Professional Documents

Culture Documents

Manufacturing Process Design and Costing - An Integrated Approach

Uploaded by

NIKKO ARBILOOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manufacturing Process Design and Costing - An Integrated Approach

Uploaded by

NIKKO ARBILOCopyright:

Available Formats

1.

3 Manufacturing System Design 7

Product

Product Product Attributes

Product Planning Lifecycle Issues

Optimisation Number of Parts

Part Part Attributes

Part Planning Task Sequence

Optimisation Tooling

Assembly Assembly Attributes

Assembly Planning Task Sequence

Optimisation Time

Time and Cost

No

Acceptable

Yes

Workstations Manufacturing Time

Workstations Product Volume

Optimisation Line Balance

Layout Process Equipment

Layout Planning Transfer Systems

Optimisation Layout Design

Throughput Just in Time

Throughput Strategy Kanban

Optimisation Buffer Levels

Manufacturing System

No

Acceptable

Yes

Production

Fig. 1.6 Manufacturing system design

occupied and this leads to inefficiencies. The cycle time reflects the throughput

rate or how many will be made per hour or per day, as for example in a bakery or

in a car plant. If the production requirement is very high then the cycle time can be

significantly less than the smallest task time. This leads to problems which are

overcome by parallel workstations performing the same task. This helps to reduce

You might also like

- Service-Oriented Modeling: Service Analysis, Design, and ArchitectureFrom EverandService-Oriented Modeling: Service Analysis, Design, and ArchitectureNo ratings yet

- BMC Control-M 7: A Journey from Traditional Batch Scheduling to Workload AutomationFrom EverandBMC Control-M 7: A Journey from Traditional Batch Scheduling to Workload AutomationNo ratings yet

- FMEA Training TextDocument54 pagesFMEA Training TextCHULYUN JUNGNo ratings yet

- MILAN Auto Page-3 PDFDocument1 pageMILAN Auto Page-3 PDFRawnak PrajapatiNo ratings yet

- Oracle PSDocument39 pagesOracle PSSribidya MishraNo ratings yet

- MD Lecture 2 PDFDocument5 pagesMD Lecture 2 PDFDeekshaomarNo ratings yet

- PTI05Document50 pagesPTI05leonny slNo ratings yet

- SaaS Execution Map ProjectDocument1 pageSaaS Execution Map ProjectraviNo ratings yet

- ISPE CCChPlantFacilitiesEngPharmaIndDocument28 pagesISPE CCChPlantFacilitiesEngPharmaIndHamidNo ratings yet

- AM COE Brochure - v2Document4 pagesAM COE Brochure - v2sanjit kadneNo ratings yet

- To Understand The Application of Computers in Various Aspects of Manufacturing Viz., Design, Proper Planning, Manufacturing Cost, Layout & Material Handling SystemDocument33 pagesTo Understand The Application of Computers in Various Aspects of Manufacturing Viz., Design, Proper Planning, Manufacturing Cost, Layout & Material Handling Systemmkumar_234155No ratings yet

- Enhanced Order Fulfillment Using Oracle Global Order PromisingDocument37 pagesEnhanced Order Fulfillment Using Oracle Global Order PromisingParth DesaiNo ratings yet

- Performix Inc: Implementing MES in SAP LandscapeDocument46 pagesPerformix Inc: Implementing MES in SAP LandscaperusumdarNo ratings yet

- Mistake Proofing & Poka-Yoke: A Strategy For Performance ExcellenceDocument73 pagesMistake Proofing & Poka-Yoke: A Strategy For Performance Excellencekumarkk1969No ratings yet

- CADDocument20 pagesCADmuh rezki fpNo ratings yet

- PM Work, Time and Motion StudyDocument47 pagesPM Work, Time and Motion StudyUtkarsh Sharma100% (1)

- Advanced Production System Design: Prof. Dr. Dr.-Ing. Yilmaz UygunDocument27 pagesAdvanced Production System Design: Prof. Dr. Dr.-Ing. Yilmaz UygunDally KunNo ratings yet

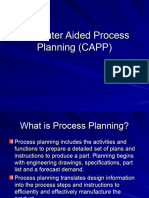

- CAPPDocument16 pagesCAPPvirug1994No ratings yet

- Cad Cam Cae PDFDocument30 pagesCad Cam Cae PDFAritra GoswamiNo ratings yet

- Scenario Overview SAP Best Practices For DBM V1.600: AB0 - Time RecordingDocument22 pagesScenario Overview SAP Best Practices For DBM V1.600: AB0 - Time RecordingCABUTOTANNo ratings yet

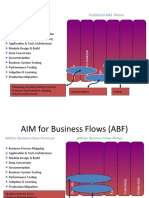

- ABF MethodologyDocument25 pagesABF MethodologyhariraoNo ratings yet

- Manufacturing Planning and Control System FrameworkDocument9 pagesManufacturing Planning and Control System FrameworkFebriaji AjiNo ratings yet

- By: M. Asjad Aamir (2016-ME-10) Umar Imtiaz (2016-ME-11) Naeemullah (2016-ME-12)Document20 pagesBy: M. Asjad Aamir (2016-ME-10) Umar Imtiaz (2016-ME-11) Naeemullah (2016-ME-12)MUHAMMAD ASJAD AAMIR AAMIR AMINNo ratings yet

- Implementing MES in SAP Landscape to Improve Manufacturing OperationsDocument46 pagesImplementing MES in SAP Landscape to Improve Manufacturing Operationsclemen_ang100% (1)

- Day 8 Aggregate Planng Operation SchedulingDocument68 pagesDay 8 Aggregate Planng Operation SchedulingAKSHAY NANGIANo ratings yet

