Professional Documents

Culture Documents

Heat Exchanger Data Sheet-English Unit Rev01 PDF

Heat Exchanger Data Sheet-English Unit Rev01 PDF

Uploaded by

12mchc070 ratings0% found this document useful (0 votes)

12 views1 pageOriginal Title

Heat Exchanger Data sheet-English Unit rev01.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageHeat Exchanger Data Sheet-English Unit Rev01 PDF

Heat Exchanger Data Sheet-English Unit Rev01 PDF

Uploaded by

12mchc07Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

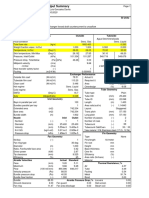

TAG NO.

: EQUIPMENT:

LOCATION: PROJECT:

Practical Engineering Guidelines REV: 01 CLIENT:

for Processing Plant Solutions PAGE 1 OF 1

SERVICE: TOWER CONDENSER INSTALLATION: HORZ

MFR'S SIZE IN ID FT LENGTH MFR'S TYPE: VERT

BATTERIES EACH CONSISTING OF PARALLEL BANKS OF SHELLS IN SERIES INCL

(FT2) PER SHELL SHELLS PER BATTERY (FT2) PER BATTERY

SHELL SIDE TUBE SIDE

FLUID NAME UNITS HC WATER

INLET OUTLET INLET OUTLET

TOTAL FLUID LB/HR

VAPOR LB/HR

LIQUID LB/HR

STEAM LB/HR

WATER LB/HR

NONCONDENSABLES LB/HR

MOLECULAR WEIGHT VAPOR

NONCON

OPERATING T F

OPERATING P PSIG

PHYSICAL PROPERTIES OF VAPOR (INCLUDE STEAM AND NONCONDENSABLES)

THERMAL COND. BTU/HR.FT.F

VISCOSCITY cP

SPECIFIC HEAT BTU/LB.F

DENSITY LB/FT3

PHYSICAL PROPERTIES OF LIQUID (INCLUDES WATER)

THERMAL COND. BTU/HR.FT.F

VISCOSCITY cP

SPECIFIC HEAT BTU/LB.F

DENSITY LB/FT3

LATENT HEAT BTU/LB

DEW PT / BUBBLE PT F

NO. PASSES

VELOCITY FT/S

PRESSURE DROP PSI ALLOW CALC ALLOW CALC

SENSIBLE HEAT MMBTU/H

LATENT HEAT MMBTU/H

TOTAL DUTY MMBTU/H

FILM RATE BTU/FT2.HR.F HO HIO

FOULING FACTOR RO RI

LMTD: F MTD: F U CLEAN U CALC U DESIGN BTU/FT2.HR.F

CONATRUCTION OF ONE SHELL

DESIGN & TEST PRES. PSIG

DESIGN TEMP. F MAX: MIN: MAX: MIN:

TUBES: LENGTH= FT Le= FT

TUBES: TYPE OD= TH'K (AVE) = PITCH= (IN)

SHELL: ID, TH'K = (IN) BAFFLE SPACING C/C INLET (IN)

BAFFLE CROSS: NO.: /SHELL TH'K: TYPE: %CUT

BAFFLE LONG: NO.: /SHELL BAFFLE-DAM: %OF AREA (FT2) IMPING BAFFLE: <Y/N>

RV2: INLET NOZZLE BUNDLE ENTRANCE: BUNDLE EXIT: (LB/FT.S2)

MATERIALS SHELL & COVER . t TUBE . t GASKET SHELL

& THICK FLOAT HEAD COVER . t TUBE SHEET(S) . t GASKET FLOAT HEAD

BAFFLES . t TUBE SHEET(F) . t GASKET CHANNEL

TUBE SUPPORT . t CHANNEL & COVER . t SOACERS & TIE RODS

CORROSION ALLOWANCE:SHELL SIDE TUBE SIDE (IN) STRESS REL.(SR) RADI. (XR)

CODE REQ. TEMA CLASS WEIGHTS: SHELL BUNDLE FULL OF WATER (LB)

NOZZLES SHELL: SIZE & RATING TUBE: SIZE & RATING SKETCH

INLET

OUTLET

INTERMED

DRAIN

VENT

REMARKS:

DATE

PREPARED

REVIEWED

You might also like

- 411 E10AB AdequacyDocument7 pages411 E10AB AdequacyMuhammadUsmanSaeed100% (1)

- Propane Storage TankDocument1 pagePropane Storage TankMarakanaMaheshNo ratings yet

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAnonymous xrBCp9Ej50% (4)

