Professional Documents

Culture Documents

Ig100 Calculation PDF

Ig100 Calculation PDF

Uploaded by

Paul Mendoza0 ratings0% found this document useful (0 votes)

326 views6 pagesOriginal Title

ig100 calculation.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

326 views6 pagesIg100 Calculation PDF

Ig100 Calculation PDF

Uploaded by

Paul MendozaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

Ay

PA VISION SDN BHD

Nitrogen I 00

VAS Listed

System Design and Operation

PA Vision ineri=< JQ systems are designed, installed and maintained according to NFPA 2001

(Clean Agent Fire Extinguishing Systems and ISO 14520 Gaseous Fire Extinguishing Systems)

standards.

iner?=<' 790 is a total fooding system whereby the required amount of gas is discharged into an enclosed

area to extinguish fire:The gas is stored as compressed gas at 200bar. The system can be actuated

electrically from a control panel or manually from the cylinder bank, and the discharged gas pressure

is reduced from 200bar to less than 60 bar after the manifold via the pressure reducing unit

The system is normally designed as such that 95% of the gas will be discharged into the protected

area within 60 seconds.

Muitiple storage options are possible with iner=:'79Q as the system has been designed for long

distance delivery. This means that the cylinder bank can be slored remotely from the risk area when

storage space is a concem,

1. Smoke /heat detector

2 Nozzle

3. Slave cyindors

4. Master evindor

5 Pressure reducer unt

8 Manifold

7. Contro! pane!

Alarm bell,

8. Manual Call Point (break glass)

| 10. Discharge light

When two or more areas of protection do not require flooding of gas at the same time, directional

or selector valves can be used to allow the same bank of cylinders to protect multiple areas. Such

sub-systems can reduce substantial equipment costs and storage area for cylinders. Maintenance and

inspection locations can also be reduced accordingly.

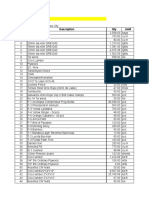

Example of typical calculation for iner2=:i100 total flooding requirement: Designing Te Pipe Sie iner=<: 799

Dimensions of rom tobe protected

room obs protected

“0.0mx6.2mx3.0m (4)

150.00"

ave

(ier 2000) 37.2% (or Claes A&C haart)

‘Agent required = Volume of oom to be protected x loosing Factor

Volume of agent required = a7

‘Agent capacity par 80 tre cylinder 182m" (17 kg)

Number of eynders required Ager equa Agent eapacty pr eynder

7397/182

Round vp to nex

7 5

of cylinders required = S numbers of 20 eyinders of Iner=2! 100

Gas Flow & Pipe Sizing Table

Norminal Pipe | Norminal Pipe

io ea Der CRU Tcy

Chica

st92 =152x5 =m

1334 76m

1438 216m

1526 = 76m

sa 230m

e324 230m

From Pipe Sizing Tabl

From Sizing Table» Section 1-8 should use 1%" Section 12-17 should use 1”

‘Nolo: The above is just estate the actu pipe sze shal be determined using Ve Softwar. Plsase contact PA Vision fr Vis calculation.

neh Norse can Covor 58 metre 02,

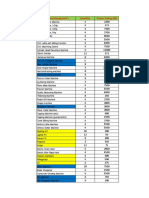

Comparative table - inert and chemical gases

Camparison Chart - Alternatives Fire Suppression Agents to Halon 1301

oy ‘awe ere Pen eee ete

Towractoa | 100%N2 0 ° ° ry 2 200 bar 2

INERGEN sam Ne

Oka o a ° 0 2 ssorz00eer| 6

e002

(co2in design

carton iia | 002 a 1 ° =| eonentstion | 58 ara Ey

ills people’ | 20°C,

rz00 | crscurcrs | 0 | 2080 aaa ° 108 25142980 ’

Wc 227 oa

Feta cura 0 | 800 200 «0 : asurae | 16

Hee 2s

sam Horc22

A758 HCFE123

ners | ssxnore-ze | aos | +600 6 0 >to | asmane| a8

275% organic

‘ibeanee

‘Sclenite Assessment of Ozone Depletion: 1998." Wons eteoralogies!Organsaton, Global Ozone Research and Mantoring Project.

