Professional Documents

Culture Documents

Method Statement - Cross Hole Sonic Test

Uploaded by

Indra Nath Mishra0 ratings0% found this document useful (0 votes)

217 views11 pagesMethod Statement - Cross Hole Sonic Test

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMethod Statement - Cross Hole Sonic Test

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

217 views11 pagesMethod Statement - Cross Hole Sonic Test

Uploaded by

Indra Nath MishraMethod Statement - Cross Hole Sonic Test

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

“Anand”, 49, Atmajyot Nagar Society, Near Atmalyotl Ashram, Ellora Park,

Vadodara - 380 023. INDIA. Tolofax : +91-265-2388139, 2393205.

E-mail: info@goodynamics.not, Website : ww.goodynamics. net

gd GEO DYNAMICS

METHOD STATEMENT FOR CROSS HOLE SONIC LOGGING TESTING FOR

‘1500MM, 200MM AND 2200MM DIAMETER BORED PILES

CONTRACTOR =: M/S. L&T CONSTRUCTION

PROJECT 1 MTHL PROJECT

TESTING COMPANY: M/S, GEO DYNAMICS

Objective:

The objective of the testing is to conduct cross hole sonic logging tests on pile foundations at

the above project as per ASTM 6760 - 08. Here one transmitter and one receiver is lowered in

the pile shaft through access pipes and then pulled at a reasonably constant rato to

continuously record the artival time of pulses between the probes and also record the loss of

‘energy during transmission, as the probes are drawn up from the bottom to the top of the pile.

This is a quallty assurance program to ensure that the pile shatt is formed properly and is of

targeted depth. The purpose of this test is to check the structural integrity, extent & location of

defects & quality of concrete, between pairs of mild steel pipes pre-installed in cast-in-situ bored

pile.

Responsibility of Contractor & Testing Agency :

The contractor shall permanently install access pipes placed with the main reinforcement inside

the reinforcement cage all through the pile depth and cast the pile with the tubes intact, as

explained in this method statemont, It is the responsibility of the contractor to ensure the verticality

of the access tubes & unobstructed passage of the probes through access tubes. The contractor

shall fi water inside the pipes before or immediately within 2 hrs of concreting without

any leakage of wate

The testing agency will conduct the actual Test, Interpret & Analyse the test data and furnish

recommendation for each individual pile tested.

Expert Agency to Perform the Test :

Contractor shall engage an Expert Agency of national repute and shall be approved by Client to

conduct the test, The testing agency shall be experienced independent entity with at least fifteen

years experience in non destructive testing of pile foundations (low strain and high strain) and a

minimum of 5 years documented experience in cross hole sonic logging tests. The agency should

also be able to prove its competence by submitting past studies and expertise, Performanoe

certificates for completed projects shall be submitted. The projects shall be completed at least 3

years ago. Demonstration of case studies/correlation between CSL and HSDPT or PIT will be

referred. CV of the personnel monitoring the test shall be submitted before performing the test.

MUMBAI € DELHI ® VADODARA® CHENNAI ® KOLKATA ® KOCH!

Rogd. Office : 4, Ravideop Society, Near Atmajyoti Ashram, Ellora Park, Vadodara - 380 023. INDIA. Tol. : 0265 - 2300613,

Anand’, 49, Almajyoti Nagar Socioty, Near Atmaiyoti Ashram, Ellora Park,

Vadodara - 390 023. INDIA. Tolofax : +91-265-2388139, 2303205,

E-mail: Info@geodynamics.nel, Webs : www. gaodynamics.not

ga GEO DYNAMICS

Testing Program +

‘As, itis of utmost importance to have complete control of concrete work belng done at site on a

realtime basis, itis important to have the CSL tests done as early as possible after concreting (no

sooner than 5 ~ 7 days). This will help in understanding the quality of workmanship of the team at

an early stage of construction and also the actions to be taken in case defects are found. These

tesis should be conducted by an independent specialist even though the contractor may have his

‘own capabiltios to conduct the test. The specialist should have adequate experiance in work such

that he is in a position to understand the reason of defects, if any.

