Professional Documents

Culture Documents

Key Elements Procedure 1 General Requirements: List of Contents

Uploaded by

Sivan RajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Key Elements Procedure 1 General Requirements: List of Contents

Uploaded by

Sivan RajCopyright:

Available Formats

General Requirements

Key Elements Procedure 1

General Requirements

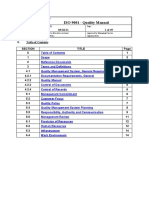

LIST OF CONTENTS

1. Foreword .........................................................…............ Page 2

2. Approved level in SEM.......................................…......... 2

3. Volvo as preferred customer............................................. 5

4. Honouring the Volvo Purchasing Agreement.................. 6

5. EDI-communication in the whole chain.................…..... 6

Issue 1 11 DEC 2006 1 Key Elements Procedure 1

General Requirements

1 FOREWORD

Quality has successively come to mean more than quality assurance itself. The supplier

must be able to take complete responsibility for his effect on the environment and also take

a holistic view regarding material handling and information exchange. The ability to

achieve effective continuous improvement requires good knowledge of modern tools and

methods that are offered by the quality technology.

2 APPROVED LEVEL IN SEM

2.1 Principles

The supplier evaluation shall comprise all aspects that are important for an environment

of co-operation between the Volvo Company and the supplier.

The SEM shall be used in all cases where the standard of a supplier for production

material is to be defined. It can be used both for existing and potential suppliers.

2.2 Co-operation between the Volvo companies

Supplier Evaluation Model has been accepted and will be applied for deliveries to:

• Volvo Trucks

• Renault Trucks

• Mack Trucks

• Volvo Powertrain

• Volvo Parts

• Volvo Aero

• Volvo Buses

• Volvo Penta

• Volvo Construction Equipment

The evaluation model is common for the companies as well as the criteria set up for the

evaluation. In principle evaluation is carried out by the company having the biggest business

share, or in case of potential supplier by the company planning potential future business.

Issue 1 11 DEC 2006 2 Key Elements Procedure 1

General Requirements

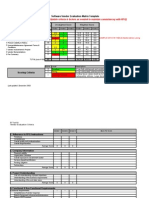

2.3 Evaluation model - SEM

Within the framework for SEM a broad spectrum of the suppliers management capability

and systems with regard to engineering and production capabilities are evaluated Each

evaluation area is scored depending upon result as follows: 0, 1, 2 or 3 points, with zero

indicating a poor result and three equating to excellent, or fully meeting the expectations.

For each criteria, the result is calculated as a percentage ratio of the total sum. Some

parameters may deal with activities that are not relevant for all suppliers, in such cases it

is marked ”not applicable” (N/A) and the question is deleted from total calculation.

The purpose with the model is to:

• Make available a basis for evaluation of existing and potential suppliers.

• Provide a unified procedure for all Volvo companies to allow full exploitation of the

results within Volvo.

• Deepen the knowledge about each supplier.

• Act as an improvement tool for developing suppliers and the supplier structure.

• Assist in fact-based decision making.

• Share information about a supplier to the Volvo Group organisations.

Volvo personnel carry out evaluations in cross-functional teams (Supplier Quality Assurance,

Product Development , Logistics, After-market etc.). A SEM-lead auditor normally located in

the purchasing organisation manages the team.

Evaluations can be performed for existing as well as potential suppliers. As to potential

suppliers there are some ”stopping parameters” which must be evaluated as approved

(min.1pt) in order to be selected as a Volvo supplier.

In exceptional circumstances a business decision may be taken to accept a supplier for new

business even if a stopping parameter is present at the SEM audit. Again, this will be in

exceptional circumstances only and can only be taken if supported by a detailed supplier

improvement plan to address the stopping parameter. The plan should be approved by the

supplier’s senior management and be over a time scale of not more than 12 months. The plan

should also contain regular planned regular review of status and feedback to Volvo nominated

representatives.

2.4 Preparations and collection of facts

In connection with the planning of an evaluation the supplier company can be asked

beforehand to present fact based data and presentation material in order to carry out the

evaluation as efficiently as possible. Likewise internally in Volvo available data are collected

to make the evaluation as objective as possible.

