Professional Documents

Culture Documents

050 To 056test Reports

050 To 056test Reports

Uploaded by

Rahul MoottolikandyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

050 To 056test Reports

050 To 056test Reports

Uploaded by

Rahul MoottolikandyCopyright:

Available Formats

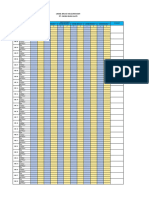

TEST REPORT FOR NEW EMPTY LPG CYLINDERS

(To meet the requirements of UAE'S GSO ISO 22991 (E) )

QCP-08-F03 Revision#1, Dt:01/03/2013

Report No. : LPG/TR/26.2L/050 Date : 30/06/2019

Client : ADNOC DISTRIBUTION Bottling Plant : ABU DHABI / AJMAN

Order No. : 590087 Date : 06/12/2018

CYLINDER DESCRIPTION MANUFACTURING DETAILS

Water Capacity : 26.2 Ltr Method of support : Backing Strip by joggling

Outer diameter : 300.0mm Welding Process : Submerged Arc Welding

Working Pressure : 17.0bar Heat treatment : Normalizing

Min.Designed thickness : 2.1 mm Min. Burst Pressure : 74.5bar

Heat No. : A-223024 & A-123025

Steel Used : JIS G 3116 SG 295

Coil No. : K-93334024A & K-93364055A

ACCEPTANCE TEST

Batch No. : LPG/TR/26.2L/050

Sr. Nos. From: 24648 To : 25150

Test Cylinder Sr Nos. MT (1): 24707 (2) 25066 & BT (1) : 24889

Sr.No Test Code Followed Requirements Results

1 Visual Examination Visual Complies

2 Hydro-test Test Pressure @ 33.1Bar (100%) Complies

3 Pneumatic Test Test Pressure @ 7Bar (100%) Complies

UAE'S GSO ISO 22991

4 Burst Test As per Burst test report (Random) Complies

5 Mechanical Test As per Mechanical test report (Random) Complies

6 Macro Test Visual (Random) Complies

Test Cylinder No. : : -----

: 17636:2013 Tested By : HI-TECH INSPECTION SERVICES

Code of Test (As

Per UAE'S GSO ISO 22991:2008)

: 17636-1:2013 Report No. : -----

Code of Assessment Joint Details : As per attached report

: 5817:2014

(As Per GSO ISO 22991:2008) Test Result : Accepted

This is to certify that the cylinders manufactured, inspected and tested at the above plant meet the

requirements of UAE'S GSO ISO 22991:2008 (E)

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

TEST REPORT FOR NEW EMPTY LPG CYLINDERS

(To meet the requirements of UAE'S GSO ISO 22991 (E) )

QCP-08-F03 Revision#1, Dt:01/03/2013

Report No. : LPG/TR/26.2L/051 Date : 30/06/2019

Client : ADNOC DISTRIBUTION Bottling Plant : ABU DHABI / AJMAN

Order No. : 590087 Date : 06/12/2018

CYLINDER DESCRIPTION MANUFACTURING DETAILS

Water Capacity : 26.2 Ltr Method of support : Backing Strip by joggling

Outer diameter : 300.0mm Welding Process : Submerged Arc Welding

Working Pressure : 17.0bar Heat treatment : Normalizing

Min.Designed thickness : 2.1 mm Min. Burst Pressure : 74.5bar

Heat No. : A-223024 & A-123025

Steel Used : JIS G 3116 SG 295

Coil No. : K-93334024A & K-93364055A

ACCEPTANCE TEST

Batch No. : LPG/TR/26.2L/051

Sr. Nos. From: 25151 To : 25653

Test Cylinder Sr Nos. MT (1): 25202 (2) 25588 & BT (1) : 25336

Sr.No Test Code Followed Requirements Results

1 Visual Examination Visual Complies

2 Hydro-test Test Pressure @ 33.1Bar (100%) Complies

3 Pneumatic Test Test Pressure @ 7Bar (100%) Complies

UAE'S GSO ISO 22991

4 Burst Test As per Burst test report (Random) Complies

5 Mechanical Test As per Mechanical test report (Random) Complies

6 Macro Test Visual (Random) Complies

Test Cylinder No. : : 25200

: 17636:2013 Tested By : HI-TECH INSPECTION SERVICES

Code of Test (As

Per UAE'S GSO ISO 22991:2008)

: 17636-1:2013 Report No. : RT-239

Code of Assessment Joint Details : As per attached report

: 5817:2014

(As Per GSO ISO 22991:2008) Test Result : Accepted

This is to certify that the cylinders manufactured, inspected and tested at the above plant meet the

requirements of UAE'S GSO ISO 22991:2008 (E)

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

TEST REPORT FOR NEW EMPTY LPG CYLINDERS

(To meet the requirements of UAE'S GSO ISO 22991 (E) )

QCP-08-F03 Revision#1, Dt:01/03/2013

Report No. : LPG/TR/26.2L/052 Date : 30/06/2019

Client : ADNOC DISTRIBUTION Bottling Plant : ABU DHABI / AJMAN

Order No. : 590087 Date : 06/12/2018

CYLINDER DESCRIPTION MANUFACTURING DETAILS

Water Capacity : 26.2 Ltr Method of support : Backing Strip by joggling

Outer diameter : 300.0mm Welding Process : Submerged Arc Welding

Working Pressure : 17.0bar Heat treatment : Normalizing

Min.Designed thickness : 2.1 mm Min. Burst Pressure : 74.5bar

Heat No. : A-223024 & A-123025

Steel Used : JIS G 3116 SG 295

Coil No. : K-93334024A & K-93364055A

ACCEPTANCE TEST

Batch No. : LPG/TR/26.2L/052

Sr. Nos. From: 25654 To : 26256

Test Cylinder Sr Nos. MT (1): 25711 (2) 26066 & BT (1) : 25833

Sr.No Test Code Followed Requirements Results

1 Visual Examination Visual Complies

2 Hydro-test Test Pressure @ 33.1Bar (100%) Complies

3 Pneumatic Test Test Pressure @ 7Bar (100%) Complies

UAE'S GSO ISO 22991

4 Burst Test As per Burst test report (Random) Complies

5 Mechanical Test As per Mechanical test report (Random) Complies

6 Macro Test Visual (Random) Complies

Test Cylinder No. : : -----

: 17636:2013 Tested By : HI-TECH INSPECTION SERVICES

Code of Test (As

Per UAE'S GSO ISO 22991:2008)