Preparation for the test. =

‘The number of pipes installed for the 1 ASTM 6760 It In th

contract specifications. In general one pipe is installed for every som dametr of pie, Thus 4,

i i 5 1.5m, whereas 6 pipes shall be installed for 2.0m and 2.0m

The pipes for CSL testing shall be placed inside the pile by tying them to the cage as per sketch

described at the end of this method statement. The pipes shall be minimum 38mm to 60mm

intemal diameter and shall be of Miki Steel (MS). These pipes shall extend at full length along the

pple and also long enough to protrude about 300 mm above the working platform lavel. These

pipes shall be closed at both the ends by caps to prevent the possible entry of soil or concrete.

For MS pipes, if longer pipes are not avallable, then welding of plpes should be avoided and

couplers shall be used or pipe shall be joined by threaded sockeis or with a push fit technology.

‘The thiokness of MS pipes shall be as per contract specifications or as mentioned in ASTM

6760.

However, contract specifications (if mentioned) shall govern the selection and thickness of pipes

and the number of pipes.

MS pipos shall be tied at every 300mm along the length of the cage to avoid bending or damage.

MS pipes can be welded or tied using steel wire. To avoid debonding of access tubes due to

differential temperatures, the access pipes shall be filed up with water while lowering or

immediately after concreting. It shall be checked thal there is no water leakage through the pipes

and it will remain water filled all through, as the test will be conducted in that condition by the

testing agency. The contractor will be responsible for proper installation of these pipes and its

maintenance tll the tests are over.

Equipment:

‘The equipment used for testing shall be manufactured by Pile Dynamics, Inc., based in USA or

equivalent. A transmitter sending not less than one pulse per second (or one pulse per 50mm

depth interval) with a sampling frequency of not less than 250 kHz, a compatible receiver and a

sultable computer for control, measurement and recording functions. All components shall be in

good working order. Details of equipment mentioning its model and probe diameter etc shall be

Submitted to the main client for prior approval.

MUMBAI ¢ DELHI 8 VADODARA® CHENNAI ® KOLKATA® KOCHI

Rogd. Office ; 1, Ravideep Soctoty, Near Atmajyoli Ashram, Ellora Park, Vadodera - 390 023, INDIA. Tel. : 0265 - 2990513.

“Anand”, 49, Almejyot! Nagar Society, Noar Atmajyoti Ashram, Ellora Park,

Vadodara - 390 023, INDIA. Telefax : +91-265-2388139, 2383205,

E-mail : info@goodynamics.not, Website : www.goodynamios.net

gd GEO DYNAMICS

Preparations:

Before commencing the test, the Contractor shall ensure that there is adequate access to the

pipes. The Contractor shall then open the top of the pipes and ensure, with an approved dummy

probs having a length of 800 mm and diameter of 25 mm, that the pipes are straight and free of

obstacles throughout its length. The Contractor shall Keep them full of water until all testing on site

is concluded,

Testing Method:

Testing stall consist of Inserting the probes Ini to pipes ofthe plo ushg a pully with a dopth

encoder. wh

obiained if 6 pes are installed, Tho probes shall So ao Brought aus cele

level, activated and then pulled back with arrival times versus depth continuously recorded.

Optionally, data can be collected while lowering the probes from the top. The output for all tests

shall clearly identify the project, pile designation, date, time, depth scale, defect if any and all

other relevant information. Readings shall be obtained for First Arrival Times (FAT), Energy and

Wave speed.

Reporting :

‘A final report for each testing stage shall be presented not later than 7 (seven) working days after

completion of that stage. The report shall consist of a printout of the original output, as well as a

summary table for every pile tested, the depth and the Engineers! interpretation regarding ts

integrity.

Posttest Activity :

Alter completion of the CSL testing & after the acceptance of the pile by the main client, the

contractor shall fill the access tubes with cement sand grout & seal.

CSLresults :

Results of the CSL shall be presented in a written report within seven working days of completion

of testing. The report shall include presentation of CSL logs for all tested pipe shaft pairs

including:

1. Presentation of the traditional nested signal peak (e.g. ‘waterfall”) diagram as a function

of time plotted versus depth.

2. Computed pulse first arrival ime (FAT) or pulse wave speed versus depth.

3. Computed relative pulse energy or amplitude versus depth.

Defects for any of the logs shall be included in the report.