oper No 44: 1998,

ry

+ | INCOM Vato series 8 0480 1 erase

2 | noose Pneumatic and Marval atte 80480 + erase

3_|INcor7 Prossure gauge 80207 2 paste

NGOE Pressure gauge dw leakage nariorng Swick BO2572

4 | inco0e Discharge hose DN12 Wire braided rabbor hose

5 | incoos (Chock valve 3° Brats Atoy 352

6 | iNco08 Pressure reducer unit, NSO ‘Stee oy

7 | 1nco3e antl single socket sonia

INGORE anol double socket sah60

8 | incoro Plt nose BNE Wir braided rubber hose

2 | incors Elecromagnatc Actuator B 04801 erase

10 | iwcoza BOLI40L,TPED CE or DOT Cylinder Chromium Molybdenum Stes!

st | woos Oylnéer Sap Stet

12 | cosa Oylnéer wal bracket Stel Alloy

1a | woo? Selector Vaive ONO GB2 ‘Auminum Aloy

14 | wo02s. Discharge pressure swch model FF Beats

15 | cozoas.anet12 | Solenoid vave ay model ADST12 Brass

1a_| woos Prossure regulator modo 0.900 Bar, Output 6 Bar

Inertec System Components

INERTEC VALVE SERIES B0480 1

Material

Valve Body

Max. Werking Prossuro

“Temperatue Range

Inet Connection

Outtet Connection

Release Device

Connection

Pressure Gauge

Connection

Burst Dise

Approval

‘Approval No

Part No

Brass

250 Bar

H 18°C to + 50°C

W288 x 1/14" DIN

W218 x 1/14" DIN

Mares

M10 x1

270 Bar

ves

16302028 Typ 80480 1 208

= Inert Gases 200 Ba

Incosa

PNEUMATIC RELEASE DEVICE FOR

SERIES B0480 1

Material

Body

Min. Actuating Pressure

Max. Working Prossure

‘Valve Connection

Pneumatic Connection

Approval

‘Approval No|

Part No

\

MANUAL / PNEUMATIC RELEASE DEVICE

Brass

15 Bar

280 Bar

Marts

se" BSP

ves

(6302028 Typ 804420068

INcore

FOR SERIES B0480 1

Material

Body

Lever

Safely Pin

Min. Actuating Pressure

Max. Working Pressure

\Valve Connection

Pneumatic Connection

Aoproval

‘Approval No

Part No

Brass

Stainiess Steal

Stainiess Steal

15 Bar

250 Bar

Mare 1s

+18 BSP.

vas

(6202023 Typ 80«420065

INcor2

ELECTROMAGNETIC RELEASE DEVICE FOR

SERIES B0480 1

Material

Body Brass, Stainless Stoo!

‘Actuating Pin Stainless Stoo!

Nominal Votage 24.Vde

Nominal Curent 42a

Valve Connection | MA2x1.5.

Approval ves

‘Approval No (6302028 Typ 804420875

Part No INcor3

DISCHARGE HOSE TYP DN12

Material ‘Symthotc rubber Hose with 2 high

{ensile steel wie braids

reinforcement

Max. Working Prossure : 280 Bar

‘Temperature Range: - 18°C to + 60°C

Hose Connections: W21.8 x 1/14" DIN

Approval vas

‘Approval No 6304026 Typ DN12

Part No INco0e:

PILOT LINE HOSE TYP DNO8

Material ‘Synthetic ripber Hose with 2 high

tensile steel wie braids

reinforcement

Max. Working Pressure : 350 Bar

Temperature Range: - 15°C to + 50%

Hose Connections: 18° BSP

Fiting Connections: 18° BSP

‘Adaptor Connection (used on plat cyinder ony)

Inet W218 x 1/14" DIN

Outlet 18" BSP

Approval vas

‘Approval No (6304027 Typ DNOS

Part No INGOTO- Hot

Inertec System Components

80 LITER INERTEC CYLINDER

Material

Cyinder Cchronium Moyenum Sto

Filing 18.r0 | 22.249 - G55

48:2n0 17.5kq~ 16100

7400 (27.4 ~ 160

Filing Pressure + 200 Bar @ 20°C

Test Pressure: minimum 300 Bar

apron Weight 115g (Tee) 137 ka (oes)

