Professional Documents

Culture Documents

Er70s-6 Aws 5.18 (Esab 70-S6)

Er70s-6 Aws 5.18 (Esab 70-S6)

Uploaded by

Aldo RafaelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Er70s-6 Aws 5.18 (Esab 70-S6)

Er70s-6 Aws 5.18 (Esab 70-S6)

Uploaded by

Aldo RafaelCopyright:

Available Formats

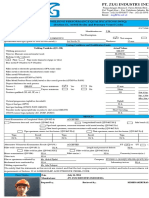

MIG/MAG WIRES (GMAW)

MILD STEEL WIRES

WELD 70S-6

ESAB WELD 70S-6 is a copper-coated AWS ER70S-6 solid wire, suited for general purpose, manual and semiautomatic

applications in most industries. It is manufactured under ESAB’s Quality Control programs and meets AWS standards.

Classifications: AWS A5.18: ER70S-6

Approvals: ABS 3YSA (C1), ABS 3YSA (M21), JIS YGW12, LR 3Y H15 (C1), LR 3Y H15 (M21)

Industry: Ship/Barge Building, Civil Construction, Mobile Equipment, Industrial and General

Fabrication, Automotive

Approvals are based on factory location. Please contact ESAB for more information.

Typical Tensile Properties

Condition Yield Strength Tensile Strength Elongation

75% Ar - 25% CO2

As Welded 538 MPa (78 ksi) 607 MPa (88 ksi) 27 %

90% Ar - 10% CO2

As Welded 538 MPa (78 ksi) 620 MPa (90 ksi) 24 %

Typical Charpy V-Notch Properties

Condition Testing Temperature Impact Value

75% Ar - 25% CO2

As Welded -40 °C (-40 °F) 122 J (90 ft-lb)

As Welded -45 °C (-50 °F) 96 J (71 ft-lb)

As Welded As welded -29 °C (-20 °F) 144 J (106 ft-lb)

90% Ar - 10% CO2

As Welded -29 °C (-20 °F) 141 J (104 ft-lb)

As Welded -40 °C (-40 °F) 110 J (81 ft-lb)

As Welded -45 °C (-50 °F) 110 J (81 ft-lb)

Typical Wire Composition %

C Mn Si S P Ni Cr Mo V Cu

0.12 1.80 1.15 0.025 0.025 0.15 0.15 0.15 0.03 0.35

Deposition Data

Diameter Optimal Current Voltage Wire Feed Speed Electrode Unit

Amps

Short Arc Transfer

69-en_US-FactSheet_Main-01 11/28/18

0.9 mm (.035 in.) 130 A 90-160 A 15-19 V 457-762 cm/min (180-300 in./min) 206 m/kg (3670 in./lb)

1.2 mm (.045 in.) 160 A 130-200 A 17-19 V 318-508 cm/min (125-200 in./min) 124 m/kg (2220 in./lb)

Spray Transfer

0.9 mm (.035 in.) 200 A 180-230 A 25-27 V 1016-1397 cm/min (400-550 in./min) 206 m/kg (3670 in./lb)

1.2 mm (.045 in.) 300 A 260-340 A 25-30 V 762-1270 cm/min (300-500 in./min) 124 m/kg (2220 in./lb)

esab.com

You might also like

- D0107 (2013-N) NES: Characteristic of Car Body Spot WeldsDocument8 pagesD0107 (2013-N) NES: Characteristic of Car Body Spot WeldsRicardo F.A.No ratings yet

- Ds Universal Wps Migmag enDocument6 pagesDs Universal Wps Migmag enMarija Ivanovska0% (1)

- Tata Steel - YMPRESS S500MC - Data SheetDocument2 pagesTata Steel - YMPRESS S500MC - Data SheetpnagarajjNo ratings yet

- Corewire Weldclad 01 PDFDocument31 pagesCorewire Weldclad 01 PDFRaviTeja BhamidiNo ratings yet

- Star Core 6Document2 pagesStar Core 6jmur10No ratings yet

- Murex Arc Gas Conumables 3Document58 pagesMurex Arc Gas Conumables 3cfcshaker100% (1)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- GXHQ - EN - CLIPS - RailLok Clip W25 Instal & Weld Instruc - 2018-02 - R1.1Document4 pagesGXHQ - EN - CLIPS - RailLok Clip W25 Instal & Weld Instruc - 2018-02 - R1.1Emmanuel Hernandez100% (1)

