Professional Documents

Culture Documents

Gecolsa-Calenturitas: Departamento de Ingenieria

Uploaded by

Sixto Guarniz AnticonaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gecolsa-Calenturitas: Departamento de Ingenieria

Uploaded by

Sixto Guarniz AnticonaCopyright:

Available Formats

GECOLSA-CALENTURITAS

DEPARTAMENTO DE INGENIERIA

MONITORING CONDITION REPORT

ENGINE FILTER CUTTING- INSPECTION PROCEDURE

Background: Sometimes it is difficult to quantify the filter inspection. One way to include the

filter cut into your own fluid analysis program is giving numbers that helps to quantify the state

of the cut filter element. In order to have the same criteria for all cut filters, we have

developed an easy and fast way to quantify the visual inspection. This number could be

ranked and added in your own component monitoring hot sheet.

A qualitative inspection is given by a quantitative value.

Procedure:

1. Use an adequate cut bench in order to cut and inspect the filter element. Refers

to CAT Best Practices Series Oil Filter Cutting Bench[1].

Cortador de filtro P/N 175-7546

Banco prensa

Tijeras Mesa de corte

Magneto

Housing cutter

PDF created with pdfFactory trial version www.pdffactory.com

GECOLSA-CALENTURITAS

DEPARTAMENTO DE INGENIERIA

2. Once you have a dry filter element extend the filter element and observe the condition

of the filter.

3. Define the particle size according to human eyes perception. Normally, human eyes

detect particles greater that 40 micron.

From[2] From[3]

4. Once the particle size is detected , add one value according to table 1. ( reference pics)

Particles 1000 µm Catastrophic failure

Particles 100 µm Advance failure mode

Particles 10 µm Begin wear

PDF created with pdfFactory trial version www.pdffactory.com

GECOLSA-CALENTURITAS

DEPARTAMENTO DE INGENIERIA

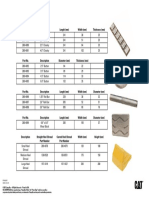

Table1. Monitoring table with ranking values, these values define the condition of the filter.

Compare the visual inspection with the table below.

PARTICLE SIZE

MONITORING COMPONENT

Quantitative value FEATURE PARTICLES

LIGHT VALUE STATE

( 10 µm) COMMENTS

the

component Components in the

No evidences of visible has desirable middle useful age in

OK 10 particles or debris. wear good conditions.

Small and shiny dots

among the filter Initial critical

element. Only it can wear, action These particles can be

be taken with one must be notice in the initial or

MONITORING 100 magneto. taken. final useful life.

These particles can be

noticed in the final

Visible and touchable age of the component

particles are easy to Engine close or when the

see and easy to take to imminent component has

ACTION 1000 with the fingers. failure abnormal wear.

Conclusion

This is a simple and low cost method helps to prevent damages in the components by

classifying the real condition of the filter element. This method helps to quantify visual

inspection.

Good inspection at the right time of filter will help to take action even before the SOS lab

results.

These values can be easily tabulated and quantify in the spread sheet ( hot sheet)

______

IVAN GOMEZ

Ingeniero de Servicio

Gecolsa-Calenturitas.

References:

1. CAT Best Practices Series Oil Filter Cutting Bench.

2. Blau PJ, editor. Friction, Lubrication and Wear Technology.ASM handbook, 18. 1992.

3. Contamination Control Fundamentals SCHROEDER INDUSTRIES LLC

PDF created with pdfFactory trial version www.pdffactory.com

You might also like

- Kitfs1 ManualDocument30 pagesKitfs1 ManualGowtham VenkatNo ratings yet

- 2.1.1.2A Microsectioning Automatic TechniqueDocument4 pages2.1.1.2A Microsectioning Automatic TechniqueAndres RojasNo ratings yet

- Guide To Selecting A Particle Counter For Cleanroom CertificationDocument2 pagesGuide To Selecting A Particle Counter For Cleanroom CertificationsombatseNo ratings yet

- Manual-Winner802 DLS Nano Particle Size AnalyzerDocument25 pagesManual-Winner802 DLS Nano Particle Size AnalyzerNhat Dinh DoNo ratings yet

