Professional Documents

Culture Documents

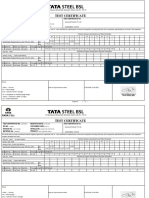

Certification As Per en 10204 3.1: Chemical Composition %

Uploaded by

BHUSHANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certification As Per en 10204 3.1: Chemical Composition %

Uploaded by

BHUSHANCopyright:

Available Formats

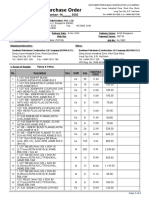

MASK FASTENERS PVT. LTD.

C 129/1 Industrial Area Supa,Tal Parner, Dist AhmedNagar-414301 Maharastra India

Tel:02488213108 Email : ganesh.thorve@maskgroups.com

Regd.Office:S Block 72/4 MIDC Bhosari,Pune-411026(Maharastra)

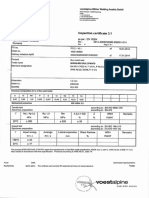

CERTIFICATION AS PER EN 10204 3.1

Customer : MICROFINISH VALVES PVT LIMITED. Material : AISI 4140 T.C. No. : 0463/18-19

PO No. : 1819/Z-4199 PO Date : 28/12/2018 Raw Material : RMRBR00025 Date : 21/01/2019

LOT No. : WO/1819/SUA/01311/4 Heat No. : RM Lot No : 4803360 Inv. No. : 18-19/DM/0694

01/11.01.19/002 Bar Size : 16 Inv Date : 21/01/2019

CHEMICAL COMPOSITION %

Elements C Mn P S Si Cr Ni Mo V

Min : 0.380 0.750 0.150 0.800 0.150 0.000 Mill Name: JINDAL STEEL &

POWER LTD

Max : 0.480 1.000 0.035 0.040 0.350 1.100 0.000 0.250 0.000 Mill TC No: 191160

Actual : 0.4393 0.8437 0.0160 0.0028 0.2753 0.9447 0.1578 Mill TC Dt : 01/08/2018

Elements

Min :

Max :

Actual :

LAB Name: MFPL TC No: GU/CL 1366/1366 TC Dt: 15/09/2018

HEAT TREATMENT

HARDNING TEMPERING 2ND TEMPERING

Temp °C Min : 850 °C Temp °C Min : 620 °C Temp °C Recorded(CARBIDE

Temp °C Recorded : 865 °C Temp °C Recorded : 680 °C SOLUTION TREATMENT): °C

Soaking Time(in Minutes) : 75 Soaking Time(in Minutes) : 120

Quenching Medium : OIL Cooling Medium : AIR

Heat Treatment Chart No : SE H Heat Treatment Chart No :SE T

MECHANICAL PROPERTIES

Lab TC No. : Lab Name : MFPL

301_2019

PROPERTIES % ELONGATION(IN 2 YIELD STRENGTH 0.2% TENSILE % REDUCTION AREA HARDNESS

inc.) offset(Mpa) STRENGTH(Mpa)

Min : 16.000 720.000 860.000 50.000 HRB 93

Max : HRB 99

Actual : 23.40 1279.478 1458.787 57.59 HRB 98

AVG VALUE LATERAL EXPANSION AT

We confirm that the material was manufactured, sampled, tasted and inspected in accordance with drawing, material specification and

purchase order requirements.

Remarks :

Material Confirms To : ASTM A193/A193M For Mask Fasteners Pvt. Ltd

GR B7M

Mss No. : Special Requirements

Dimensions As Per : AS PER DRG. NO PMI :

R0501110760XX REV

0

Threads As Per : ASME B1.13M CL-6g LPE :

Any Other Procedure : UT : Quality Control

Marking & MFG ID : B7M/MF MPI : OK

1

MASK FASTENERS PVT. LTD.

C 129/1 Industrial Area Supa,Tal Parner, Dist AhmedNagar-414301 Maharastra India

Tel:02488213108 Email : ganesh.thorve@maskgroups.com

Regd.Office:S Block 72/4 MIDC Bhosari,Pune-411026(Maharastra)

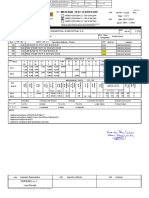

CERTIFICATION AS PER EN 10204 3.1

Customer : MICROFINISH VALVES PVT LIMITED. Material : AISI 4140 T.C. No. : 0463/18-19

PO No. : 1819/Z-4199 PO Date : 28/12/2018 Raw Material : RMRBR00025 Date : 21/01/2019

LOT No. : WO/1819/SUA/01311/4 Heat No. : RM Lot No : 4803360 Inv. No. : 18-19/DM/0694

