Professional Documents

Culture Documents

MOM Processing 280619

MOM Processing 280619

Uploaded by

DINESH SINGH BHATIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MOM Processing 280619

MOM Processing 280619

Uploaded by

DINESH SINGH BHATICopyright:

Available Formats

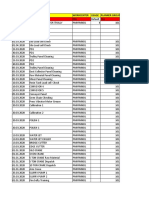

Issue

Gate entry an GRN

FG Code availability

Quality Check

Production Order

Additives

Reprocessing

FG code in SO

Grey to Shop floor

Auto beam

Routing

BOM

Job card

Dispatch

Inward

Price

Inquiry and sales contract

Barcoding

Roll / lump

Weigh bridge

DPR

Discussion

No sales order will be prepared at the time of receipt of grey material. At the time of GRN, grey

material code will be known.

FG Code will prepared once the beam is issued and quality check is done for the blending purpose.

At the time of issue of issue without quality check approval in the system, goods will be in restricted

area

It is confirmed by the production team that process route will be known at the time of issue of beam

to shop floor after quality approval. Thus, production order with proper routing till the final stage can

be processed

All the additives will be charged against their respective production order.

Whenever reprocessing of fabric is to be done due to inferior quality or other any other reason. How

it will charged to production order

Revision in SOP - On receipt, SO needs to be created on the basis of grey material code.

Quality check before issue of grey material to shop floor

No auto beam. Beam duplicity check

Route can be fixed - 1. Process sequence to be defined for each type

BOM defines the standard costing

1. Beam wise job card to be done

2. No reprint allowed

3. Manual controls are required

4. Job card for rework

Dispatch notification

1. Goods receipt notification to customer for grey inward. Challan is mandatory.

2. Gate entry only after customer code creation

3. Received for - customer and received from - sender (name and address) in GRN and SO

Rate card / Pricing - Maintenance

1. After treatment, only we know the actual price, so difficult to maintain

No inquiry and no sales contract

Barcoding -

Roll or lump

Weigh bridge -

Re-work invoice / DPR (invoice)

Decision point

Gate entry will be done on the basis of delivery challan

received from the customer. No gate entry will be

allowed without delivery challan (Revision in SOP)

FG code will be available before the creation of

production order (i.e. At the time of issue of beam to

shop floor)

Quality personnel will record the quality data in the

system at the time of quality checking and upon his

approval it will get transferred to unrestricted area

Single production order with multiple operation will be

created after issue of beam

It will get charged against respective production order

but the addition needs to be shown separately in the

production order for tracking purpose

It is confirmed by Novel team, same operation can be

confirmed twice and against the same production order

No FG in SO and hence no MRP run

Quality check before issue of grey material

No auto beam. Beam duplicity check

1. Route can be fixed, and hence process sequence to be

defined for each type

2. Only one production order

BOM to be defined for each material code

1. Job card will be prepared (QR code)

2. Printing to be done only once. No reprint allowed

DO and invoice to be sent

Notification for grey

Price master to be maintained. However, the basis /

parameters to be decided

Not possible

Possible

Routing and in Job card

Not possible

This needs to be checked in SAP

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- JSA-017 Lifting With ForkliftDocument3 pagesJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Finance and Project Management AssignmentDocument22 pagesFinance and Project Management AssignmentMashaal FNo ratings yet

- Enterprise-Wide Incident Response (Part 1: GRR)Document27 pagesEnterprise-Wide Incident Response (Part 1: GRR)Saw GyiNo ratings yet

- Fisheries Statistics of The Philippines, 2017-2019Document321 pagesFisheries Statistics of The Philippines, 2017-2019Meidior CuetoNo ratings yet

- Key Date Description Workcenter Usage Planner Group Default Fill Fill Default FILLDocument6 pagesKey Date Description Workcenter Usage Planner Group Default Fill Fill Default FILLDINESH SINGH BHATINo ratings yet

- Z Modular Construction StepsDocument4 pagesZ Modular Construction StepsDINESH SINGH BHATINo ratings yet

- SAP PM Standard Reports PDFDocument19 pagesSAP PM Standard Reports PDFDINESH SINGH BHATINo ratings yet

- Work CenterDocument2 pagesWork CenterDINESH SINGH BHATINo ratings yet

- MIC TemplateDocument3 pagesMIC TemplateDINESH SINGH BHATINo ratings yet

- AMC Process in Plant Maintenance PDFDocument8 pagesAMC Process in Plant Maintenance PDFDINESH SINGH BHATINo ratings yet

- Needle Gate (MS01-NG02) : Key Date Description Workcenter Usage Planner Group 01.01.2020 Task List For Hopper 11MECH 2 010Document3 pagesNeedle Gate (MS01-NG02) : Key Date Description Workcenter Usage Planner Group 01.01.2020 Task List For Hopper 11MECH 2 010DINESH SINGH BHATINo ratings yet

- Dying TTTSKK 1200Document1 pageDying TTTSKK 1200DINESH SINGH BHATINo ratings yet

- Measuring Point TemplateDocument3 pagesMeasuring Point TemplateDINESH SINGH BHATINo ratings yet

- Characterstics TemplateDocument2 pagesCharacterstics TemplateDINESH SINGH BHATINo ratings yet