: 17636-1:2013 Report No. : -----

Code of Assessment Joint Details : As per attached report

: 5817:2014

(As Per GSO ISO 22991:2008) Test Result : Accepted

This is to certify that the cylinders manufactured, inspected and tested at the above plant meet the

requirements of UAE'S GSO ISO 22991:2008 (E)

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

TEST REPORT FOR NEW EMPTY LPG CYLINDERS

(To meet the requirements of UAE'S GSO ISO 22991 (E) )

QCP-08-F03 Revision#1, Dt:01/03/2013

Report No. : LPG/TR/26.2L/053 Date : 25/07/2019

Client : ADNOC DISTRIBUTION Bottling Plant : ABU DHABI / AJMAN

Order No. : 590087 Date : 06/12/2018

CYLINDER DESCRIPTION MANUFACTURING DETAILS

Water Capacity : 26.2 Ltr Method of support : Backing Strip by joggling

Outer diameter : 300.0mm Welding Process : Submerged Arc Welding

Working Pressure : 17.0bar Heat treatment : Normalizing

Min.Designed thickness : 2.1 mm Min. Burst Pressure : 74.5bar

Heat No. : A-123025 & A-223024

Steel Used : JIS G 3116 SG 295

Coil No. : K-93364055B & K-93364056B

ACCEPTANCE TEST

Batch No. : LPG/TR/26.2L/053

Sr. Nos. From: 26157 To : 26659

Test Cylinder Sr Nos. MT (1): 26211 (2) 26577 & BT (1) : 26335

Sr.No Test Code Followed Requirements Results

1 Visual Examination Visual Complies

2 Hydro-test Test Pressure @ 33.1Bar (100%) Complies

3 Pneumatic Test Test Pressure @ 7Bar (100%) Complies

UAE'S GSO ISO 22991

4 Burst Test As per Burst test report (Random) Complies

5 Mechanical Test As per Mechanical test report (Random) Complies

6 Macro Test Visual (Random) Complies

Test Cylinder No. : : 26355

: 17636:2013 Tested By : HI-TECH INSPECTION SERVICES

Code of Test (As

Per UAE'S GSO ISO 22991:2008)

: 17636-1:2013 Report No. : RT-240

Code of Assessment Joint Details : As per attached report

: 5817:2014

(As Per GSO ISO 22991:2008) Test Result : Accepted

This is to certify that the cylinders manufactured, inspected and tested at the above plant meet the

requirements of UAE'S GSO ISO 22991:2008 (E)

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

TEST REPORT FOR NEW EMPTY LPG CYLINDERS

(To meet the requirements of UAE'S GSO ISO 22991 (E) )

QCP-08-F03 Revision#1, Dt:01/03/2013

Report No. : LPG/TR/26.2L/054 Date : 25/07/2019

Client : ADNOC DISTRIBUTION Bottling Plant : ABU DHABI / AJMAN

Order No. : 590087 Date : 06/12/2018

CYLINDER DESCRIPTION MANUFACTURING DETAILS

Water Capacity : 26.2 Ltr Method of support : Backing Strip by joggling

Outer diameter : 300.0mm Welding Process : Submerged Arc Welding

Working Pressure : 17.0bar Heat treatment : Normalizing

Min.Designed thickness : 2.1 mm Min. Burst Pressure : 74.5bar

Heat No. : A-123025 & A-223024

Steel Used : JIS G 3116 SG 295

Coil No. : K-93364055B & K-93364056B

ACCEPTANCE TEST

Batch No. : LPG/TR/26.2L/054

Sr. Nos. From: 26660 To : 27162

Test Cylinder Sr Nos. MT (1): 26717 (2) 27072 & BT (1) : 26900

Sr.No Test Code Followed Requirements Results

1 Visual Examination Visual Complies

2 Hydro-test Test Pressure @ 33.1Bar (100%) Complies

3 Pneumatic Test Test Pressure @ 7Bar (100%) Complies

UAE'S GSO ISO 22991

4 Burst Test As per Burst test report (Random) Complies

5 Mechanical Test As per Mechanical test report (Random) Complies

6 Macro Test Visual (Random) Complies

Test Cylinder No. : : -----

: 17636:2013 Tested By : HI-TECH INSPECTION SERVICES

Code of Test (As

Per UAE'S GSO ISO 22991:2008)

: 17636-1:2013 Report No. : -----

Code of Assessment Joint Details : As per attached report

: 5817:2014

(As Per GSO ISO 22991:2008) Test Result : Accepted

This is to certify that the cylinders manufactured, inspected and tested at the above plant meet the

requirements of UAE'S GSO ISO 22991:2008 (E)

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

TEST REPORT FOR NEW EMPTY LPG CYLINDERS

(To meet the requirements of UAE'S GSO ISO 22991 (E) )