Issue 1 11 DEC 2006 3 Key Elements Procedure 1

General Requirements

2.5 Evaluation criteria

N/A 0 pts 1 pt 2 pts 3 pts

1 Company Profile

1.1 Ownership 0

1.2 Global ability 0

1.3 Dependency 0

2 Management

2.1 Management 0

2.2 Customer satisfaction 0

2.3 Ethical standards 0

2.4 Risk management 0

3 Environment

3.1 Environmental Management System 0

4 Quality

4.1 Quality system 0

4.2 Quality planning,

0

Part Quality Assurance

4.3 Quality performance of deliveries 0

4.4 Reliability 0

4.5 Problem solving 0

4.6 Management of critical characteristics 0

5 Logistics

5.1 Capacity management 0

5.2 Delivery precision/

0

Service level

5.3 Electronic communication 0

6 After-market

6.1 Documentation 0

6.2 Service literature 0

6.3 Co-operation & support 0

7 Competence

7.1 Product and industrial technology 0

7.2 Industrial engineering 0

7.3 Customer support and communication 0

7.4 Maintenance 0

8 Product development

8.1 Product development process/ 0

Project support

8.2 Product engineering 0

technology

8.3 Prototypes 0

8.4 R&D 0

8.5 Design changes 0

9 Finance

9.1 Financial evaluation 0

10 Productivity

10.1 Process of internal cost reduction 0

11 Sourcing

11.1 Sourcing process 0

11.2 Subcontractor performance 0

Total average

Summary

stopping parameter

x = N/A not applicable (reduces number of applicable points accordingly)

Issue 1 11 DEC 2006 4 Key Elements Procedure 1

General Requirements

2.6 Summary of results and follow-up

After the evaluation a summary of the results are made, the result of each criterion and the

total summarised output is calculated as a percentages. . The result is informed to the supplier

who may be asked to submit a plan for improvement actions depending on the result.

3 VOLVO AS PREFERRED CUSTOMER

We like to be valued as preferred customer by our suppliers and want the suppliers to take the

view of business with Volvo as a mutually beneficial relationship. With both parties

benefiting from shared technical knowledge, with a secured long term business relationship.

We need to be the first to benefit from the suppliers’ innovation and like to benefit from their

best performances on current business and preferred status in capacity allocation.

Suppliers shall give necessary support to Volvo in relation to other customers. A well-covered

and represented business in the automotive/aerospace branch should be considered to be

positive for Volvo. Normally the preferred range of dependency upon Volvo is 10 - 30%. The

turnover relation between Volvo and other customers need to be in balance.

The supplier shall not depend on another customer to a too high extent.

Suppliers must be willing to work in a confidential manner, and willing to enter into a long-

term relationship. The supplier shall give Volvo a high priority in all aspects.

The supplier’s attitude to actively support Volvo in solving problems is essential.

Suppliers shall exceed the Volvo basic requirements and also give proposals for improvement

in cost, quality, logistics etc.

The supplier is outstanding in commitment and handling of relations with Volvo.

The Volvo meaning of Supplier Co-operation is the creation of long-term relationship through the stating and

integration of knowledge and understanding of each other’s processes, procedures and ideals.

From co-operation to integration

Process-driven development requires that the supplier is involved in the early stages of the

product development process and that the supplier participates regularly as a full member of

the cross-functional working groups at Volvo.

Some suppliers take complete responsibility for a certain system and thus obtain the position

as system supplier.

Issue 1 11 DEC 2006 5 Key Elements Procedure 1

General Requirements

4 Honouring the Volvo Purchasing Agreement

The Volvo Purchasing Agreement mirrors the corporate view on a relation with the supplier.

From a Volvo point of view, it is important that the agreement is accepted and honoured by

our supplying partners.

Honouring the agreement implies that suppliers are considered as preferred.