- Loeffler Engineering Group 20511 Highland Lake Drive, Lago Vista, Texas 78645 512-267-8700Document5 pagesLoeffler Engineering Group 20511 Highland Lake Drive, Lago Vista, Texas 78645 512-267-8700mkpasha55mpNo ratings yet

- Datasheet AcDocument9 pagesDatasheet AcMohan VarkeyNo ratings yet

- Reciprocating Compressor Rod Position Rod Drop Whats The DifferenceDocument5 pagesReciprocating Compressor Rod Position Rod Drop Whats The DifferenceMuhd Fadzlee ZNo ratings yet

- TEMA Data SheetDocument2 pagesTEMA Data SheetKarthik AnandanNo ratings yet

- Equipment SizingDocument5 pagesEquipment SizingPandu RockingNo ratings yet

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriNo ratings yet

- Pefd Baru RevisiDocument1 pagePefd Baru RevisiInnes AzizahNo ratings yet

- Diseño Aeroenfriador para Agua Desmineralizada 66 Tubos - 2 PassesDocument25 pagesDiseño Aeroenfriador para Agua Desmineralizada 66 Tubos - 2 PassesLuis AlexanderNo ratings yet

- General Arrangement Drawing: Pump DataDocument1 pageGeneral Arrangement Drawing: Pump DataJwardNo ratings yet

- 761-V-103 (Vessel With Demister), PDFDocument1 page761-V-103 (Vessel With Demister), PDFAlvin SmithNo ratings yet

- Api 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetDocument22 pagesApi 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetmaruthigabbitaNo ratings yet

- Front Matte - 2007 - Ludwig S Applied Process Design For Chemical and Petrochemi PDFDocument1 pageFront Matte - 2007 - Ludwig S Applied Process Design For Chemical and Petrochemi PDFKemal Faza HastadiNo ratings yet

- Reboiler DatasheetDocument6 pagesReboiler DatasheetMIHNo ratings yet

- Hydrofoil - US5297938Document8 pagesHydrofoil - US5297938rwtoorresdNo ratings yet

- Manual PipephaseDocument202 pagesManual PipephaseWil Vasquez CNo ratings yet

- Korf BrochureDocument1 pageKorf Brochurelhphong021191No ratings yet

- 254624-400-DS-PRO-310, Rev F - Datasheet of VRUDocument18 pages254624-400-DS-PRO-310, Rev F - Datasheet of VRURamesh SharmaNo ratings yet

- Demister DatasheetDocument1 pageDemister Datasheetdeion29No ratings yet

- 7-12-0026 Rev6 (Earthing Lug)Document1 page7-12-0026 Rev6 (Earthing Lug)sumit kumarNo ratings yet

- 12 Chaturvedi EIL PresentationDocument12 pages12 Chaturvedi EIL Presentationget2anushNo ratings yet

- DP08 TocDocument1 pageDP08 TocFRANKLIN REVILLANo ratings yet

- Resistance Equivalent LengthDocument3 pagesResistance Equivalent LengthATUL SONAWANENo ratings yet

- Pump Hydraulic CalculationsDocument14 pagesPump Hydraulic CalculationsJosue GonzalezNo ratings yet

- Flare Stack Design PDF ReportDocument2 pagesFlare Stack Design PDF Reportrutuja100% (2)

- 03 EsempiAspenDocument45 pages03 EsempiAspensukanyagggNo ratings yet

- Steam Tracing AppendixDocument13 pagesSteam Tracing AppendixAmin BagheriNo ratings yet

- 3.1 Data From Process Data Sheet: Short Text CF Blower, 530 CFM, Ss316 Contact Part Moc Sr. No. AIL Attributes UOM ValuesDocument1 page3.1 Data From Process Data Sheet: Short Text CF Blower, 530 CFM, Ss316 Contact Part Moc Sr. No. AIL Attributes UOM ValuesBhaumik BhuvaNo ratings yet

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedDocument44 pagesNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelNo ratings yet

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFDocument1 pageFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263No ratings yet

- Pressure Vacuum Breather ValvesDocument4 pagesPressure Vacuum Breather ValvesAdhitya DarmadiNo ratings yet

- Control Valve Data Sheet Form S20 50 PDFDocument4 pagesControl Valve Data Sheet Form S20 50 PDFPanner2009No ratings yet

- PACE Structured Column Packings: Datasheet For Existing ColumnDocument2 pagesPACE Structured Column Packings: Datasheet For Existing ColumnAabbhas GargNo ratings yet

- Manual de Pro IIDocument48 pagesManual de Pro IIMiguel Jiménez FloresNo ratings yet

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocument10 pagesRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1No ratings yet

- Compressor Power CalculatorDocument2 pagesCompressor Power CalculatorLorenzoNo ratings yet