QCP-08-F03 Revision#1, Dt:01/03/2013

Report No. : LPG/TR/26.2L/055 Date : 25/07/2019

Client : ADNOC DISTRIBUTION Bottling Plant : ABU DHABI / AJMAN

Order No. : 590087 Date : 06/12/2018

CYLINDER DESCRIPTION MANUFACTURING DETAILS

Water Capacity : 26.2 Ltr Method of support : Backing Strip by joggling

Outer diameter : 300.0mm Welding Process : Submerged Arc Welding

Working Pressure : 17.0bar Heat treatment : Normalizing

Min.Designed thickness : 2.1 mm Min. Burst Pressure : 74.5bar

Heat No. : A-123025 & A-223024

Steel Used : JIS G 3116 SG 295

Coil No. : K-93364055B & K-93364056B

ACCEPTANCE TEST

Batch No. : LPG/TR/26.2L/055

Sr. Nos. From: 27163 To : 27665

Test Cylinder Sr Nos. MT (1): 27222 (2) 27584 & BT (1) : 27355

Sr.No Test Code Followed Requirements Results

1 Visual Examination Visual Complies

2 Hydro-test Test Pressure @ 33.1Bar (100%) Complies

3 Pneumatic Test Test Pressure @ 7Bar (100%) Complies

UAE'S GSO ISO 22991

4 Burst Test As per Burst test report (Random) Complies

5 Mechanical Test As per Mechanical test report (Random) Complies

6 Macro Test Visual (Random) Complies

Test Cylinder No. : : 27450

: 17636:2013 Tested By : HI-TECH INSPECTION SERVICES

Code of Test (As

Per UAE'S GSO ISO 22991:2008)

: 17636-1:2013 Report No. : RT-241

Code of Assessment Joint Details : As per attached report

: 5817:2014

(As Per GSO ISO 22991:2008) Test Result : Accepted

This is to certify that the cylinders manufactured, inspected and tested at the above plant meet the

requirements of UAE'S GSO ISO 22991:2008 (E)

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

TEST REPORT FOR NEW EMPTY LPG CYLINDERS

(To meet the requirements of UAE'S GSO ISO 22991 (E) )

QCP-08-F03 Revision#1, Dt:01/03/2013

Report No. : LPG/TR/26.2L/056 Date : 25/07/2019

Client : ADNOC DISTRIBUTION Bottling Plant : ABU DHABI / AJMAN

Order No. : 590087 Date : 06/12/2018

CYLINDER DESCRIPTION MANUFACTURING DETAILS

Water Capacity : 26.2 Ltr Method of support : Backing Strip by joggling

Outer diameter : 300.0mm Welding Process : Submerged Arc Welding

Working Pressure : 17.0bar Heat treatment : Normalizing

Min.Designed thickness : 2.1 mm Min. Burst Pressure : 74.5bar

Heat No. : A-123025 & A-223024

Steel Used : JIS G 3116 SG 295

Coil No. : K-93364055B & K-93364056B

ACCEPTANCE TEST

Batch No. : LPG/TR/26.2L/056

Sr. Nos. From: 27666 To : 28168

Test Cylinder Sr Nos. MT (1): 27727 (2) 28080 & BT (1) : 27900

Sr.No Test Code Followed Requirements Results

1 Visual Examination Visual Complies

2 Hydro-test Test Pressure @ 33.1Bar (100%) Complies

3 Pneumatic Test Test Pressure @ 7Bar (100%) Complies

UAE'S GSO ISO 22991

4 Burst Test As per Burst test report (Random) Complies

5 Mechanical Test As per Mechanical test report (Random) Complies

6 Macro Test Visual (Random) Complies

Test Cylinder No. : : -----

: 17636:2013 Tested By : HI-TECH INSPECTION SERVICES

Code of Test (As

Per UAE'S GSO ISO 22991:2008)

: 17636-1:2013 Report No. : -----

Code of Assessment Joint Details : As per attached report

: 5817:2014

(As Per GSO ISO 22991:2008) Test Result : Accepted

This is to certify that the cylinders manufactured, inspected and tested at the above plant meet the

requirements of UAE'S GSO ISO 22991:2008 (E)

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 24707

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.76

Area : mm2 -------- 69.00

Yield Load :N -------- 21740.00

Yield Strength : N/mm 2

295 min. 315.07

Tensile Load :N -------- Nil 31554.00

Tensile Strength : N/mm2 440 min. 457.30

Gauge Length : mm -------- 50.00

Final Length : mm -------- 65.72

Elongation : mm -------- 15.72

Elongation Percentage :% 26 min. 31.44

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.16

Thickness : mm -------- 3.02

Area : mm 2

-------- Nil 75.98

Tensile Load :N -------- 41260.00

Tensile Strength : N/mm2 440 min. 543.01

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.75 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 25066

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.88

Area : mm2 -------- 72.00

Yield Load :N -------- 23894.00

Yield Strength : N/mm 2

295 min. 331.86

Tensile Load :N -------- Nil 32968.00

Tensile Strength : N/mm2 440 min. 457.89

Gauge Length : mm -------- 50.00

Final Length : mm -------- 65.28

Elongation : mm -------- 15.28

Elongation Percentage :% 26 min. 30.56

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.18

Thickness : mm -------- 3.04

Area : mm 2

-------- Nil 76.55

Tensile Load :N -------- 43128.00

Tensile Strength : N/mm2 440 min. 563.42

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.84 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 25202

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.86

Area : mm2 -------- 71.50

Yield Load :N -------- 24890.00

Yield Strength : N/mm 2

295 min. 348.11

Tensile Load :N -------- Nil 33668.00

Tensile Strength : N/mm2 440 min. 470.88

Gauge Length : mm -------- 50.00

Final Length : mm -------- 66.25

Elongation : mm -------- 16.25

Elongation Percentage :% 26 min. 32.50

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.13

Thickness : mm -------- 3.03

Area : mm 2

-------- Nil 76.14

Tensile Load :N -------- 42308.00

Tensile Strength : N/mm2 440 min. 555.63

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.84 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 25588

