Professional Documents

Culture Documents

Ia PDF

Uploaded by

Navin SabbanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ia PDF

Uploaded by

Navin SabbanCopyright:

Available Formats

INTRODUCTION TO INSTRUMENTATION AND PROCESS CONTROL

Understand instrumentation and process control CLASS FORMAT:

to become more valuable as your multi-skill set Lab + classroom

expands. You’ll spend approximately 50% of the time

The participant is able to “learn-by-doing” in the

working with various instruments and controllers.

course; this knowledge can be transferred to the

You will learn to program, connect input/output

workplace.

devices, as well as how to troubleshoot process

controls including sensors, transmitters, controllers

and final elements. STANDARD CLASS SIZE:

Use various instruments to measure temperature, NTT recommends a class of 12 participants to obtain

pressure, flow rate, level and position, pH and the best results.

analysis and weight and density. Understand the

differences between open and closed-loop controls, NTT PROVIDES:

feedback and feed forward controls, PLC, DCS and

• 3 days (24 contact hours) of on-site instruction

stand-alone controllers.

• Textbooks, “Introduction to Instrumentation and

Find out how analog signals are produced, processed, Process Control,” “Instrumentation and Process

and protected from noise and differences in Control Lab Manual”

proportional, PI and PID control strategies. Understand • “Supertech” (a pocket reference for instrument

what causes errors in instruments and how to technicians)

minimize and troubleshoot them. Learn to calibrate • Classroom consumables

transmitters and tune controller.

• Completion certificates

• Shipping, instructor fees and travel expenses

CLIENT PROVIDES:

• Classroom, with easy access, of 750 square feet or

greater

• Projection screen, white board and/or flip chart(s)

• Tables and seating for participants

• Tables for hands-on trainers (two 8’ tables or four

6’ tables)

• A dock facility or a forklift to unload the training

equipment

• A pallet jack to move the crates after they have

been unloaded may also be needed

• The equipment should be placed in the training

room for the NTT instructor to set up and test prior

to the start of training

SHIPPING:

• 3 crates at 1,150 lbs

-- 1 crate @ 54” x 49” x 38” = 600 lbs

-- 1 crate @ 58” x 37” x 28” = 375 lbs

-- 1 crate @ 35” x 35” x 27” = 175 lbs

Training 800.922.2820 | www.NTTInc.com

INTRODUCTION TO INSTRUMENTATION AND PROCESS CONTROL

COURSE AGENDA

BASIC CONCEPTS LEVEL INSTRUMENTATION AND MEASUREMENTS

• Purposes for control systems • Level measurement methods—sight glass, differential

• Terminology pressure level measurement, bubbler, displacer level sensor,

• Signal types float level sensors, capacitance, radiation-based, radar and

• Shielding and grounding ultrasonic level sensors

• Signal conversion

• Final control elements DENSITY, SPECIFIC GRAVITY AND ANALYSIS

• Density and specific gravity measurement

PIPING AND INSTRUMENT DIAGRAMS (P AND IDS) • Monitoring and analyzing pH, conductivity

• Line symbols

• Instrument identification tags MANIPULATING THE PROCESS

• Instrument bubbles • Final control element

• Loop diagrams • Actuators, valve positioners, I/P, valves

• Variable frequency drives

CONTROL TECHNOLOGIES

• Local manual, remote electrical TROUBLESHOOTING

• Local pneumatic • Testing for open/short circuits

• Remote analog/digital • Troubleshooting/maintenance suggestions

BASIC ELECTRICAL AND MATH CONCEPTS CONTROLLERS

• Applications to instruments • Control modes—proportional, integral, derivative

• Electrical principles and symbols • Tuning feedback controllers—¼ decay, Zeigler-Nichols,

