Professional Documents

Culture Documents

T700SDataSheet PDF

T700SDataSheet PDF

Uploaded by

Thắng TQ7Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T700SDataSheet PDF

T700SDataSheet PDF

Uploaded by

Thắng TQ7Copyright:

Available Formats

TECHNICAL ®

DATA SHEET

No. CFA-005

T700S DATA SHEET

Highest strength, standard modulus fiber available with excellent processing

characteristics for filament winding and prepreg. This never twisted fiber is used in

high tensile applications like pressure vessels, recreational, and industrial.

F I B E R P R O P E R T I E S

English Metric Test Method

Tensile Strength 711 ksi 4,900 MPa TY-030B-01

Tensile Modulus 33.4 Msi 230 GPa TY-030B-01

Strain 2.1 % 2.1 % TY-030B-01

Density 0.065 lbs/in 3 1.80 g/cm 3 TY-030B-02

Filament Diameter 2.8E-04 in. 7 µm

Yield 6K 3,724 ft/lbs 400 g/1000m TY-030B-03

12K 1,862 ft/lbs 800 g/1000m TY-030B-03

24K 903 ft/lbs 1,650 g/1000m TY-030B-03

Sizing Type 50C 1.0 % TY-030B-05

& Amount 60E 0.3 % TY-030B-05

F0E 0.7 % TY-030B-05

Twist Never twisted

F U N C T I O N A L P R O P E R T I E S

CTE -0.38 α⋅10 -6 /˚C

Specific Heat 0.18 Cal/g⋅˚C

Thermal Conductivity 0.0224 Cal/cm⋅s⋅˚C

Electric Resistivity 1.6 x 10 -3 Ω⋅cm

Chemical Composition: Carbon 93 %

Na + K <50 ppm

C O M P O S I T E P R O P E R T I E S *

Tensile Strength 370 ksi 2,550 MPa ASTM D-3039

Tensile Modulus 20.0 Msi 135 GPa ASTM D-3039

Tensile Strain 1.7 % 1.7 % ASTM D-3039

Compressive Strength 215 ksi 1,470 MPa ASTM D-695

Flexural Strength 245 ksi 1,670 MPa ASTM D-790

Flexural Modulus 17.5 Msi 120 GPa ASTM D-790

ILSS 13 ksi 9 kgf/mm 2 ASTM D-2344

90˚ Tensile Strength 10.0 ksi 69 MPa ASTM D-3039

* To r a y 2 5 0 ˚ F E p o x y R e s i n . N o r m a l i z e d t o 6 0 % f i b e r v o l u m e .

TORAY CARBON FIBERS AMERICA, INC.

T700S

C O M P O S I T E P R O P E R T I E S * *

Tensile Strength 355 ksi 2,450 MPa ASTM D-3039

Tensile Modulus 18.0 Msi 125 GPa ASTM D-3039

Tensile Strain 1.7 % 1.7 % ASTM D-3039

Compressive Strength 230 ksi 1,570 MPa ASTM D-695

Compressive Modulus --- Msi --- GPa ASTM D-695

In-Plane Shear Strength 14 ksi 98 MPa ASTM D-3518

ILSS 15.5 ksi 11 kgf/mm 2 ASTM D-2344

90˚ Tensile Strength 10.0 ksi 70 MPa ASTM D-3039

** Toray Semi-Toughened 350˚F Epoxy Resin. Normalized to 60% fiber volume.

See Section 4 for Safety & Handling information. The above properties do not constitute any warranty or guarantee of values.

These values are for material selection purposes only. For applications requiring guaranteed values, contact our sales and technical team

to establish a material specification document.

P A C K A G I N G

The table below summarizes the tow sizes, twists, sizing types, and packaging available

for standard material. Other bobbin sizes may be available on a limited basis.

Bobbin Spools Case

Tow Net Bobbin Bobbin Size (mm)

per Net

Sizes Twist1 Sizing Weight Type2 Weight

a b c d e Case

(kg) (kg)

6K C 50C 2.0 III 76.5 82.5 280 140 252 12 24

C 50C 6.0 III 76.5 82.5 280 200 252 4 24

12K C 60E 6.0 III 76.5 82.5 280 200 252 4 24

C F0E 6.0 III 76.5 82.5 280 200 252 4 24

C 50C 6.0 III 76.5 82.5 280 200 252 4 24

24K C 60E 6.0 III 76.5 82.5 280 200 252 4 24

C F0E 6.0 III 76.5 82.5 280 200 252 4 24

1 Twist A: Twisted yarn B: Untwisted yarn made from a twisted yarn through an untwisting process C: Never twisted yarn

2 Bobbin Type See Diagram below

T Y P E I T Y P E II T Y P E III

TORAY CARBON FIBERS AMERICA, INC.