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.84

Area : mm2 -------- 71.00

Yield Load :N -------- 24628.00

Yield Strength : N/mm 2

295 min. 346.87

Tensile Load :N -------- Nil 34626.00

Tensile Strength : N/mm2 440 min. 487.69

Gauge Length : mm -------- 50.00

Final Length : mm -------- 66.24

Elongation : mm -------- 16.24

Elongation Percentage :% 26 min. 32.48

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.19

Thickness : mm -------- 3.03

Area : mm 2

-------- Nil 76.33

Tensile Load :N -------- 41186.00

Tensile Strength : N/mm2 440 min. 539.61

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.81 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 25711

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.87

Area : mm2 -------- 71.75

Yield Load :N -------- 25032.00

Yield Strength : N/mm 2

295 min. 348.88

Tensile Load :N -------- Nil 33396.00

Tensile Strength : N/mm2 440 min. 465.45

Gauge Length : mm -------- 50.00

Final Length : mm -------- 64.89

Elongation : mm -------- 14.89

Elongation Percentage :% 26 min. 29.78

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.14

Thickness : mm -------- 3.04

Area : mm 2

-------- Nil 76.43

Tensile Load :N -------- 40688.00

Tensile Strength : N/mm2 440 min. 532.39

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.84 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 26066

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.85

Area : mm2 -------- 71.25

Yield Load :N -------- 24584.00

Yield Strength : N/mm 2

295 min. 345.04

Tensile Load :N -------- Nil 33664.00

Tensile Strength : N/mm2 440 min. 472.48

Gauge Length : mm -------- 50.00

Final Length : mm -------- 65.48

Elongation : mm -------- 15.48

Elongation Percentage :% 26 min. 30.96

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.21

Thickness : mm -------- 3.03

Area : mm 2

-------- Nil 76.39

Tensile Load :N -------- 42738.00

Tensile Strength : N/mm2 440 min. 559.50

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.83 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 26211

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.78

Area : mm2 -------- 69.50

Yield Load :N -------- 22292.00

Yield Strength : N/mm 2

295 min. 320.75

Tensile Load :N -------- Nil 31048.00

Tensile Strength : N/mm2 440 min. 446.73

Gauge Length : mm -------- 50.00

Final Length : mm -------- 66.12

Elongation : mm -------- 16.12

Elongation Percentage :% 26 min. 32.24

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.11

Thickness : mm -------- 3.03

Area : mm 2

-------- Nil 76.08

Tensile Load :N -------- 39880.00

Tensile Strength : N/mm2 440 min. 524.16

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.75 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 26577

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.84

Area : mm2 -------- 71.00

Yield Load :N -------- 24444.00

Yield Strength : N/mm 2

295 min. 344.28

Tensile Load :N -------- Nil 32988.00

Tensile Strength : N/mm2 440 min. 464.62

Gauge Length : mm -------- 50.00

Final Length : mm -------- 65.86

Elongation : mm -------- 15.86

Elongation Percentage :% 26 min. 31.72

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.24

Thickness : mm -------- 3.02

Area : mm 2

-------- Nil 76.22

Tensile Load :N -------- 40490.00

Tensile Strength : N/mm2 440 min. 531.19

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.81 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 26717

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.82

Area : mm2 -------- 70.50

Yield Load :N -------- 24130.00

Yield Strength : N/mm 2

295 min. 342.27

Tensile Load :N -------- Nil 32318.00

Tensile Strength : N/mm2 440 min. 458.41

Gauge Length : mm -------- 50.00

Final Length : mm -------- 65.36

Elongation : mm -------- 15.36

Elongation Percentage :% 26 min. 30.72

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.19

Thickness : mm -------- 3.02

Area : mm 2

-------- Nil 76.07

Tensile Load :N -------- 43804.00

Tensile Strength : N/mm2 440 min. 575.81

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.80 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 27072

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.76

Area : mm2 -------- 69.00

Yield Load :N -------- 22670.00

Yield Strength : N/mm 2

295 min. 328.55

Tensile Load :N -------- Nil 30942.00

Tensile Strength : N/mm2 440 min. 448.43

Gauge Length : mm -------- 50.00

Final Length : mm -------- 66.27

Elongation : mm -------- 16.27

Elongation Percentage :% 26 min. 32.54

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.21

Thickness : mm -------- 3.04

Area : mm 2

-------- Nil 76.64

Tensile Load :N -------- 40090.00

Tensile Strength : N/mm2 440 min. 523.11

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.74 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 27222

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.84

Area : mm2 -------- 71.00

Yield Load :N -------- 21814.00

Yield Strength : N/mm 2

295 min. 307.24

Tensile Load :N -------- Nil 30164.00

Tensile Strength : N/mm2 440 min. 424.85

Gauge Length : mm -------- 50.00

Final Length : mm -------- 65.28

Elongation : mm -------- 15.28

Elongation Percentage :% 26 min. 30.56

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.15

Thickness : mm -------- 3.03

Area : mm 2

-------- Nil 76.20

Tensile Load :N -------- 42254.00

Tensile Strength : N/mm2 440 min. 554.48

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.81 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 27584