• Series/parallel circuits damped oscillation

• Ratio, cascade and feed-forward control

PRESSURE INSTRUMENTATION & MEASUREMENTS

CONTROL SYSTEMS

• Pressure measurement devices

-- U-tube manometer, bourdon gauge, bellows gauge, • Overview of PLCs, DCS and SCADA systems

piezoelectric

HANDS-ON EXERCISES

TEMPERATURE INSTRUMENTATION AND • Density and specific gravity measurement

MEASUREMENTS • Sensor checkout

• Measurement devices and techniques • Hookup to calibration stands

• Bimetallic temperature measurement • Transmitter calibration check

• Filled capillary and bulb, thermocouple, resistance temperature • Program/tune controller

detector (RTD), thermistors, thermowells, infrared • Set up of differential pressure, temperature, and other

process-simulation devices

FLOW INSTRUMENTATION AND MEASUREMENTS • Calibration or set up with hand-held calibrator

• Flow measurement methods • Checking current output with VOM & tracing around loop

• Factors influencing flow measurement • Simulate and source 4-20mA-DC signals

• Flow measurement devices—orifice plates, venturi

tube, flow nozzle, elbow taps, pitot tube, parshall flume,

magnetic flowmeter (Mag meter), vortex shedding meter,

turbine meter, target flowmeter, ultrasonic, variable area

rotameter, coriolis meter, nutating disc

Training 800.922.2820 | www.NTTInc.com

INTRODUCTION TO INSTRUMENTATION AND PROCESS CONTROL

Training 800.922.2820 | www.NTTInc.com

You might also like

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationFrom EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationRating: 5 out of 5 stars5/5 (1)

- Designer's Handbook Instrmtn/Contr CircuitsFrom EverandDesigner's Handbook Instrmtn/Contr CircuitsRating: 5 out of 5 stars5/5 (1)

- Pentra C400 Brochure WEB Final 220322 190720Document6 pagesPentra C400 Brochure WEB Final 220322 190720opalNo ratings yet

- Testing of High Voltage Equipment PDFDocument2 pagesTesting of High Voltage Equipment PDFsarabNo ratings yet

- Basics of Industrial Electricity and Troubleshooting Electrical Control CircuitsDocument4 pagesBasics of Industrial Electricity and Troubleshooting Electrical Control CircuitsjjithendranathNo ratings yet

- Pneumatic/Electro-Pneumatic Systems and Principles: Course OutcomesDocument2 pagesPneumatic/Electro-Pneumatic Systems and Principles: Course OutcomesIwan KurniawanNo ratings yet

- Automation in Clinical ChemistryDocument28 pagesAutomation in Clinical ChemistryJoyce VitalNo ratings yet

- Qualification of High-Performance LiquidDocument9 pagesQualification of High-Performance LiquidGauri KokaneNo ratings yet

- SIRIMCal Corporate Slides 2024 - SQAS Update SessionDocument34 pagesSIRIMCal Corporate Slides 2024 - SQAS Update Sessionakulaanombor4No ratings yet

- ENVOY 500+: Clinical Chemistry SystemDocument4 pagesENVOY 500+: Clinical Chemistry SystemIvann PérezNo ratings yet

- Chapter4 Liquid Level Measurement 09Document50 pagesChapter4 Liquid Level Measurement 09ggleichgesinntenNo ratings yet

- Measurement Systems - An Overview and Basic ConceptsDocument33 pagesMeasurement Systems - An Overview and Basic ConceptsDeepali ShirkeNo ratings yet

- EI - Module 1Document41 pagesEI - Module 1Deepa ShreeNo ratings yet

- 13 Vacuum and Leak Detection TrainingDocument27 pages13 Vacuum and Leak Detection TrainingsinytellsNo ratings yet

- Module 4 GCLP Laboratory EquipmentDocument25 pagesModule 4 GCLP Laboratory EquipmentShafici CqadirNo ratings yet

- Instrumentation: (And Process Control)Document9 pagesInstrumentation: (And Process Control)azitaggNo ratings yet