6 H u t t o n C e n t r e D r i v e , S u i t e # 1 2 7 0 , S a n t a A n a , C A 9 2 7 0 7 T E L : ( 7 1 4 ) 4 3 1 - 2 3 2 0 FA X : ( 7 1 4 ) 4 2 4 - 0 7 5 0

S a l e s @ To r a y c f a . c o m Te c h n i c a l @ To r a y c f a . c o m w w w . t o r a y u s a . c o m

You might also like

- Babaji - The Lightning Standing Still PDFDocument17 pagesBabaji - The Lightning Standing Still PDFpraveen kumarNo ratings yet

- Strapping, Nonmetallic (And Joining Methods) : Standard Specification ForDocument9 pagesStrapping, Nonmetallic (And Joining Methods) : Standard Specification ForAlevj DbNo ratings yet

- Torques PDFDocument2 pagesTorques PDFarmin_fernandez75% (4)

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresFrom EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresRating: 5 out of 5 stars5/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- SOPDocument3 pagesSOPprasadmehta80% (5)

- Prasad SOPDocument3 pagesPrasad SOPprasadmehta100% (1)

- CSETI Project PDFDocument59 pagesCSETI Project PDFAlejandro SanchezNo ratings yet

- Antamount: Vishay SpragueDocument22 pagesAntamount: Vishay SpraguemohamedNo ratings yet

- Collar EyeBolt To BS4278 Table 1Document9 pagesCollar EyeBolt To BS4278 Table 1Rajesh N Priya GopinathanNo ratings yet

- CIR CatalogDocument12 pagesCIR Catalogchaupha1No ratings yet

- Bushman C HookDocument2 pagesBushman C Hookperdhana2000100% (1)

- R&M Brouchure-Nov 21 2013Document6 pagesR&M Brouchure-Nov 21 2013Okan KöksalNo ratings yet

- Securing Straps & RatchetsDocument2 pagesSecuring Straps & RatchetsKhurram S. MuzammilNo ratings yet

- Cable TSJ y TSJ-N PDFDocument4 pagesCable TSJ y TSJ-N PDFmakv12100% (1)

- Cabaccat2012k RITZDocument28 pagesCabaccat2012k RITZKosong SudahanNo ratings yet

- Our Mission: The Coax LeaderDocument3 pagesOur Mission: The Coax LeaderArindam BanerjeeNo ratings yet

- CA IndustrialDocument55 pagesCA IndustrialTimon2005No ratings yet

- All-Purpose Chain & Fittings Guarante Ed To Make The Right ConnectionDocument8 pagesAll-Purpose Chain & Fittings Guarante Ed To Make The Right ConnectionHong Chee FongNo ratings yet

- Jetweigh5 PDFDocument3 pagesJetweigh5 PDFTihomir ZrinščakNo ratings yet

- Power Stream Couplings-Specn SheetsDocument6 pagesPower Stream Couplings-Specn SheetsAmol PatkiNo ratings yet

- 8 t2 SC SeriesDocument16 pages8 t2 SC SeriesAntony VeNo ratings yet

- Type 501 453 UniversalDocument1 pageType 501 453 Universalrambala123No ratings yet

- RMCable AccessoriesDocument16 pagesRMCable AccessoriesvajiravjNo ratings yet

- Vishay Roederstein: L Max. WDocument12 pagesVishay Roederstein: L Max. Wdrs22No ratings yet

- LandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Document3 pagesLandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- Nuhas BrochureDocument71 pagesNuhas BrochuremealysrNo ratings yet

- 497 Airfield LightingDocument4 pages497 Airfield LightingmolgarNo ratings yet

- Sieve Sizes ASTM E 11Document5 pagesSieve Sizes ASTM E 11RigobertoGuerraNo ratings yet

- Mangas PDFDocument14 pagesMangas PDFluisfer811No ratings yet

- P6 Limit SwitchDocument3 pagesP6 Limit SwitchABCdude1No ratings yet

- Gall5231328512232fip PDFDocument15 pagesGall5231328512232fip PDFAndres CortezNo ratings yet