- Selection of Filler Metal For WeldingDocument21 pagesSelection of Filler Metal For WeldingRegu vlogsNo ratings yet

- 2015 Asme CodesDocument2 pages2015 Asme CodeswholenumberNo ratings yet

- ABS EH36 Steel Plate, ABS EH36 Steel Sheet, ABS Grade EH36 Shipbuilding Steel Price, ABS Grade EH36 Steel Supplier and ManufacturerDocument3 pagesABS EH36 Steel Plate, ABS EH36 Steel Sheet, ABS Grade EH36 Shipbuilding Steel Price, ABS Grade EH36 Steel Supplier and ManufacturerElizabeth HarrisNo ratings yet

- The Nelson System Catalouge Version 2 2017 Shear StudsDocument8 pagesThe Nelson System Catalouge Version 2 2017 Shear StudsMacNo ratings yet

- A867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsDocument4 pagesA867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsdcardonasterNo ratings yet

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- A 269 - 04 Qti2oqDocument6 pagesA 269 - 04 Qti2oqfekihassan100% (1)

- Catalago Pernos Stud PDFDocument2 pagesCatalago Pernos Stud PDFErick German Fuentes PollicardoNo ratings yet

- Corwire Katalog YiceDocument54 pagesCorwire Katalog YiceAlexandar Marinkovic100% (1)

- Ssab WeldingDocument16 pagesSsab WeldingOscar Jiménez100% (1)

- As 1554.5-1995 Amdt 1-1998 Structural Steel Welding - WeldiDocument7 pagesAs 1554.5-1995 Amdt 1-1998 Structural Steel Welding - WeldiThaiminh VoNo ratings yet

- Al Si 7 MG 03Document2 pagesAl Si 7 MG 03CSayanavaramNo ratings yet

- Sae j429 Vs Astm A354 BDDocument2 pagesSae j429 Vs Astm A354 BDAdam GordonNo ratings yet

- General Documentation - RecrystallizationDocument11 pagesGeneral Documentation - RecrystallizationAlbokeaNo ratings yet

- Wps Guides 2006Document25 pagesWps Guides 2006BE GNo ratings yet

- Filler Metal Selector GuideDocument11 pagesFiller Metal Selector GuideKrishnamoorthi VenkatesanNo ratings yet

- Aerospace Material Specification: Plating, Nickel General PurposeDocument8 pagesAerospace Material Specification: Plating, Nickel General PurposeSURYAS63No ratings yet

- Hydro Aluminium - AlSi7Mg0.6Document2 pagesHydro Aluminium - AlSi7Mg0.6Raj PrasanthNo ratings yet

- Fcaw Welding Guide PDFDocument2 pagesFcaw Welding Guide PDFElizabethNo ratings yet

- Soldadura de Hierro ColadoDocument10 pagesSoldadura de Hierro ColadoclnNo ratings yet

- Cold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDocument3 pagesCold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDanZel DanNo ratings yet

- Astm B 240-07 PDFDocument4 pagesAstm B 240-07 PDFRamsi AnkziNo ratings yet

- Brass MachiningDocument68 pagesBrass MachiningVaibhav ShuklaNo ratings yet

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocument2 pagesSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- 177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQDocument4 pages177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Mil S 13165Document20 pagesMil S 13165Francisco Ribeiro FernandesNo ratings yet

- Din 1681-GS 60Document9 pagesDin 1681-GS 60Vishnu AgawaneNo ratings yet

- No. 46 European Crane RailDocument3 pagesNo. 46 European Crane RailLainhatanhNo ratings yet

- HARDOX400 - 10mm Plate - MTCDocument2 pagesHARDOX400 - 10mm Plate - MTCMohammad Adil100% (1)

- BohlerThyssen PDFDocument386 pagesBohlerThyssen PDFElMacheteDelHuesoNo ratings yet

- Oliver Equation Paper-1928Document38 pagesOliver Equation Paper-1928dps32100% (1)

- Astm A192 Asme Sa192 PDFDocument4 pagesAstm A192 Asme Sa192 PDFWil Vasquez C100% (1)