MUMBA DELHI ® VADODARA® CHENNAI © KOLKATA @ KOCHI

Rogd. Oifice : 1, Ravideop Society, Near Atmalyoll Ashram, Eilora Park, Vadodara - 390 023. INDIA. Tol, : 0265- 2390513.

|

"Anand, 49, Almajyoti Nagar Socioty, Near Atmajyot! Ashram, Ellora Park,

‘Vadodara - 390 023, INDIA, Tolofax ; +91-265-2388139, 2303205.

E-mail :info@geodynamics.net, WebsRe : vww.geadynamics.not

gd GEO DYNAMICS

INTERPRETATION OF RESULTS:

By sending ultrasonic pulse through concrete from one probe to another, the CSL procedure

inspects the pile's structural integrity, extent and location of defects, if any. At the receiver probe,

pulse arrival time and signal strength are affected by the quality of conorete. Uniform concrete

yields consistent first arrival times (FAT) with reasonable pulse wave speed and signal strengths.

Non-uniformities such as contamination, soft concrete, and honeycombing, voids, or Inclusions

exhibit delayed arrival times (FAT) with reduced signal strength.

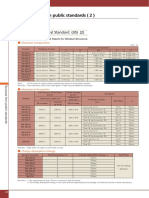

Typically the following classttication will explains interpretation of defects in the pile. Here, the

rating of the integrity considers the increases in “first arrival time" (FAT) and the energy reduction

relative to the arrival time or energy in a nearby zone of goad concrete.

: Energy reduelion

Classification FAT Inctease relative to | To RYelto good

good concrete eee

Satisfactory / Good 0-10% <6db

Minor Defect 11-20% <9do

PoorFlaw 21 to 3076 291012

Poor/Defedt 331% >12

‘The wave speed obtained is a useful tool to evaluate concrete quality. However, ifthe holes are

not truly plumb or even parallel, a fixed absolute limit of a wave speed value cannot many times

bo used for evaluation for perimeter proflloe. Wave epood le best determined from the test reeulte

from the major diagonals. The wave speed is also affected by age of concrete, plumb of the

holes, reinforcement if any between the holes and hence many times the energy is considered a

more important parameter in evaluating the results.

‘Schematic of pipes installed for CSL for 4 & 6 pipes

MUMBAI ¢ DELHI # VADODARA® CHENNAI ® KOLKATA ® KOCHI

Rogd. Office : 1, Ravidesp Socioty, Near Atmalyoti Ashram, Ellora Park, Vadadar

390 023. INDIA. Tol. : 0265 - 2390513.

GEO DYNAMICS

“Anand”, 49, Atmajyoli Nagar Sociely, Noar Atmajyoti Ashram, Ellora Park,

Vadodara - 390 023, INDIA. Tolofax:: +91-266-2368139, 2893205,

E-mail ; info@goodynamics.net, Website : www.geodynamics.not

METHOD LIMITATIONS

1. The method tells about integrity only inside the reinforcement cage and does not tell any

potential loss in concrate cover.

2. Itis very important that water is filled inside the tubes prior to concreting or immadietely

after concreting within 2 hours. i tis is not done, than loss of bond between concrete and

steel may occur commonly known as debonding. This may result in loss of signal and

‘show a potential defect when it may not be a defect.

MUMBAI @ DELHI @ VADODARA® CHENNAI @ KOLKATA @ KOCHI

Regs. Office : 4, Ravidoep Socialy, Near Atmajyotl Ashram, Ellora Park, Vadodara - 390 023, INDIA, Tel, : 0265 - 2390513.

Areas of Expertise

NDI of Pile Hoanations

NDT of Superstractues

Wave Theory

Years of Experience

With Geo Dynamics: 20 Years

Wich Other Bitms: 4 Years

Education

MLE. / 1994 / Structural

Engineering / Univecsity of Baroda

/ 1991 / Civil Engineering /

‘of Baroda

GEO DYNAMICS

AN ISO 9001-2008 Company

Ravikiran R. Vaidya, M.E.

Principal

Overview

Me, Vaidya is the owner of a nationally acclaimed company in NDT of

Pile Foundations & Inrgest in India. He is zesponsible for making the

technology of Non Destructive Testing of Pile Foundations popular in

India resulting in huge benefits to the construction industry. He has

introduced Non Destructive Testing of Pile Foundations on major

infrasteucture and realestate projects in. India,

Experience

Y Me. Vaidya is solely sesponsible for introducing High Strain

Dynamic Testing st the following projects of National

Importance.