01/11.01.19/002 Bar Size : 16 Inv Date : 21/01/2019

IMPACT TEST Specified Value J 27 min Value 1 Value 2 Value 3 Avg.Value

Achieved Value J 34 38 64 38.66

TC No: AAEA/MET/19/16G 08/01 Date: 16/01/2019 Name : AAEA Result: SATISFACTORY

MACRO ETCH AS PER ASTM E-381 SURFACE TREATMENT PROCESS

RESULT : BLACKODIZE

TC NO: / / OF

ITEM DETAILS

Item Code Item Description Quantity Units

M0000000023 HALF THREADED STUD M16 X 2 PX 54 (TL B = 18MM & C = 28MM) ASTM 1908 Nos

A193 GR. B7M, WITH BLACKODIZING DRG. NO R0501110760XX REV 0

We confirm that the material was manufactured, sampled, tasted and inspected in accordance with drawing, material specification and

purchase order requirements.

Remarks :

Material Confirms To : ASTM A193/A193M For Mask Fasteners Pvt. Ltd

GR B7M

Mss No. : Special Requirements

Dimensions As Per : AS PER DRG. NO PMI :

R0501110760XX REV

0

Threads As Per : ASME B1.13M CL-6g LPE :

Any Other Procedure : UT : Quality Control

Marking & MFG ID : B7M/MF MPI : OK

2

You might also like

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Mask Fasteners Pvt. Ltd. CertificationDocument2 pagesMask Fasteners Pvt. Ltd. CertificationGaurav100% (1)

- MILL TEST CERTIFICATE FOR 304 STAINLESS STEELDocument1 pageMILL TEST CERTIFICATE FOR 304 STAINLESS STEELMANIMARAN QC100% (1)

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh MehtaNo ratings yet

- Certified Material Test Report for EN 19-T Steel ForgingsDocument4 pagesCertified Material Test Report for EN 19-T Steel ForgingsashokNo ratings yet

- SS420, 12mm-RamDocument1 pageSS420, 12mm-RamganeshNo ratings yet

- MFF Spect. Blind 6 CL 150Document1 pageMFF Spect. Blind 6 CL 150Mohamed RaafatNo ratings yet

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- Heat C090 SK3RQ1.5X1Document1 pageHeat C090 SK3RQ1.5X1Keshia Murillo PinnockNo ratings yet

- Page 1 of 1: Test Certificate No. 0000141878Document1 pagePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNo ratings yet

- 2.5 MM 1250....Document1 page2.5 MM 1250....Balaji Defence100% (1)

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- MTC 17 4PH Al20201127a174Document1 pageMTC 17 4PH Al20201127a174Ajeng PratiwiNo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- JCOUSER03Document1 pageJCOUSER03Neem LalNo ratings yet

- QM-System: Certification As Per ISO 9001: (WWW - Dillinger.de/certificate)Document20 pagesQM-System: Certification As Per ISO 9001: (WWW - Dillinger.de/certificate)hemantmech099200No ratings yet

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

- WNRF 2 MFF ItalyDocument1 pageWNRF 2 MFF ItalyMohamed RaafatNo ratings yet

- Vedanta Limited Integrated Field Plan Inspection ReportsDocument23 pagesVedanta Limited Integrated Field Plan Inspection ReportsPRAKASH PANDEYNo ratings yet

- Global Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiDocument1 pageGlobal Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiSonu Singh100% (1)

- ASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Document1 pageASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Omar Bautista Díaz100% (1)

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- 622888Document1 page622888DeepakNo ratings yet

- 1.20mm T.C - Mehta SteelsDocument1 page1.20mm T.C - Mehta SteelsRonak FireNo ratings yet

- 60 MM SA 516 GR 70 MTCDocument21 pages60 MM SA 516 GR 70 MTCgeoanburajaNo ratings yet

- Purchase Order: Number: 14 - SOODocument4 pagesPurchase Order: Number: 14 - SOOLê Đức ThiệnNo ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- TC - ASTM 517 GR FDocument1 pageTC - ASTM 517 GR FPremnath YadavNo ratings yet

- Sarma Tub Inox Certificat PDFDocument1 pageSarma Tub Inox Certificat PDFJacob HarrisNo ratings yet

- 1jsl Ltd. TPI 3 (31803) MMDocument2 pages1jsl Ltd. TPI 3 (31803) MMPratik KarekarNo ratings yet

- 9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFDocument1 page9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFantonio larotta100% (1)

- ISO 9001-2015 Certified Co. supplies ASME certified pipe fittingsDocument1 pageISO 9001-2015 Certified Co. supplies ASME certified pipe fittingsSACHIN PATELNo ratings yet

- Fittings ThrededDocument2 pagesFittings ThrededreniNo ratings yet

- TC No-1451Document1 pageTC No-1451Structures ProductionNo ratings yet

- Flange 24 InchDocument2 pagesFlange 24 InchreniNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- S355J2 Plate MTCDocument2 pagesS355J2 Plate MTCHarminder Kumar100% (1)

- Hebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEDocument1 pageHebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEAnonymous TPoO5u8MeNo ratings yet

- Mechnical Property For Q235B Carbon SteelDocument3 pagesMechnical Property For Q235B Carbon SteelPritom Ahmed100% (1)

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Document2 pagesMill'S Test Certificate ACC. TO EN 10204 / 3.1Durulsan MakinaNo ratings yet

- 4140 Material For TubeDocument2 pages4140 Material For Tubesharafudheen_sNo ratings yet

- Test CertificateDocument2 pagesTest CertificateTARUNKUMARNo ratings yet

- M12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Document1 pageM12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Athul T.NNo ratings yet

- 075P80-321 TubacexDocument1 page075P80-321 Tubacexsakshi patilNo ratings yet

- Outokumpu: Si MN P S CR NiDocument3 pagesOutokumpu: Si MN P S CR NiDarkedgeNo ratings yet

- 041101Document1 page041101Carolina MolfinoNo ratings yet

- Abnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Document1 pageAbnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Mohamed RaafatNo ratings yet

- QD62-H-103 DocumentationDocument16 pagesQD62-H-103 DocumentationAlam MD SazidNo ratings yet

- Img 0001Document1 pageImg 0001Harish RanaNo ratings yet

- 1613 00443 PDFDocument69 pages1613 00443 PDFzaheerNo ratings yet

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- Sample Test Certificate (24.12.2022)Document1 pageSample Test Certificate (24.12.2022)PalaniyandiNo ratings yet

- Certificate of ComplianceDocument7 pagesCertificate of ComplianceNabilah HusnaNo ratings yet

- Nacla Z540 3Document12 pagesNacla Z540 3Somsak Navayon100% (1)

- Fasteners - Non-Electrolytically Applied Zinc Flake Coating Systems (ISO 10683:2018)Document14 pagesFasteners - Non-Electrolytically Applied Zinc Flake Coating Systems (ISO 10683:2018)BHUSHANNo ratings yet

- Astm A490Document7 pagesAstm A490vu hungNo ratings yet

- NB-CPD SG02 03 002r2 - EN 934 series-FPC Cert - Admixtures For Concrete Mortar and Grout PDFDocument15 pagesNB-CPD SG02 03 002r2 - EN 934 series-FPC Cert - Admixtures For Concrete Mortar and Grout PDFAlban TabakuNo ratings yet

- Alloy-Steel and Stainless Steel Bolting For Low-Temperature ServiceDocument8 pagesAlloy-Steel and Stainless Steel Bolting For Low-Temperature ServiceHui LiuNo ratings yet

- Api 3Q - 2017 PDFDocument29 pagesApi 3Q - 2017 PDFBHUSHANNo ratings yet

- 04 1 Sec IV STD Specs PipingDocument152 pages04 1 Sec IV STD Specs PipingdzungNo ratings yet

- API Q1 Approved InterpretationsDocument4 pagesAPI Q1 Approved InterpretationsKrishna VachaNo ratings yet

- ASTM Statistic PDFDocument110 pagesASTM Statistic PDFAbidi HichemNo ratings yet

- API Q2 - Audit ChecklistDocument43 pagesAPI Q2 - Audit ChecklistBHUSHAN100% (4)

- Determining Damage-Based Design Criteria For Fiberglass Reinforced Plastics (FRP) MaterialsDocument6 pagesDetermining Damage-Based Design Criteria For Fiberglass Reinforced Plastics (FRP) MaterialsBHUSHANNo ratings yet

- PED 2014-68-EU Guidelines en v5.1Document241 pagesPED 2014-68-EU Guidelines en v5.1Uğur özdemirNo ratings yet

- Astm E448 82 R02 E02 PDFDocument40 pagesAstm E448 82 R02 E02 PDFPacifier NothingfaceNo ratings yet

- NQA ISO 45001 Implementation GuideDocument36 pagesNQA ISO 45001 Implementation GuideAnonymous 3eHGEDbx100% (11)

- Aerospace Material Specification: Nickel Plating (Electrodeposited)Document12 pagesAerospace Material Specification: Nickel Plating (Electrodeposited)BHUSHAN100% (2)

- Understanding NACE MR0175 - ISO 15156Document3 pagesUnderstanding NACE MR0175 - ISO 15156yagolain100% (4)

- NQA ISO 45001 Implementation GuideDocument36 pagesNQA ISO 45001 Implementation GuideAnonymous 3eHGEDbx100% (11)

- Din, En, Ansi, Asme, Astm, IsoDocument19 pagesDin, En, Ansi, Asme, Astm, IsoBHUSHANNo ratings yet

- Ped-Guidelines en PDFDocument261 pagesPed-Guidelines en PDFAnte NinićNo ratings yet

