Professional Documents

Culture Documents

Aluminum Die Casting Draft Angles Guide PDF

Uploaded by

YAGANTIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminum Die Casting Draft Angles Guide PDF

Uploaded by

YAGANTICopyright:

Available Formats

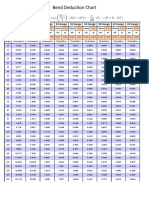

PRODUCT STANDARDS FOR ALUMINUM DIE CASTING DRAFT ANGLES

(metric)

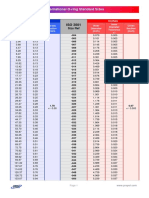

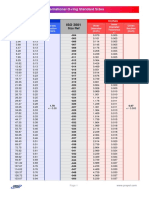

Linear Dimensional Tolerance

DISTANCE

mm 1/2° 1° 2° 3° 4° 5° 6°

±0.004” for the first inch, or ±0.10 mm for the first 25.4 mm

1.00 0.009 0.017 0.035 0.052 0.070 0.087 0.105

±0.0015” for each additional inch, or ±0.04 mm for each additional 25.4 mm

1.50 0.013 0.026 0.052 0.079 0.105 0.131 0.158

2.00 0.017 0.035 0.070 0.105 0.140 0.175 0.210

Draft Requirements - Inside & Outside Walls 2.50 0.022 0.044 0.087 0.131 0.175 0.219 0.263

Wall Length Draft for Draft for 3.00 0.026 0.052 0.105 0.157 0.210 0.262 0.315

Inches mm Inside Walls Outside Walls 3.50 0.031 0.061 0.122 0.183 0.245 0.306 0.368

0.13 3.2 6° 3° 4.00 0.035 0.070 0.140 0.210 0.280 0.350 0.420

0.25 6.4 4° 2° 4.50 0.039 0.079 0.157 0.236 0.315 0.394 0.473

0.50 12.7 2.5° 1.25° 5.00 0.044 0.087 0.175 0.262 0.350 0.437 0.526

0.75 19.1 2° 1° 5.50 0.048 0.096 0.192 0.288 0.385 0.481 0.578

1.00 25.4 1° .5° 6.00 0.052 0.105 0.210 0.314 0.420 0.525 0.631

6.50 0.057 0.113 0.227 0.341 0.455 0.569 0.683

Flatness Requirement 7.00 0.061 0.122 0.244 0.367 0.489 0.612 0.736

7.50 0.065 0.131 0.262 0.393 0.524 0.656 0.788

0.002” per inch, or 0.05 mm per 25.4 mm

8.00 0.070 0.140 0.279 0.419 0.559 0.700 0.841

9.00 0.079 0.157 0.314 0.472 0.629 0.787 0.946

Cored Hole Requirements 10.00 0.087 0.175 0.349 0.524 0.699 0.875 1.051

Hole Diameter Max. Hole Depth Total Draft 11.00 0.096 0.192 0.384 0.576 0.769 0.962 1.156

Inches mm Inches mm Requirement 12.00 0.105 0.209 0.419 0.629 0.839 1.050 1.261

0.13 3.2 0.31 7.9 5° 13.00 0.113 0.227 0.454 0.681 0.909 1.137 1.366

0.25 6.4 1.00 25.4 3° 14.00 0.122 0.244 0.489 0.734 0.979 1.225 1.471

0.50 12.7 2.00 50.8 2° 15.00 0.131 0.262 0.524 0.786 1.049 1.312 1.577

1.00 25.4 6.00 152.4 1.5° 16.00 0.140 0.279 0.559 0.839 1.119 1.400 1.682

2.00 50.8 — — 1° 17.00 0.148 0.297 0.594 0.891 1.189 1.487 1.787

18.00 0.157 0.314 0.629 0.943 1.259 1.575 1.892

Other Requirements 19.00 0.166 0.332 0.663 0.996 1.329 1.662 1.997

Inches mm 20.00 0.175 0.349 0.698 1.048 1.399 1.750 2.102

21.00 0.183 0.367 0.733 1.101 1.468 1.837 2.207

Commercial trim is within 0.015 0.38 from the edge of the casting

22.00 0.192 0.384 0.768 1.153 1.538 1.925 2.312

Machining stock is 0.010 0.25 normal per side

23.00 0.201 0.401 0.803 1.205 1.608 2.012 2.417

Sharp corners minimum 0.020 0.51 corner radii & fillet radii

24.00 0.209 0.419 0.838 1.258 1.678 2.100 2.523

Wall thickness normal 0.090 2.29 standard minimum

25.40 0.222 0.443 0.887 1.331 1.776 2.222 2.670

Wall thickness minimum 0.030 0.76 produced in specific areas only

EXAMPLE: To determine the amount of taper per side for a die cast part

having a draft angle of 2° per side for a distance of 8 mm:

In the “Distance” column, go down to 8 mm, then across to the column

showing the 2° taper. The amount of taper shown here is .279 mm per side.