- Sayham Calibration c1Document37 pagesSayham Calibration c1Md.Amir hossain khanNo ratings yet

- TroubleshootingDocument39 pagesTroubleshootingTrí NguyễnNo ratings yet

- Electrical Switchboards, Circuit Breakers, Protective Relays, Cables and PlcsDocument2 pagesElectrical Switchboards, Circuit Breakers, Protective Relays, Cables and PlcsIndika JayasundaraNo ratings yet

- Multi-Parameter Colorimeter: 6456 Parkland Drive, Sarasota, FL 34243Document4 pagesMulti-Parameter Colorimeter: 6456 Parkland Drive, Sarasota, FL 34243Fabio Corpas UlloaNo ratings yet

- Servicing The Philips Family Ultrasound Epiq 5/7 (2.5 Day)Document1 pageServicing The Philips Family Ultrasound Epiq 5/7 (2.5 Day)Mai Thanh SơnNo ratings yet

- CV Taufik Setiawan NewDocument2 pagesCV Taufik Setiawan Newbayu pratamaNo ratings yet

- Dacon PAUT PresentationDocument20 pagesDacon PAUT Presentationbacabacabaca100% (1)

- CalibrationDocument45 pagesCalibrationDeb RoyNo ratings yet

- INTCV385 - HV and MV Switchgear (CB, CT, CVT, DC and SA) Operaion, Maintenance - L2 - v1Document3 pagesINTCV385 - HV and MV Switchgear (CB, CT, CVT, DC and SA) Operaion, Maintenance - L2 - v1PMG Bhuswal ProjectNo ratings yet

- Abl90 Flex PlusDocument1 pageAbl90 Flex PlusTW RHKLNo ratings yet

- PentraDocument8 pagesPentraDV0% (1)

- Logiq p5 Premium bt11 Datasheet 131010 PDFDocument14 pagesLogiq p5 Premium bt11 Datasheet 131010 PDFanon_767958162No ratings yet

- Iris Power Stator Wedge Analyzer SWA BrochureDocument2 pagesIris Power Stator Wedge Analyzer SWA BrochureLeandro AriasNo ratings yet

- Training: Benefit From The Alderley ExperienceDocument2 pagesTraining: Benefit From The Alderley ExperienceMohamed Abdul KaderNo ratings yet

- Instrumentation and Measurement (3 + 1)Document27 pagesInstrumentation and Measurement (3 + 1)Haider AliNo ratings yet

- ISO 18436 Category II ISO 18436 Category IIDocument1 pageISO 18436 Category II ISO 18436 Category IImaria alejandraNo ratings yet

- Intermediate Vibration Analysis Training Topics - Cat II - BKV - FVDocument2 pagesIntermediate Vibration Analysis Training Topics - Cat II - BKV - FVCory O'DonnellNo ratings yet

- Ultrasound Training Catalog: Leading The Industry With TrainingDocument8 pagesUltrasound Training Catalog: Leading The Industry With TrainingMai Thanh SơnNo ratings yet

- Phased Array Ultrasonic Testing: Inspection ServicesDocument19 pagesPhased Array Ultrasonic Testing: Inspection ServicesAnkur desaiNo ratings yet

- Circuit Breakers and Switch GearDocument2 pagesCircuit Breakers and Switch GearMilind DombaleNo ratings yet

- ISO 18436 Category II Vibration Analyst Training TopicsDocument1 pageISO 18436 Category II Vibration Analyst Training TopicsDean LofallNo ratings yet

- Brosur RapidLab 348EX BrochureDocument8 pagesBrosur RapidLab 348EX BrochureFarly AugusNo ratings yet

- Testing of High Voltage EquipmentDocument2 pagesTesting of High Voltage EquipmentRabin Babu GhimireNo ratings yet