© Major Flyover Projects in Mumbai, Delhi and the

county.

© Delhi Metro, Mumbai Metso, Nagpur Metro, Cochin

Metro, Lucknow Metro, Kolkatta Metro, Chennai Metro,

Alimedabad Meteo Projects

0 LNG Projects in the country, eg, Shell end Peteonet

LNG.

(© Jetties & Matine Structures in India for various Port

Teasts

© National Highway Golden Quadsilatersl and E-W, N-S

Link Projects

© Major Railway Projects & ROB’ ia India.

Power Projects across the country

9 Major real estate projects in Mumbai and across the

country,

Y Mr. Vaidya is also directly responsible as overall incharge of the

company for Non Destructive Testing of concrete structures and

have handled major projects for testing of chimneys, TG Decks,

buildings, silos, DMRC etc. Refer t client list for complete

detail.

Y Mr. Vaidya has successfully executed many major jobs for

conetete / steel driven piles jobs as the overall incharge of the

company. Refer to client list, Some of them aze as follows

© Complete monitoring of 1200mm steel pipe piles for

initial and routine tests for Major Jeity Project at

Madagascar & West Attica

© Monitoring of steel pipe piles at Mauritius and Qatar for

Royal Haskoning,

GEO DYNAMICS

AN ISO 9001-2008 Company

(© Monitoting and ‘Testing of more then 900 pre-cast piles

for Reliance Industries - Oil & Gas Division at Kakinada,

AP, India

© Monitoring and Testing of Steel H-Piles, Pre-Stressed

Spun Piles as Testing engineer dutiag my work

Singapore work experience.

V Mr. Vaidya is the authorized training representative of Pile

Dynamics, Inc., USA and has conducted training programs

for companies in Gulf and India. Some of them ate listed

below:

© Advanced Construction ‘Technology Services, Doha,

Qatar

© Huta Foundations, Shibh Al Jazeera Companies,

Saudi Arabia

‘0 Gulf Consult, Al Khobar, Saudi Arabia — HSDPT,

PIT, CAPWAP, GRLWEAP

o Al ‘Tatiq Engg. Bureau, Traq — HSDPT, PIT,

CAPWAP, GRLWEAP

© Al Hoty Stanger Limited, Al Khobat, Saudi Arabia —

PIT

‘© National Council of Cement & Building Materials,

New Delhi —PIT

V Responsible for testing projects in Bangladesh,

Saudi Arabia, Qatat, Madagascar, Mauritius.

singapore,

Y Successfully got the govemment and private sector

companies to change their practices and implement the

techaology of High Strain Dynamic ‘Testing and Pile

Integrity Testing on major projects

Y Introduced and implemented Cross Hole Sonic Logging

‘Testing for Pile Foundations at Railway Bridge on River

Sone (3 km, long tiver btidge) in Bihat.

¥ Involved in providing solutions to various piling problems

to govt, and private agencies and infrastructure projects.

Y Experienced in evaluation of static load tests

Y Invited as speaker at various conferences, universities and

p

professional companies.

¥ He has guided dissertation of Two P.G. Students at M.S

University, Baroda.

GEO DYNAMICS

AN ISO 9001-2008 Company

Past Experience

Civil Engincet, AL Technologies (S) Pte Ltd, Singapore

In-chatge of dynamic pile testing, pile, integdty testing, NDT of

structures. Was actively involved in Testing of Driven Steel, Concrete Pre-

Cast and Pre-Stressed piles, also large diameter drilled shaft, driven and

bored micto piles of various sizes at project sites in Singapore. Active

wotking experience on project sites of Housing Development Board,

Singapore, Port of Singapore Authority & other authorities. Also

involved in Ground Penetrating Radars, restoration and rehab of

structures, dilapidation surveys etc. During work in Singzpore, also

hhandled oversees assignments at Malaysia and Vietnam.

Senior Engines, NDM Technologies Pvt Ltd.

Involved in Non Destructive Testing of Piles, client interaction, market

development, providing solutions to various piling problems.