To determine distances greater than 25.40 mm, i.e. for 37.4 mm distance,

take the figure for 25.4 mm distance plus the figure for the 12.0 mm distance.

Yoder Industries’ Visi-Trak® Yoder’s well-equipped Automated and manual Example: 25.4 @ 2° = .887 mm

process shot monitoring quality assurance lab with assembly capabilities for

ensures the highest die real time X-ray analysis a wide range of products

+ 12.0 @ 2° = .419 mm

casting quality 37.4 @ 2° = 1.306 mm

Page 2 of 3

You might also like

- Tubing Data Card: Oilfiled Equipment Marketing, IncDocument1 pageTubing Data Card: Oilfiled Equipment Marketing, IncWenyerMillanGonzalezNo ratings yet

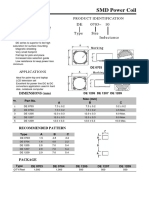

- SMD Power Coil: FerrocoreDocument2 pagesSMD Power Coil: FerrocorePuiu BercioiuNo ratings yet

- Resistance Calculations.: Delft Series ('98)Document2 pagesResistance Calculations.: Delft Series ('98)Joseph IsraelNo ratings yet

- Diameters InterDocument1 pageDiameters InterseenudesignNo ratings yet

- Mesh To Micron Conversion ChartDocument2 pagesMesh To Micron Conversion ChartKovarthanan EzhumalaiNo ratings yet

- International O-Ring Standar Sizes PDFDocument14 pagesInternational O-Ring Standar Sizes PDFJoseJSanchezNo ratings yet

- O-Ring Standar Sizes PDFDocument14 pagesO-Ring Standar Sizes PDFJoseJSanchezNo ratings yet

- Iso 3601 PDFDocument14 pagesIso 3601 PDFSujalsathwara0% (1)

- MILLIMDocument3 pagesMILLIMRhap Lumaban0% (1)

- Frigate ResistanceDocument2 pagesFrigate ResistancemxNoNameNo ratings yet

- Dimensões Das TubulaçõesDocument2 pagesDimensões Das TubulaçõesAlice Boll AltieriNo ratings yet

- API 5ct S Pipe Drifts Casing Data ChartDocument1 pageAPI 5ct S Pipe Drifts Casing Data ChartghanNo ratings yet

- De1207 220Document2 pagesDe1207 220Stoica VictorNo ratings yet

- Table of Gauges: Inch MM Inch MM Inch MM Inch MM Inch MM Inch MM No. S.W.G B.W.G B.G B.S U.S.G M.S.GDocument1 pageTable of Gauges: Inch MM Inch MM Inch MM Inch MM Inch MM Inch MM No. S.W.G B.W.G B.G B.S U.S.G M.S.GSamiul IslamNo ratings yet

- Standard Gauge For Sheet and Plate Iron & SteelDocument3 pagesStandard Gauge For Sheet and Plate Iron & Steelnelson121No ratings yet

- Resistance According To Delft Series ('98) : V V FN RF RR Rtotal PeDocument2 pagesResistance According To Delft Series ('98) : V V FN RF RR Rtotal Pegreicel marianjas sihombingNo ratings yet

- Standard Wire Gauge (SWG) Conversion To MetricDocument1 pageStandard Wire Gauge (SWG) Conversion To Metricmani317No ratings yet

- Kolmogorov SmirnovTableDocument2 pagesKolmogorov SmirnovTabledita riskaNo ratings yet

- Particle Size Conversion: Inches MM Microns Standard (MM) Mesh Sieve Opening Sieve DesignationDocument1 pageParticle Size Conversion: Inches MM Microns Standard (MM) Mesh Sieve Opening Sieve DesignationsayoneeNo ratings yet

- Fkyeah: F (X) 0.7741304415x + 0.0638312014 R 0.9954951224Document3 pagesFkyeah: F (X) 0.7741304415x + 0.0638312014 R 0.9954951224GregoriusTimothyNo ratings yet

- MektanDocument4 pagesMektanricha fitamalaNo ratings yet

- Comparison of Wire GaugesDocument6 pagesComparison of Wire GaugesshrishkapsiNo ratings yet

- Pipe Schedules Chart Imperial and Metric HFT50-WEB-P PDFDocument2 pagesPipe Schedules Chart Imperial and Metric HFT50-WEB-P PDFAnonymous ITKbMGWMNo ratings yet