- Abl90 FlexDocument1 pageAbl90 FlexTW RHKLNo ratings yet

- CalibrationDocument14 pagesCalibrationMaurin laura andaniNo ratings yet

- 5/15/2019 Introducing IIA1217-Hard/Soft Sensors in Process Measurements 1Document12 pages5/15/2019 Introducing IIA1217-Hard/Soft Sensors in Process Measurements 1Abu Zanki Gina KusumaNo ratings yet

- Programmable Logic Controllers (PLCS) For Automation and Process ControlDocument2 pagesProgrammable Logic Controllers (PLCS) For Automation and Process ControlYashveer TakooryNo ratings yet

- Instrumentation & Measurement (ME342) : Calibration of Measuring Sensors and InstrumentsDocument11 pagesInstrumentation & Measurement (ME342) : Calibration of Measuring Sensors and InstrumentsYahya AleswedNo ratings yet

- Difference Between Elastic and Resilient ModulusDocument28 pagesDifference Between Elastic and Resilient Moduluspawan kumarNo ratings yet

- Brochure Emerson Meter Verification Diagnostics Micro Motion en 65300Document4 pagesBrochure Emerson Meter Verification Diagnostics Micro Motion en 65300yarubNo ratings yet

- EIT IP Brochure EgyptDocument4 pagesEIT IP Brochure Egyptheka2006No ratings yet

- ABB - Measurement and Analytics - Brochre 2019Document4 pagesABB - Measurement and Analytics - Brochre 2019Luis Ruben Torres QuispeNo ratings yet

- Selectra Prom: Delivering Trouble-Free Results Laboratories Can TrustDocument6 pagesSelectra Prom: Delivering Trouble-Free Results Laboratories Can TrustaliNo ratings yet

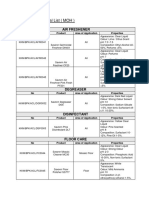

- Electrical Installation AND Maintenance NC Ii: Reporters: Meril S. Mercado Elizabeth P. OlarveDocument30 pagesElectrical Installation AND Maintenance NC Ii: Reporters: Meril S. Mercado Elizabeth P. Olarveelizabeth olarveNo ratings yet

- Competency Assessment AgreementDocument2 pagesCompetency Assessment AgreementDyril Kleine DacanayNo ratings yet

- PRD LC 300Document5 pagesPRD LC 300G_ASantosNo ratings yet

- Multifunction Process Calibrator: FeaturesDocument2 pagesMultifunction Process Calibrator: Featuresrmorenodx4587No ratings yet

- EXTECH Kalibrator PRC30 - DS-en PDFDocument2 pagesEXTECH Kalibrator PRC30 - DS-en PDFpredragstojicicNo ratings yet

- Iadc Wellsharp Drilling: Supervisor LevelDocument8 pagesIadc Wellsharp Drilling: Supervisor LevelNazzta allezNo ratings yet

- Multisensor Instrumentation 6σ Design: Defined Accuracy Computer-Integrated Measurement SystemsFrom EverandMultisensor Instrumentation 6σ Design: Defined Accuracy Computer-Integrated Measurement SystemsNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Parameter Estimation and Adaptive Control for Nonlinear Servo SystemsFrom EverandParameter Estimation and Adaptive Control for Nonlinear Servo SystemsNo ratings yet

- Why Do Firms Do Basic Research With Their Own Money - 1989 - StudentsDocument10 pagesWhy Do Firms Do Basic Research With Their Own Money - 1989 - StudentsAlvaro Rodríguez RojasNo ratings yet

- The Role of Mahatma Gandhi in The Freedom Movement of IndiaDocument11 pagesThe Role of Mahatma Gandhi in The Freedom Movement of IndiaSwathi Prasad100% (6)

- Approved Chemical ListDocument2 pagesApproved Chemical ListSyed Mansur Alyahya100% (1)

- 1.quetta Master Plan RFP Draft1Document99 pages1.quetta Master Plan RFP Draft1Munir HussainNo ratings yet

