Professional Documents

Culture Documents

Portland Cement ASTM C 150 - 994179184395419179.pdf - 4

Uploaded by

Bayu AmartaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Portland Cement ASTM C 150 - 994179184395419179.pdf - 4

Uploaded by

Bayu AmartaCopyright:

Available Formats

C 150 – 07

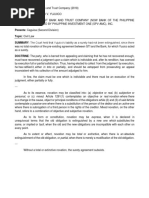

TABLE 4 Optional Physical RequirementsA

Cement Type Applicable I IA II IIA III IIIA IV V

Test Method

False set, final penetration, min, % C 451 50 50 50 50 50 50 50 50

Heat of hydration: C 186

7 days, max, kJ/kg (cal/g) ... ... 290 (70)B 290 (70)B ... ... 250 (60)C ...

28 days, max, kJ/kg (cal/g) ... ... ... ... ... ... 290 (70)C ...

Strength, not less than the values shown:

Compressive strength, MPa (psi) C 109/

C 109M

28 days 28.0 22.0 28.0 22.0 ... ... ... ...

(4060) (3190) (4060) (3190)

22.0B 18.0B

(3190)B (2610)B

Sulfate resistance,D 14 days, max, % expansion C 452 ... ... ...E ...E ... ... ... 0.040

Gillmore test: C 266

Initial set, min, not less than 60 60 60 60 60 60 60 60

Final set, min, not more than 600 600 600 600 600 600 600 600

A

These optional requirements apply only when specifically requested. Verify availability before ordering. See Note 2.

B

The limit for the sum of C3S + 4.75C3A in Table 1 shall not apply when this optional limit is requested. These strength requirements apply when the optional heat of

hydration requirement is requested.

C

When the heat of hydration limit is specified, it shall be instead of the limits of C3S, C2S, C3A, and Fe2O3 listed in Table 1.

D

When the sulfate resistance is specified, it shall be instead of the limits of C3A, C4AF + 2 C3A, and Fe2O3 listed in Table 1.

E

Cement meeting the high sulfate resistance limit for Type V is deemed to meet the moderate sulfate resistance requirement of Type II.

9.1.11 Sulfate Resistance—Test Method C 452 (sulfate ex- shall supply comparative test data on chemical and physical

pansion). properties of the cement with and without the limestone (See

9.1.12 Calcium Sulfate (expansion of) Mortar—Test Note 5). The comparative tests do not supersede the normal

Method C 1038. testing to confirm that the cement meets chemical and physical

9.1.13 Optimum SO3—Test Method C 563. requirements of this standard. The amount of limestone in

cement shall be determined in accordance with Annex A2.

10. Inspection

NOTE 5—Comparative test data may be from qualification tests per-

10.1 Inspection of the material shall be made as agreed upon formed by the manufacturer during formulation of the cement with

between the purchaser and the seller as part of the purchase limestone.

contract.

13. Packaging and Package Marking

11. Rejection 13.1 When the cement is delivered in packages, the words

11.1 The cement shall be rejected if it fails to meet any of “Portland Cement,” the type of cement, the name and brand of

the requirements of this specification. the manufacturer, and the mass of the cement contained therein

11.2 At the option of the purchaser, retest, before using, shall be plainly marked on each package. When the cement is

cement remaining in bulk storage for more than 6 months or an air-entraining type, the words “air-entraining” shall be

cement in bags in local storage in the custody of a vendor for plainly marked on each package. Similar information shall be

more than 3 months after completion of tests and reject the provided in the shipping documents accompanying the ship-

cement if it fails to conform to any of the requirements of this ment of packaged or bulk cement. All packages shall be in

specification. Cement so rejected shall be the responsibility of good condition at the time of inspection.

the owner of record at the time of resampling for retest. NOTE 6—With the change to SI units, it is desirable to establish a

11.3 Packages shall identify the mass contained as net standard SI package for portland cements. To that end 42 kg (92.6 lb)

weight. At the option of the purchaser, packages more than 2 % provides a convenient, even-numbered mass reasonably similar to the

traditional 94-lb (42.6-kg) package.

below the mass marked thereon shall be rejected and if the

average mass of packages in any shipment, as shown by 14. Storage

determining the mass of 50 packages selected at random, is less 14.1 The cement shall be stored in such a manner as to

than that marked on the packages, the entire shipment shall be permit easy access for proper inspection and identification of

rejected. each shipment, and in a suitable weather-tight building that

will protect the cement from dampness and minimize ware-

12. Manufacturer’s Statement

house set.