- Wallchart PDFDocument1 pageWallchart PDFJee SelvaNo ratings yet

- Obscuration Table: Page 1 of 4Document4 pagesObscuration Table: Page 1 of 4Sreekanth Suresh KamathNo ratings yet

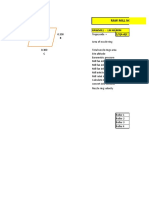

- A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BDocument4 pagesA Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BYhaneNo ratings yet

- SP 16 TablesDocument2 pagesSP 16 TablesPrashant Bhimrao KamateNo ratings yet

- Grafik Pipa SCH 40Document2 pagesGrafik Pipa SCH 40koirulraharjoNo ratings yet

- Doi Don VI GageDocument3 pagesDoi Don VI Gagetrung1983No ratings yet

- Mesh To Micron Conversion ChartDocument2 pagesMesh To Micron Conversion ChartMayur Agarwal100% (1)

- Spectru ProiectareDocument27 pagesSpectru ProiectareHoria Ionut MihneaNo ratings yet

- Spectru ProiectareDocument27 pagesSpectru ProiectareHoria Ionut MihneaNo ratings yet

- Lab 2 Compression Test - 192061589Document15 pagesLab 2 Compression Test - 192061589Ichi YanaNo ratings yet

- ANSI Pipe Schedule Chart: Pipe Weight Conversion FormulaDocument6 pagesANSI Pipe Schedule Chart: Pipe Weight Conversion FormulaHoangNo ratings yet

- Solubility of Carbon Dioxide in Water at Various Temperatures and PressuresDocument1 pageSolubility of Carbon Dioxide in Water at Various Temperatures and PressuresterrorfordNo ratings yet

- Datasheet 1x19 Stainless Steel Strand Wire RopeDocument1 pageDatasheet 1x19 Stainless Steel Strand Wire RopePrattyNo ratings yet

- Análisis Tamaño de Partícula (Sólidos)Document4 pagesAnálisis Tamaño de Partícula (Sólidos)Adriana QuirogaNo ratings yet

- Quantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingDocument12 pagesQuantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingpopemiNo ratings yet

- Quantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingDocument12 pagesQuantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingpopemiNo ratings yet

- Quantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingDocument12 pagesQuantity Between OGL & ETL C/S Area (In SQM.) Quantity (In Cum.) Chainage Cutting Filling CuttingpopemiNo ratings yet

- Annexe Tubing Casing Size PDFDocument81 pagesAnnexe Tubing Casing Size PDFKoffi Franck N'driNo ratings yet

- Poro-Perm GraphDocument7 pagesPoro-Perm GraphJordan WongNo ratings yet

- 03) Analysis TabelDocument8 pages03) Analysis TabelYogo StruggleNo ratings yet

- Miguel Quispe MolloDocument5 pagesMiguel Quispe Mollomaruja olveaNo ratings yet

- Pipe TolerancesDocument1 pagePipe TolerancesPamungkasNo ratings yet

- Alex ExcwlllDocument8 pagesAlex ExcwlllALEX WAGNER MANRIQUE QUISPENo ratings yet

- American Strand ConstructionDocument1 pageAmerican Strand Constructionpratul acharyaNo ratings yet

- Benfard's LawDocument5 pagesBenfard's LawMoises PedrazaNo ratings yet

- UC Davis Cenrifuge Data KKR 03Document5 pagesUC Davis Cenrifuge Data KKR 03Ravi SalimathNo ratings yet

- Lab 2 AdsorcionDocument10 pagesLab 2 AdsorcionPatricia JaraNo ratings yet

- ClearDocument4 pagesClearMacedo S OliveiraNo ratings yet

- Calculo PluvialDocument4 pagesCalculo PluvialAlejandro Caranton RinconNo ratings yet

- Pitch Conversions Threads Per Inch TPI Pitch in Inches and Pitch in MM For Taps and DiesDocument3 pagesPitch Conversions Threads Per Inch TPI Pitch in Inches and Pitch in MM For Taps and DiesChetan HinganeNo ratings yet

- Spears - PIPE SCH80Document1 pageSpears - PIPE SCH80F. AhmadNo ratings yet

- Mesh SizesDocument1 pageMesh SizesSohan SinghNo ratings yet

- Bend DeductionDocument2 pagesBend Deductionalung lungNo ratings yet

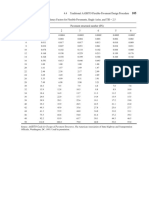

- Table 4.1 Axle-Load Equivalency Factors For Flexible Pavements, Single Axles, and TSI 2.5Document6 pagesTable 4.1 Axle-Load Equivalency Factors For Flexible Pavements, Single Axles, and TSI 2.5fadi eidNo ratings yet