The purchasing agreement is a fundamental platform for the business relationship with our

suppliers. It outlines the conditions between Volvo and the supplier for the purchase and

delivery of production parts and spare parts. In addition to traditional commercial terms on

delivery, payment etc the purchasing agreement is also part of the key elements for a Volvo

group supplier.

Purchasing agreements shall be signed with all of our suppliers.

Honouring the purchasing agreement and complying to the contract also means:

• Delivering quality parts – supporting our demanding customers expectations on

Quality products.

• Maintaining a safe and reliable material supply system.

• Contributing to Volvo’s core values.

In addition the Volvo Purchasing Agreement is an important document for compliance with

The Sarbanes-Oxley Act (SOX) rules, providing internal control of business transactions

related to contracts and the business administration process with a supplier. The SOX is a

legislation for US financial market to protect investor’s interests.

5 EDI-COMMUNICATION IN THE WHOLE CHAIN

To support reducing development and order to delivery leadtimes EDI (Electronic Data

Interchange) communication throughout the supply chain is a considered as a key success

factor to support this.

In addition other benefits can be gained including:

•Reduced costs: information is registered automatically instead of manually. The information

can be re-used. Both parts can obtain cost savings.

•Higher quality: Manual work is reduced, which means that the error rate is reduced. Quality

is the most evident advantage; it both lowers the costs and gives satisfied customers.

•Reduced lead-times: Fast handling of the information is a condition for more efficient

distribution and reduced lead-times. To obtain full effect of the EDI-implementation, the EDI-

messages have to be automatically processed in the receiving system.

Issue 1 11 DEC 2006 6 Key Elements Procedure 1

General Requirements

•Reduced stock: By reduced lead-times you can reduce the stock level at both the buyer and

supplier. It is not so important to keep a buffer stock. The possibility to automatically scan the

received goods, results in a more efficient warehouse administration.

•Competitive advantages: Some assignments disappear and some are changed or simplified.

The resulting cost savings will represent a strategic competitiveness improvement.

•Better customer service: The most common reason for a company to start using EDI is to

meet customer demands.

•Improved environment: Less paper consumption, printed and distributed.

Hence it is expected that our suppliers should have EDI implementation not only with Volvo

but also with their 2nd tier suppliers.

What does Volvo communicate with the suppliers via EDI?

•Product design

•Request for Quotations

•Quotations

•Purchasing agreements

•Prices, payment / delivery conditions

•Delivery schedules / Material Releases

•Ship Notices

•Invoices

•Inspection Reports

Specifications and versions to be found at http://www.volvo.com/volvoit/edi/en-gb

Issue 1 11 DEC 2006 7 Key Elements Procedure 1

You might also like

- VDA 6.3 - Jan 2023Document108 pagesVDA 6.3 - Jan 2023Cem Alsat95% (93)

- QD83 - Global Supplier Quality Directive - Edition 2018Document66 pagesQD83 - Global Supplier Quality Directive - Edition 2018mirosek100% (1)

- Isoqual, Inc.: 9001 - Quality ManualDocument33 pagesIsoqual, Inc.: 9001 - Quality ManualErika Licon100% (1)

- Project Quality PlanDocument29 pagesProject Quality PlanRami KhedroNo ratings yet

- Quality Manual Rev-27Document103 pagesQuality Manual Rev-27sambhaji100% (1)

- SQAM-2019 VolvoGroupDocument52 pagesSQAM-2019 VolvoGroupJanNo ratings yet

- Case - 2 - 6 - Case#2.6 The Fund of Funds Independence IDocument3 pagesCase - 2 - 6 - Case#2.6 The Fund of Funds Independence IYismaw100% (1)

- Toy Factory CaseDocument6 pagesToy Factory Caseramandipk51161100% (1)

- Golden Book of Accounting Finance Interviews Part I Site Version V 1.0 PDFDocument62 pagesGolden Book of Accounting Finance Interviews Part I Site Version V 1.0 PDFRAJESH M S100% (2)

