Professional Documents

Culture Documents

Standard Specification For Film Lining Covered With Concrete Lining For Earthen Reservoir

Uploaded by

JITENDER KUMAROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Specification For Film Lining Covered With Concrete Lining For Earthen Reservoir

Uploaded by

JITENDER KUMARCopyright:

Available Formats

STANDARD SPECIFICATION STANDARD SPECIFICATION

ENGINEERS No.

loll e_J FOR FILM LINING COVERED

digeji fet5leg

INRtf errant 0,1340,-,0

INDIA LIMITED

(A Govt of India Undertaking)

WITH CONCRETE LINING 6-65-0046 Rev. 4

FOR EARTHEN RESERVOIR Page 1 of 7

41-1-Acri tOvIzmi4f4Tithivd

fffR

1-1114) q

STANDARD SPECIFICATION

FOR FILM LINING

COVERED WITH CONCRETE LINING

FOR

EARTHEN RESERVOIR

4 21.09.16 REAFFIRMED AND ISSUED AS STD. SPEC. BP DCB RS R.NANDA

3 21.06.11 REVISED AND ISSUED AS STD. SPEC. JKU GYAS RBB DM

2 10.03.08 REVISED AND ISSUED AS STD. SPEC. GAURAV RKS NK VC

1 01.07.99 REVISED AND ISSUED AS STD. SPEC. PCS MMK ASONI

0 21.3.90 ISSUED AS STD. SPEC. RP PCS RPB RCPC

Standards Standards

Committee Bureau

Rev. Prepared Checked

Date Purpose Convenor Chairman

No by by

Approved By

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1327 of 2303

STANDARD SPECIFICATION STANDARD SPECIFICATION

ENGINEERS FOR FILM LINING COVERED No.

INDIA LIMITED 6-65-0046 Rev. 4

clezme os1 ) IA Govt of India Undeftalong) WITH CONCRETE LINING

FOR EARTHEN RESERVOIR Page 2 of 7

Abbreviations:

c/c Center to Center

HM HDPE. High Molecular High Density Poly Ethylene

IS Indian Standard

LSTK Lump Sum Turn Key

w/c Water Cement Ratio

Structural Standards Committee

Convenor: Mr. Rajanji Srivastava

Members: Mr. JK Bhagchandani

Mr. Anurag Sinha

Mr. SK Naskar

Mr. VK Panwar

Mr. Charanjit Singh (Proj.)

Mr. Ravindra Kumar (Const.)

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1328 of 2303

STANDARD SPECIFICATION STANDARD SPECIFICATION

1of it4 ENGINEERS FOR FILM LINING COVERED No.

ogej. Ofirdg INDIA LIMITED

(A Govt of India Undenakm WITH CONCRETE LINING 6-65-0046 Rev. 4

FOR EARTHEN RESERVOIR Page 3 of 7

CONTENTS

1.0 SCOPE 4

2.0 CODES & STANDARDS 4

3.0 MATERIALS 4

4.0 SUB-GRADE PREPARATION 4

5.0 SAND CUSHION 5

6.0 FILM LAYING 5

7.0 CEMENT MORTAR LAYER 5

8.0 CEMENT CONCRETE LINING 5

9.0 ACCEPTANCE/TESTING 5

10.0 JOINTS IN CONCRETE LINING 5

11.0 PAYMENT 6

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1329 of 2303

STANDARD SPECIFICATION STANDARD SPECIFICATION

ENGINEERS FOR FILM LINING COVERED No.

keg INDIA LIMITED

Govt of India Undertaking) WITH CONCRETE LINING 6-65-0046 Rev. 4

FOR EARTHEN RESERVOIR Page 4 of 7

1.0 SCOPE

This specification covers the general requirements for construction of film lining covered with

concrete lining.

2.0 CODES & STANDARDS

IS: 2250 Code of practice for preparation and use of masonry mortars

IS: 2720 Part VIII Method of Test for Soils

IS: 2720 Part XIV Method of Test for Soils, Part-14, Determination of Density Index

(Relative Density) of Cohesion less Soils.

IS: 5256 Sealing expansion joints in concrete lining of canals-code of practice.

IS: 10889 Specification for HDPE films.

6-68-0002 Technical specification - Civil & Structural works - Materials.

6-68-0004 Technical specification - Civil & Structural works - Plain &

Reinforced cement concrete.

NOTE: -Latest Edition of all Codes and Standards shall be followed.

3.0 MATERIALS

3.1 Cement, sand and water shall be as described in EIL specification no. 6-68-0002.

3.2 Film Specification

Film specification shall be generally as per IS: 10889. The various requirements shall be as

follows:

1. Material HM HDPE Grade-I

2. Appearance Uniform in colour, texture and finish. No visible

defects, free from un-dispersed raw material, streaks

and foreign matter particles.