- BPML PMDocument6 pagesBPML PMDINESH SINGH BHATINo ratings yet

- Scanned by CamscannerDocument9 pagesScanned by CamscannerDINESH SINGH BHATINo ratings yet

- PM FioriDocument10 pagesPM FioriDINESH SINGH BHATINo ratings yet

- Sap WarrantyDocument2 pagesSap WarrantyDINESH SINGH BHATINo ratings yet

- MIC TemplateDocument3 pagesMIC TemplateDINESH SINGH BHATINo ratings yet

- Legacy System Migration WorkbenchDocument16 pagesLegacy System Migration WorkbenchDINESH SINGH BHATINo ratings yet

- Sil Mom002 PMDocument2 pagesSil Mom002 PMDINESH SINGH BHATINo ratings yet

- BPML PMDocument6 pagesBPML PMDINESH SINGH BHATINo ratings yet

- S.No. T.Code Material DescriptionDocument2 pagesS.No. T.Code Material DescriptionDINESH SINGH BHATINo ratings yet

- BP-SD-03-S:-Domestic Sales ProcessDocument9 pagesBP-SD-03-S:-Domestic Sales ProcessDINESH SINGH BHATINo ratings yet

- Z and Y T.code Atun DivDocument6 pagesZ and Y T.code Atun DivDINESH SINGH BHATINo ratings yet

- 1510 Side Mounted Level Switch Cat498Document4 pages1510 Side Mounted Level Switch Cat498thotalnNo ratings yet

- Chico Resume 2015 For WebsiteDocument2 pagesChico Resume 2015 For Websiteapi-87866586No ratings yet

- Service Manual: 1 Channel Power AmplifierDocument18 pagesService Manual: 1 Channel Power AmplifierPaulo chagas paulo ratoNo ratings yet

- Human Resource Management in Case of Hawassa Industry ParkDocument11 pagesHuman Resource Management in Case of Hawassa Industry ParkFiker Er MarkNo ratings yet

- TSA - 01 Project Cost Management PDFDocument96 pagesTSA - 01 Project Cost Management PDFAndiatma Nur Irfan WicaksonoNo ratings yet

- Cleveland 42CKEM48Document2 pagesCleveland 42CKEM48wsfc-ebayNo ratings yet

- Strategy de RiemerDocument2 pagesStrategy de RiemerBleak NarrativesNo ratings yet

- Economics (030) Set 58 C1 Marking Scheme Comptt 2020Document11 pagesEconomics (030) Set 58 C1 Marking Scheme Comptt 2020bhumika aggarwal100% (1)

- Write An ALP To Interface An LCD To 8051 Display A MessageDocument2 pagesWrite An ALP To Interface An LCD To 8051 Display A MessageAkash AmanNo ratings yet

- 08 VESDA Pipe Network Design Guide A4 IE LoresDocument56 pages08 VESDA Pipe Network Design Guide A4 IE Loresvlaya1984No ratings yet

- AutoPLANT PID To OpenPlant PID Symbol MigrationDocument17 pagesAutoPLANT PID To OpenPlant PID Symbol MigrationananthNo ratings yet

- Global Supply Chain Compliance: The Greening of Electronics in A Global EconomyDocument37 pagesGlobal Supply Chain Compliance: The Greening of Electronics in A Global EconomyMadhusudana Reddy BhumaNo ratings yet

- 18V2000G63-TB 0-10000hDocument9 pages18V2000G63-TB 0-10000hNabesterNajamNo ratings yet

- Hms Hmsi 27 316Document135 pagesHms Hmsi 27 316davoodnasehi1No ratings yet

- DocumentsDocument5 pagesDocumentsRayyan JamaluddinNo ratings yet

- Sample MCQ - Facility Location and LayoutDocument3 pagesSample MCQ - Facility Location and LayoutJITENDRA SINGHNo ratings yet

- Video and Image Processing Suite User Guide: Subscribe Send FeedbackDocument360 pagesVideo and Image Processing Suite User Guide: Subscribe Send FeedbackRiccNo ratings yet

- (English) Contoh Resume PBKL Batch 5Document1 page(English) Contoh Resume PBKL Batch 5PanitiaAmalia NurNo ratings yet

- Software Engineering Tutorial2Document3 pagesSoftware Engineering Tutorial2NOOR AZLAN BIN MAHMUDNo ratings yet

- Matkins 2Document50 pagesMatkins 2api-311938182No ratings yet

- Marketing ManagementDocument3 pagesMarketing ManagementVamshi palakurthiNo ratings yet

- Sociol 2z03, Spring 2022, Z. LuoDocument6 pagesSociol 2z03, Spring 2022, Z. LuoGarcía MarlinhoNo ratings yet

- Screw Thread ReportDocument17 pagesScrew Thread Reportkittikhun_simlee100% (1)

- Mt. Laurel - 0525Document24 pagesMt. Laurel - 0525elauwitNo ratings yet

- Account Receivable ClassDocument30 pagesAccount Receivable ClassBeast aNo ratings yet

- CL 5313 17021-1 Requirements Matrix-1458-5Document6 pagesCL 5313 17021-1 Requirements Matrix-1458-5Ana AnaNo ratings yet