- Quality ManualDocument30 pagesQuality ManualCarl WilliamsNo ratings yet

- Iso 9001 Quality ManualDocument29 pagesIso 9001 Quality ManualsNo ratings yet

- Draft 1 Smash AqmDocument35 pagesDraft 1 Smash AqmMeghan GhoneNo ratings yet

- QMS Vol. 1 PDFDocument436 pagesQMS Vol. 1 PDFCamilo Jorquera100% (2)

- Quality Assurance POLICY & Quality ManualDocument150 pagesQuality Assurance POLICY & Quality Manualayman100% (1)

- QS MN 001 REV K Quality Systems ManualDocument36 pagesQS MN 001 REV K Quality Systems ManualpnagarajjNo ratings yet

- Iso 9001:2008 Iso/ts 16949:2009Document3 pagesIso 9001:2008 Iso/ts 16949:2009Anonymous di3fxBNo ratings yet

- Free 16949 QMDocument52 pagesFree 16949 QMleewodon88% (8)

- QMS Manual IS 9001 2015Document28 pagesQMS Manual IS 9001 2015Parag WadekarNo ratings yet

- SQA Manual - 25.01.2014Document17 pagesSQA Manual - 25.01.2014NEELNo ratings yet

- ISO 9001 Quality ManualDocument33 pagesISO 9001 Quality Manualramrom100% (4)

- Automotive Quality Management System Manual: Century Metal Recycling LimitedDocument7 pagesAutomotive Quality Management System Manual: Century Metal Recycling LimitedsunilNo ratings yet

- Quality Control Manual SofascoDocument91 pagesQuality Control Manual Sofascosiddhartha dua100% (1)

- QD 002 - Quality Manual 2022 - Feb22-Rev2.6 - RBDocument35 pagesQD 002 - Quality Manual 2022 - Feb22-Rev2.6 - RBAjibade SukuratNo ratings yet

- Micron Quality ManualDocument21 pagesMicron Quality ManualRakesh SNo ratings yet

- Security Operations: BS EN ISO 9001: 2008Document23 pagesSecurity Operations: BS EN ISO 9001: 2008nipun sharmaNo ratings yet

- SW Vendor Evaluation Matrix TemplateDocument4 pagesSW Vendor Evaluation Matrix TemplateDavid TingNo ratings yet

- Quality Manual Template: WWW - Iso-9001-Checklist - Co.ukDocument10 pagesQuality Manual Template: WWW - Iso-9001-Checklist - Co.ukNavnath TamhaneNo ratings yet

- NORSU Quality Manual 2017 Draft PDFDocument34 pagesNORSU Quality Manual 2017 Draft PDFAna Hidayah Syuhada100% (2)

- Supplier Quality Manual 2022Document67 pagesSupplier Quality Manual 2022rc2834338No ratings yet

- Sample Quality Management Manual TOC-StandardDocument3 pagesSample Quality Management Manual TOC-Standardazeem dilawarNo ratings yet

- Audit FormDocument6 pagesAudit FormmartinusteddyNo ratings yet

- ISO 9001 Compliance Audit Schedule ExampleDocument5 pagesISO 9001 Compliance Audit Schedule ExampleMohamedNo ratings yet

- Quality Manual Quality Manual Quality Manual Quality Manual ISO9001:2008Document75 pagesQuality Manual Quality Manual Quality Manual Quality Manual ISO9001:2008Darshana Herath LankathilakNo ratings yet

- 2015 Quality Manual TemplateDocument4 pages2015 Quality Manual Templatehusankar2103100% (1)

- Kopano - Quality Policy ManualDocument42 pagesKopano - Quality Policy ManualDanie Grobler100% (1)

- S. Vinodh - Lean Manufacturing - Fundamentals, Tools, Approaches, and Industry 4.0 Integration-CRC - Focal Press (2022)Document133 pagesS. Vinodh - Lean Manufacturing - Fundamentals, Tools, Approaches, and Industry 4.0 Integration-CRC - Focal Press (2022)gutierrez19111144fNo ratings yet

- Quality Management Systems Manual: C&H Die Casting, IncDocument26 pagesQuality Management Systems Manual: C&H Die Casting, IncСтанислав ПодольскийNo ratings yet