- 2 Maglumi X3 SOP Presentation 20230714 V2 Antony 240305 103146Document40 pages2 Maglumi X3 SOP Presentation 20230714 V2 Antony 240305 103146minale bazezwNo ratings yet

- Guide Microscope MantainDocument22 pagesGuide Microscope MantainrifqiNo ratings yet

- User Manual - Air PurifierDocument10 pagesUser Manual - Air Purifierjef1234321No ratings yet

- Coating Thickness Gages: Instruction Manual V. 7.1Document30 pagesCoating Thickness Gages: Instruction Manual V. 7.1Hayderr HassNo ratings yet

- F10-AR User ManualDocument110 pagesF10-AR User ManualRendraNo ratings yet

- Condition Monitoring of Rotating EquipmeDocument14 pagesCondition Monitoring of Rotating EquipmessshettyNo ratings yet

- Implementation of Poka Yoke and Safety Push Button in Rubber Grommet and Sleeve Assembly Bracket MachineDocument4 pagesImplementation of Poka Yoke and Safety Push Button in Rubber Grommet and Sleeve Assembly Bracket MachineEditor IJTSRDNo ratings yet

- 03 Iris1Document12 pages03 Iris1AndiosoNo ratings yet

- Wind Turbine Gearbox Condition Assessment: Benefits of Onsite InspectionDocument2 pagesWind Turbine Gearbox Condition Assessment: Benefits of Onsite InspectionmadjadNo ratings yet

- Measurement of Residual Particulate Contamination On ComponentsDocument20 pagesMeasurement of Residual Particulate Contamination On Componentsdivyesh khuntNo ratings yet

- Alcon Centurion Operators Manual ScannedDocument197 pagesAlcon Centurion Operators Manual ScannedhernandezzNo ratings yet

- User Manual For Opacity MeterDocument25 pagesUser Manual For Opacity MeterEryf ADRNo ratings yet

- Firebeam-100m ManualDocument17 pagesFirebeam-100m Manualreivax694495No ratings yet

- Datasheet 276150 - MD 100 Suspended Solids, No Reagents Required enDocument3 pagesDatasheet 276150 - MD 100 Suspended Solids, No Reagents Required enlabkes karangasemNo ratings yet

- 16-19 RJ1701 WebDocument4 pages16-19 RJ1701 WebtotyozNo ratings yet

- UniQ Instruction Manual Rev01Document31 pagesUniQ Instruction Manual Rev01Humayun KabirNo ratings yet

- E7224 2 11 16 - ON Katalogversion PDFDocument4 pagesE7224 2 11 16 - ON Katalogversion PDFHANIF AKBARNo ratings yet

- 5991-5224EN AppNote 620FTIR PolymersDocument6 pages5991-5224EN AppNote 620FTIR Polymersade muchlasNo ratings yet

- P-T Ultrafine Particle Counter: Exposure MonitoringDocument2 pagesP-T Ultrafine Particle Counter: Exposure MonitoringindrasabNo ratings yet

- SOP For Calibration of AASDocument1 pageSOP For Calibration of AASbudi_alamsyahNo ratings yet

- AM - Step 1Document17 pagesAM - Step 1Sydney DodooNo ratings yet

- Quantum Performance Report: 0 Base Unit ModuleDocument9 pagesQuantum Performance Report: 0 Base Unit ModuleMasih TukaranNo ratings yet

- Vacutron Suction Regulators Vacuum Regulators For Continuous or Intermittent Drainage Operation and Maintenance ManualDocument16 pagesVacutron Suction Regulators Vacuum Regulators For Continuous or Intermittent Drainage Operation and Maintenance ManualAnne Stephany ZambranoNo ratings yet

- 2i Aerosol PhotometerDocument3 pages2i Aerosol PhotometerBalaji BalasubramanianNo ratings yet

- Ad PVC Iq: User ManualDocument28 pagesAd PVC Iq: User ManualEsteve PermanyerNo ratings yet

- The Shot Peening Operator's Checklist: Part One of Two-Part SeriesDocument2 pagesThe Shot Peening Operator's Checklist: Part One of Two-Part SeriessyafiqNo ratings yet