Professional Societies/ Affiliates

* On the Code Committee for zevising 18:2911 for piling and

1S:14898 for ple integsty testing

* Life Member, Indian Geotechnical Society,

Associate Member, Institution of Engineers (India)

Member of India Chapter of Ametican Concrete Tastiate

* Membes, Indian Society of Structural Engineers, Mumbai

Publications

High Stisin Dynamic Pile ‘Testing On Rock Socketed Reinforced

Concrete Piles -Mumbai Experience, Vaidya, Ravikiran, 8th International

Conference on the Application of Stress Wave Theory to Piles, Lisbon,

Portugal, September 2008

Introduction to High Strain Dynatnic Pile Testing and Reliability Studies

in Southern Indis, Indian Geotechnical Conference, Chennai, December

2006.

High Strain Dyoamic Pile Testing Studies in Mamba; Ravikican Vaidya, et

al, laternational Seminar on “Hands on Demo with Exhibition, Case

Studies and Expert Presentation on NDT, Mumbai, January 2006

Low Strain Integrity & High Stain Dynamic Testing of Piles ~ An Indian

Overview; Ravikiran Vaidya, “7th Intemational Conference on the

Application of Stresswave Theory to Piles’, Kaula Lumpur, Malaysia,

‘August 2004,

High Strain Dynamic Pile Load Test at Delhi Metro Rail Project; Rajan.

Kataria, R. Subramanian & Ravikiean Vaidya, The Indian Conerete

Journal, July 2008.

GEO DYNAMICS

AN ISO 9001-2008 Company

Static and High Strain Dynamic ‘Test Co-Relation Studies on Cast-Ia-Situ-

Concrete Bored Piles; Ds. N. V. Nayak, D.K. Kanhere & Revikizan

Vaidya, Deep Foundations Institute, New York, October 2000

Pile Diagnostics By Low Strain Invepsty Testing, Ravikitan Vaidya & DL.

Shah, Indian Geotechnical Conference 2001, Indote, India, December

2001

Review of methods to evaluate concrete quality ia castinplace piles;

Ravikiran Vaidya & N. Narendeanathan, Our World of Concrete and

Steuctures, Singapore, August 1997

Non Destructive Testing of Piles; Ravikiean Vaidya & D.B. Mehta,

Workshop on Application of Non-Destructive Testing in Civil

Engineering, School of Building Science & ‘Technology, CEPT,

‘Abmedabad, February 1996

‘A Knowledge Based Expert System for the Design of Cizeular Columns;

8.C. Patodi and R.R. Vaidya, International Conference on Knowledge

Based Computer Systems, Bombay, December 1996

PC Based Expert System for the Desiga of Reinforced Concrete

Columns; RR. Vaidya & S.C. Patodi, Published in “Civil Enginecting &

Construction Review”, September, 1994

Expert Systems for the Design of Footings; LR. Vaidya & Dt. SC.

Patodi, Presented by RR. Vaidya at National Symposium on Structural

Mechanien, (NESM.'91), Dept of Civil Ragg,, Indian Toatinte nf Sriewer,

Bangelore, June 94

‘Chronology

06/98 ~ Present: Principsl Enpincer, Geo Dynamics, Vadodasa, Gujarat,

India

(09/96 ~ 02/98: Civil Ragineer, AL Technologies (8) Pte Lad, Singapore

07/94 ~ 08/96: Senior Engineer, NDM Technologies Pvt Ltd,

Contact Information

“Anand”, 49, Atmajyoti Nagar Society,

Near Atmsjyoti Ashtam, Ellota Park

Vadodara, G) 390 023 India

‘Telefax: +91-265-2388139, 2393205,

Email: Ravikiran@geodynamies.net

Areas of Expertise

NDT of Deep Foundations

NDI of Superstructres

Years of Experience

With Geo Dynamics: 19 Years

With Other Firms: 3 ens

Education

ITT. / 1994 / Draughtsman Civil

GEO DYNAMICS

AN ISO 9001-2008 Company

Rakesh Patel

Project Coordinator

Overview

Mr, Rakesh Patel is working with Geo Dynamics a3 Project Coosdinator

for several years and also responsible for managing the projects from

India as well as abtoad. He is responsible for coocdinating all the projects

Jn the North and Northeast region and also actively involved in

performing various types of Pile Foundation ‘Testing including Pile

Integrity Tests, Crosshole Sonic Logging ‘Tests and High Stesin Dynamic

Pile Load ‘Testing. He is also skilled in pesforming various NDTs for

superstructure, A list of the select projects is presented below.