12.1 At the request of the purchaser, the manufacturer shall

state in writing the nature, amount, and identity of any 15. Manufacturer’s Certification

air-entraining addition and of any processing addition used, 15.1 Upon request of the purchaser in the contract or order,

and also, if requested, shall supply test data showing compli- a manufacturer’s report shall be furnished at the time of

ance of such air-entraining addition with Specification C 226 shipment stating the results of tests made on samples of the

and of such processing addition with Specification C 465. material taken during production or transfer and certifying that

12.2 When limestone is used, the manufacturer shall state in the cement conforms to applicable requirements of this speci-

writing the amount thereof and, if requested by the purchaser, fication.

--``,,,,``,````````,,`,``,`,`-`-`,,`,,`,`,,`---

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=Purdue University/5923082001

No reproduction or networking permitted without license from IHS Not for Resale, 05/06/2008 13:32:45 MDT

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Letter of Intent LOI TemplateDocument4 pagesLetter of Intent LOI Templatew_fib100% (1)

- The Swot of Taco BellDocument2 pagesThe Swot of Taco BellJennyfer PaizNo ratings yet

- Critically Discuss The Extent of Directors Duties and The Changes Made by The Companies Act 2006Document14 pagesCritically Discuss The Extent of Directors Duties and The Changes Made by The Companies Act 2006Lingru WenNo ratings yet

- Portland Cement ASTM C 150 - 994179184395419179.pdf - 3Document1 pagePortland Cement ASTM C 150 - 994179184395419179.pdf - 3Bayu AmartaNo ratings yet

- Portland Cement ASTM C 150 - 994179184395419179.pdf - 5Document1 pagePortland Cement ASTM C 150 - 994179184395419179.pdf - 5Bayu AmartaNo ratings yet

- g992 8803120702750081391.pdf 6 PDFDocument1 pageg992 8803120702750081391.pdf 6 PDFBayu AmartaNo ratings yet

- Portland Cement ASTM C 150 - 994179184395419179.pdf - 2Document1 pagePortland Cement ASTM C 150 - 994179184395419179.pdf - 2Bayu AmartaNo ratings yet

- g992 8803120702750081391.pdf 6 PDFDocument1 pageg992 8803120702750081391.pdf 6 PDFBayu AmartaNo ratings yet

- Portland Cement: Standard Specification ForDocument1 pagePortland Cement: Standard Specification ForBayu AmartaNo ratings yet

- g992 8803120702750081391.pdf 3Document1 pageg992 8803120702750081391.pdf 3Bayu AmartaNo ratings yet

- Calculation and Reporting: N 3-Rough Surfaces Make Wear Scar Measurement DifficultDocument1 pageCalculation and Reporting: N 3-Rough Surfaces Make Wear Scar Measurement DifficultBayu AmartaNo ratings yet

- g992 8803120702750081391.pdf 6 PDFDocument1 pageg992 8803120702750081391.pdf 6 PDFBayu AmartaNo ratings yet

- g992 8803120702750081391.pdf 1Document1 pageg992 8803120702750081391.pdf 1Bayu AmartaNo ratings yet

- TABLE 1 Characteristics of The Interlaboratory Wear Test SpecimensDocument1 pageTABLE 1 Characteristics of The Interlaboratory Wear Test SpecimensBayu AmartaNo ratings yet

- Astm g99 95aDocument6 pagesAstm g99 95aSuraj Rarath0% (1)