- Unit 6 Clause Wise Interpretation OF ISO 9001:2000: 6.0 ObjectivesDocument18 pagesUnit 6 Clause Wise Interpretation OF ISO 9001:2000: 6.0 ObjectivesamarNo ratings yet

- QSRMC Regulations 2017 PDFDocument107 pagesQSRMC Regulations 2017 PDFEvonne TanNo ratings yet

- TI Automotive - Global-Supplier-Requirements-Manual-Rev-ADocument28 pagesTI Automotive - Global-Supplier-Requirements-Manual-Rev-AMert AtayNo ratings yet

- ISO 9001 QMS Standard Certification Documents PDFDocument9 pagesISO 9001 QMS Standard Certification Documents PDFravi00098No ratings yet

- Iso Presentation Asq 1114 Dec 2010 HandoutDocument25 pagesIso Presentation Asq 1114 Dec 2010 HandoutHarish YadavNo ratings yet

- Compare ISO 9001 and ISO 13485Document2 pagesCompare ISO 9001 and ISO 13485umarNo ratings yet

- Iatf UpgradingDocument6 pagesIatf UpgradingAhmad AzrilNo ratings yet

- Magna Global Supply Chain Requirements 1 1 Jan24 01Document38 pagesMagna Global Supply Chain Requirements 1 1 Jan24 01cycatymichalNo ratings yet

- Q R ManualDocument118 pagesQ R Manualangela1590No ratings yet

- The Internal Factor Evaluation (IFE) MatrixDocument1 pageThe Internal Factor Evaluation (IFE) Matrixiqra gillaniNo ratings yet

- Quality Manual With Supporting ProceduresDocument58 pagesQuality Manual With Supporting ProceduresAbdisalamNo ratings yet

- Quality Manual 2020 V5.0Document84 pagesQuality Manual 2020 V5.0KKSAT100% (1)

- You Must ISO 9001 2015Document2 pagesYou Must ISO 9001 2015ScribdTranslationsNo ratings yet

- Temecula Quality Plating AS9100 REV C MANUALDocument13 pagesTemecula Quality Plating AS9100 REV C MANUALHoang TanNo ratings yet

- Quality Manual - Numbered by Clauses 01.09.2021Document20 pagesQuality Manual - Numbered by Clauses 01.09.2021vNo ratings yet

- PQP Rev. 001Document60 pagesPQP Rev. 001rkssNo ratings yet

- SW Vendor Evaluation Matrix TemplateDocument5 pagesSW Vendor Evaluation Matrix Templatemanno200No ratings yet

- Silo - Tips Quality Manual Iso 90012000Document19 pagesSilo - Tips Quality Manual Iso 90012000Mariel GentilesNo ratings yet

- Quality ManualDocument21 pagesQuality Manualananth rajanNo ratings yet

- Table of ContentDocument5 pagesTable of ContentIsmail Hamzah KiagusNo ratings yet

- IRIS Rev Vs IS022163 Correlation Matrix 1Document6 pagesIRIS Rev Vs IS022163 Correlation Matrix 1Centre For Total Quality ManagementNo ratings yet

- Process Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesFrom EverandProcess Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesKatherine A. BakeevNo ratings yet

- Corporate Management, Governance, and Ethics Best PracticesFrom EverandCorporate Management, Governance, and Ethics Best PracticesNo ratings yet

- Gemba Walk Introduction 20150226Document7 pagesGemba Walk Introduction 20150226lorenzordzrmzNo ratings yet

- Responsible Dog OwnersDocument45 pagesResponsible Dog OwnerslorenzordzrmzNo ratings yet

- Sherwin-Williams Primer E67BC1704 20141007Document2 pagesSherwin-Williams Primer E67BC1704 20141007lorenzordzrmzNo ratings yet

- OG204-TDS Tooke Paint Inspection Gage 201409Document3 pagesOG204-TDS Tooke Paint Inspection Gage 201409lorenzordzrmzNo ratings yet

- Supplier Letter June 6 2014Document1 pageSupplier Letter June 6 2014lorenzordzrmzNo ratings yet