3. Film thickness 250 micron minimum.

Mechanical properties and other requirements shall be as per IS: 10889.

4.0 SUB-GRADE PREPARATION

The sub grade shall be well compacted, dressed and rolled true to the level to form a firm

compacted bed for the lining. The sub grade shall be compacted to 95% of modified Proctor

density as per IS: 2720 Part VIII. Also, one test shall be conducted per 500 Sq.m, for each

layer.

If at any point, material of prepared sub grade has been excavated beyond the required levels

for lining; the excess excavation shall be filled with material compatible with sub grade

material and thoroughly compacted. The sub grade shall be free from sharp objects such as

stone, weed roots etc. and shall be smooth without any depressions and humps etc.

Copyright EIL — All rights reserved

Format No. 8-00-0001-F1 Rev. 0

Page 1330 of 2303

STANDARD SPECIFICATION STANDARD SPECIFICATION

0 ENGINEERS

el

FOR FILM LINING COVERED No.

5ligar 22ft INDIA LIMITED 6-65-0046 Rev. 4

laiven elecnieashioeszl) f A Govt of India Undertaking) WITH CONCRETE LINING

FOR EARTHEN RESERVOIR Page 5 of 7

5.0 SAND CUSHION

75 mm layer of fine sand shall be spread over the prepared sub-grade and well compacted as

per IS: 2720, Part XIV.

6.0 FILM LAYING

The film shall be spread over the sand cushion layer. The film shall be laid loose so as to

provide for the thermal contraction etc. The adjacent layer of film should be jointed firmly so

as to avoid seepage losses through these joints. A minimum of 200 mm overlap and jointing by

heat sealing shall be done. The loose ends of the film shall be firmly anchored at junction

points as shown in drawings and as per the instructions of the Engineer-in-Charge. The joints

of the film are vulnerable to seepage and thus shall be kept to the minimum.

7.0 CEMENT MORTAR LAYER

A layer of 10 mm thick cement mortar in 1:5 cement mortar (1 cement: 5 sand) shall be laid

over the film lining. The mortar shall conform to IS: 2250.

8.0 CEMENT CONCRETE LINING

Concrete mix, method of mixing, placing, compaction, finishing and curing of cement concrete

lining shall be as described in EIL standard specification no. 6-68-0004.

9.0 ACCEPTANCE/TESTING

On completion of the work, the reservoir shall be filled with water upto maximum water level.

Level of water shall be recorded for a period of 3 days at an interval of 24 hr. The average

water loss shall not be more than 0.60 m 3/sec. per million square meter of wetted perimeter.

Any defect noted or pointed out by the Engineer-in-charge shall be rectified by contractor at

his own cost to the satisfaction of Engineer-in-charge.

10.0 JOINTS IN CONCRETE LINING

10.1 Contraction/Construction Joints

Contraction/Construction joints shall be provided at 3.0 m c/c transversely along the length of

reservoir and at junction of bed concrete and berm side along the length of reservoir or at

places shown in the drawing or as directed by the Engineer-in-Charge.

Lining shall be cast in panels of size 3.0mx3.0m. Transverse and longitudinal grooves shall be

provided as per above paragraph. Before casting adjacent panel, the edges of earlier cast panel

shall be painted with sealing compound as shown in figure on page 7 of 7.

In situ sleepers in case of bed and precast in case of sides, shall be provided under the joints.

The sleeper shall be 20 cm wide and 7.5 cm deep. Refer fig. on page 7 of 7. The sleepers shall

be placed centrally below the joint and painted with two layers of sealing compound as shown

in figure on page 7 of 7, before laying concrete lining. Concrete used for sleepers shall be of

the same grade as for lining.

10.1.1 Filler

The grooves in concrete lining shall be filled with mastic filler as per IS: 5256 after applying

primer to exposed surface of groove as shown in figure on page 7 of 7.

The grooves shall be clean and free from foreign substances where mastic filler is applied.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1331 of 2303

STANDARD SPECIFICATION STANDARD SPECIFICATION

ENGINEERS FOR FILM LINING COVERED No.

$fgzir lailjeg INDIA LIMITED 6-65-0046 Rev. 4

rairen eteianeaer.eraroar (A Goof of India Undertaking) WITH CONCRETE LINING

FOR EARTHEN RESERVOIR Page 6 of 7

Grooves shall not be filled while it is raining or while there is free water in the grooves. The

grooves shall be filled as soon as the concrete has become sufficiently stiff to prevent

appreciable distortion of groove and damage to the concrete.