Standard of

Comalianes DOT 3AA/ TPED 1999136108

ar eccordng to iterator

Standards

Colour Red or Gey according o

Navona Reguiton

PartNo INco‘e.cS-060|

N50 CYLINDER MANIFOLD

Material

Pipe 2 Sch 160 ASTRA A1O58 oF API

BL seamiess pip, gavanzed

Ccneck Valve Connection: 34" BSPT

ax. Working Pressure © 240 Bar

Tet Prowsure 360 Bar

‘Aproximate Weight 11.5kg

Part No ING038.CS.002 to INGO38-CS.018

INERTEC PRESSURE GAUGE WITH

INTEGRATED PRESSURE SWITCH

Temperature Range: -18°C to + 50°C

Connection to Valve: M10 X1

Indication Range 180 - 360 Bar

Nomina Size samm

Electrical Data

Contact Pin and Lug: Gold Ptated

Switch Votage 45 to 24 VOC VAC

‘Switch Curent 5 mAto 100 mA

Contact Load max 3 W

‘Switeh Point nominal 180 Bar

Setting increasing pressure max 185 bar

‘docreasing pressure min 180 bar

Serios 8 02972

Part No Incors

INERTEC SELECTOR / DIRECTIONAL VALVE

Type Ball valve GB2: way:

Body round

Material A105

Size (68:2: from DN32 up to DNSO

O-Rings NBR, FPM, MQV, EPDM, FFKM

Operating Pressure: GB2: 350 Bar

Temp Range “10°C to + 100°C depending on

eal materials selected

Air for actuator 56 Bar

Part No INg027-GM.050

SOLENOID VALVE

Operating voltage: 24VDC,0:75A

Part No ‘co2003.AD8112

DISCHAGE NOZZLE TYP 1/2” AND TYP 1”

Material

Body Brass

Orifice Pi Brass

Max. Area Coverage!

Nowe 30m2 (6m x 6m)

Max. Height 5m

Working Pressure: 20 Bar (min), 60 Bar (max)

Avalabie Orifice Diameter

112! Nozzle Sm - 10mm (rm increments)

1 Nozzle ‘mem - 20m (a tm increments)

Approval vas

‘Approval No ‘G 305005

Part No INGO02 - 1/2" Nozzle,

INGOO4 - + Nozzle

INERTEC PRESSURE GAUGE

Type Spring Tube Manometer

“Temperature

Range “18°C to + 50°C

Connection to Valve: M404

8 02972

Inco17

Approval

The iners<' JQ gas extinguishing system is approved ineriss 190

by VaS Schadenverhdtung (Loss Prevention) Germany to [_ Gartiiare

VS 2452 Gas Extinguishing System Requirements and | yen

Test Methods.

Al £100 gas extinguishing system equipment

such as manifold valve, actuator, pressure reducer, nozzle,

discharge hose and check valves are certified by VAS.

\VdS is a company of the German Insurance Association

Gesamtverband der Deutschen Vesi cherungswi rtschaft

(GDV). For further details visit www.vds.de

Tetj00 Bomba Con

Why Nitrogen Gas Suppression Is Considered

The Ultimate Choice?

iners2< 100 The Natural Solution.

PA Vision introduced the iner:s 10) fire suppression systems which meets all three objectives of a

responsible and modem fre protection system ; Protect Lives, Protect Properties and Protect the Environment.

» Safe for Human

Nitrogen is a natural gas which occupies the biggest percentage (78 %) of atmosphere ai

It produces no toxic or corrosive decomposition by-products, and no post-fire hazard.

The discharge of nitrogen does not impair visibility which is necessary for the safe evacuation

of occupants.

» GREEN

Itis 100 % environment friendly, it has zero Ozone Depletion Potential (ODP) and zero Global

Warming Potential (GWP). The use of ineri=:' JQ is in line with the current global Green

Initiatives for buildings e.g, Green Building Index (GBI) in Malaysia

» Limited Professional Liabi

The whole system, all its components including manifolds and the hydraulic software has gone

through rigorous tests and validations by in-house R & D and also listed by independent

certification body e.g, VdS Germany, which is compulsory in order to comply to NFPA 2001

A peace of mind solution in terms of potential exposure to professional liability

» Safe For Sensitive Equipment

Since it is inert in nature, nitrogen is electrically non-conductive and does not leave residue or

damage the protected equipment. There is no condensation of moisture in the air upon

discharge of the agent. It is the safest solution without secondary damage.