- TG900 Operating ManualDocument12 pagesTG900 Operating ManualSazzad Hossan RaselNo ratings yet

- Thermal Imaging and Vibration Based Multi-Sensor Fault Detection For Rotating MachineryDocument12 pagesThermal Imaging and Vibration Based Multi-Sensor Fault Detection For Rotating MachineryEliel LinsNo ratings yet

- PosiTector 6000 Full Manual 7.1Document30 pagesPosiTector 6000 Full Manual 7.1Ctr YlNo ratings yet

- Om10 Maintenance - Plant EngineeringDocument2 pagesOm10 Maintenance - Plant EngineeringJing CruzNo ratings yet

- Professional Weather Center: Save This Manual For Future ReferenceDocument24 pagesProfessional Weather Center: Save This Manual For Future ReferenceEd RiderNo ratings yet

- Integrity SOPs For VeinDocument3 pagesIntegrity SOPs For VeinziadddNo ratings yet

- Hettich Cleaning-Care of CentrifugesDocument1 pageHettich Cleaning-Care of CentrifugesShahid AkhterNo ratings yet

- Product ProposalDocument28 pagesProduct Proposalgreensolution0084No ratings yet

- Pool Masters Digital Test Kit Cat MD 200Document4 pagesPool Masters Digital Test Kit Cat MD 200Ahamed ImranNo ratings yet

- CAT - NO.B0000EN00A00 16050000ry Printed in JapanDocument16 pagesCAT - NO.B0000EN00A00 16050000ry Printed in JapanĐèn Ngủ XinhNo ratings yet

- AvCount Profile PDFDocument8 pagesAvCount Profile PDFal yasaNo ratings yet

- Whitepaper - Particle Counters For Oil Analysis - Design & Specifications PDFDocument4 pagesWhitepaper - Particle Counters For Oil Analysis - Design & Specifications PDFAhmed El-ShafeiNo ratings yet

- Test On Abrasive Blasting MachineDocument7 pagesTest On Abrasive Blasting MachineTarundeep SinghNo ratings yet

- 7080 AccuSizer BrochureDocument8 pages7080 AccuSizer BrochureI SunnahNo ratings yet

- Manual TAMAÑO DE PARTICULASDocument20 pagesManual TAMAÑO DE PARTICULASCristhianNo ratings yet

- AirFiltration - Brochure - Eng - June 2009Document8 pagesAirFiltration - Brochure - Eng - June 2009Dercio CostaNo ratings yet

- MC55UVM6Document28 pagesMC55UVM6Ujianto Timotius NugrohoNo ratings yet

- Datasheet 276205 - MD 100 Aluminium, Powder Reagents enDocument3 pagesDatasheet 276205 - MD 100 Aluminium, Powder Reagents encristi5cNo ratings yet

- Tgs5141-p00 Technical Infomation (En) Rev08Document16 pagesTgs5141-p00 Technical Infomation (En) Rev08Ankit JainNo ratings yet

- Optical End Face Inspection GuidelinesDocument7 pagesOptical End Face Inspection Guidelineschuang xuNo ratings yet

- 1ANSORL IRBD Conventional Infrared Beam Smoke Detector User ManualDocument14 pages1ANSORL IRBD Conventional Infrared Beam Smoke Detector User ManualGiovani SanchezNo ratings yet

- FTIR - Nicolet Is10 - D21515 PDFDocument12 pagesFTIR - Nicolet Is10 - D21515 PDFtamiaNo ratings yet

- Reference Material CertificateDocument2 pagesReference Material CertificateAGATHA RIA BUDIYANANo ratings yet

- Maintenance Service Intervals: InstructionsDocument2 pagesMaintenance Service Intervals: InstructionsRoldan Jeremy LozanoNo ratings yet

- Contamination Control Tool Catalog 2007 Web PDFDocument132 pagesContamination Control Tool Catalog 2007 Web PDFwhmidi7331No ratings yet

- Pastel Uv - GBDocument2 pagesPastel Uv - GBJaime CalmetNo ratings yet

- Pub en 2014 03 ETM - March - 2014 - MEDocument1 pagePub en 2014 03 ETM - March - 2014 - MEAlbertoNo ratings yet