10.2 Expansion Joints

Expansion joint shall be provided and constructed at places shown in the drawing and as

directed by the Engineer-in-Charge. The joints wherever required shall be 20 mm wide.

The joints shall be thoroughly cleaned of all dirt, organic matters, dust, etc. The joints then

shall be filled with bitumen mix filler as specified in the item except for 25 mm depth at top.

The top 25 mm depth of the joints shall be filled with approved hot applied sealing compound

conforming to IS: 5256.

11.0 PAYMENT

11.1 Sand Cushion, Film Laying, Cement Mortar and Cement Lining

Payment for Sand Cushion, film laying with concrete lining shall be made on sq.m basis of

area paved and shall include all the operations specified in clause no. 5.0, 6.0, 7.0 and 8.0.

11.2 Contraction Joints

The payment shall be made on per running meter basis. This rate shall include making of the

joints, supplying and filling in the mastic filler etc. complete.

11.3 Expansion Joints

The payment shall be made on running meter basis. The rate shall include cleaning, filling the

joint with bitumen mix filler, sealing with approved compound, finishing the joint, clearing of

the adjoining surface after sealing of the joints etc. all complete.

11.4 The payment clause(s) as described in this specification shall not be referred/applicable for

LSTK Jobs.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1332 of 2303

STANDARD SPECIFICATION STANDARD SPECIFICATION

lar&id aft,

- - ENGINEERS FOR FILM LINING COVERED No.

acs INDIA LIMITED

(A Govt of Indra Undertaking) WITH CONCRETE LINING 6-65-0046 Rev. 4

FOR EARTHEN RESERVOIR Page 7 of 7

E 20mm

N..

E R=1 Omm (MAX.)

E 17mm

1.0

N

:MILP

SHAPE OF GROOVE

MASTIC FILLER CONFORMING TO IS:5256

FACE TO BE PAINTED WITH

PRIMER ® 1 LITRE/4.0 SQ.M SEALING COMPOUND

75 THK. M-20 CONC.

FILM LINING

SAND FILLING

75 THK.

10 THK. 1:5 CEMENT MORTAR COMPACTED EARTH

TWO LAYERS OF SEALING COMPOUND AS PER IS: 13143

M20 CEMENT CONC. BED FIRST LAYER ® 1 LITRE / 2 SQ.M

SLEEPER 1500 LONG x 200 WIDE x 75 DEEP SECOND LAYER ® 1 LITRE / 4 SQ.M

DETAIL OF CONTRACTION JOINT FOR

PANELS CAST IN SIZE OF 3.0M x 3.0M

NOTES:-

1. ALL DIMENSIONS ARE IN MM UNLESS NOTED OTHERWISE.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1333 of 2303

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Standard Specification For Restriction Orifice PlatesDocument6 pagesStandard Specification For Restriction Orifice PlatesJITENDER KUMARNo ratings yet

- Standard Specification For Concrete Lining in CanalsDocument6 pagesStandard Specification For Concrete Lining in CanalsJITENDER KUMARNo ratings yet

- Specification For Flameproof Control StationsDocument7 pagesSpecification For Flameproof Control StationsJITENDER KUMARNo ratings yet

- Standard Specification For Storage TanksDocument22 pagesStandard Specification For Storage TanksJITENDER KUMAR75% (4)

- Standard Specification For Inspection, Flushing and Testing of Piping SystemsDocument9 pagesStandard Specification For Inspection, Flushing and Testing of Piping SystemsJITENDER KUMARNo ratings yet

- Technical 03of05 35Document6 pagesTechnical 03of05 35JITENDER KUMARNo ratings yet

- Standard Specification For Mechanical AgitatorsDocument11 pagesStandard Specification For Mechanical AgitatorsJITENDER KUMARNo ratings yet

- Weldable Structural Quality Steel Plates For Storage Tanks and VesselsDocument5 pagesWeldable Structural Quality Steel Plates For Storage Tanks and VesselsJITENDER KUMARNo ratings yet

- Tank Erection ProcedureDocument9 pagesTank Erection ProcedureJITENDER KUMARNo ratings yet

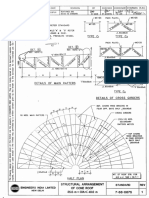

- Structural Arrangment of Cone Roof Tanks - 12Document1 pageStructural Arrangment of Cone Roof Tanks - 12JITENDER KUMARNo ratings yet

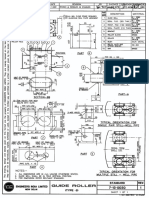

- Guide Roller - 2Document1 pageGuide Roller - 2JITENDER KUMARNo ratings yet

- Engineering DrawingDocument30 pagesEngineering DrawingDeepak MmechNo ratings yet