» Advantages for Owner & Contractor

Nitrogen gas, elements of the iner:=<' 100 fire suppressant is readily available everywhere and

is affordable. There is no dependency on specialised authorised suppliers. System discharge

tests can be carried out regularly by facility managers to ensure system functionality

> Low Cost Refills

Itis the cheapest gas for refilling due to any accidental or false discharge. Its refill cost is about

3-5 times cheaper than premixed inert gas and more than 10 times cheaper compared with

genuine halocarbon gas.

Sole Disribaor: PA VISION SDN BHD (652605) {Reseter

22+, Jalan Awan Makmur, OUG Square,

Off Jalan Klang Lama, 58200 Kuala Lumpur

Tel: 603-7783 6512 Fax: 603-783 6510

Email: pavision@streamyx.com

Website: www pavision.com my L

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Daikin FUW Cabinet Fan Coil UnitDocument29 pagesDaikin FUW Cabinet Fan Coil UnitPaul Mendoza100% (1)

- Daikin DDM-E Air Handling UnitDocument19 pagesDaikin DDM-E Air Handling UnitPaul MendozaNo ratings yet

- Daikin UAL-D5 Air-Cooled Modular Scroll ChillerDocument76 pagesDaikin UAL-D5 Air-Cooled Modular Scroll ChillerPaul MendozaNo ratings yet

- Daikin FUW-FE Cabinet Fan Coil UnitDocument8 pagesDaikin FUW-FE Cabinet Fan Coil UnitPaul MendozaNo ratings yet

- Daikin DDM-C Air Handling UnitDocument18 pagesDaikin DDM-C Air Handling UnitPaul MendozaNo ratings yet

- Daikin UAM-C Air-Cooled Scroll ChillerDocument8 pagesDaikin UAM-C Air-Cooled Scroll ChillerPaul MendozaNo ratings yet

- Daikin UAL Mini Air-Cooled Modular Scroll ChillerDocument15 pagesDaikin UAL Mini Air-Cooled Modular Scroll ChillerPaul MendozaNo ratings yet

- Ventilation Unit BOQDocument1 pageVentilation Unit BOQPaul MendozaNo ratings yet

- Fire Pro Hotel 101Document3 pagesFire Pro Hotel 101Paul MendozaNo ratings yet

- Document 134Document2 pagesDocument 134Paul MendozaNo ratings yet

- CombinepdfDocument14 pagesCombinepdfPaul MendozaNo ratings yet

- (Const. Method) SAMPLEDocument2 pages(Const. Method) SAMPLEPaul MendozaNo ratings yet

- For Canvass1Document18 pagesFor Canvass1Paul MendozaNo ratings yet

- 1 0Document6 pages1 0Paul MendozaNo ratings yet

- Ee PlanDocument1 pageEe PlanPaul MendozaNo ratings yet

- Document 36Document2 pagesDocument 36Paul MendozaNo ratings yet

- QT-2022-2598 - Angelio ResidenceDocument1 pageQT-2022-2598 - Angelio ResidencePaul MendozaNo ratings yet

- Chapter 4Document26 pagesChapter 4Paul MendozaNo ratings yet

- Mao Nani Beast Mode Na Ako!!Document26 pagesMao Nani Beast Mode Na Ako!!Paul MendozaNo ratings yet

- For Canvass1Document5 pagesFor Canvass1Paul MendozaNo ratings yet

- Chapter 5Document22 pagesChapter 5Paul MendozaNo ratings yet

- Ahu Diagram PDFDocument3 pagesAhu Diagram PDFPaul MendozaNo ratings yet

- PipesDocument2 pagesPipesPaul MendozaNo ratings yet

- Chapter 1-3Document8 pagesChapter 1-3Paul MendozaNo ratings yet

- Chapter 4.1Document58 pagesChapter 4.1Paul MendozaNo ratings yet