- 1 SMD Fuse Marking Code 32Document7 pages1 SMD Fuse Marking Code 32rohitsingh2909No ratings yet

- Anixter TECK Control CablesDocument2 pagesAnixter TECK Control CablesAnonymous KsH6a0JNo ratings yet

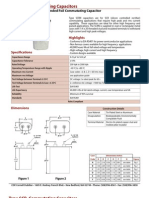

- Specifications: Type SCRN Film-Paper/Extended Foil Commutating CapacitorDocument4 pagesSpecifications: Type SCRN Film-Paper/Extended Foil Commutating CapacitorCheranjeevi ChiruNo ratings yet

- LocDocument2 pagesLocCarlso Andres GuerreroNo ratings yet

- For Harsh and Hazardous Locations: Exe EnclosuresDocument79 pagesFor Harsh and Hazardous Locations: Exe EnclosuresSimon LyonNo ratings yet

- CTRLDocument57 pagesCTRLpbontyNo ratings yet

- Cat-CMP Cable GlandDocument64 pagesCat-CMP Cable GlandSyahirul Alim100% (1)

- Swan Neck HookDocument11 pagesSwan Neck HookKhaled SalemNo ratings yet

- Structural Bolting GuideDocument24 pagesStructural Bolting GuideJoseph BookerNo ratings yet

- Example Vessel Re RatingDocument9 pagesExample Vessel Re RatingRBKUMARNo ratings yet

- Master Building WiresDocument14 pagesMaster Building Wireskrishnan_88No ratings yet

- BAT Series BatteriesDocument2 pagesBAT Series BatteriesReginald D. De GuzmanNo ratings yet

- Tapping Screw Performance Specifications: Greenslade & Company, IncDocument22 pagesTapping Screw Performance Specifications: Greenslade & Company, Inco_l_0No ratings yet

- Kem A4003 ExvDocument16 pagesKem A4003 ExvAndrzej GomulaNo ratings yet

- Garlock Gasket Tech Manual GSK3 1 EmpaquetaduraDocument57 pagesGarlock Gasket Tech Manual GSK3 1 EmpaquetaduraJavier AndrésNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Cilpsal Ti Series Part 1Document29 pagesCilpsal Ti Series Part 1Meor SyaediNo ratings yet

- Data KapasitorDocument7 pagesData KapasitorMuhammad Ardi AnggaraNo ratings yet

- ASTM E 11-01 Standard Specification For Wire Cloth and Sieves For Testing PurposesDocument5 pagesASTM E 11-01 Standard Specification For Wire Cloth and Sieves For Testing PurposesPablo Antonio Valcárcel VargasNo ratings yet

- Cable Glands Technical InformationDocument16 pagesCable Glands Technical Informations_hassan_167419No ratings yet

- 501 453 RacDocument1 page501 453 RacJacqueline AdamsNo ratings yet

- EMMVEE On-Grid Data Sheet Revised 2014Document2 pagesEMMVEE On-Grid Data Sheet Revised 2014pradeepq100% (1)

- Is 3063-Spring WashersDocument11 pagesIs 3063-Spring Washerspbp2956No ratings yet

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- Viking Extended Coverage Quick Respons SidewallDocument6 pagesViking Extended Coverage Quick Respons SidewallguspriyNo ratings yet

- EPR 5KV 100% y 133%Document2 pagesEPR 5KV 100% y 133%ssimental71No ratings yet

- TB 00700001 eDocument9 pagesTB 00700001 eRicardo LopezNo ratings yet

- ENG DS OMI 2 Pole Series Relay Data Sheet E 0411Document3 pagesENG DS OMI 2 Pole Series Relay Data Sheet E 0411letterniNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Handloader's Digest: The World's Greatest Handloading BookFrom EverandHandloader's Digest: The World's Greatest Handloading BookRating: 2 out of 5 stars2/5 (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Carbon Fiber MaterialDocument119 pagesCarbon Fiber MaterialprasadmehtaNo ratings yet

- Mat 024 TheoryDocument2 pagesMat 024 TheoryprasadmehtaNo ratings yet

- WP3.3 033051 095Document93 pagesWP3.3 033051 095prasadmehtaNo ratings yet

- Dynamic Color Tuning With Electrochemically Actuated TiO2Document7 pagesDynamic Color Tuning With Electrochemically Actuated TiO2Basudeb SainNo ratings yet