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.88

Area : mm2 -------- 72.00

Yield Load :N -------- 25420.00

Yield Strength : N/mm 2

295 min. 353.06

Tensile Load :N -------- Nil 33182.00

Tensile Strength : N/mm2 440 min. 460.86

Gauge Length : mm -------- 50.00

Final Length : mm -------- 65.22

Elongation : mm -------- 15.22

Elongation Percentage :% 26 min. 30.44

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.11

Thickness : mm -------- 3.02

Area : mm 2

-------- Nil 75.83

Tensile Load :N -------- 41412.00

Tensile Strength : N/mm2 440 min. 546.10

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.85 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 27727

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.82

Area : mm2 -------- 70.50

Yield Load :N -------- 25342.00

Yield Strength : N/mm 2

295 min. 359.46

Tensile Load :N -------- Nil 33666.00

Tensile Strength : N/mm2 440 min. 477.53

Gauge Length : mm -------- 50.00

Final Length : mm -------- 66.35

Elongation : mm -------- 16.35

Elongation Percentage :% 26 min. 32.70

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.15

Thickness : mm -------- 3.02

Area : mm 2

-------- Nil 75.95

Tensile Load :N -------- 42140.00

Tensile Strength : N/mm2 440 min. 554.82

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.81 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

MECHANICAL TEST REPORT

Tensile Test for the Parent Material

Test Cylinder No. : 28080

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) Shell Dishend/Halve

Width : mm -------- 25.00

Thickness : mm -------- 2.86

Area : mm2 -------- 71.50

Yield Load :N -------- 21268.00

Yield Strength : N/mm 2

295 min. 297.45

Tensile Load :N -------- Nil 31662.00

Tensile Strength : N/mm2 440 min. 442.83

Gauge Length : mm -------- 50.00

Final Length : mm -------- 65.48

Elongation : mm -------- 15.48

Elongation Percentage :% 26 min. 30.96

Position of fracture -------- Within gauge length

Tensile Test for the Weld Material

Requirements: UAE'S GSO Results

Particulars

ISO 22991 (E) L-weld C-weld

Width : mm -------- 25.12

Thickness : mm -------- 3.04

Area : mm 2

-------- Nil 76.36

Tensile Load :N -------- 42302.00

Tensile Strength : N/mm2 440 min. 553.95

Position of fracture -------- At Weld line

Bend Test for the Weld Material

Result

Location of specimen Remarks

OK NOT OK

RB-1 : YES NO Not Applicable

L-Welding

FB-1: YES NO Not Applicable

RB-1 : YES NO Accepted

C-Welding

FB-1 : YES NO Accepted

Minimum Thickness of Convex end 2.83 mm.

QC.INSPECTOR THIRD PARTY INSPECTOR QA. ENGINEER

BURST TEST REPORT

REQUIRMENTS : UAE'S GSO ISO 22991(E) Date : 30.06.2019

Test Cylinder No. 24889

Wt. Of Cylinder (T.wt) 15.45 kg

Water Capacity 27.40 ltr.

Wt. Of filled Cylinder 42.85 kg

Burst Pressure 118.12 bar

Volumetric Expansion of Cylinder at Burst 30.29%

Cylinder Burst without Fragmentation YES NO

Satisfactory

Static Loading Test

Not Satisfactory

Testing Used Pr.Gauge Range 0-200 Bar

Pressure Gauge No. 1388-03

Pressure Gauge Calibration C.No. 150856383

Pr.Gauge Calibrn. Dt 21.04.2019

Pressure Gauge Calibration Due Dt 20.04.2020

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

BURST TEST REPORT

REQUIRMENTS : UAE'S GSO ISO 22991(E) Date : 30.06.2019

Test Cylinder No. 25336

Wt. Of Cylinder (T.wt) 15.45 kg

Water Capacity 27.30 ltr.

Wt. Of filled Cylinder 42.75 kg

Burst Pressure 117.62 bar

Volumetric Expansion of Cylinder at Burst 25.27%

Cylinder Burst without Fragmentation YES NO

Satisfactory

Static Loading Test

Not Satisfactory

Testing Used Pr.Gauge Range 0-200 Bar

Pressure Gauge No. 1388-03

Pressure Gauge Calibration C.No. 150856383

Pr.Gauge Calibrn. Dt 21.04.2019

Pressure Gauge Calibration Due Dt 20.04.2020

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

BURST TEST REPORT

REQUIRMENTS : UAE'S GSO ISO 22991(E) Date : 30.06.2019

Test Cylinder No. 25833

Wt. Of Cylinder (T.wt) 15.50 kg

Water Capacity 27.25 ltr.

Wt. Of filled Cylinder 42.75 kg

Burst Pressure 119.62 bar

Volumetric Expansion of Cylinder at Burst 26.05%

Cylinder Burst without Fragmentation YES NO

Satisfactory

Static Loading Test

Not Satisfactory

Testing Used Pr.Gauge Range 0-200 Bar

Pressure Gauge No. 1388-03

Pressure Gauge Calibration C.No. 150856383

Pr.Gauge Calibrn. Dt 21.04.2019

Pressure Gauge Calibration Due Dt 20.04.2020

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

BURST TEST REPORT

REQUIRMENTS : UAE'S GSO ISO 22991(E) Date : 25.07.2019

Test Cylinder No. 26335

Wt. Of Cylinder (T.wt) 15.40 kg

Water Capacity 27.25 ltr.

Wt. Of filled Cylinder 42.65 kg

Burst Pressure 118.12 bar

Volumetric Expansion of Cylinder at Burst 25.32%

Cylinder Burst without Fragmentation YES NO

Satisfactory

Static Loading Test

Not Satisfactory

Testing Used Pr.Gauge Range 0-200 Bar

Pressure Gauge No. 1388-03

Pressure Gauge Calibration C.No. 150856383

Pr.Gauge Calibrn. Dt 21.04.2019

Pressure Gauge Calibration Due Dt 20.04.2020

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

BURST TEST REPORT

REQUIRMENTS : UAE'S GSO ISO 22991(E) Date : 25.07.2019

Test Cylinder No. 26900

Wt. Of Cylinder (T.wt) 15.45 kg

Water Capacity 27.30 ltr.