- Physical Property Methods and ModelsDocument436 pagesPhysical Property Methods and Modelstranhoangan100% (1)

- Process Design Data Sheet C-401Document2 pagesProcess Design Data Sheet C-401Tej ChoksiNo ratings yet

- Heat Exchanger Checklist As Per TEMADocument6 pagesHeat Exchanger Checklist As Per TEMAMONANo ratings yet

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BAgus MarpaungNo ratings yet

- ISA SymbolsDocument2 pagesISA Symbolsmahesh009No ratings yet

- Korf Hydraulic ReportDocument10 pagesKorf Hydraulic ReportMuthuKumar ArunachalamNo ratings yet

- Filter CalculationDocument4 pagesFilter CalculationRashmi RanjanNo ratings yet

- Vessel 2 Is To 1 Ellipsoidal VesselDocument3 pagesVessel 2 Is To 1 Ellipsoidal VesselHoang-Vu BuiNo ratings yet

- Linked inDocument47 pagesLinked inProcess GeeksNo ratings yet

- Item Symbol Description: Course No. HEIGHT (M) MaterialDocument12 pagesItem Symbol Description: Course No. HEIGHT (M) MaterialReza SaeeNo ratings yet

- Heat Exchanger Sizing E-5000 #1Document2 pagesHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleNo ratings yet

- Waste Heat Recovery UnitDocument15 pagesWaste Heat Recovery UnitEDUARDONo ratings yet

- Description: Tab L E of Nozzl EsDocument2 pagesDescription: Tab L E of Nozzl EsNehal VaghelaNo ratings yet

- English Unit Spec SheetDocument3 pagesEnglish Unit Spec SheetDanang PrakosaNo ratings yet

- Steam BoilerDocument10 pagesSteam BoilerEDUARDONo ratings yet

- Data Sheet: Description and Site ConditionsDocument2 pagesData Sheet: Description and Site ConditionsEDUARDONo ratings yet

- API Data SheetsDocument7 pagesAPI Data SheetsalfruizpNo ratings yet

- API Datasheet Heat ExchangerDocument4 pagesAPI Datasheet Heat ExchangerSoraya ZahraNo ratings yet

- Design HeatexchangerDocument15 pagesDesign HeatexchangerMayurMahajan100% (1)

- LFG Design 1Document6 pagesLFG Design 1dzari6738No ratings yet

- Fcu Schedule Dubai Inn Port Saeed 19-05-2015Document8 pagesFcu Schedule Dubai Inn Port Saeed 19-05-20152767141No ratings yet

- PE ASME Boiler Initial Report NB-405Document3 pagesPE ASME Boiler Initial Report NB-405Jeanette BeukesNo ratings yet

- Energy Saving System Box-3-HydroCOMDocument8 pagesEnergy Saving System Box-3-HydroCOMMuhd Fadzlee ZNo ratings yet

- Piston LubricationDocument9 pagesPiston LubricationMuhd Fadzlee ZNo ratings yet

- AvailabilityDocument9 pagesAvailabilityMuhd Fadzlee ZNo ratings yet

- KT-23201 Turbine Linkage RecordDocument1 pageKT-23201 Turbine Linkage RecordMuhd Fadzlee ZNo ratings yet

- Introduction To Vibration Problems at Compressor StationsDocument20 pagesIntroduction To Vibration Problems at Compressor StationsMuhd Fadzlee ZNo ratings yet

- P-1809B Mechanical Seal Leak RCFADocument18 pagesP-1809B Mechanical Seal Leak RCFAMuhd Fadzlee Z100% (1)

- RCFA K-23252 Blower Trip Due Motor Overload - FinalDocument19 pagesRCFA K-23252 Blower Trip Due Motor Overload - FinalMuhd Fadzlee ZNo ratings yet

- Failure Analysis of Centrifugal Fan's BearingDocument8 pagesFailure Analysis of Centrifugal Fan's BearingMuhd Fadzlee ZNo ratings yet

- Compressor Surge!!: Muhammad Fadzlee Samsuba HADocument12 pagesCompressor Surge!!: Muhammad Fadzlee Samsuba HAMuhd Fadzlee ZNo ratings yet

- Compressor Oil Carry OverDocument14 pagesCompressor Oil Carry OverMuhd Fadzlee ZNo ratings yet

- PRESSOL SYN RH 32-150-v09-3Document1 pagePRESSOL SYN RH 32-150-v09-3Muhd Fadzlee ZNo ratings yet

- Compressors Selection and SizingDocument2 pagesCompressors Selection and SizingMuhd Fadzlee ZNo ratings yet

- Detecting Premature Bearing FailureDocument4 pagesDetecting Premature Bearing FailureMuhd Fadzlee ZNo ratings yet