- 3474462-Actividad 1Document10 pages3474462-Actividad 1PALOMA MORGADO FRANCONo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Streamline SWR (S) - Rev - 00-04-2019 PDFDocument2 pagesStreamline SWR (S) - Rev - 00-04-2019 PDFarjun 11No ratings yet

- 2003 Nissan Altima 2.5 Serivce Manual RSUDocument12 pages2003 Nissan Altima 2.5 Serivce Manual RSUAndy Dellinger100% (1)

- Manual de Taller sk350 PDFDocument31 pagesManual de Taller sk350 PDFLeo Perez100% (1)

- Movimiento Circular, Momentun Lineal y EnergíaDocument92 pagesMovimiento Circular, Momentun Lineal y EnergíaJulio César Macías ZamoraNo ratings yet

- Module 12. Big Issues Lesson 12a. Reading. Pages 140-141: No Words TranslationDocument4 pagesModule 12. Big Issues Lesson 12a. Reading. Pages 140-141: No Words TranslationLeonardo Perez AlegriaNo ratings yet

- Panasonic Refrigeraor NR-B472TZ - B412TZ v1.1Document24 pagesPanasonic Refrigeraor NR-B472TZ - B412TZ v1.1Anonymous 2iQ1B59No ratings yet

- Logistics Operation PlanningDocument25 pagesLogistics Operation PlanningLeonard AntoniusNo ratings yet

- Sermo 13 de Tempore (2 Feb in Praes)Document1 pageSermo 13 de Tempore (2 Feb in Praes)GeorgesEdouardNo ratings yet

- Latihan Soal BlankDocument8 pagesLatihan Soal BlankDanbooNo ratings yet

- TR189 Kathuria PDFDocument168 pagesTR189 Kathuria PDFuqiNo ratings yet

- The Ecological Effects of Eucalyptus PDFDocument97 pagesThe Ecological Effects of Eucalyptus PDFgejuinaNo ratings yet

- Dinacharya HandbookDocument5 pagesDinacharya Handbookvera sirakovaNo ratings yet

- Solomon On Sex - Avoiding Marital Disaster: February 12, 2012Document14 pagesSolomon On Sex - Avoiding Marital Disaster: February 12, 2012baimareanNo ratings yet

- EET - Formulas - Christmas TermDocument3 pagesEET - Formulas - Christmas TermJMDNo ratings yet

- Electric Bike Monitoring and Controlling System Based On Internet of ThingsDocument8 pagesElectric Bike Monitoring and Controlling System Based On Internet of ThingsEarl PhamtonhiveNo ratings yet

- Paper 2 With Solution MathematicsDocument17 pagesPaper 2 With Solution MathematicsFaiz AhmadNo ratings yet

- Art and Geography: Patterns in The HimalayaDocument30 pagesArt and Geography: Patterns in The HimalayaBen WilliamsNo ratings yet

- CDM816DSpare Parts Manual (Pilot Control) 2Document55 pagesCDM816DSpare Parts Manual (Pilot Control) 2Mohammadazmy Sobursyakur100% (1)

- 1 Introduction To Microsoft VirtualizationDocument36 pages1 Introduction To Microsoft VirtualizationRavinder KantNo ratings yet

- Tank Gauging TankvisionDocument31 pagesTank Gauging Tankvisionkhangduongda3No ratings yet

- M1-Safety StandardsDocument9 pagesM1-Safety StandardscarlNo ratings yet

- 1 Name of Work:-Improvement of Epum Road (Northern Side) Connecting With Imphal-Saikul Road I/c Pucca DrainDocument1 page1 Name of Work:-Improvement of Epum Road (Northern Side) Connecting With Imphal-Saikul Road I/c Pucca DrainHemam PrasantaNo ratings yet

- PalmistryDocument116 pagesPalmistrymarinoyogaNo ratings yet

- Scientific Exploration and Expeditions PDFDocument406 pagesScientific Exploration and Expeditions PDFana_petrescu100% (2)

- CopernikDocument2 pagesCopernikSinister JinNo ratings yet

- Group Collaborative Activity TaskonomyDocument2 pagesGroup Collaborative Activity TaskonomyTweeky SaureNo ratings yet

- The World S Finest Ideas in Cooling!: A Division ofDocument4 pagesThe World S Finest Ideas in Cooling!: A Division ofChiragNo ratings yet

- English 8 - B TR Và Nâng CaoDocument150 pagesEnglish 8 - B TR Và Nâng CaohhNo ratings yet

- Soal Bahasa Inggris X - XiDocument6 pagesSoal Bahasa Inggris X - XiBydowie IqbalNo ratings yet

- ONGC Buyout GOI's Entire 51.11% Stake in HPCLDocument4 pagesONGC Buyout GOI's Entire 51.11% Stake in HPCLArpan AroraNo ratings yet