Wt. Of filled Cylinder 42.75 kg

Burst Pressure 117.62 bar

Volumetric Expansion of Cylinder at Burst 23.80%

Cylinder Burst without Fragmentation YES NO

Satisfactory

Static Loading Test

Not Satisfactory

Testing Used Pr.Gauge Range 0-200 Bar

Pressure Gauge No. 1388-03

Pressure Gauge Calibration C.No. 150856383

Pr.Gauge Calibrn. Dt 21.04.2019

Pressure Gauge Calibration Due Dt 20.04.2020

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

BURST TEST REPORT

REQUIRMENTS : UAE'S GSO ISO 22991(E) Date : 25.07.2019

Test Cylinder No. 27355

Wt. Of Cylinder (T.wt) 15.30 kg

Water Capacity 27.15 ltr.

Wt. Of filled Cylinder 42.45 kg

Burst Pressure 117.12 bar

Volumetric Expansion of Cylinder at Burst 23.57%

Cylinder Burst without Fragmentation YES NO

Satisfactory

Static Loading Test

Not Satisfactory

Testing Used Pr.Gauge Range 0-200 Bar

Pressure Gauge No. 1388-03

Pressure Gauge Calibration C.No. 150856383

Pr.Gauge Calibrn. Dt 21.04.2019

Pressure Gauge Calibration Due Dt 20.04.2020

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

BURST TEST REPORT

REQUIRMENTS : UAE'S GSO ISO 22991(E) Date : 25.07.2019

Test Cylinder No. 27900

Wt. Of Cylinder (T.wt) 15.50 kg

Water Capacity 27.25 ltr.

Wt. Of filled Cylinder 42.75 kg

Burst Pressure 118.12 bar

Volumetric Expansion of Cylinder at Burst 23.11%

Cylinder Burst without Fragmentation YES NO

Satisfactory

Static Loading Test

Not Satisfactory

Testing Used Pr.Gauge Range 0-200 Bar

Pressure Gauge No. 1388-03

Pressure Gauge Calibration C.No. 150856383

Pr.Gauge Calibrn. Dt 21.04.2019

Pressure Gauge Calibration Due Dt 20.04.2020

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

e : 30.06.2019

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

e : 30.06.2019

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

e : 30.06.2019

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

e : 25.07.2019

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

e : 25.07.2019

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

e : 25.07.2019

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

e : 25.07.2019

QC.INSPECTOR THIRD PARTY INSPECTOR QA.ENGINEER

You might also like

- Asme Section Ix Latest EditionDocument2 pagesAsme Section Ix Latest Editionroma hidayatNo ratings yet

- BASS SETUP - Yamaha Bass - ManualDocument7 pagesBASS SETUP - Yamaha Bass - ManualVirgil Popescu100% (1)

- Astm A578-A578m-07Document5 pagesAstm A578-A578m-07Renato MassanoNo ratings yet

- API 5L Grades and SpecsDocument4 pagesAPI 5L Grades and Specsamir_hayfaNo ratings yet

- List of Welding Processes - Wikipedia, The Free EncyclopediaDocument5 pagesList of Welding Processes - Wikipedia, The Free EncyclopediaSafeer MNo ratings yet

- Grain Drying and Dryers: Agricultural Mechanization For Sustainable Farming System Course 2004Document71 pagesGrain Drying and Dryers: Agricultural Mechanization For Sustainable Farming System Course 2004RamilArtates100% (2)

- Data Sheet For MercuryDocument5 pagesData Sheet For MercuryMohamed hamza souissiNo ratings yet

- 2062Document17 pages2062hswed91100% (1)

- JIS G3452 PipeDocument0 pagesJIS G3452 PipefaridyeniNo ratings yet

- Pressure Test REPORTDocument6 pagesPressure Test REPORTMANIMARAN QCNo ratings yet

- ServiceNow BasicsDocument60 pagesServiceNow BasicsAladNo ratings yet

- Ms0750 Vanguard 3-Cylinder Ohv LC Gasoline Briggs & StrattonDocument132 pagesMs0750 Vanguard 3-Cylinder Ohv LC Gasoline Briggs & StrattonKenn Ferro80% (5)

- Construction Methodology 2019: List TablesDocument13 pagesConstruction Methodology 2019: List TablesDenis Dwayne DizzleNo ratings yet

- LTE Network Planning - Huawei TechnologiesDocument54 pagesLTE Network Planning - Huawei TechnologiesayodNo ratings yet

- Charles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelDocument66 pagesCharles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelAlarmakNo ratings yet

- F71-F90 Dial IndicatorApplication PDFDocument20 pagesF71-F90 Dial IndicatorApplication PDFKiranNo ratings yet

- Cloning and Refreshing An Oracle DatabaseDocument11 pagesCloning and Refreshing An Oracle Databasechandramani.tiwari0% (1)

- TDC QapDocument69 pagesTDC QapKuppuraj ParamsivamNo ratings yet

- Industrial Hose: Formerly Black Gold Choke & Kill HoseDocument4 pagesIndustrial Hose: Formerly Black Gold Choke & Kill HoseRahul MoottolikandyNo ratings yet

- Astm A578 A578m 17 2023Document2 pagesAstm A578 A578m 17 2023VictorRobladillo0% (1)

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Document4 pagesApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNo ratings yet

- ASTM C90700 - CuSn11 - Tin Bronze AlloysDocument1 pageASTM C90700 - CuSn11 - Tin Bronze Alloysİrem Şebnem SorucuNo ratings yet