- LF413T IDS Electrodes 220 KB English PDFDocument12 pagesLF413T IDS Electrodes 220 KB English PDFEdinson Vallejo VidalNo ratings yet

- Tango: Innovation With IntegrityDocument2 pagesTango: Innovation With IntegritySARL AKMEDICALNo ratings yet

- CAT Self-Service Options: Elements of The Stabilizer Pad Replacement Self-Service OptionDocument1 pageCAT Self-Service Options: Elements of The Stabilizer Pad Replacement Self-Service OptionSixto Guarniz AnticonaNo ratings yet

- Greenfield GuidebookDocument32 pagesGreenfield GuidebookSixto Guarniz Anticona100% (1)

- Hose Inspection - All Cat MachinesDocument12 pagesHose Inspection - All Cat MachinesSixto Guarniz Anticona100% (1)

- Fuel System Tune-Up - 2-5-19 - Hi ResDocument1 pageFuel System Tune-Up - 2-5-19 - Hi ResSixto Guarniz AnticonaNo ratings yet

- M&R HandbookDocument20 pagesM&R HandbookVikranth Reddy100% (1)

- Control de Contaminación FuidosDocument23 pagesControl de Contaminación FuidosSixto Guarniz AnticonaNo ratings yet

- C10129001Document1 pageC10129001noel_manroeNo ratings yet

- 2015 Filter and Fluid Application Guide PDFDocument1,073 pages2015 Filter and Fluid Application Guide PDFv100% (3)

- J To K Equivalent ChartDocument1 pageJ To K Equivalent ChartSixto Guarniz AnticonaNo ratings yet

- Wheel Loader Bucket InspectionDocument1 pageWheel Loader Bucket InspectionSixto Guarniz AnticonaNo ratings yet

- Wear Products PEWJ0187Document1 pageWear Products PEWJ0187Sixto Guarniz AnticonaNo ratings yet

- Hex Bucket InspectionDocument1 pageHex Bucket InspectionSixto Guarniz AnticonaNo ratings yet

- Bucket Inspection FormDocument1 pageBucket Inspection FormSixto Guarniz AnticonaNo ratings yet

- Bulk Lubricant and Storage HandlingDocument62 pagesBulk Lubricant and Storage HandlingWaleedNo ratings yet

- When Required (30000 HOUR Interval) : ChecklistDocument2 pagesWhen Required (30000 HOUR Interval) : ChecklistSixto Guarniz AnticonaNo ratings yet

- Performing An ECM Replacement Using The Feature Protection SystemDocument7 pagesPerforming An ECM Replacement Using The Feature Protection SystemSixto Guarniz AnticonaNo ratings yet

- Dynamometer Testing of Caterpillar EnginesDocument98 pagesDynamometer Testing of Caterpillar EnginesSixto Guarniz Anticona100% (1)

- Dynamometer Testing of Caterpillar EnginesDocument98 pagesDynamometer Testing of Caterpillar EnginesSixto Guarniz Anticona100% (1)

- Tier 4 PM Agreements Jan 2012Document46 pagesTier 4 PM Agreements Jan 2012Sixto Guarniz AnticonaNo ratings yet

- Guide To EPA Tier 4 Emissions Limits LEXE0152 01Document4 pagesGuide To EPA Tier 4 Emissions Limits LEXE0152 01Sixto Guarniz AnticonaNo ratings yet

- Cat Filter and Filter Application GuideDocument255 pagesCat Filter and Filter Application GuideSixto Guarniz Anticona83% (6)

- Sistema Hidraulico Cat 416cDocument2 pagesSistema Hidraulico Cat 416cMarvin Nta DgzNo ratings yet

- MikoritkDocument6 pagesMikoritkChris Jonathan Showip RouteNo ratings yet

- State Farm Claims: PO Box 52250 Phoenix AZ 85072-2250Document2 pagesState Farm Claims: PO Box 52250 Phoenix AZ 85072-2250georgia ann polley-yatesNo ratings yet