- FCA US LLC Customer Specific Requirements For IATF 16949 June 8 2018Document48 pagesFCA US LLC Customer Specific Requirements For IATF 16949 June 8 2018lorenzordzrmzNo ratings yet

- Fraud in The Accounting Profession Accounting 1Document23 pagesFraud in The Accounting Profession Accounting 1karen hudesNo ratings yet

- T.B - CH10Document17 pagesT.B - CH10MohammadYaqoobNo ratings yet

- f9 02 The Financial Management EnvironmentDocument27 pagesf9 02 The Financial Management EnvironmentGAURAVNo ratings yet

- GTAG3Document37 pagesGTAG3Diego BermudezNo ratings yet

- Processing SystemDocument2 pagesProcessing SystemInday MiraNo ratings yet

- Corporate Governance - UK N USDocument15 pagesCorporate Governance - UK N USvarunNo ratings yet

- Advanced Company Law & Practice: NoteDocument4 pagesAdvanced Company Law & Practice: NoteabhinandNo ratings yet

- Good-Day!!: Prepared By: Prof. Melissa Francia L. Almadrones Cob-CdsgaDocument45 pagesGood-Day!!: Prepared By: Prof. Melissa Francia L. Almadrones Cob-CdsgaJashi SiosonNo ratings yet

- The Rise and Fall of EnronDocument22 pagesThe Rise and Fall of EnronDhanwantri SharmaNo ratings yet

- Chapter 1 - Auditing and Assurance ServicesDocument27 pagesChapter 1 - Auditing and Assurance ServicesBilal KhalidNo ratings yet

- Multiple-Choice QuestionsDocument20 pagesMultiple-Choice QuestionsRafael GarciaNo ratings yet

- Mitigating Sod Violations: 2 HoursDocument63 pagesMitigating Sod Violations: 2 HoursT. LyNo ratings yet

- Dissertation TopicsDocument3 pagesDissertation TopicsDjimmy BoyjonauthNo ratings yet

- Intelligent Business Advanced TBDocument196 pagesIntelligent Business Advanced TBОксана100% (2)

- 25 Landmarks in Corporate GovernanceDocument25 pages25 Landmarks in Corporate Governancem_dattaias100% (5)

- Managerial Auditing Journal: Article InformationDocument32 pagesManagerial Auditing Journal: Article InformationRuwan DileepaNo ratings yet

- Chapter 7 FinalDocument11 pagesChapter 7 FinalMuhammad M BhattiNo ratings yet

- Cost Accounting and Reporting Chapter 1 ReviewerDocument8 pagesCost Accounting and Reporting Chapter 1 ReviewerTrisha Anne ClataroNo ratings yet

- Internal ControlDocument23 pagesInternal ControlIstiq OmahNo ratings yet

- Managing and Using Information Systems: A Strategic Approach - Sixth EditionDocument32 pagesManaging and Using Information Systems: A Strategic Approach - Sixth EditionvamshiNo ratings yet

- Chapter 1 Introducing The Concepts: Strategic Management in Action, 6e (Coulter)Document17 pagesChapter 1 Introducing The Concepts: Strategic Management in Action, 6e (Coulter)蔥蔥No ratings yet

- Ethics in Construction Challenges and DilemmasDocument27 pagesEthics in Construction Challenges and DilemmasbshibruNo ratings yet

- What Led To The Eventual Collapse of Enron Under Lay and Skilling?Document15 pagesWhat Led To The Eventual Collapse of Enron Under Lay and Skilling?Ananya MNo ratings yet

- Resume ExampleDocument2 pagesResume ExamplesplinterNo ratings yet

- Sanjukta Paul's Marxist Legal HistoriographyDocument6 pagesSanjukta Paul's Marxist Legal HistoriographyVivek BalramNo ratings yet

- Take Two 2021 Annual ReportDocument103 pagesTake Two 2021 Annual ReportNguyen Hong Quang (FGW HCM)No ratings yet

- Finance Cluster Core: Sample Exam QuestionsDocument31 pagesFinance Cluster Core: Sample Exam QuestionsEdwin UcheNo ratings yet