Experience with Geo Dynamics

© Performed Crosshole Sonic Logging, HSDPT and PIT for bored

piles for various projects across India as well as abroad.

© Coordinator and expert for Crosshole Sonic Logging test.

Responsible for CSL. testing all over India as well as absond.

© Miscellaneous letters and repost writing,

+ Responsible for marketing and client interaction from various

‘major sectors in India like National Hlighways Authosity of India

(NHAND, National Thermal Power Corporation (NTPC), Delt

‘Meto Rail Corporation (DMRO) ete.

© Involved in creating awareness for ethical testing practices for

various technologies like Low-Strain Pile Integriry ‘Testing and

Cross-Hole Sonic Logging esting ete.

* Following is list of some selected projects having national and

International importance

(© Delhi Metro Rail Project

‘Chennai Metro Rail Project

Kollata Metro Rail Project

Cohin Metro Project

Titcknow Metzo Project

[Now Railway Sone Bridge at Dehti on Sone, Bihar

South East Central Railway work.

Construetion of Bandra Worl Sea Link Projeet at Bandra

(W), Mumbai

Modernization of GRSE Main Unit (PHASE-II) st

Kolkata

© Construction of New Chambal Bridge at Kota (Cable

Stayed Bridge) at Kota, Rajasthan

eoa0000

°

GEO DYNAMICS

AN ISO 9001-2008 Company

(© Saidabad Watce Treatment Plant Project Phasell At

Dhaka, Bangladesh

© Construction of King Tower and World One Project,

Mumbat

© Additional Civil Works of SATL-ISP at Burnpur, West

Bengal

© High Strain Dynamic Pile Testing at Bangladesh for

construction uf 150MW peaking power plant project at

shikolbaha, Chittagong.

9 Low Stesin Integrity Testing and HSDPT at

Construction of Oil Jetty, Mauritius

(© Complete CSL Testing, Analysis and Report of 250mm

Dia and 70m Length R. C, Bored piles for NHAI Project

at Paina

© Complete CSL Testing, Analysis and Report of 1200mm

Dia RC. Bored piles tor India tallest Residency Tower

Project at Mumbai

(© Complete CSL Testing, Analysis and Report of 1200uun1

Dia R. C. Bored piles for North India tallest Residency

Tower Project at Noida

‘© Complete CSL Testing, Analysis and Report of 1500mm

Dia R. C. Bored piles for India First See link Project

Project at Mumbai

(© Complete CSL Testing, Analysis and Report of 100mm

Dia RC. Bored piles for India First Monorail Project at

Mambai

© Testing and Analysis and Reporting of more than 2500

piles for Cross Hole Sonic Logging Testing at India

Chronology

09/98 — Present: Project Coordinator, Geo Dynamics, Vadodara, Garjarat

01/95 08/98: Site Supervisor, RR Vaidya & Sons, Vadodara, Gujarat,

Contact Information

“Anand”, 49, Aumajyoti Nagar Society,

eae Atonajyoti Ashtam, Ellor Pack

‘Vadodara, GJ 390 023 India

“Telefax: +91-265-2388139, 2393205

Mobile: 9384626000

Email Nelson@geodynamics.net

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Shop Welding InspectionDocument4 pagesShop Welding InspectionIndra Nath MishraNo ratings yet

- Letter No. 1568 QA QC Audit Report For Approval of Fabrication ShopsDocument2 pagesLetter No. 1568 QA QC Audit Report For Approval of Fabrication ShopsIndra Nath MishraNo ratings yet

- Orthotropic Steel Deck Suez Canal Bridge GADDocument4 pagesOrthotropic Steel Deck Suez Canal Bridge GADIndra Nath MishraNo ratings yet

- Bridge Comes To San Francisco, With Made-In-China Label - The New York TimesDocument3 pagesBridge Comes To San Francisco, With Made-In-China Label - The New York TimesIndra Nath MishraNo ratings yet