- A Short Guide To Anyons and Modular Functors: Abc D Ab CDocument16 pagesA Short Guide To Anyons and Modular Functors: Abc D Ab Cfarsad ahmadNo ratings yet

- Roving FrameDocument4 pagesRoving FrameShailendra MishraNo ratings yet

- L13 070314Document10 pagesL13 070314Srikanth BatnaNo ratings yet

- Solution Manual For Mathematical Proofs A Transition To Advanced Mathematics 3 e 3rd Edition Gary Chartrand Albert D Polimeni Ping ZhangDocument17 pagesSolution Manual For Mathematical Proofs A Transition To Advanced Mathematics 3 e 3rd Edition Gary Chartrand Albert D Polimeni Ping ZhangChristopherRamosfgzo100% (39)

- Racetrack Memory Based Reconfigurable ComputingDocument4 pagesRacetrack Memory Based Reconfigurable ComputingAnonymous 9Yv6n5qvSNo ratings yet

- E1239Document11 pagesE1239LLNo ratings yet

- Identifying Computer Hardware ProblemsDocument10 pagesIdentifying Computer Hardware ProblemsOzkr RodzNo ratings yet

- Quiz-5 - Geography Questions Asked in UPSC, APPSC & Other PSC ExamsDocument13 pagesQuiz-5 - Geography Questions Asked in UPSC, APPSC & Other PSC ExamsCharan Reddy100% (1)

- A Seminar Presentation On Wireless Power Transmission Via Solar Power SatellitesDocument26 pagesA Seminar Presentation On Wireless Power Transmission Via Solar Power SatellitesASHWIN KUMAR YADAVNo ratings yet

- T80Document4 pagesT80Rashid AzizNo ratings yet

- Accidental Eccentricity: Manual ImplementationDocument1 pageAccidental Eccentricity: Manual ImplementationxicmenNo ratings yet

- Sumi Mini Tools Catalog LRDocument262 pagesSumi Mini Tools Catalog LRWilson DantasNo ratings yet

- Systemair CatalogueDocument21 pagesSystemair CataloguePARVEZ AMEENNo ratings yet

- Tabel Baja KanalDocument4 pagesTabel Baja KanalMuhammad ThirafiNo ratings yet

- Physics: Final Syllabus For NEET-UGDocument8 pagesPhysics: Final Syllabus For NEET-UGVansh SainiNo ratings yet

- Ei 1001 Fibre Optics and Laser Instruments 3 0 0 100Document2 pagesEi 1001 Fibre Optics and Laser Instruments 3 0 0 100Hari KumarNo ratings yet

- Online Class - XII/2077Document9 pagesOnline Class - XII/2077zoomNo ratings yet

- Developer's Note On Quantum EspressoDocument39 pagesDeveloper's Note On Quantum EspressoMatsushima KhodaijiNo ratings yet

- Ejma 8TDocument3 pagesEjma 8TpiziyuNo ratings yet

- 1953 Glacier Variations and Climatic Fluctuations - BY H. W.son AHLMANNDocument76 pages1953 Glacier Variations and Climatic Fluctuations - BY H. W.son AHLMANNKnut LunsenNo ratings yet

- Wind Load CalcsDocument10 pagesWind Load CalcsUmange RanasingheNo ratings yet

- 6ra80 Mit Motoren Parallel Oder Seriell 76Document3 pages6ra80 Mit Motoren Parallel Oder Seriell 76pwmvsiNo ratings yet

- On The Use of Two Versions of Theforce Concept Inventory To Testconceptual Understanding Ofmechanics 4207Document12 pagesOn The Use of Two Versions of Theforce Concept Inventory To Testconceptual Understanding Ofmechanics 4207Mohamed AnsarNo ratings yet

- Review Sheet-Exam 1 - 21, 22, 23, 24Document12 pagesReview Sheet-Exam 1 - 21, 22, 23, 24Desiree WilliamsNo ratings yet

- Ddec Iv Egr DescriptionsDocument5 pagesDdec Iv Egr DescriptionsBJNo ratings yet

- Phased Array AntennaDocument24 pagesPhased Array AntennaPranabKumarGoswamiNo ratings yet

- Distance Based ModelsDocument58 pagesDistance Based ModelsShivam ChadhaNo ratings yet