- Welding Position PosterDocument1 pageWelding Position PosterbenzinaNo ratings yet

- En 10140-2006Document14 pagesEn 10140-2006KaanMertNo ratings yet

- Esab Buddy TIG400iDocument2 pagesEsab Buddy TIG400iJeganeswaranNo ratings yet

- FT Grease 22Document2 pagesFT Grease 22Edgar Leonel CortésNo ratings yet

- Blank Sample PQR Form (GMAW & FCAW - Page 1) Procedure Qualification Record (PQR)Document2 pagesBlank Sample PQR Form (GMAW & FCAW - Page 1) Procedure Qualification Record (PQR)GMNo ratings yet

- Filler Metal Selection GuideDocument32 pagesFiller Metal Selection GuideSamuel LatumahinaNo ratings yet

- ASTM A36 Steel, PlateDocument1 pageASTM A36 Steel, PlateWahyu DarmajatiNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- L80 - Continental AlloysDocument2 pagesL80 - Continental Alloystoxa0707No ratings yet

- Welding BisplateDocument12 pagesWelding BisplateLim Senglin100% (1)

- 30 CR Ni Mo 8Document2 pages30 CR Ni Mo 8Amy GriffinNo ratings yet

- Thermanit MTS 3 - GTAWDocument1 pageThermanit MTS 3 - GTAWdnageshm4n244No ratings yet

- Cast OlinDocument24 pagesCast OlinAnonymous CZHJN2EU0U100% (1)

- Superarc La-75: Conformances Key FeaturesDocument1 pageSuperarc La-75: Conformances Key FeaturesH_DEBIANENo ratings yet

- Superarc La-100: Conformances Key FeaturesDocument1 pageSuperarc La-100: Conformances Key FeaturesH_DEBIANENo ratings yet

- Superarc L-59: Conformances Key FeaturesDocument1 pageSuperarc L-59: Conformances Key FeaturesH_DEBIANENo ratings yet

- Creep Resisting Steels ESABDocument6 pagesCreep Resisting Steels ESABElias KapaNo ratings yet

- Low HydrogenDocument3 pagesLow Hydrogenseeralan balakrishnanNo ratings yet

- N, BNDocument1 pageN, BNmomenziNo ratings yet

- Idalloy: C MN Si CR Mo V P S CuDocument1 pageIdalloy: C MN Si CR Mo V P S CuiocephNo ratings yet

- General Description: Plug Fan ER..C With Standard MotorDocument7 pagesGeneral Description: Plug Fan ER..C With Standard MotorwildanNo ratings yet

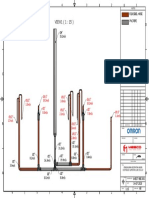

- Existing Dan Planning Drain ShinwaDocument2 pagesExisting Dan Planning Drain ShinwawildanNo ratings yet

- VIEW1 (1: 15) : 1/2" 1.3m/s 1.5" 10.3m/s 2" 8.3m/s 1/2" 2.1m/s 1/2" 3.0m/s 1.5" 10.2m/s 2" 7.8m/s 1.5" 1.1m/sDocument1 pageVIEW1 (1: 15) : 1/2" 1.3m/s 1.5" 10.3m/s 2" 8.3m/s 1/2" 2.1m/s 1/2" 3.0m/s 1.5" 10.2m/s 2" 7.8m/s 1.5" 1.1m/swildanNo ratings yet

- WLDN 22/05/2018: Designed by Checked by Approved by Date DateDocument1 pageWLDN 22/05/2018: Designed by Checked by Approved by Date DatewildanNo ratings yet

- Logo Gaia IptDocument1 pageLogo Gaia IptwildanNo ratings yet

- ADELE Send My LoveDocument2 pagesADELE Send My LovewildanNo ratings yet

- Stress Analysis Report Platform: Project Info (Iproperties)Document8 pagesStress Analysis Report Platform: Project Info (Iproperties)wildanNo ratings yet

- NounDocument14 pagesNounwildanNo ratings yet

- AWS C5 6 89 Recommended Practices For Gas Metal Arc Welding PDFDocument75 pagesAWS C5 6 89 Recommended Practices For Gas Metal Arc Welding PDFwildan100% (3)