwamahoroNo ratings yet

- Formulation and Evaluation of Bisoprolol Fumarate Buccal Patches by Using Selected PolymersDocument7 pagesFormulation and Evaluation of Bisoprolol Fumarate Buccal Patches by Using Selected PolymersAlinaDianaNo ratings yet

- Sodium Cyanide BrochureDocument2 pagesSodium Cyanide Brochuresatyendra singhNo ratings yet