- 7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionDocument2 pages7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionJitender Kumar GuptaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ENV Assignment 03Document9 pagesENV Assignment 03Ahnaf AkibNo ratings yet

- Lecture 4 Calculations With Chemical Formulas and Equations PDFDocument8 pagesLecture 4 Calculations With Chemical Formulas and Equations PDFHani TamimiNo ratings yet

- 5 半導體與光電材料 1112 2021Document131 pages5 半導體與光電材料 1112 2021谭晨晞No ratings yet

- Astm A255Document26 pagesAstm A255Yherson Cerin Chavarria100% (1)

- Nickel Laterite WebinarDocument44 pagesNickel Laterite Webinarherryadi.wachyudinNo ratings yet

- Art I GoooooDocument13 pagesArt I GoooooAnaLuizaNobregaNo ratings yet

- C T Sun Mechanics of Aircraft Structures SolutionDocument270 pagesC T Sun Mechanics of Aircraft Structures SolutionTharshan Rajasekar60% (5)

- Owner's Manual: Powered byDocument20 pagesOwner's Manual: Powered byKeny Anchante100% (1)

- Lattice Steel Towers and Steel PolesDocument7 pagesLattice Steel Towers and Steel Polesyudha_hermawan_kinoy0% (1)

- Refrigerant Selection and Environmental ImpactsDocument67 pagesRefrigerant Selection and Environmental Impactsdamola2realNo ratings yet

- Wood Connectors - Houtverbindingen - 2013 - LRDocument168 pagesWood Connectors - Houtverbindingen - 2013 - LRjanm2008No ratings yet

- Lanthides EmissionDocument33 pagesLanthides EmissionashNo ratings yet

- Paints & CoatsDocument29 pagesPaints & CoatsMaitreyi YellapragadaNo ratings yet

- Water Jet MachiningDocument20 pagesWater Jet MachiningRazvan MargineanNo ratings yet

- Kimia Kertas 2 Set 2 (Soalan)Document25 pagesKimia Kertas 2 Set 2 (Soalan)kimia chemistryNo ratings yet

- Materials For Shoe SolesDocument6 pagesMaterials For Shoe SolesLawrence Theunissen100% (1)

- Phenolic: The Offshore FRP Grating StandardDocument2 pagesPhenolic: The Offshore FRP Grating StandardBirendra2706No ratings yet

- Glyphosate MSDS SummaryDocument5 pagesGlyphosate MSDS SummaryAhfi Rizqi FajrinNo ratings yet

- Hydrocarbons (Alkanes and Alkenes)Document16 pagesHydrocarbons (Alkanes and Alkenes)Soham NagNo ratings yet

- Vicat Opc 43 48 2019Document1 pageVicat Opc 43 48 2019bhushan deoreNo ratings yet

- Laynes - Chapter 10 GasesDocument142 pagesLaynes - Chapter 10 GasescharleneNo ratings yet

- General Practices Manual Maintenance Procedures Aircraft Wheel BearingsDocument26 pagesGeneral Practices Manual Maintenance Procedures Aircraft Wheel Bearingskien Duy PhanNo ratings yet

- PES-4035 - PCO123402 FLEX HOSE (R134a) FOR REFRIGERANT PIPING IN CAR A - C UNITDocument10 pagesPES-4035 - PCO123402 FLEX HOSE (R134a) FOR REFRIGERANT PIPING IN CAR A - C UNITNaswadi NawiNo ratings yet

- A Review On Minimum Quantity Lubrication For Machining ProcessesDocument20 pagesA Review On Minimum Quantity Lubrication For Machining ProcessesYanuar Hennry ChristianNo ratings yet

- Specification Sheet: Alloy 316/316L Stainless SteelDocument3 pagesSpecification Sheet: Alloy 316/316L Stainless SteelSaúl L Hdez TNo ratings yet

- Investigation and Characterization of Solid Waste Disposal Sites' Impact on SoilDocument22 pagesInvestigation and Characterization of Solid Waste Disposal Sites' Impact on SoilVAISHNAVI RAJENDRA ARORANo ratings yet

- SDS PP 306 Hi10ho PDFDocument4 pagesSDS PP 306 Hi10ho PDFFitra Isni RositaNo ratings yet

- Size of Base Plate and Anchor Connection: 1 Material PropertiesDocument2 pagesSize of Base Plate and Anchor Connection: 1 Material PropertiesPrayush RajbhandariNo ratings yet

- Swing Check Valve - Grooved: Technical FeaturesDocument1 pageSwing Check Valve - Grooved: Technical Featuresprvns0074377No ratings yet

- Chemistry Micro ProjectDocument29 pagesChemistry Micro Projectnikhil9923707734No ratings yet