- 01 Ultimos Desarrollos PDFDocument36 pages01 Ultimos Desarrollos PDFrajmagiNo ratings yet

- VIVADocument16 pagesVIVASakshiShineNo ratings yet

- SAP SD Interview Questions: Rajendra BabuDocument4 pagesSAP SD Interview Questions: Rajendra Babusyed hyder ALINo ratings yet

- 10 Steps To Starting A Business in Ho Chi Minh CityDocument5 pages10 Steps To Starting A Business in Ho Chi Minh CityRahul PatilNo ratings yet

- Sparsh Gupta AprDocument4 pagesSparsh Gupta Aprshivamtyagihpr001No ratings yet

- Business CombinationDocument20 pagesBusiness CombinationabhaybittuNo ratings yet

- New 7 QC ToolsDocument106 pagesNew 7 QC ToolsRajesh SahasrabuddheNo ratings yet

- Customer Loyalty AttributesDocument25 pagesCustomer Loyalty Attributesmr_gelda6183No ratings yet

- AideD&D n5 Basse-Tour (Suite Pour Un Diamant)Document7 pagesAideD&D n5 Basse-Tour (Suite Pour Un Diamant)Etan KrelNo ratings yet

- A Study On Customer Preference Towards Heavy Commercial Vehicle-3145 PDFDocument6 pagesA Study On Customer Preference Towards Heavy Commercial Vehicle-3145 PDFAkash DasNo ratings yet

- Tank+Calibration OP 0113 WebsiteDocument2 pagesTank+Calibration OP 0113 WebsiteMohamed FouadNo ratings yet

- Internship ReportDocument20 pagesInternship ReportbumbumpingNo ratings yet

- Upload 1 - Heirs of Tan Eng Kee v. CADocument4 pagesUpload 1 - Heirs of Tan Eng Kee v. CAPatricia VillamilNo ratings yet

- Project On Max Life InsuranseDocument48 pagesProject On Max Life InsuranseSumit PatelNo ratings yet

- Work Instruction For Bin Management (From Customer) : Doc#: Issue No./Dt:01/10-10-18 Rev No./DtDocument3 pagesWork Instruction For Bin Management (From Customer) : Doc#: Issue No./Dt:01/10-10-18 Rev No./Dtyathish babu M ANo ratings yet

- Chocolate Industry Final Case AnalysisDocument10 pagesChocolate Industry Final Case AnalysisSadia SaeedNo ratings yet

- Sales Flow Chart 2019Document2 pagesSales Flow Chart 2019grace hutallaNo ratings yet

- Set 5Document21 pagesSet 5Ako Si Paula MonghitNo ratings yet

- Ready To Eat Food DM20204Document18 pagesReady To Eat Food DM20204Akai GargNo ratings yet

- Service Inventory & Service Supply RelationshipsDocument46 pagesService Inventory & Service Supply RelationshipsSuraj JayNo ratings yet

- Solutions ArtLog Edition9Document15 pagesSolutions ArtLog Edition9scottstellNo ratings yet

- Strategic Management Nokia Case AnalysisDocument10 pagesStrategic Management Nokia Case Analysisbtamilarasan88100% (1)

- SBI ProjectDocument82 pagesSBI Projectchandan sharmaNo ratings yet

- Heller - Sues - GT Heller V Greenberg TraurigDocument45 pagesHeller - Sues - GT Heller V Greenberg TraurigRandy PotterNo ratings yet

- Maruti Car ManufactureDocument37 pagesMaruti Car ManufactureVema AbhiramNo ratings yet

- Pledge, REM, Antichresis DigestsDocument43 pagesPledge, REM, Antichresis DigestsAnonymous fnlSh4KHIgNo ratings yet

- Aplicatie Practica Catapulta TUVDocument26 pagesAplicatie Practica Catapulta TUVwalaNo ratings yet

- Yujuico vs. Far East Bank and Trust Company DigestDocument4 pagesYujuico vs. Far East Bank and Trust Company DigestEmir MendozaNo ratings yet