- Focus Charting of FDocument12 pagesFocus Charting of FRobert Rivas0% (2)

- VtDA - The Ashen Cults (Vampire Dark Ages) PDFDocument94 pagesVtDA - The Ashen Cults (Vampire Dark Ages) PDFRafãoAraujo100% (1)

- Serological and Molecular DiagnosisDocument9 pagesSerological and Molecular DiagnosisPAIRAT, Ella Joy M.No ratings yet

- Reflection On Harrison Bergeron Society. 21ST CenturyDocument3 pagesReflection On Harrison Bergeron Society. 21ST CenturyKim Alleah Delas LlagasNo ratings yet

- MasterMind 1 Unit 5 Extra LifeSkills Lesson 2Document2 pagesMasterMind 1 Unit 5 Extra LifeSkills Lesson 2Hugo A FENo ratings yet

- E TN SWD Csa A23 3 94 009 PDFDocument5 pagesE TN SWD Csa A23 3 94 009 PDFRazvan RobertNo ratings yet

- RR 10-76Document4 pagesRR 10-76cheska_abigail950No ratings yet

- Hercules Industries Inc. v. Secretary of Labor (1992)Document1 pageHercules Industries Inc. v. Secretary of Labor (1992)Vianca MiguelNo ratings yet

- A Guide To Relativity BooksDocument17 pagesA Guide To Relativity Bookscharles luisNo ratings yet

- Reported Speech StatementsDocument1 pageReported Speech StatementsEmilijus Bartasevic100% (1)

- Acts 1 Bible StudyDocument4 pagesActs 1 Bible StudyPastor Jeanne100% (1)

- Counselling and PsychotherapyDocument12 pagesCounselling and PsychotherapyD.Sreenivasa ReddyNo ratings yet

- Name Numerology Calculator - Chaldean Name Number PredictionsDocument2 pagesName Numerology Calculator - Chaldean Name Number Predictionsarunamurugesan7No ratings yet

- Chapter 4 INTRODUCTION TO PRESTRESSED CONCRETEDocument15 pagesChapter 4 INTRODUCTION TO PRESTRESSED CONCRETEyosef gemessaNo ratings yet

- MCN Drill AnswersDocument12 pagesMCN Drill AnswersHerne Balberde100% (1)

- CU 8. Johnsons Roy NeumanDocument41 pagesCU 8. Johnsons Roy NeumanPatrick MatubayNo ratings yet

- Hilti Product Technical GuideDocument16 pagesHilti Product Technical Guidegabox707No ratings yet

- Mathematics Paper 1 TZ2 HLDocument16 pagesMathematics Paper 1 TZ2 HLPavlos StavropoulosNo ratings yet

- 221-240 - PMP BankDocument4 pages221-240 - PMP BankAdetula Bamidele OpeyemiNo ratings yet

- Grammar Reference With Practice Exercises: Unit 1Document25 pagesGrammar Reference With Practice Exercises: Unit 1violet15367% (3)

- Old San Agustin NHS MSISAR Sept 2021Document2 pagesOld San Agustin NHS MSISAR Sept 2021ERICSON SABANGANNo ratings yet

- 28Document12 pages28physicsdocsNo ratings yet

- Professional Experience Report - Edu70012Document11 pagesProfessional Experience Report - Edu70012api-466552053No ratings yet

- (Dan Stone) The Historiography of The HolocaustDocument586 pages(Dan Stone) The Historiography of The HolocaustPop Catalin100% (1)

- Activity Lesson PlanDocument2 pagesActivity Lesson PlanPsiho LoguseNo ratings yet

- The Preparedness of The Data Center College of The Philippines To The Flexible Learning Amidst Covid-19 PandemicDocument16 pagesThe Preparedness of The Data Center College of The Philippines To The Flexible Learning Amidst Covid-19 PandemicInternational Journal of Innovative Science and Research TechnologyNo ratings yet