- Reason Behind Failure of Central Hinge Bearings Modifications Proposed in The Central Hinge Bearings of The Mahatma Gandhi Setu in Patna by I.N. MishraDocument8 pagesReason Behind Failure of Central Hinge Bearings Modifications Proposed in The Central Hinge Bearings of The Mahatma Gandhi Setu in Patna by I.N. MishraIndra Nath MishraNo ratings yet

- Orthotropic Steel Deck Construction SupervisionDocument29 pagesOrthotropic Steel Deck Construction SupervisionIndra Nath MishraNo ratings yet

- ITP-precast SegmentsDocument3 pagesITP-precast SegmentsIndra Nath MishraNo ratings yet

- Recent Developement in Concrete & SteelDocument4 pagesRecent Developement in Concrete & SteelIndra Nath MishraNo ratings yet

- Tekla BIM AwardsDocument2 pagesTekla BIM AwardsIndra Nath MishraNo ratings yet

- Weld & Material Data LogDocument7 pagesWeld & Material Data LogIndra Nath MishraNo ratings yet

- DFG Analysis Roads 2019Document6 pagesDFG Analysis Roads 2019Indra Nath MishraNo ratings yet

- Salient Features of Chenab BridgeDocument2 pagesSalient Features of Chenab BridgeIndra Nath MishraNo ratings yet

- Non Destructive Weld ExaminationDocument4 pagesNon Destructive Weld ExaminationIndra Nath MishraNo ratings yet

- Schedule K TestsDocument2 pagesSchedule K TestsIndra Nath MishraNo ratings yet

- IHI Fabrication, CaliforniaDocument8 pagesIHI Fabrication, CaliforniaIndra Nath MishraNo ratings yet

- JFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisDocument1 pageJFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisIndra Nath MishraNo ratings yet

- Bogibeel Rail-cum-Road Bridge PDFDocument2 pagesBogibeel Rail-cum-Road Bridge PDFIndra Nath MishraNo ratings yet

- JFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisDocument1 pageJFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisIndra Nath MishraNo ratings yet

- World Highways - Kuwait's Sheikh Jaber Al-Ahmad Al-Sabah Causeway OpensDocument5 pagesWorld Highways - Kuwait's Sheikh Jaber Al-Ahmad Al-Sabah Causeway OpensIndra Nath MishraNo ratings yet

- Western Flank of Gandhi Setu To Be Ready by June' - Times of IndiaDocument2 pagesWestern Flank of Gandhi Setu To Be Ready by June' - Times of IndiaIndra Nath MishraNo ratings yet

- Bay Bridge Steel FactsDocument2 pagesBay Bridge Steel FactsIndra Nath MishraNo ratings yet

- The Fall of SkyscrapersDocument6 pagesThe Fall of SkyscrapersIndra Nath MishraNo ratings yet

- Statue of Unity in Shortlist For Best Engineered StructuresDocument2 pagesStatue of Unity in Shortlist For Best Engineered StructuresIndra Nath MishraNo ratings yet

- IHI Fabrication, CaliforniaDocument8 pagesIHI Fabrication, CaliforniaIndra Nath MishraNo ratings yet

- Professional Engineers Registration Bill 2019 - Professional EngineersDocument1 pageProfessional Engineers Registration Bill 2019 - Professional EngineersIndra Nath MishraNo ratings yet

- Statue of Unity in Shortlist For Best Engineered Structures PDFDocument2 pagesStatue of Unity in Shortlist For Best Engineered Structures PDFIndra Nath MishraNo ratings yet

- Stonecutters Bridge Hong Kong, China - Verdict TrafficDocument5 pagesStonecutters Bridge Hong Kong, China - Verdict TrafficIndra Nath MishraNo ratings yet

- Defective Construction Work at Hung Hom Station Tunnel Was Subcontractor's Fault, Not Ours', Says Main Contractor at MTR Commission of Inquiry - South China Morning PostDocument5 pagesDefective Construction Work at Hung Hom Station Tunnel Was Subcontractor's Fault, Not Ours', Says Main Contractor at MTR Commission of Inquiry - South China Morning PostIndra Nath MishraNo ratings yet

- Professional Engineers Registration Bill 2019 - Professional EngineersDocument1 pageProfessional Engineers Registration Bill 2019 - Professional EngineersIndra Nath MishraNo ratings yet