- Remaining For Generating Work OrderDocument1 pageRemaining For Generating Work OrderBHUSHANNo ratings yet

- Architecturally Exposed Structural Steel 05125Document16 pagesArchitecturally Exposed Structural Steel 05125Hugo Mario Ariza PalacioNo ratings yet

- Manganese Steel Standard Designation SAE 13xxDocument196 pagesManganese Steel Standard Designation SAE 13xxJom BautistaNo ratings yet

- Proses Sheet MetalDocument66 pagesProses Sheet MetalAnonymous B6NOrvoxRhNo ratings yet

- Tube Products of India Cold Rolling DivisionDocument45 pagesTube Products of India Cold Rolling DivisionAditya TripathiNo ratings yet

- STD00017 Issue 18 Corrosion Prevention (26-07-2017)Document28 pagesSTD00017 Issue 18 Corrosion Prevention (26-07-2017)Ace LeeNo ratings yet

- CoA - 689516-100 722ADocument1 pageCoA - 689516-100 722AAmapola VillalobosNo ratings yet

- C 955 - 03Document4 pagesC 955 - 03Tarek FennicheNo ratings yet

- Secondary Steelmaking: Topics To Discuss ..Document10 pagesSecondary Steelmaking: Topics To Discuss ..Mir RafsanNo ratings yet

- General 2Document6 pagesGeneral 2skynyrd75No ratings yet

- Production ESE GATE 2020Document500 pagesProduction ESE GATE 2020NAMAN GARG CO18139No ratings yet

- 7902 17709 1 SMDocument10 pages7902 17709 1 SMSyaiful Ramadhan HarahapNo ratings yet

- Process for Electroplating Rhodium to Produce Black or Blue ColorDocument6 pagesProcess for Electroplating Rhodium to Produce Black or Blue ColorDhandapani PNo ratings yet

- Ferrous Alloys Feah: March Author: R. ADocument22 pagesFerrous Alloys Feah: March Author: R. AsunsirNo ratings yet

- Technology Tig 182 Ac/Dc-Hf/Lift 230V+AcDocument2 pagesTechnology Tig 182 Ac/Dc-Hf/Lift 230V+AcPedja BekicNo ratings yet

- Extraction of Manganese From Ferro-Manganese Slag: 'Karnataka Regional F, Rrgineerirtg College, Suratlrkal, IndiaDocument7 pagesExtraction of Manganese From Ferro-Manganese Slag: 'Karnataka Regional F, Rrgineerirtg College, Suratlrkal, IndiaravibelavadiNo ratings yet

- 278 en US FactSheet Main 01Document1 page278 en US FactSheet Main 01Jorge Manuel GuillermoNo ratings yet

- Sulphuric AcidDocument37 pagesSulphuric AcidBaskaran SubramaniyanNo ratings yet

- Asme Section II A Sa-193 Sa-193mDocument18 pagesAsme Section II A Sa-193 Sa-193mAnonymous GhPzn1xNo ratings yet

- Severe Plastic DeformationDocument7 pagesSevere Plastic Deformationvolkan çiçekNo ratings yet

- PDFsam_B 395 - B 395M - 16Document12 pagesPDFsam_B 395 - B 395M - 16mike.jensen0581No ratings yet

- What Are 10 Advantages of Aluminum Roofing Sheets - QuoraDocument10 pagesWhat Are 10 Advantages of Aluminum Roofing Sheets - QuoraParameswaran GanesanNo ratings yet

- ReportDocument18 pagesReportKrishna KKNo ratings yet

- 2020 ISRI Scrap Specificiations CircularDocument62 pages2020 ISRI Scrap Specificiations CircularRod AguirreNo ratings yet

- GTU Bachelor Engineering Material Science MetallurgyDocument4 pagesGTU Bachelor Engineering Material Science MetallurgyjanakNo ratings yet

- Efficient Hard Finishing of Asymmetric Tooth ProfilesDocument1 pageEfficient Hard Finishing of Asymmetric Tooth ProfilesgioNo ratings yet

- Certificate of Conformity Number # 241413C: ContaminantDocument2 pagesCertificate of Conformity Number # 241413C: ContaminantAdrian HolotteNo ratings yet

- Metric Version Catalog 2012 GROOVE-TURN TOOLSDocument413 pagesMetric Version Catalog 2012 GROOVE-TURN TOOLSbrusilicaNo ratings yet

- Commenly Used Materials: Rolta Training Center, Mumbai - IndiaDocument1 pageCommenly Used Materials: Rolta Training Center, Mumbai - IndiaTAMIZHKARTHIKNo ratings yet

- SSP - Structural Steel GuideDocument72 pagesSSP - Structural Steel GuideKevin HuangNo ratings yet

- TDS of 1037Document3 pagesTDS of 1037prakash mondalNo ratings yet