- Is 12818-2010 PDFDocument22 pagesIs 12818-2010 PDFINFOHEPL RCLNo ratings yet

- ASTM C91000 - CuSn15 - Tin Bronze AlloysDocument1 pageASTM C91000 - CuSn15 - Tin Bronze Alloysİrem Şebnem SorucuNo ratings yet

- Conceptual Database DesignDocument22 pagesConceptual Database DesignMunNo ratings yet

- GOST 6996-66 Welded Joints Methods For Determining Mechanical PropertiesDocument51 pagesGOST 6996-66 Welded Joints Methods For Determining Mechanical PropertiesSree SudhaNo ratings yet

- POSCO Brochure (플랜트소개용)Document27 pagesPOSCO Brochure (플랜트소개용)German Jaramillo VillarNo ratings yet

- A 872 - 91 R02 Qtg3mi05mviwmgDocument3 pagesA 872 - 91 R02 Qtg3mi05mviwmgsachinguptachdNo ratings yet

- Astm F1554 20Document5 pagesAstm F1554 20dguerrero83cuentasNo ratings yet

- LET ReviewerDocument4 pagesLET ReviewerJaycee Silveo SeranNo ratings yet

- Weld Visual Inspection For Store Girder 1Document1 pageWeld Visual Inspection For Store Girder 1Ashwani DograNo ratings yet

- TDS005-Grade 2 and ASTM A307 BoltingDocument2 pagesTDS005-Grade 2 and ASTM A307 BoltingKrish DoodnauthNo ratings yet

- C547 PDFDocument4 pagesC547 PDFAhmedNo ratings yet

- Bhel-Quality Plan PipingDocument7 pagesBhel-Quality Plan PipingMl Jain100% (1)

- Msbte Concrete Lab Manual-9021Document13 pagesMsbte Concrete Lab Manual-9021Mohammed Faiz67% (3)

- Iso 2503 1998 en FR PDFDocument8 pagesIso 2503 1998 en FR PDFInversiones thinkupNo ratings yet

- A A 58092Document5 pagesA A 58092AbieNo ratings yet

- Golden Joint ChecklistDocument2 pagesGolden Joint ChecklistMohd Effiezool YaserNo ratings yet

- HK CS2 - 2012Document50 pagesHK CS2 - 2012bobbyccwNo ratings yet

- PTC Test Program For ASTM A351Document3 pagesPTC Test Program For ASTM A351Deepak DasNo ratings yet

- F15-04 (2013) Standard Specification For Iron-Nickel-Cobalt Sealing AlloyDocument7 pagesF15-04 (2013) Standard Specification For Iron-Nickel-Cobalt Sealing Alloymercab15No ratings yet

- Astm A744-A744m 2010Document6 pagesAstm A744-A744m 2010Júlio RosaNo ratings yet

- FEM0017 Rev 1 EMSTest ChargesDocument55 pagesFEM0017 Rev 1 EMSTest ChargesganmosesNo ratings yet

- Cahier de Soudage G 11950 - Ver B - WPS 14Document1 pageCahier de Soudage G 11950 - Ver B - WPS 14YassineElabdNo ratings yet

- Is 15328 PDFDocument28 pagesIs 15328 PDFakgupta7337790% (1)

- Luxathane 5000 Polyurethane High Gloss Finish: Technical DataDocument3 pagesLuxathane 5000 Polyurethane High Gloss Finish: Technical DataPV AnandNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- Iso 9863 1 2016Document9 pagesIso 9863 1 2016Samer MohamedNo ratings yet

- Astm D4385-10Document7 pagesAstm D4385-10roshniNo ratings yet

- Admixture Redo SingDocument2 pagesAdmixture Redo SingShivaji JadhavNo ratings yet

- Nut & Bolt ScienceDocument3 pagesNut & Bolt SciencetanujaayerNo ratings yet

- Astm A-351 GR CF8MDocument2 pagesAstm A-351 GR CF8MVictor Castellanos AlegriaNo ratings yet

- Astm A409 A409m 2001Document6 pagesAstm A409 A409m 2001Roland CepedaNo ratings yet

- MIV Product Overview PDFDocument13 pagesMIV Product Overview PDFugljevikNo ratings yet

- AA59807 Rev 04 PDFDocument5 pagesAA59807 Rev 04 PDFAjit SamalNo ratings yet

- MITS-34 Rev 6Document17 pagesMITS-34 Rev 6Srinivasan RNo ratings yet

- Holiday Detector PoroTest 7 enDocument4 pagesHoliday Detector PoroTest 7 enabcNo ratings yet

- Astm2012 PDFDocument3 pagesAstm2012 PDFRiyas UdheenNo ratings yet

- Swagelok Magnehelic Gauge InstructionsDocument4 pagesSwagelok Magnehelic Gauge InstructionsAnonymous vF4wgBTdSbNo ratings yet

- TDC-10B Heat Treatment For C12A Steel CastingsDocument2 pagesTDC-10B Heat Treatment For C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- WFP 2 01 Procedure R1Document8 pagesWFP 2 01 Procedure R1leodavid87No ratings yet

- BS 1449 PT 1 Sec 1 - 5 1991 Cold Rolled S - S by BS EN 10268Document10 pagesBS 1449 PT 1 Sec 1 - 5 1991 Cold Rolled S - S by BS EN 10268Fu Ki chunNo ratings yet

- Phoenix Steel Processing Co., LTD: Mill'S Test CertificateDocument1 pagePhoenix Steel Processing Co., LTD: Mill'S Test CertificateANTONIO CAMARGONo ratings yet

- A 1031 - 04 Qtewmze - PDFDocument4 pagesA 1031 - 04 Qtewmze - PDFqueno1No ratings yet