- Weekly Lesson Plan: Pry 3 (8years) Third Term Week 1Document12 pagesWeekly Lesson Plan: Pry 3 (8years) Third Term Week 1Kunbi Santos-ArinzeNo ratings yet

- Investing in Granada's Property Market - Gaspar LinoDocument1 pageInvesting in Granada's Property Market - Gaspar LinoGaspar LinoNo ratings yet

- 5G NR Essentials Guide From IntelefyDocument15 pages5G NR Essentials Guide From IntelefyUzair KhanNo ratings yet

- Ict's - 2022 - Mentorship - Summarized - Thread - by - Trader - Theory - Sep 22, 22 - From - RattibhaDocument11 pagesIct's - 2022 - Mentorship - Summarized - Thread - by - Trader - Theory - Sep 22, 22 - From - RattibhaChristiana OnyinyeNo ratings yet

- Turnbull CV OnlineDocument7 pagesTurnbull CV Onlineapi-294951257No ratings yet

- Chapter 3 Depreciation - Sum of The Years Digit MethodPart 4Document8 pagesChapter 3 Depreciation - Sum of The Years Digit MethodPart 4Tor GineNo ratings yet

- Serenity RPG Firefly Role Playing Game PDFDocument225 pagesSerenity RPG Firefly Role Playing Game PDFNathaniel Broyles67% (3)

- ACTIX Basic (Sample CDMA)Document73 pagesACTIX Basic (Sample CDMA)radhiwibowoNo ratings yet

- Catalogo Escavadeira EC27CDocument433 pagesCatalogo Escavadeira EC27CNilton Junior Kern50% (2)

- How Muslim Inventors Changed The WorldDocument4 pagesHow Muslim Inventors Changed The WorldShadab AnjumNo ratings yet

- Synchronous Machines-1Document41 pagesSynchronous Machines-1Rouxcel abutoNo ratings yet

- Ericsson For Sale From Powerstorm 4SA03071242Document8 pagesEricsson For Sale From Powerstorm 4SA03071242wd3esaNo ratings yet

- New Text DocumentDocument13 pagesNew Text DocumentJitendra Karn RajputNo ratings yet

- LET-English-Structure of English-ExamDocument57 pagesLET-English-Structure of English-ExamMarian Paz E Callo80% (5)

- One and Half SindromeDocument4 pagesOne and Half SindromeYulia DamayantiNo ratings yet

- Quiz 2 I - Prefix and Suffix TestDocument10 pagesQuiz 2 I - Prefix and Suffix Testguait9No ratings yet

- 2012 Conference NewsfgfghsfghsfghDocument3 pages2012 Conference NewsfgfghsfghsfghabdNo ratings yet

- Limestone Standards PDFDocument2 pagesLimestone Standards PDFJacqueline BerueteNo ratings yet

- NCPDocument6 pagesNCPJoni Lyn Ba-as BayengNo ratings yet

- ADMT Guide: Migrating and Restructuring Active Directory DomainsDocument263 pagesADMT Guide: Migrating and Restructuring Active Directory DomainshtoomaweNo ratings yet

- Chalcedony Value, Price, and Jewelry Information - International Gem SocietyDocument8 pagesChalcedony Value, Price, and Jewelry Information - International Gem Societyasset68No ratings yet

- Patricio Gerpe ResumeDocument2 pagesPatricio Gerpe ResumeAnonymous 3ID4TBNo ratings yet

- Pds Hempel's Maestro Water Borne Primer 28830 En-GbDocument2 pagesPds Hempel's Maestro Water Borne Primer 28830 En-GbKalaiyazhagan ElangeeranNo ratings yet

- Ace 2Document184 pagesAce 2Raju LaxmipathiNo ratings yet

- OnTime Courier Software System Requirements PDFDocument1 pageOnTime Courier Software System Requirements PDFbilalNo ratings yet

- 4BT3 9-G2 PDFDocument5 pages4BT3 9-G2 PDFNv Thái100% (1)

- Jaiib QpapersDocument250 pagesJaiib Qpapersjaya htNo ratings yet

- King Saud UniversityDocument10 pagesKing Saud UniversitypganoelNo ratings yet