- Actividad B4. Mapa Mental de ConceptosDocument1 pageActividad B4. Mapa Mental de ConceptosEduardo GarcíaNo ratings yet

- 2014 - Curs VerifDocument7 pages2014 - Curs VerifMihaita SmintinaNo ratings yet

- ME8793 - Process Planning and Cost Estimation (Ripped From Amazon Kindle Ebooks by Sai Seena)Document364 pagesME8793 - Process Planning and Cost Estimation (Ripped From Amazon Kindle Ebooks by Sai Seena)Johnson Johnson100% (2)

- Business Process TestingDocument3 pagesBusiness Process TestingSap_Tao_Qtp_Bp_125No ratings yet

- Business Process TestingDocument3 pagesBusiness Process TestingSap_Tao_Qtp_Bp_125No ratings yet

- Business Process TestingDocument3 pagesBusiness Process TestingSap_Tao_Qtp_Bp_125No ratings yet

- Business Process TestingDocument3 pagesBusiness Process TestingSap_Tao_Qtp_Bp_125No ratings yet

- Business Process TestingDocument3 pagesBusiness Process TestingSap_Tao_Qtp_Bp_125No ratings yet

- Business Process TestingDocument3 pagesBusiness Process TestingSap_Tao_Qtp_Bp_125No ratings yet

- BPT TrainingDocument3 pagesBPT TrainingSap_Tao_Qtp_Bp_125No ratings yet

- Smed PDFDocument72 pagesSmed PDFNaveen MalikNo ratings yet

- GEOPLM Siemens PLM Tecnomatix 11 Manufacturing Process Management Fs - tcm1023 207282Document5 pagesGEOPLM Siemens PLM Tecnomatix 11 Manufacturing Process Management Fs - tcm1023 207282behnyaNo ratings yet

- Panaya Test Automation DatasheetDocument4 pagesPanaya Test Automation DatasheetpravalikakaranNo ratings yet

- A Strategy For Performance ExcellenceDocument73 pagesA Strategy For Performance ExcellenceHéctor Eduardo CazotNo ratings yet

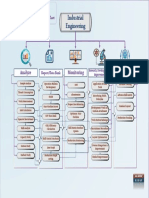

- Industrial Engineering Process Flow ChartDocument1 pageIndustrial Engineering Process Flow ChartImran sarkerNo ratings yet

- HP QC - Test Management ToolDocument21 pagesHP QC - Test Management ToolKrešimir PrekratNo ratings yet

- 8 RELIABILITY WeibulDocument20 pages8 RELIABILITY WeibulFajarKomara100% (1)

- PPIC Production Planning & Inventory ControlDocument27 pagesPPIC Production Planning & Inventory ControlOzora YisraelNo ratings yet

- SAP Cloud ALM Functional OverviewDocument27 pagesSAP Cloud ALM Functional OverviewJoanne CaballesNo ratings yet

- S4 PEO 1809 L2 - July19Document68 pagesS4 PEO 1809 L2 - July19Ramachandrareddy G100% (3)

- Manufacturing Execution Systems (MES)Document21 pagesManufacturing Execution Systems (MES)sudhavelNo ratings yet

- Prototype: Build Review Refine & IterateDocument7 pagesPrototype: Build Review Refine & IterateANILNo ratings yet

- LT Project - CallibrationDocument33 pagesLT Project - Callibrationmangesh chidrawar100% (1)

- Worksoft Process Automation Life Cycle v04252017Document1 pageWorksoft Process Automation Life Cycle v04252017rcanepaNo ratings yet

- Enhancing Safety and Minimizing Corrosion in Refineries Through Process Intelligence ToolsDocument20 pagesEnhancing Safety and Minimizing Corrosion in Refineries Through Process Intelligence Toolspapaya123No ratings yet

- Parts Description Database: Generative CAPP SystemDocument26 pagesParts Description Database: Generative CAPP Systemganesh100% (1)

- 2.4 Capacity PlanningDocument22 pages2.4 Capacity PlanningAlfian Purwanto0% (1)

- A Strategy For Performance ExcellenceDocument73 pagesA Strategy For Performance Excellenceravi.youNo ratings yet

- Wipros Endur Test Automation Framework W EtafDocument6 pagesWipros Endur Test Automation Framework W Etafmr.sharma11No ratings yet

- Ibm Maximo Key Concepts v43Document80 pagesIbm Maximo Key Concepts v43uk4789100% (1)

- ASAPDocument29 pagesASAPgamerboy143No ratings yet

- Fundamentals of Process Plant Design - TrainingDocument110 pagesFundamentals of Process Plant Design - TrainingLisa Malone100% (1)

- 2# Location AnalysisDocument22 pages2# Location AnalysisVikash GathalaNo ratings yet

- Intangible Heritage and The Museum New Perspectives On Cultural PreservationDocument226 pagesIntangible Heritage and The Museum New Perspectives On Cultural PreservationNIKKO ARBILONo ratings yet

- UAP Docs 200-208Document85 pagesUAP Docs 200-208Julia Esquivias-Virtucio60% (5)

- 2015 OrdinanceDocument193 pages2015 Ordinanceglaisa23100% (1)

- 5 - Trends in Library DesignDocument2 pages5 - Trends in Library DesignNIKKO ARBILONo ratings yet

- The Impact of Design On BusinessDocument4 pagesThe Impact of Design On BusinessNIKKO ARBILONo ratings yet

- The Language of ART LectureDocument37 pagesThe Language of ART LectureNIKKO ARBILONo ratings yet