- G12MF TypeDocument1 pageG12MF Typeosto72No ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- JIS5402 For FRC Rooftile PDFDocument5 pagesJIS5402 For FRC Rooftile PDFQuảng Nguyễn HồngNo ratings yet

- Product Catalogue For Steel Re-BarsDocument35 pagesProduct Catalogue For Steel Re-BarsCrazyBookWormNo ratings yet

- 9452 SamsungDocument13 pages9452 SamsungEdward José Chacín R.No ratings yet

- Need of Surface TreatmentDocument6 pagesNeed of Surface TreatmentRahul MoottolikandyNo ratings yet

- What Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Document1 pageWhat Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Rahul MoottolikandyNo ratings yet

- Presented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaDocument6 pagesPresented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaRahul MoottolikandyNo ratings yet

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- Inspection NotesDocument1 pageInspection NotesRahul MoottolikandyNo ratings yet

- Mass Earth's Atmosphere: DensityDocument23 pagesMass Earth's Atmosphere: DensityRahul MoottolikandyNo ratings yet

- Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesItem Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- Material Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDocument5 pagesMaterial Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyNo ratings yet

- Date Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalDocument1 pageDate Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalRahul MoottolikandyNo ratings yet

- Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDocument5 pagesMarking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyNo ratings yet

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDocument7 pagesMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyNo ratings yet

- IZZ-HAIMO-PTR-067!06!3inch Hose Pressure Test ReportDocument1 pageIZZ-HAIMO-PTR-067!06!3inch Hose Pressure Test ReportRahul MoottolikandyNo ratings yet

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- Gate Pass Request Form: Requested Date: Reference NoDocument1 pageGate Pass Request Form: Requested Date: Reference NoRahul MoottolikandyNo ratings yet

- Mandays 100Document1 pageMandays 100Rahul MoottolikandyNo ratings yet

- Date Inspectors Mandays Rahul Sujai 7pm To 7am 7am To 7pm ### 1.5 - 1.5 ### - 1 1 Total 2.5Document1 pageDate Inspectors Mandays Rahul Sujai 7pm To 7am 7am To 7pm ### 1.5 - 1.5 ### - 1 1 Total 2.5Rahul MoottolikandyNo ratings yet

- Gate Pass Request FormDocument38 pagesGate Pass Request FormRahul MoottolikandyNo ratings yet

- The Relational ModelDocument34 pagesThe Relational Modellouarianedlr17No ratings yet

- 12th Round MTech WeblistDocument4 pages12th Round MTech Weblistsm69xdNo ratings yet

- Technical Specifications For Three Phase Meters PDFDocument6 pagesTechnical Specifications For Three Phase Meters PDFAamir MasoodiNo ratings yet

- 03 Handout 1Document7 pages03 Handout 1Adrasteia ZachryNo ratings yet

- Artificial Intelligence (Professional Elective - I) Ech. III Year II Sem. LTP C Course Code: CS613PE 3 0 0 3Document2 pagesArtificial Intelligence (Professional Elective - I) Ech. III Year II Sem. LTP C Course Code: CS613PE 3 0 0 3Swathi TudicherlaNo ratings yet

- High Pda and Corona Probe Readings: Confirmation ofDocument53 pagesHigh Pda and Corona Probe Readings: Confirmation ofenmelmartNo ratings yet

- TP U3Document14 pagesTP U3Vignesh KNo ratings yet

- Data FusionDocument3 pagesData FusionAnonymous 2lMI3jbZbNo ratings yet

- مُثَلَّث: Maslas Meaning in EnglishDocument1 pageمُثَلَّث: Maslas Meaning in EnglishMr Asraf AllyNo ratings yet

- Sim CCDocument8 pagesSim CCLivya GeorgeNo ratings yet

- CS109B Quiz Directions Sign The PledgeDocument7 pagesCS109B Quiz Directions Sign The PledgeK. M. Junayed AhmedNo ratings yet

- Locking Table Practice S5 Locking Table Practice Locking Table PracticeDocument34 pagesLocking Table Practice S5 Locking Table Practice Locking Table PracticePrasun Singhal100% (1)

- Chapter - 08 - Lipids Membranes-TestDocument10 pagesChapter - 08 - Lipids Membranes-Testendang dian lestariNo ratings yet

- S7500 Troubleshooting PDFDocument53 pagesS7500 Troubleshooting PDFDaniel CekulNo ratings yet

- 1060 M Hydraulic Operated Concrete Block Making MachineDocument6 pages1060 M Hydraulic Operated Concrete Block Making MachineTejas T S TejasNo ratings yet

- IJSTR TemplateDocument4 pagesIJSTR TemplateGiridhar ParameswaranNo ratings yet

- Effect of Cleaning Point of Uniclean Machine in Blow Room On Cleaning Efficiency and Yarn QualityDocument21 pagesEffect of Cleaning Point of Uniclean Machine in Blow Room On Cleaning Efficiency and Yarn QualitySantoshNo ratings yet

- 10 1021@ie000063qDocument11 pages10 1021@ie000063qjuan diegoNo ratings yet

- Drum and Lining Brake 2Document4 pagesDrum and Lining Brake 2albert svensenNo ratings yet

- Mathematics Grade 10Document11 pagesMathematics Grade 10Yoga PratamaNo ratings yet

- DB Managment Ch7 ProblemsDocument6 pagesDB Managment Ch7 ProblemsJuan Manuel Garcia NoguesNo ratings yet

- Mathematical Modeling of Dynamic Induction Motor With Bearing FaultDocument5 pagesMathematical Modeling of Dynamic Induction Motor With Bearing FaultTawhid Bin TarekNo ratings yet